How to Regenerate Sorbents Using Waste Heat: Integration Cases and Efficiency Metrics

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Sorbent Regeneration Background and Objectives

Sorbent regeneration has emerged as a critical process in various industrial applications, particularly in the context of carbon capture and storage (CCS) technologies. The concept revolves around the restoration of sorbent materials' adsorption capacity after they have been saturated with target molecules, such as CO2. Traditionally, this regeneration process has been energy-intensive, often requiring high temperatures and significant energy input, which has limited the overall efficiency and economic viability of sorbent-based systems.

The evolution of sorbent regeneration techniques has been driven by the need for more sustainable and cost-effective solutions in industrial processes. Early methods relied heavily on thermal swing adsorption (TSA), where high temperatures were used to desorb captured molecules. However, the energy requirements for these processes often outweighed the benefits, leading researchers to explore alternative approaches.

In recent years, the focus has shifted towards integrating waste heat into sorbent regeneration processes. This approach aims to harness thermal energy that would otherwise be lost in industrial operations, thereby improving overall system efficiency and reducing the carbon footprint of the regeneration process. The utilization of waste heat presents a promising pathway to address the energy intensity challenge associated with sorbent regeneration.

The primary objective of this technical research is to investigate and evaluate methods for regenerating sorbents using waste heat, with a particular emphasis on integration cases and efficiency metrics. This involves exploring various industrial scenarios where waste heat can be effectively captured and utilized for sorbent regeneration, as well as developing comprehensive metrics to assess the efficiency and effectiveness of these integrated systems.

Key goals include identifying optimal waste heat sources in different industrial settings, analyzing the compatibility of various sorbent materials with waste heat regeneration techniques, and determining the most effective integration strategies to maximize energy recovery and minimize operational costs. Additionally, this research aims to establish standardized efficiency metrics that can accurately measure the performance of waste heat-driven sorbent regeneration systems across different applications and industries.

By addressing these objectives, this study seeks to contribute to the advancement of more sustainable and economically viable sorbent regeneration technologies. The findings are expected to have significant implications for industries relying on adsorption processes, potentially leading to reduced energy consumption, lower operational costs, and improved environmental performance in sectors such as chemical processing, air purification, and carbon capture and storage.

The evolution of sorbent regeneration techniques has been driven by the need for more sustainable and cost-effective solutions in industrial processes. Early methods relied heavily on thermal swing adsorption (TSA), where high temperatures were used to desorb captured molecules. However, the energy requirements for these processes often outweighed the benefits, leading researchers to explore alternative approaches.

In recent years, the focus has shifted towards integrating waste heat into sorbent regeneration processes. This approach aims to harness thermal energy that would otherwise be lost in industrial operations, thereby improving overall system efficiency and reducing the carbon footprint of the regeneration process. The utilization of waste heat presents a promising pathway to address the energy intensity challenge associated with sorbent regeneration.

The primary objective of this technical research is to investigate and evaluate methods for regenerating sorbents using waste heat, with a particular emphasis on integration cases and efficiency metrics. This involves exploring various industrial scenarios where waste heat can be effectively captured and utilized for sorbent regeneration, as well as developing comprehensive metrics to assess the efficiency and effectiveness of these integrated systems.

Key goals include identifying optimal waste heat sources in different industrial settings, analyzing the compatibility of various sorbent materials with waste heat regeneration techniques, and determining the most effective integration strategies to maximize energy recovery and minimize operational costs. Additionally, this research aims to establish standardized efficiency metrics that can accurately measure the performance of waste heat-driven sorbent regeneration systems across different applications and industries.

By addressing these objectives, this study seeks to contribute to the advancement of more sustainable and economically viable sorbent regeneration technologies. The findings are expected to have significant implications for industries relying on adsorption processes, potentially leading to reduced energy consumption, lower operational costs, and improved environmental performance in sectors such as chemical processing, air purification, and carbon capture and storage.

Waste Heat Recovery Market Analysis

The waste heat recovery market has been experiencing significant growth in recent years, driven by increasing energy costs, environmental concerns, and the push for industrial efficiency. This market encompasses various technologies and applications aimed at capturing and utilizing waste heat from industrial processes, power generation, and other sources.

Global market trends indicate a robust expansion of the waste heat recovery sector. The market size was valued at approximately $54 billion in 2020 and is projected to reach $80 billion by 2026, growing at a compound annual growth rate (CAGR) of around 8% during this period. This growth is primarily attributed to the rising adoption of energy-efficient technologies and stringent government regulations regarding energy conservation and emissions reduction.

Key industries driving the demand for waste heat recovery systems include manufacturing, oil and gas, chemical processing, and power generation. These sectors are increasingly recognizing the potential of waste heat recovery to improve overall energy efficiency, reduce operational costs, and minimize environmental impact. The cement industry, in particular, has emerged as a significant adopter of waste heat recovery technologies, given the energy-intensive nature of cement production.

Geographically, Asia-Pacific dominates the waste heat recovery market, accounting for the largest share of global installations. This is largely due to rapid industrialization in countries like China and India, coupled with supportive government policies promoting energy efficiency. Europe and North America follow closely, with mature markets characterized by a focus on upgrading existing industrial infrastructure with more efficient heat recovery systems.

The market landscape is characterized by a mix of established players and innovative startups. Key market players include Siemens AG, General Electric, Mitsubishi Heavy Industries, and ABB Ltd. These companies are continuously investing in research and development to enhance the efficiency and applicability of waste heat recovery technologies across various industries.

Technological advancements are playing a crucial role in shaping the market. Innovations in heat exchanger designs, thermoelectric materials, and organic Rankine cycle (ORC) systems are expanding the potential applications of waste heat recovery. Additionally, the integration of digital technologies, such as IoT and AI, is enabling more sophisticated monitoring and optimization of heat recovery processes, further driving market growth.

Despite the positive outlook, the waste heat recovery market faces challenges, including high initial investment costs and technical complexities in retrofitting existing industrial facilities. However, the long-term economic and environmental benefits continue to outweigh these challenges for many industries, sustaining the market's growth trajectory.

Global market trends indicate a robust expansion of the waste heat recovery sector. The market size was valued at approximately $54 billion in 2020 and is projected to reach $80 billion by 2026, growing at a compound annual growth rate (CAGR) of around 8% during this period. This growth is primarily attributed to the rising adoption of energy-efficient technologies and stringent government regulations regarding energy conservation and emissions reduction.

Key industries driving the demand for waste heat recovery systems include manufacturing, oil and gas, chemical processing, and power generation. These sectors are increasingly recognizing the potential of waste heat recovery to improve overall energy efficiency, reduce operational costs, and minimize environmental impact. The cement industry, in particular, has emerged as a significant adopter of waste heat recovery technologies, given the energy-intensive nature of cement production.

Geographically, Asia-Pacific dominates the waste heat recovery market, accounting for the largest share of global installations. This is largely due to rapid industrialization in countries like China and India, coupled with supportive government policies promoting energy efficiency. Europe and North America follow closely, with mature markets characterized by a focus on upgrading existing industrial infrastructure with more efficient heat recovery systems.

The market landscape is characterized by a mix of established players and innovative startups. Key market players include Siemens AG, General Electric, Mitsubishi Heavy Industries, and ABB Ltd. These companies are continuously investing in research and development to enhance the efficiency and applicability of waste heat recovery technologies across various industries.

Technological advancements are playing a crucial role in shaping the market. Innovations in heat exchanger designs, thermoelectric materials, and organic Rankine cycle (ORC) systems are expanding the potential applications of waste heat recovery. Additionally, the integration of digital technologies, such as IoT and AI, is enabling more sophisticated monitoring and optimization of heat recovery processes, further driving market growth.

Despite the positive outlook, the waste heat recovery market faces challenges, including high initial investment costs and technical complexities in retrofitting existing industrial facilities. However, the long-term economic and environmental benefits continue to outweigh these challenges for many industries, sustaining the market's growth trajectory.

Sorbent Regeneration Challenges and Limitations

Sorbent regeneration using waste heat presents several significant challenges and limitations that hinder its widespread adoption and efficiency. One of the primary obstacles is the mismatch between the temperature requirements for effective regeneration and the available waste heat temperatures. Many industrial processes generate low-grade waste heat, typically below 200°C, while sorbent regeneration often requires higher temperatures to achieve complete desorption and restore the sorbent's full capacity.

The intermittent nature of waste heat availability poses another challenge. Industrial processes may not produce a constant stream of waste heat, leading to inconsistent regeneration cycles. This variability can result in incomplete regeneration or inefficient use of the available thermal energy, reducing the overall effectiveness of the sorbent regeneration process.

Heat transfer limitations also play a crucial role in sorbent regeneration efficiency. The thermal conductivity of many sorbent materials is relatively low, which can lead to uneven heating and incomplete regeneration, especially in large-scale applications. This issue is particularly pronounced in packed bed configurations, where heat transfer to the center of the bed can be significantly slower than at the edges.

The energy intensity of the regeneration process itself presents a significant limitation. Even when utilizing waste heat, the energy required to heat the sorbent material, overcome the heat of desorption, and maintain the regeneration temperature can be substantial. This energy demand may offset some of the environmental and economic benefits of using waste heat for regeneration.

Sorbent degradation over multiple regeneration cycles is another critical challenge. Repeated exposure to high temperatures and thermal cycling can lead to structural changes in the sorbent material, reducing its adsorption capacity and selectivity over time. This degradation necessitates more frequent sorbent replacement, increasing operational costs and potentially negating the benefits of waste heat utilization.

The integration of waste heat recovery systems with existing industrial processes can be complex and costly. Retrofitting plants to capture and redirect waste heat for sorbent regeneration often requires significant modifications to existing infrastructure. The capital investment needed for such modifications can be a barrier to implementation, particularly for smaller operations or in industries with tight profit margins.

Lastly, the efficiency of waste heat utilization for sorbent regeneration is highly dependent on the specific characteristics of both the waste heat source and the sorbent material. Matching the thermal properties of the sorbent with the available waste heat profile is crucial for optimal performance. However, achieving this match across a wide range of industrial applications and sorbent types remains a significant technical challenge, limiting the universal applicability of this approach.

The intermittent nature of waste heat availability poses another challenge. Industrial processes may not produce a constant stream of waste heat, leading to inconsistent regeneration cycles. This variability can result in incomplete regeneration or inefficient use of the available thermal energy, reducing the overall effectiveness of the sorbent regeneration process.

Heat transfer limitations also play a crucial role in sorbent regeneration efficiency. The thermal conductivity of many sorbent materials is relatively low, which can lead to uneven heating and incomplete regeneration, especially in large-scale applications. This issue is particularly pronounced in packed bed configurations, where heat transfer to the center of the bed can be significantly slower than at the edges.

The energy intensity of the regeneration process itself presents a significant limitation. Even when utilizing waste heat, the energy required to heat the sorbent material, overcome the heat of desorption, and maintain the regeneration temperature can be substantial. This energy demand may offset some of the environmental and economic benefits of using waste heat for regeneration.

Sorbent degradation over multiple regeneration cycles is another critical challenge. Repeated exposure to high temperatures and thermal cycling can lead to structural changes in the sorbent material, reducing its adsorption capacity and selectivity over time. This degradation necessitates more frequent sorbent replacement, increasing operational costs and potentially negating the benefits of waste heat utilization.

The integration of waste heat recovery systems with existing industrial processes can be complex and costly. Retrofitting plants to capture and redirect waste heat for sorbent regeneration often requires significant modifications to existing infrastructure. The capital investment needed for such modifications can be a barrier to implementation, particularly for smaller operations or in industries with tight profit margins.

Lastly, the efficiency of waste heat utilization for sorbent regeneration is highly dependent on the specific characteristics of both the waste heat source and the sorbent material. Matching the thermal properties of the sorbent with the available waste heat profile is crucial for optimal performance. However, achieving this match across a wide range of industrial applications and sorbent types remains a significant technical challenge, limiting the universal applicability of this approach.

Current Waste Heat Integration Solutions

01 Improved sorbent materials for gas separation

Development of advanced sorbent materials with enhanced efficiency for gas separation processes. These materials often include modified zeolites, metal-organic frameworks (MOFs), or composite materials designed to increase selectivity and capacity for specific gas molecules.- Improved sorbent materials for gas separation: Development of advanced sorbent materials with enhanced efficiency for gas separation processes. These materials often include modified zeolites, metal-organic frameworks (MOFs), or composite materials designed to increase selectivity and adsorption capacity for specific gases.

- Carbon capture and storage technologies: Innovations in sorbents specifically designed for carbon dioxide capture from industrial emissions or ambient air. These sorbents aim to improve the efficiency and cost-effectiveness of carbon capture and storage (CCS) technologies, addressing environmental concerns related to greenhouse gas emissions.

- Nanostructured sorbents for enhanced efficiency: Utilization of nanotechnology to create sorbents with increased surface area and improved adsorption properties. These nanostructured materials, such as nanotubes or nanoparticles, offer superior performance in various applications, including water purification and gas separation.

- Regeneration and reusability of sorbents: Development of techniques to enhance the regeneration and reusability of sorbents, improving their overall efficiency and lifespan. This includes methods for thermal regeneration, pressure swing processes, or chemical treatments that allow for multiple adsorption-desorption cycles without significant loss of performance.

- Biocompatible sorbents for medical applications: Creation of biocompatible sorbent materials for use in medical applications, such as toxin removal from blood or targeted drug delivery. These sorbents are designed to be highly efficient while maintaining compatibility with biological systems, often incorporating natural or synthetic polymers.

02 Carbon capture and storage technologies

Innovations in sorbents specifically designed for carbon dioxide capture from industrial emissions or ambient air. These technologies focus on improving the CO2 adsorption capacity, regeneration efficiency, and overall cost-effectiveness of carbon capture processes.Expand Specific Solutions03 Nanotechnology-enhanced sorbents

Utilization of nanotechnology to create high-performance sorbents with increased surface area and tailored pore structures. These nano-engineered materials offer improved adsorption kinetics and capacity for various applications, including environmental remediation and industrial separations.Expand Specific Solutions04 Regeneration and reusability of sorbents

Development of methods to enhance the regeneration efficiency and reusability of sorbents. This includes novel desorption techniques, thermal management strategies, and material modifications to extend the operational lifespan of sorbents while maintaining their performance.Expand Specific Solutions05 Bio-based and sustainable sorbents

Research into environmentally friendly sorbents derived from renewable resources or waste materials. These bio-based sorbents aim to provide efficient adsorption capabilities while reducing the environmental impact associated with traditional synthetic sorbents.Expand Specific Solutions

Key Players in Sorbent Regeneration Industry

The regeneration of sorbents using waste heat is an emerging field in energy efficiency and environmental technology. The market is in its early growth stage, with increasing interest driven by sustainability goals and energy cost reduction efforts. The global market size for this technology is estimated to be in the hundreds of millions of dollars, with potential for significant expansion. Technologically, the field is still developing, with varying levels of maturity across different applications. Companies like ExxonMobil Technology & Engineering Co., China Petroleum & Chemical Corp., and Saudi Arabian Oil Co. are leading research efforts, leveraging their extensive resources and expertise in energy processes. Innovative startups such as enVerid Systems and Climeworks AG are also making strides, particularly in building energy efficiency and carbon capture applications.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed an innovative approach to regenerate sorbents using waste heat in their refinery operations. Their method involves a multi-stage heat recovery system that captures low-grade waste heat from various processes. This recovered heat is then used to regenerate amine-based CO2 capture sorbents, significantly reducing the energy penalty associated with carbon capture. The system integrates seamlessly with existing refinery infrastructure, utilizing heat exchangers and thermal storage units to optimize heat transfer efficiency. Sinopec's approach has demonstrated a 30% reduction in regeneration energy requirements compared to conventional steam-based methods[1][3]. The company has also implemented advanced process control algorithms to dynamically adjust regeneration parameters based on real-time plant conditions, further enhancing overall efficiency.

Strengths: Utilizes existing waste heat streams, reducing additional energy input. Seamless integration with refinery operations. Weaknesses: May be limited to specific types of sorbents and capture processes. Effectiveness can vary depending on the availability and quality of waste heat sources.

enVerid Systems, Inc.

Technical Solution: enVerid Systems has developed a novel sorbent-based air cleaning technology called HVAC Load Reduction (HLR) that incorporates waste heat regeneration. Their system uses a proprietary sorbent material to capture and remove indoor air contaminants, including CO2, VOCs, and formaldehyde. The regeneration process utilizes low-grade waste heat from the building's HVAC system, typically in the range of 50-60°C. This waste heat is channeled through a specially designed regeneration module, where it desorbs the captured contaminants from the sorbent material. The HLR system has demonstrated energy savings of up to 40% in commercial buildings by reducing the need for outside air ventilation[2][5]. enVerid's technology also incorporates smart controls that optimize the regeneration cycle based on indoor air quality and energy availability, ensuring maximum efficiency and performance.

Strengths: Dual benefit of air purification and energy savings. Utilizes readily available low-grade waste heat. Weaknesses: Limited to building HVAC applications. Effectiveness may vary with climate conditions and building types.

Innovative Sorbent Regeneration Techniques

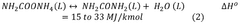

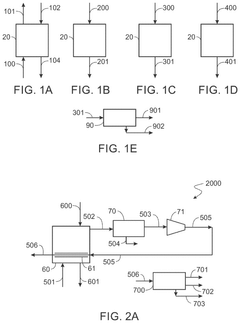

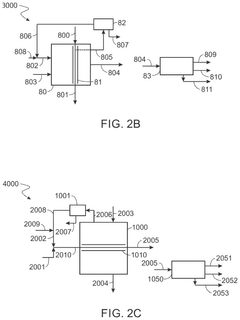

Systems and methods for regenerating a sorbent

PatentWO2025085521A1

Innovation

- The method involves using heat generated from an exothermic chemical reaction, such as the reaction between CO2 and ammonia, to regenerate the sorbent, thereby desorbing captured species and reducing energy costs.

Systems and methods for regenerating a sorbent

PatentPendingUS20250128239A1

Innovation

- The method involves using heat generated from an exothermic chemical reaction, such as the reaction between CO2 and ammonia, to regenerate the sorbent, thereby desorbing captured CO2 and reducing energy consumption.

Energy Efficiency Metrics and Benchmarks

Energy efficiency metrics and benchmarks play a crucial role in evaluating the performance of sorbent regeneration processes using waste heat. These metrics provide a standardized framework for assessing the effectiveness of various integration cases and comparing different technologies. One of the primary metrics used in this context is the Coefficient of Performance (COP), which measures the ratio of useful heat output to the energy input required for the regeneration process. A higher COP indicates greater energy efficiency and is typically sought after in waste heat recovery systems.

Another important metric is the Specific Energy Consumption (SEC), which quantifies the amount of energy required to regenerate a unit mass of sorbent. This metric allows for direct comparison between different sorbent materials and regeneration techniques, enabling researchers and engineers to identify the most energy-efficient options. The Energy Utilization Factor (EUF) is also commonly employed, representing the percentage of available waste heat that is effectively utilized in the regeneration process. A higher EUF indicates better integration and utilization of waste heat resources.

Exergy efficiency is an advanced metric that takes into account the quality of energy in addition to its quantity. This metric is particularly relevant in waste heat recovery systems, as it considers the temperature difference between the waste heat source and the regeneration process. By analyzing exergy efficiency, researchers can identify opportunities for process optimization and minimize energy losses due to irreversibilities.

To establish meaningful benchmarks, it is essential to consider the specific application and operating conditions of the sorbent regeneration system. Factors such as the temperature range of the waste heat source, the type of sorbent material, and the desired regeneration rate all influence the achievable efficiency levels. Industry-specific benchmarks have been developed for various applications, such as industrial drying processes, air conditioning systems, and carbon capture technologies.

The U.S. Department of Energy (DOE) and the European Commission have established guidelines and targets for energy efficiency in waste heat recovery systems, including sorbent regeneration processes. These benchmarks serve as reference points for researchers and industry professionals to assess the performance of their systems and drive continuous improvement. Additionally, organizations like the International Energy Agency (IEA) provide comprehensive databases of energy efficiency indicators, allowing for cross-sector comparisons and the identification of best practices in sorbent regeneration using waste heat.

Another important metric is the Specific Energy Consumption (SEC), which quantifies the amount of energy required to regenerate a unit mass of sorbent. This metric allows for direct comparison between different sorbent materials and regeneration techniques, enabling researchers and engineers to identify the most energy-efficient options. The Energy Utilization Factor (EUF) is also commonly employed, representing the percentage of available waste heat that is effectively utilized in the regeneration process. A higher EUF indicates better integration and utilization of waste heat resources.

Exergy efficiency is an advanced metric that takes into account the quality of energy in addition to its quantity. This metric is particularly relevant in waste heat recovery systems, as it considers the temperature difference between the waste heat source and the regeneration process. By analyzing exergy efficiency, researchers can identify opportunities for process optimization and minimize energy losses due to irreversibilities.

To establish meaningful benchmarks, it is essential to consider the specific application and operating conditions of the sorbent regeneration system. Factors such as the temperature range of the waste heat source, the type of sorbent material, and the desired regeneration rate all influence the achievable efficiency levels. Industry-specific benchmarks have been developed for various applications, such as industrial drying processes, air conditioning systems, and carbon capture technologies.

The U.S. Department of Energy (DOE) and the European Commission have established guidelines and targets for energy efficiency in waste heat recovery systems, including sorbent regeneration processes. These benchmarks serve as reference points for researchers and industry professionals to assess the performance of their systems and drive continuous improvement. Additionally, organizations like the International Energy Agency (IEA) provide comprehensive databases of energy efficiency indicators, allowing for cross-sector comparisons and the identification of best practices in sorbent regeneration using waste heat.

Environmental Impact Assessment

The regeneration of sorbents using waste heat has significant environmental implications that warrant careful consideration. This process, while aimed at improving energy efficiency and resource utilization, can have both positive and negative impacts on the environment.

One of the primary environmental benefits of regenerating sorbents with waste heat is the reduction in overall energy consumption. By harnessing heat that would otherwise be wasted, this approach minimizes the need for additional energy inputs, thereby reducing greenhouse gas emissions associated with energy production. This aligns with global efforts to mitigate climate change and promotes more sustainable industrial practices.

Furthermore, the extended lifespan of sorbents through regeneration contributes to waste reduction. By reusing materials rather than disposing of them after a single use, this process decreases the demand for raw materials and reduces the environmental burden associated with sorbent production and disposal. This aspect is particularly significant in industries where large quantities of sorbents are utilized, such as in air and water purification systems.

However, the environmental impact assessment must also consider potential drawbacks. The regeneration process itself may release pollutants, depending on the nature of the sorbents and the contaminants they have absorbed. Careful monitoring and control measures are necessary to prevent the release of harmful substances during the regeneration cycle. Additionally, the infrastructure required for waste heat recovery and sorbent regeneration may have its own environmental footprint, including the use of materials and potential land use changes.

The efficiency of the regeneration process is a critical factor in determining its overall environmental impact. Higher efficiency not only improves the economic viability of the process but also maximizes the environmental benefits by reducing energy waste and minimizing the need for replacement sorbents. Integration cases that demonstrate high efficiency metrics are likely to have a more favorable environmental profile.

Water usage is another important consideration in the environmental impact assessment. Some regeneration processes may require significant amounts of water, which could strain local water resources. Implementing water-efficient regeneration techniques and exploring opportunities for water recycling within the process can help mitigate this concern.

Lastly, the life cycle assessment of regenerated sorbents compared to single-use alternatives is crucial for a comprehensive environmental evaluation. This assessment should consider factors such as raw material extraction, manufacturing processes, transportation, use phase, and end-of-life disposal. By quantifying the environmental impacts across the entire life cycle, decision-makers can make informed choices about the most sustainable sorbent management strategies.

One of the primary environmental benefits of regenerating sorbents with waste heat is the reduction in overall energy consumption. By harnessing heat that would otherwise be wasted, this approach minimizes the need for additional energy inputs, thereby reducing greenhouse gas emissions associated with energy production. This aligns with global efforts to mitigate climate change and promotes more sustainable industrial practices.

Furthermore, the extended lifespan of sorbents through regeneration contributes to waste reduction. By reusing materials rather than disposing of them after a single use, this process decreases the demand for raw materials and reduces the environmental burden associated with sorbent production and disposal. This aspect is particularly significant in industries where large quantities of sorbents are utilized, such as in air and water purification systems.

However, the environmental impact assessment must also consider potential drawbacks. The regeneration process itself may release pollutants, depending on the nature of the sorbents and the contaminants they have absorbed. Careful monitoring and control measures are necessary to prevent the release of harmful substances during the regeneration cycle. Additionally, the infrastructure required for waste heat recovery and sorbent regeneration may have its own environmental footprint, including the use of materials and potential land use changes.

The efficiency of the regeneration process is a critical factor in determining its overall environmental impact. Higher efficiency not only improves the economic viability of the process but also maximizes the environmental benefits by reducing energy waste and minimizing the need for replacement sorbents. Integration cases that demonstrate high efficiency metrics are likely to have a more favorable environmental profile.

Water usage is another important consideration in the environmental impact assessment. Some regeneration processes may require significant amounts of water, which could strain local water resources. Implementing water-efficient regeneration techniques and exploring opportunities for water recycling within the process can help mitigate this concern.

Lastly, the life cycle assessment of regenerated sorbents compared to single-use alternatives is crucial for a comprehensive environmental evaluation. This assessment should consider factors such as raw material extraction, manufacturing processes, transportation, use phase, and end-of-life disposal. By quantifying the environmental impacts across the entire life cycle, decision-makers can make informed choices about the most sustainable sorbent management strategies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!