Sorbent Stability in DAC: Thermal/oxidative Degradation and Regeneration Strategies

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DAC Sorbent Evolution

The evolution of sorbents for Direct Air Capture (DAC) has been a critical aspect in advancing this technology's efficiency and viability. Early DAC systems primarily utilized liquid sorbents, such as sodium hydroxide solutions, which were effective but energy-intensive in the regeneration process. The shift towards solid sorbents marked a significant milestone in DAC development, offering improved energy efficiency and operational flexibility.

Amine-functionalized materials emerged as a promising class of solid sorbents in the early 2000s. These materials, including amine-grafted silica and polymeric resins, demonstrated high CO2 selectivity and capacity. However, they faced challenges related to thermal and oxidative stability, particularly during the high-temperature regeneration cycles required for sorbent reuse.

The next generation of sorbents focused on addressing these stability issues. Metal-organic frameworks (MOFs) gained attention for their high surface area and tunable pore structures, allowing for enhanced CO2 adsorption. Researchers explored various MOF compositions to balance CO2 capture capacity with thermal and chemical stability. Concurrently, the development of porous polymer networks provided another avenue for stable, high-capacity sorbents.

Recent advancements have seen the integration of multiple functionalities within a single sorbent material. Composite materials combining the benefits of different sorbent types, such as amine-functionalized MOFs or polymer-inorganic hybrids, have shown promise in achieving both high CO2 capture capacity and improved stability. These materials often exhibit synergistic effects, where the combination of components enhances overall performance beyond what individual materials can achieve.

The focus on sorbent stability has led to innovative regeneration strategies. Low-temperature swing adsorption processes have been developed to minimize thermal stress on sorbents, while maintaining efficient CO2 desorption. Additionally, the exploration of alternative regeneration methods, such as electrical swing adsorption or pressure swing processes, aims to further reduce energy requirements and extend sorbent lifetimes.

As research progresses, there is an increasing emphasis on developing sorbents that not only capture CO2 efficiently but also demonstrate long-term stability under realistic operating conditions. This includes resistance to contaminants present in ambient air, such as SOx and NOx, as well as tolerance to humidity fluctuations. The goal is to create sorbents that maintain their performance over thousands of adsorption-desorption cycles, significantly reducing the operational costs and environmental impact of DAC systems.

Amine-functionalized materials emerged as a promising class of solid sorbents in the early 2000s. These materials, including amine-grafted silica and polymeric resins, demonstrated high CO2 selectivity and capacity. However, they faced challenges related to thermal and oxidative stability, particularly during the high-temperature regeneration cycles required for sorbent reuse.

The next generation of sorbents focused on addressing these stability issues. Metal-organic frameworks (MOFs) gained attention for their high surface area and tunable pore structures, allowing for enhanced CO2 adsorption. Researchers explored various MOF compositions to balance CO2 capture capacity with thermal and chemical stability. Concurrently, the development of porous polymer networks provided another avenue for stable, high-capacity sorbents.

Recent advancements have seen the integration of multiple functionalities within a single sorbent material. Composite materials combining the benefits of different sorbent types, such as amine-functionalized MOFs or polymer-inorganic hybrids, have shown promise in achieving both high CO2 capture capacity and improved stability. These materials often exhibit synergistic effects, where the combination of components enhances overall performance beyond what individual materials can achieve.

The focus on sorbent stability has led to innovative regeneration strategies. Low-temperature swing adsorption processes have been developed to minimize thermal stress on sorbents, while maintaining efficient CO2 desorption. Additionally, the exploration of alternative regeneration methods, such as electrical swing adsorption or pressure swing processes, aims to further reduce energy requirements and extend sorbent lifetimes.

As research progresses, there is an increasing emphasis on developing sorbents that not only capture CO2 efficiently but also demonstrate long-term stability under realistic operating conditions. This includes resistance to contaminants present in ambient air, such as SOx and NOx, as well as tolerance to humidity fluctuations. The goal is to create sorbents that maintain their performance over thousands of adsorption-desorption cycles, significantly reducing the operational costs and environmental impact of DAC systems.

Market Analysis for DAC

The Direct Air Capture (DAC) market is experiencing significant growth and attracting substantial investment due to its potential to combat climate change by removing carbon dioxide directly from the atmosphere. As global efforts to reduce greenhouse gas emissions intensify, DAC technology is increasingly seen as a crucial tool in achieving net-zero emissions targets.

The market for DAC is primarily driven by the urgent need to mitigate climate change and the growing demand for carbon removal solutions. Governments worldwide are implementing stricter emissions regulations and carbon pricing mechanisms, creating a favorable environment for DAC technologies. Additionally, many corporations are setting ambitious carbon neutrality goals, further fueling the demand for carbon removal solutions.

Current market estimates suggest that the global DAC market is poised for rapid expansion. The technology is still in its early stages of commercialization, with only a handful of large-scale plants in operation. However, the potential market size is substantial, considering the vast amount of CO2 that needs to be removed from the atmosphere to meet climate targets.

Several key factors are influencing the market dynamics of DAC. The cost of carbon capture remains a significant challenge, with current estimates ranging from $100 to $600 per ton of CO2 removed. However, technological advancements and economies of scale are expected to drive these costs down significantly in the coming years, making DAC more economically viable.

The market is also being shaped by policy support and incentives. In the United States, for example, the 45Q tax credit provides a significant financial incentive for carbon capture and storage projects, including DAC. Similar policies are being implemented or considered in other countries, which could accelerate market growth.

Geographically, North America and Europe are currently leading the DAC market, with several prominent companies and research institutions based in these regions. However, there is growing interest and investment in DAC technologies in other parts of the world, particularly in countries with ambitious climate goals or those seeking to become leaders in clean energy technologies.

The market landscape for DAC is characterized by a mix of established companies, startups, and research institutions. Key players are focusing on improving sorbent technologies, reducing energy requirements, and scaling up operations to achieve commercial viability. Partnerships between technology developers, industrial companies, and governments are becoming increasingly common as the industry seeks to accelerate development and deployment.

The market for DAC is primarily driven by the urgent need to mitigate climate change and the growing demand for carbon removal solutions. Governments worldwide are implementing stricter emissions regulations and carbon pricing mechanisms, creating a favorable environment for DAC technologies. Additionally, many corporations are setting ambitious carbon neutrality goals, further fueling the demand for carbon removal solutions.

Current market estimates suggest that the global DAC market is poised for rapid expansion. The technology is still in its early stages of commercialization, with only a handful of large-scale plants in operation. However, the potential market size is substantial, considering the vast amount of CO2 that needs to be removed from the atmosphere to meet climate targets.

Several key factors are influencing the market dynamics of DAC. The cost of carbon capture remains a significant challenge, with current estimates ranging from $100 to $600 per ton of CO2 removed. However, technological advancements and economies of scale are expected to drive these costs down significantly in the coming years, making DAC more economically viable.

The market is also being shaped by policy support and incentives. In the United States, for example, the 45Q tax credit provides a significant financial incentive for carbon capture and storage projects, including DAC. Similar policies are being implemented or considered in other countries, which could accelerate market growth.

Geographically, North America and Europe are currently leading the DAC market, with several prominent companies and research institutions based in these regions. However, there is growing interest and investment in DAC technologies in other parts of the world, particularly in countries with ambitious climate goals or those seeking to become leaders in clean energy technologies.

The market landscape for DAC is characterized by a mix of established companies, startups, and research institutions. Key players are focusing on improving sorbent technologies, reducing energy requirements, and scaling up operations to achieve commercial viability. Partnerships between technology developers, industrial companies, and governments are becoming increasingly common as the industry seeks to accelerate development and deployment.

Sorbent Stability Challenges

Direct Air Capture (DAC) technology faces significant challenges in maintaining sorbent stability, which is crucial for the long-term efficiency and economic viability of carbon dioxide removal processes. The primary stability issues stem from thermal and oxidative degradation of sorbents during the capture and regeneration cycles.

Thermal degradation occurs due to the high temperatures required for sorbent regeneration, typically ranging from 80°C to 120°C for amine-based sorbents. Repeated exposure to these temperatures can lead to structural changes in the sorbent material, reducing its CO2 capture capacity over time. This degradation is often manifested as a decrease in the number of active sites available for CO2 adsorption or changes in the pore structure of the sorbent.

Oxidative degradation presents another significant challenge, particularly for amine-based sorbents. Exposure to oxygen in the air can lead to the formation of harmful byproducts, such as nitrosamines and nitramines, which not only reduce the sorbent's effectiveness but also pose potential environmental and health risks. This oxidative process is accelerated at higher temperatures, compounding the thermal degradation effects.

The cyclic nature of DAC operations exacerbates these stability issues. Sorbents undergo thousands of adsorption-desorption cycles over their lifetime, with each cycle potentially contributing to cumulative degradation. This results in a gradual decline in CO2 capture efficiency and an increase in the energy required for regeneration, ultimately impacting the overall performance and cost-effectiveness of DAC systems.

Another challenge is the presence of contaminants in ambient air, such as SOx, NOx, and particulate matter. These impurities can interact with the sorbent material, leading to irreversible chemical changes or physical blockage of active sites. This not only reduces the CO2 capture capacity but also necessitates more frequent sorbent replacement, increasing operational costs.

Moisture management is also a critical factor in sorbent stability. Many sorbents, especially those based on solid supports, are sensitive to water vapor. Excessive moisture can lead to swelling, structural changes, or even dissolution of the active components, compromising the sorbent's performance and longevity.

Addressing these stability challenges requires innovative approaches in sorbent design and process engineering. Developing thermally and oxidatively resistant materials, optimizing regeneration conditions, and implementing effective contaminant removal strategies are key areas of focus. Additionally, exploring novel sorbent architectures and composite materials that can withstand the harsh conditions of DAC operations while maintaining high CO2 capture efficiency is crucial for advancing the technology.

Thermal degradation occurs due to the high temperatures required for sorbent regeneration, typically ranging from 80°C to 120°C for amine-based sorbents. Repeated exposure to these temperatures can lead to structural changes in the sorbent material, reducing its CO2 capture capacity over time. This degradation is often manifested as a decrease in the number of active sites available for CO2 adsorption or changes in the pore structure of the sorbent.

Oxidative degradation presents another significant challenge, particularly for amine-based sorbents. Exposure to oxygen in the air can lead to the formation of harmful byproducts, such as nitrosamines and nitramines, which not only reduce the sorbent's effectiveness but also pose potential environmental and health risks. This oxidative process is accelerated at higher temperatures, compounding the thermal degradation effects.

The cyclic nature of DAC operations exacerbates these stability issues. Sorbents undergo thousands of adsorption-desorption cycles over their lifetime, with each cycle potentially contributing to cumulative degradation. This results in a gradual decline in CO2 capture efficiency and an increase in the energy required for regeneration, ultimately impacting the overall performance and cost-effectiveness of DAC systems.

Another challenge is the presence of contaminants in ambient air, such as SOx, NOx, and particulate matter. These impurities can interact with the sorbent material, leading to irreversible chemical changes or physical blockage of active sites. This not only reduces the CO2 capture capacity but also necessitates more frequent sorbent replacement, increasing operational costs.

Moisture management is also a critical factor in sorbent stability. Many sorbents, especially those based on solid supports, are sensitive to water vapor. Excessive moisture can lead to swelling, structural changes, or even dissolution of the active components, compromising the sorbent's performance and longevity.

Addressing these stability challenges requires innovative approaches in sorbent design and process engineering. Developing thermally and oxidatively resistant materials, optimizing regeneration conditions, and implementing effective contaminant removal strategies are key areas of focus. Additionally, exploring novel sorbent architectures and composite materials that can withstand the harsh conditions of DAC operations while maintaining high CO2 capture efficiency is crucial for advancing the technology.

Current Sorbent Solutions

01 Amine-based sorbents for DAC stability

Amine-based sorbents are widely used in Direct Air Capture (DAC) systems due to their high CO2 capture capacity and selectivity. These sorbents are modified to improve their stability under repeated adsorption-desorption cycles and exposure to contaminants. Strategies include immobilizing amines on porous supports, using cross-linking agents, and incorporating stabilizing additives to enhance their long-term performance and resistance to degradation.- Amine-based sorbents for DAC stability: Amine-based sorbents are widely used in Direct Air Capture (DAC) systems due to their high CO2 capture capacity and selectivity. These sorbents are modified to enhance their stability under repeated adsorption-desorption cycles. Improvements focus on preventing amine leaching, reducing degradation, and maintaining performance over extended periods.

- Metal-organic frameworks (MOFs) for DAC: Metal-organic frameworks are emerging as promising sorbents for DAC due to their high surface area and tunable pore structures. Research focuses on developing MOFs with enhanced stability in humid conditions and resistance to degradation during temperature swing cycles. Modifications aim to improve CO2 selectivity and capture efficiency.

- Zeolite-based sorbents for DAC stability: Zeolites are investigated as stable sorbents for DAC applications due to their rigid structure and thermal stability. Research efforts concentrate on modifying zeolites to enhance CO2 adsorption capacity and selectivity while maintaining their structural integrity over multiple cycles. Strategies include ion exchange and surface functionalization.

- Composite sorbents for improved DAC stability: Composite sorbents combining multiple materials are developed to leverage the advantages of different components. These composites aim to enhance overall stability, CO2 capture capacity, and regeneration efficiency. Common approaches include embedding active materials in porous supports or creating hybrid organic-inorganic structures.

- Sorbent regeneration and stability enhancement techniques: Various techniques are explored to improve sorbent regeneration and long-term stability in DAC systems. These include optimizing temperature and pressure swing processes, developing novel heating methods for efficient desorption, and incorporating stabilizing additives to prevent sorbent degradation during cycling.

02 Metal-organic frameworks (MOFs) for enhanced DAC stability

Metal-organic frameworks are emerging as promising sorbents for DAC applications due to their high surface area, tunable pore size, and chemical versatility. Research focuses on developing MOFs with improved hydrothermal stability and CO2 selectivity. Strategies include incorporating hydrophobic functional groups, using mixed-metal nodes, and post-synthetic modification to enhance their stability and performance in humid conditions typical of DAC operations.Expand Specific Solutions03 Zeolite-based sorbents for long-term DAC stability

Zeolites are investigated as stable sorbents for DAC due to their rigid crystalline structure and high thermal stability. Research focuses on modifying zeolites to enhance their CO2 adsorption capacity and selectivity while maintaining their structural integrity over multiple cycles. Approaches include ion exchange, framework substitution, and surface functionalization to optimize their performance in DAC applications.Expand Specific Solutions04 Composite sorbents for improved DAC stability

Composite sorbents combining multiple materials are developed to leverage the advantages of different components. These composites aim to achieve enhanced stability, capacity, and selectivity compared to single-component sorbents. Examples include polymer-inorganic hybrids, amine-grafted porous carbons, and mixed matrix membranes. The synergistic effects of the components result in improved resistance to degradation and enhanced performance under DAC conditions.Expand Specific Solutions05 Regeneration and stability enhancement techniques for DAC sorbents

Various techniques are developed to enhance the regeneration efficiency and long-term stability of DAC sorbents. These include optimized temperature swing adsorption processes, vacuum-assisted regeneration, and the use of novel heating methods such as microwave or electrical swing adsorption. Additionally, the incorporation of stabilizing additives and the development of protective coatings are explored to mitigate sorbent degradation and extend operational lifetimes in DAC systems.Expand Specific Solutions

Key DAC Industry Players

The direct air capture (DAC) technology for carbon dioxide removal is in an early stage of development, with the market still emerging and relatively small. The competitive landscape is characterized by a mix of established energy companies, startups, and research institutions. Key players like Climeworks, Carbon Engineering, and Global Thermostat are leading commercial efforts, while companies such as Shell, Siemens Energy, and Volkswagen are investing in research and development. The technology's maturity varies, with some companies operating pilot plants, but large-scale deployment remains limited. Academic institutions like Columbia University and Shanghai Jiao Tong University are contributing to fundamental research, indicating the technology's ongoing evolution and potential for future growth.

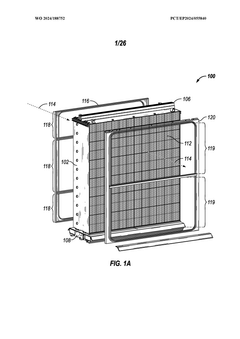

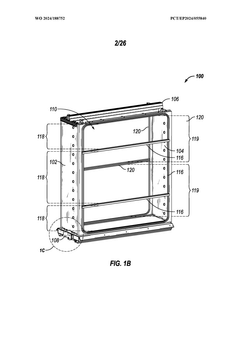

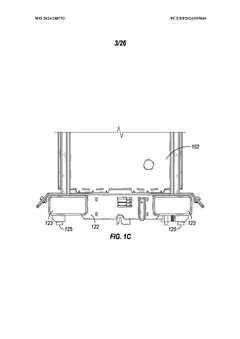

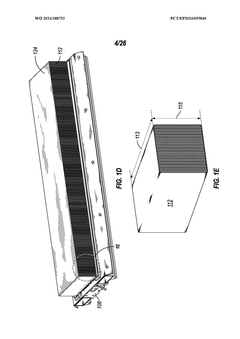

Climeworks AG

Technical Solution: Climeworks has developed a direct air capture (DAC) technology using solid sorbents. Their approach involves a two-step process: adsorption of CO2 from air onto a filter and subsequent desorption using heat. The company employs a modular design with stackable units, each capable of capturing 50 tons of CO2 annually[1]. Their sorbent material is amine-functionalized, allowing for selective CO2 capture. To address sorbent stability, Climeworks has implemented thermal regeneration strategies, heating the sorbent to around 100°C to release captured CO2[2]. They've also focused on optimizing the sorbent's cyclic stability, aiming to maintain performance over thousands of adsorption-desorption cycles. Recent improvements include enhanced heat management systems to minimize thermal degradation during regeneration[3].

Strengths: Modular design allows for scalability; proven technology with operational plants. Weaknesses: High energy requirements for thermal regeneration; potential for amine degradation over time.

Carboncapture, Inc.

Technical Solution: Carboncapture has developed a novel approach to DAC using advanced solid sorbents. Their technology, called CarbonCapture, utilizes a proprietary sorbent material that demonstrates high CO2 selectivity and capacity. The company's process involves a rapid temperature swing adsorption (TSA) cycle, which allows for faster regeneration times compared to traditional methods[1]. To enhance sorbent stability, Carboncapture has implemented a multi-stage regeneration process that minimizes thermal stress on the material. This includes a low-temperature desorption step followed by a higher temperature purge to remove residual CO2 and moisture[2]. The company has also developed advanced oxidation resistance strategies, incorporating stabilizing additives into their sorbent formulation to mitigate degradation from atmospheric oxygen exposure[3].

Strengths: Rapid TSA cycle enables higher throughput; innovative sorbent formulation with enhanced stability. Weaknesses: Technology is relatively new and less proven at large scale; potential high costs associated with proprietary materials.

Innovative Stability Research

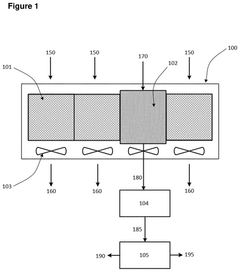

Processes and systems for regeneration of a sorbent

PatentWO2024188752A1

Innovation

- A regenerating unit with opposing doors and a sorbent housing module that creates isolated zones for fluid flow, allowing steam to traverse through flow channels from top to bottom, ensuring high purity CO2 desorption by minimizing mixing with entrained feed gas, using a regenerating-fluid-flow-path that passes multiple times through the sorbent structure.

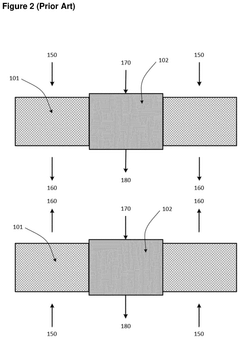

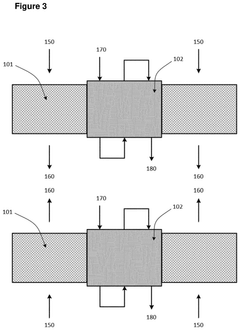

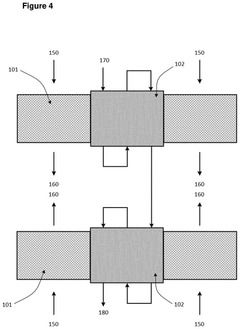

Processes and systems for regeneration of sorbent for use in capture of carbon dioxide

PatentPendingUS20240408578A1

Innovation

- The process involves recycling the regenerant gas or vapour, such as steam, through the sorbent bed multiple times in alternating directions to enhance carbon dioxide desorption and separation, reducing axial mixing and increasing the Peclet number for more efficient plug-flow displacement.

Environmental Impact of DAC

Direct Air Capture (DAC) technology, while promising in its potential to mitigate climate change, carries significant environmental implications that warrant careful consideration. The process of capturing CO2 directly from the atmosphere requires substantial energy input, which can lead to increased greenhouse gas emissions if not sourced from renewable energy. This paradoxical situation underscores the importance of utilizing clean energy sources to power DAC facilities, ensuring a net positive impact on carbon reduction efforts.

The construction and operation of DAC plants also have land-use implications. Large-scale deployment of DAC technology could compete with other land uses, including agriculture and natural habitats. This potential conflict necessitates thoughtful site selection and integration with existing infrastructure to minimize ecological disruption.

Water consumption is another critical environmental factor associated with DAC. Certain DAC methods, particularly those using liquid solvents, require significant amounts of water for the CO2 capture process and cooling systems. In water-stressed regions, this could exacerbate existing water scarcity issues, highlighting the need for water-efficient DAC technologies or strategic placement in water-rich areas.

The disposal or utilization of captured CO2 presents both challenges and opportunities. While geological sequestration offers a long-term storage solution, it raises concerns about potential leakage and seismic activity. Alternatively, utilizing captured CO2 for industrial processes or synthetic fuel production could create a circular carbon economy, but the net environmental benefit depends on the energy efficiency of these processes and their ability to displace fossil fuel-based alternatives.

The production and disposal of sorbents used in DAC systems also contribute to the technology's environmental footprint. The manufacturing of these materials often involves energy-intensive processes and may require rare or toxic substances. As research on sorbent stability progresses, it is crucial to develop regeneration strategies that extend sorbent lifespan and minimize waste generation, thereby reducing the overall environmental impact of DAC operations.

Lastly, the potential for DAC to alter local atmospheric conditions must be considered. While the global impact of CO2 removal is the primary goal, large-scale DAC deployment could potentially affect local weather patterns or ecosystems by altering CO2 concentrations in the immediate vicinity of DAC facilities. Long-term monitoring and research are necessary to understand and mitigate any unintended consequences on local environments.

The construction and operation of DAC plants also have land-use implications. Large-scale deployment of DAC technology could compete with other land uses, including agriculture and natural habitats. This potential conflict necessitates thoughtful site selection and integration with existing infrastructure to minimize ecological disruption.

Water consumption is another critical environmental factor associated with DAC. Certain DAC methods, particularly those using liquid solvents, require significant amounts of water for the CO2 capture process and cooling systems. In water-stressed regions, this could exacerbate existing water scarcity issues, highlighting the need for water-efficient DAC technologies or strategic placement in water-rich areas.

The disposal or utilization of captured CO2 presents both challenges and opportunities. While geological sequestration offers a long-term storage solution, it raises concerns about potential leakage and seismic activity. Alternatively, utilizing captured CO2 for industrial processes or synthetic fuel production could create a circular carbon economy, but the net environmental benefit depends on the energy efficiency of these processes and their ability to displace fossil fuel-based alternatives.

The production and disposal of sorbents used in DAC systems also contribute to the technology's environmental footprint. The manufacturing of these materials often involves energy-intensive processes and may require rare or toxic substances. As research on sorbent stability progresses, it is crucial to develop regeneration strategies that extend sorbent lifespan and minimize waste generation, thereby reducing the overall environmental impact of DAC operations.

Lastly, the potential for DAC to alter local atmospheric conditions must be considered. While the global impact of CO2 removal is the primary goal, large-scale DAC deployment could potentially affect local weather patterns or ecosystems by altering CO2 concentrations in the immediate vicinity of DAC facilities. Long-term monitoring and research are necessary to understand and mitigate any unintended consequences on local environments.

Techno-economic Assessment

The techno-economic assessment of Direct Air Capture (DAC) technology, particularly focusing on sorbent stability, thermal/oxidative degradation, and regeneration strategies, is crucial for evaluating its feasibility and potential for large-scale implementation. This assessment considers both the technical aspects and economic implications of DAC systems.

From a technical standpoint, the efficiency and longevity of sorbents play a pivotal role in the overall performance of DAC systems. The stability of sorbents under repeated thermal and oxidative stress cycles directly impacts the operational costs and carbon capture capacity. Current research indicates that the degradation of sorbents over time can significantly reduce the CO2 capture efficiency, necessitating frequent replacements and increasing operational expenses.

The economic viability of DAC technology is heavily influenced by the costs associated with sorbent materials, their regeneration processes, and energy requirements. Initial capital investments for DAC facilities are substantial, with estimates ranging from $300 to $600 per ton of CO2 captured. However, these costs are expected to decrease as the technology matures and economies of scale are realized.

Energy consumption represents a significant portion of operational costs in DAC systems. The regeneration of sorbents, which typically involves heating to release captured CO2, requires considerable energy input. Innovative strategies to reduce energy demands, such as utilizing waste heat from industrial processes or integrating renewable energy sources, could substantially improve the economic feasibility of DAC operations.

The development of more durable and efficient sorbents could lead to significant cost reductions. Research into novel materials with enhanced thermal and oxidative stability, as well as improved CO2 adsorption capacity, shows promise for increasing the overall efficiency of DAC systems. These advancements could potentially reduce both capital and operational expenses.

Market dynamics also play a crucial role in the techno-economic assessment of DAC. The value of captured CO2, either for utilization in industrial processes or for permanent storage, influences the economic viability of DAC projects. As carbon pricing mechanisms and markets for CO2 utilization evolve, the economic attractiveness of DAC technology is likely to improve.

In conclusion, the techno-economic assessment of DAC technology, particularly in relation to sorbent stability and regeneration strategies, reveals both challenges and opportunities. While current costs remain high, ongoing research and development efforts focused on enhancing sorbent performance and reducing energy requirements show potential for improving the economic viability of DAC systems in the future.

From a technical standpoint, the efficiency and longevity of sorbents play a pivotal role in the overall performance of DAC systems. The stability of sorbents under repeated thermal and oxidative stress cycles directly impacts the operational costs and carbon capture capacity. Current research indicates that the degradation of sorbents over time can significantly reduce the CO2 capture efficiency, necessitating frequent replacements and increasing operational expenses.

The economic viability of DAC technology is heavily influenced by the costs associated with sorbent materials, their regeneration processes, and energy requirements. Initial capital investments for DAC facilities are substantial, with estimates ranging from $300 to $600 per ton of CO2 captured. However, these costs are expected to decrease as the technology matures and economies of scale are realized.

Energy consumption represents a significant portion of operational costs in DAC systems. The regeneration of sorbents, which typically involves heating to release captured CO2, requires considerable energy input. Innovative strategies to reduce energy demands, such as utilizing waste heat from industrial processes or integrating renewable energy sources, could substantially improve the economic feasibility of DAC operations.

The development of more durable and efficient sorbents could lead to significant cost reductions. Research into novel materials with enhanced thermal and oxidative stability, as well as improved CO2 adsorption capacity, shows promise for increasing the overall efficiency of DAC systems. These advancements could potentially reduce both capital and operational expenses.

Market dynamics also play a crucial role in the techno-economic assessment of DAC. The value of captured CO2, either for utilization in industrial processes or for permanent storage, influences the economic viability of DAC projects. As carbon pricing mechanisms and markets for CO2 utilization evolve, the economic attractiveness of DAC technology is likely to improve.

In conclusion, the techno-economic assessment of DAC technology, particularly in relation to sorbent stability and regeneration strategies, reveals both challenges and opportunities. While current costs remain high, ongoing research and development efforts focused on enhancing sorbent performance and reducing energy requirements show potential for improving the economic viability of DAC systems in the future.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!