How to Report KPI for DAC Sorbents: Capture Energy per kg CO2, Cycle Life, and Throughput

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DAC Sorbents KPI Overview

Direct air capture (DAC) sorbents play a crucial role in carbon dioxide removal technologies, addressing the urgent need for climate change mitigation. To effectively evaluate and compare different DAC sorbents, it is essential to establish a standardized set of Key Performance Indicators (KPIs). This overview focuses on three critical KPIs: Capture Energy per kg CO2, Cycle Life, and Throughput.

Capture Energy per kg CO2 is a fundamental metric that quantifies the energy efficiency of the DAC process. It measures the amount of energy required to capture one kilogram of CO2 from the atmosphere. This KPI is typically expressed in units of kWh/kg CO2 or MJ/kg CO2. A lower value indicates a more energy-efficient sorbent, which is crucial for the economic viability and environmental impact of DAC technologies.

Cycle Life refers to the number of adsorption-desorption cycles a sorbent can undergo before its performance degrades significantly. This KPI is essential for assessing the long-term durability and cost-effectiveness of DAC sorbents. A higher cycle life implies lower replacement costs and reduced environmental impact associated with sorbent production and disposal. Cycle life is typically measured in the number of cycles or operating hours before a predetermined performance threshold is reached.

Throughput, often expressed in kg CO2/m3/h or similar units, measures the amount of CO2 captured per unit volume of sorbent material per unit time. This KPI is critical for evaluating the efficiency and scalability of DAC systems. A higher throughput indicates that a smaller volume of sorbent material can capture more CO2 in a given time frame, potentially reducing the overall size and capital costs of DAC installations.

These three KPIs are interconnected and often involve trade-offs. For example, a sorbent with high throughput might require more energy for regeneration, impacting the Capture Energy per kg CO2. Similarly, efforts to improve cycle life might come at the expense of reduced throughput or increased energy requirements. Therefore, a holistic approach is necessary when reporting and interpreting these KPIs.

Standardized reporting of these KPIs enables fair comparisons between different sorbent materials and DAC technologies. It also facilitates the identification of promising research directions and helps guide investment decisions in the rapidly evolving field of carbon dioxide removal. As the DAC industry matures, these KPIs will likely play a crucial role in shaping regulations, incentives, and market dynamics related to carbon capture technologies.

Capture Energy per kg CO2 is a fundamental metric that quantifies the energy efficiency of the DAC process. It measures the amount of energy required to capture one kilogram of CO2 from the atmosphere. This KPI is typically expressed in units of kWh/kg CO2 or MJ/kg CO2. A lower value indicates a more energy-efficient sorbent, which is crucial for the economic viability and environmental impact of DAC technologies.

Cycle Life refers to the number of adsorption-desorption cycles a sorbent can undergo before its performance degrades significantly. This KPI is essential for assessing the long-term durability and cost-effectiveness of DAC sorbents. A higher cycle life implies lower replacement costs and reduced environmental impact associated with sorbent production and disposal. Cycle life is typically measured in the number of cycles or operating hours before a predetermined performance threshold is reached.

Throughput, often expressed in kg CO2/m3/h or similar units, measures the amount of CO2 captured per unit volume of sorbent material per unit time. This KPI is critical for evaluating the efficiency and scalability of DAC systems. A higher throughput indicates that a smaller volume of sorbent material can capture more CO2 in a given time frame, potentially reducing the overall size and capital costs of DAC installations.

These three KPIs are interconnected and often involve trade-offs. For example, a sorbent with high throughput might require more energy for regeneration, impacting the Capture Energy per kg CO2. Similarly, efforts to improve cycle life might come at the expense of reduced throughput or increased energy requirements. Therefore, a holistic approach is necessary when reporting and interpreting these KPIs.

Standardized reporting of these KPIs enables fair comparisons between different sorbent materials and DAC technologies. It also facilitates the identification of promising research directions and helps guide investment decisions in the rapidly evolving field of carbon dioxide removal. As the DAC industry matures, these KPIs will likely play a crucial role in shaping regulations, incentives, and market dynamics related to carbon capture technologies.

Market Demand for DAC Technologies

The market demand for Direct Air Capture (DAC) technologies has been steadily growing in recent years, driven by the urgent need to address climate change and reduce atmospheric carbon dioxide levels. As global efforts to achieve net-zero emissions intensify, DAC is increasingly seen as a crucial tool in the fight against climate change, particularly for hard-to-abate sectors.

The potential market for DAC technologies is substantial, with estimates suggesting that the global carbon capture and storage market could reach $7 billion by 2028. This growth is fueled by increasing government support, corporate commitments to carbon neutrality, and the recognition of DAC as a necessary complement to other emissions reduction strategies.

Key industries driving the demand for DAC technologies include energy, manufacturing, and transportation. These sectors are under pressure to reduce their carbon footprints and are looking to DAC as a means to offset emissions that cannot be eliminated through other methods. Additionally, there is growing interest from the aviation and shipping industries, which face significant challenges in decarbonizing their operations.

The market for DAC is also being shaped by the emergence of carbon markets and pricing mechanisms. As the value of carbon credits increases, the economic viability of DAC projects improves, creating a positive feedback loop that further drives market growth. This is particularly relevant for high-quality carbon removal credits generated by DAC, which are increasingly sought after by companies looking to meet their net-zero commitments.

Geographically, North America and Europe are currently leading the DAC market, with several large-scale projects in development. However, there is growing interest and investment in DAC technologies across Asia-Pacific and other regions, as countries worldwide recognize the need for negative emissions technologies to meet their climate goals.

The demand for DAC is also influenced by the performance metrics of sorbent materials, including capture energy per kg CO2, cycle life, and throughput. Improvements in these key performance indicators (KPIs) are critical for enhancing the efficiency and cost-effectiveness of DAC systems, thereby expanding their market potential. As such, there is a strong market pull for innovations that can optimize these parameters and make DAC more economically viable at scale.

Looking ahead, the market for DAC technologies is expected to continue its upward trajectory. Factors such as stricter environmental regulations, increased corporate sustainability initiatives, and the growing recognition of the need for carbon dioxide removal to meet climate targets will likely drive further demand. As the technology matures and costs decrease, DAC is poised to play an increasingly important role in global decarbonization efforts, creating significant market opportunities for companies operating in this space.

The potential market for DAC technologies is substantial, with estimates suggesting that the global carbon capture and storage market could reach $7 billion by 2028. This growth is fueled by increasing government support, corporate commitments to carbon neutrality, and the recognition of DAC as a necessary complement to other emissions reduction strategies.

Key industries driving the demand for DAC technologies include energy, manufacturing, and transportation. These sectors are under pressure to reduce their carbon footprints and are looking to DAC as a means to offset emissions that cannot be eliminated through other methods. Additionally, there is growing interest from the aviation and shipping industries, which face significant challenges in decarbonizing their operations.

The market for DAC is also being shaped by the emergence of carbon markets and pricing mechanisms. As the value of carbon credits increases, the economic viability of DAC projects improves, creating a positive feedback loop that further drives market growth. This is particularly relevant for high-quality carbon removal credits generated by DAC, which are increasingly sought after by companies looking to meet their net-zero commitments.

Geographically, North America and Europe are currently leading the DAC market, with several large-scale projects in development. However, there is growing interest and investment in DAC technologies across Asia-Pacific and other regions, as countries worldwide recognize the need for negative emissions technologies to meet their climate goals.

The demand for DAC is also influenced by the performance metrics of sorbent materials, including capture energy per kg CO2, cycle life, and throughput. Improvements in these key performance indicators (KPIs) are critical for enhancing the efficiency and cost-effectiveness of DAC systems, thereby expanding their market potential. As such, there is a strong market pull for innovations that can optimize these parameters and make DAC more economically viable at scale.

Looking ahead, the market for DAC technologies is expected to continue its upward trajectory. Factors such as stricter environmental regulations, increased corporate sustainability initiatives, and the growing recognition of the need for carbon dioxide removal to meet climate targets will likely drive further demand. As the technology matures and costs decrease, DAC is poised to play an increasingly important role in global decarbonization efforts, creating significant market opportunities for companies operating in this space.

Current Challenges in DAC Sorbent Performance

Direct air capture (DAC) sorbents face several significant challenges in their performance, which directly impact their effectiveness and economic viability. One of the primary issues is the high energy requirement for CO2 capture and regeneration. Current sorbents often demand substantial energy inputs to release captured CO2, reducing the overall efficiency of the DAC process. This high energy demand not only increases operational costs but also potentially offsets the environmental benefits of carbon capture.

Another critical challenge is the limited cycle life of DAC sorbents. Many sorbents degrade over time, losing their CO2 capture capacity after repeated use. This degradation necessitates frequent replacement, driving up costs and creating additional waste. Improving the durability and longevity of sorbents is crucial for making DAC technologies more sustainable and economically feasible in the long term.

Throughput, or the rate at which CO2 can be captured, presents another significant hurdle. Current sorbents often exhibit slow kinetics, limiting the amount of CO2 that can be captured in a given time frame. This low throughput necessitates larger installations to achieve meaningful capture rates, increasing capital costs and spatial requirements for DAC facilities.

The selectivity of sorbents for CO2 over other atmospheric gases is also a persistent challenge. Many sorbents can be affected by moisture or other contaminants in the air, reducing their efficiency and potentially requiring additional processing steps to purify the captured CO2. This lack of selectivity can lead to increased energy consumption and reduced overall performance.

Temperature sensitivity is another factor impacting sorbent performance. Many sorbents operate optimally within narrow temperature ranges, making them less effective in varying climatic conditions. This limitation restricts the geographical locations where DAC facilities can be efficiently deployed and may require additional energy for temperature control.

Scaling up DAC technologies while maintaining sorbent performance is a significant challenge. As systems are scaled to industrial levels, issues such as uneven flow distribution, pressure drops, and heat management become more pronounced, potentially reducing the efficiency observed in smaller-scale demonstrations.

Lastly, the cost-effectiveness of sorbents remains a major hurdle. Despite ongoing research and development, the production of high-performance sorbents often involves expensive materials or complex manufacturing processes. Balancing performance improvements with cost considerations is crucial for the widespread adoption of DAC technologies.

Another critical challenge is the limited cycle life of DAC sorbents. Many sorbents degrade over time, losing their CO2 capture capacity after repeated use. This degradation necessitates frequent replacement, driving up costs and creating additional waste. Improving the durability and longevity of sorbents is crucial for making DAC technologies more sustainable and economically feasible in the long term.

Throughput, or the rate at which CO2 can be captured, presents another significant hurdle. Current sorbents often exhibit slow kinetics, limiting the amount of CO2 that can be captured in a given time frame. This low throughput necessitates larger installations to achieve meaningful capture rates, increasing capital costs and spatial requirements for DAC facilities.

The selectivity of sorbents for CO2 over other atmospheric gases is also a persistent challenge. Many sorbents can be affected by moisture or other contaminants in the air, reducing their efficiency and potentially requiring additional processing steps to purify the captured CO2. This lack of selectivity can lead to increased energy consumption and reduced overall performance.

Temperature sensitivity is another factor impacting sorbent performance. Many sorbents operate optimally within narrow temperature ranges, making them less effective in varying climatic conditions. This limitation restricts the geographical locations where DAC facilities can be efficiently deployed and may require additional energy for temperature control.

Scaling up DAC technologies while maintaining sorbent performance is a significant challenge. As systems are scaled to industrial levels, issues such as uneven flow distribution, pressure drops, and heat management become more pronounced, potentially reducing the efficiency observed in smaller-scale demonstrations.

Lastly, the cost-effectiveness of sorbents remains a major hurdle. Despite ongoing research and development, the production of high-performance sorbents often involves expensive materials or complex manufacturing processes. Balancing performance improvements with cost considerations is crucial for the widespread adoption of DAC technologies.

Existing KPI Reporting Methods

01 Sorbent materials for DAC

Various sorbent materials are developed for Direct Air Capture (DAC) of CO2. These materials are designed to efficiently capture CO2 from ambient air, with a focus on improving capture energy, cycle life, and throughput. Advanced sorbents may include engineered porous materials, functionalized polymers, or novel composite structures that enhance CO2 adsorption capacity and selectivity.- Sorbent materials for DAC: Various sorbent materials are developed for Direct Air Capture (DAC) of CO2. These materials are designed to efficiently capture CO2 from ambient air, with a focus on improving capture capacity, selectivity, and regeneration properties. Advanced sorbents may include modified zeolites, metal-organic frameworks (MOFs), or amine-functionalized materials that offer enhanced CO2 adsorption performance.

- Energy efficiency in DAC processes: Innovations in DAC technology aim to reduce the energy requirements for CO2 capture and sorbent regeneration. This includes optimizing heat management, developing low-temperature regeneration processes, and integrating renewable energy sources. Energy-efficient designs focus on minimizing the overall energy footprint of the DAC system while maximizing CO2 capture rates.

- Cycle life improvement of DAC sorbents: Enhancing the durability and longevity of DAC sorbents is crucial for sustainable operation. Research focuses on developing sorbents with improved stability over multiple adsorption-desorption cycles, resistance to degradation from contaminants, and methods to regenerate or rejuvenate sorbents to extend their operational lifespan.

- Throughput optimization in DAC systems: Increasing the CO2 capture throughput of DAC systems involves optimizing sorbent bed designs, airflow patterns, and process configurations. This includes developing advanced contactor designs, improving mass transfer efficiency, and implementing parallel processing or modular systems to scale up CO2 capture capacity while maintaining operational efficiency.

- Integration of DAC with carbon utilization: Innovative approaches combine DAC technology with carbon utilization processes to create closed-loop systems. This integration aims to not only capture CO2 but also convert it into valuable products or fuels, enhancing the economic viability of DAC operations. Such systems may incorporate catalytic conversion processes or biological utilization methods to transform captured CO2 into useful materials.

02 Energy-efficient regeneration processes

Innovations in regeneration processes aim to reduce the energy required for sorbent regeneration in DAC systems. This includes developing low-temperature desorption techniques, utilizing waste heat, or implementing novel heating methods to minimize the overall energy consumption of the capture cycle. These advancements contribute to improving the energy efficiency and economic viability of DAC technologies.Expand Specific Solutions03 Cycle life enhancement strategies

Research focuses on extending the cycle life of DAC sorbents to improve long-term performance and reduce operational costs. This involves developing sorbents with enhanced chemical and mechanical stability, implementing regeneration processes that minimize degradation, and designing system components that protect sorbents from contaminants and environmental stressors.Expand Specific Solutions04 Throughput optimization techniques

Advancements in DAC system design and operation aim to maximize CO2 capture throughput. This includes optimizing air flow patterns, enhancing mass transfer between air and sorbents, and developing modular or scalable system architectures. Innovations in this area focus on increasing the amount of CO2 captured per unit time while maintaining high efficiency and low energy consumption.Expand Specific Solutions05 Integration with renewable energy sources

DAC systems are increasingly integrated with renewable energy sources to reduce their carbon footprint and improve overall sustainability. This integration involves developing smart control systems, energy storage solutions, and flexible operation strategies that allow DAC plants to utilize intermittent renewable energy effectively. Such integration aims to enhance the environmental benefits of DAC while optimizing energy use and operational costs.Expand Specific Solutions

Key Players in DAC Industry

The competition landscape for reporting KPIs for DAC sorbents is evolving rapidly as the carbon capture industry matures. The market is in its early growth stage, with increasing investments and technological advancements driving expansion. Key players like Climeworks, Carbon Engineering, and Global Thermostat are leading the way, while established energy companies and research institutions are also entering the field. The technology is progressing from pilot projects to commercial-scale operations, with a focus on improving efficiency, reducing costs, and scaling up capacity. As the industry develops, standardization of KPI reporting methods for capture energy, cycle life, and throughput will become crucial for comparing different DAC technologies and driving further innovation.

Shell Internationale Research Maatschappij BV

Technical Solution: Shell has been developing DAC technologies focusing on both solid and liquid sorbents. Their research includes novel materials such as metal-organic frameworks (MOFs) and functionalized porous polymers. Shell's approach aims to reduce the capture energy to below 1500 kWh per ton of CO2 [6]. The company is working on improving sorbent stability and cycle life, with some materials showing promise for tens of thousands of cycles. Shell's research also focuses on process intensification to increase throughput, exploring innovative contactor designs and regeneration methods [7].

Strengths: Strong R&D capabilities, potential for breakthrough materials and processes. Weaknesses: Technology still in development stage, not yet commercially deployed at scale.

International Business Machines Corp.

Technical Solution: IBM is leveraging its expertise in materials science and AI to develop advanced DAC sorbents. Their approach involves using machine learning algorithms to design and optimize new materials with high CO2 selectivity and low regeneration energy. IBM's research aims to reduce capture energy to around 1000-1500 kWh per ton of CO2 [8]. The company is also focusing on improving cycle life through the development of more stable sorbent structures. IBM's computational methods allow for rapid screening of thousands of potential materials, potentially accelerating the discovery of high-performance sorbents with extended lifetimes and improved throughput [9].

Strengths: Advanced AI and materials science capabilities, potential for rapid innovation. Weaknesses: Limited experience in large-scale DAC deployment, technology still in early stages.

Core Metrics: Energy, Cycle Life, Throughput

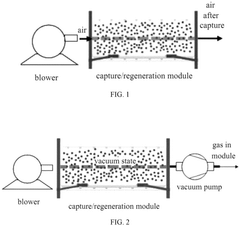

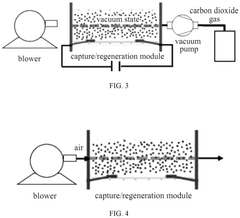

Direct air capturing method of carbon dioxide

PatentPendingEP4545168A1

Innovation

- A direct air capture method using an adsorbent prepared by mixing pulverized coal with a potassium carbonate solution, followed by activation to create a porous carbon material, and then combining this material with carbon nanotubes and an ionic liquid through carbonization. This adsorbent is used to capture CO2 from the air, with desorption and regeneration occurring at 105 to 110°C in a high vacuum state, and subsequent cooling with air for repeated cycles.

Direct air capture and bioelectrochemical conversion of co 2

PatentWO2022240659A1

Innovation

- An integrated modular system combining direct air capture using functionalized metal-organic frameworks or covalent organic frameworks with bioelectrochemical conversion by autotrophic microorganisms to produce high-purity CO2, which is then converted into value-added products like biopolymers, fuels, and chemicals, utilizing renewable energy sources to reduce carbon footprint and land occupation.

Standardization of DAC Sorbent KPI Reporting

The standardization of Key Performance Indicators (KPIs) for Direct Air Capture (DAC) sorbents is crucial for comparing different technologies and guiding research and development efforts. This standardization focuses on three primary metrics: Capture Energy per kg CO2, Cycle Life, and Throughput. These KPIs provide a comprehensive view of a sorbent's efficiency, durability, and productivity.

Capture Energy per kg CO2 is a critical measure of the energy efficiency of the DAC process. It quantifies the amount of energy required to capture one kilogram of CO2 from the atmosphere. This metric should be reported in units of kWh/kg CO2 and should include all energy inputs, such as thermal energy for regeneration and electrical energy for fans and pumps. Standardizing this metric allows for direct comparison between different sorbent technologies and helps identify the most energy-efficient solutions.

Cycle Life is an essential indicator of the sorbent's durability and longevity. It represents the number of adsorption-desorption cycles a sorbent can undergo before its performance degrades significantly. This metric should be reported as the number of cycles completed before the sorbent's CO2 capture capacity drops below a specified threshold (e.g., 80% of its initial capacity). Standardizing the reporting of Cycle Life enables better assessment of the long-term economic viability of different sorbent technologies.

Throughput is a measure of the sorbent's productivity, indicating the amount of CO2 captured per unit of time. This metric should be reported in kg CO2/day or tons CO2/year, considering the sorbent's capture capacity, cycle time, and regeneration efficiency. Standardizing throughput reporting allows for a clear comparison of the capture rates achievable by different sorbent technologies, which is crucial for scaling up DAC operations.

To ensure consistent and comparable reporting of these KPIs, it is essential to establish standardized testing protocols and conditions. These should include specifications for temperature, pressure, humidity, and CO2 concentration during testing. Additionally, the reporting should include details on the sorbent material, its preparation method, and any pre-treatment processes used.

Implementing a standardized reporting framework for DAC sorbent KPIs will facilitate more accurate comparisons between different technologies, accelerate innovation in the field, and provide clearer benchmarks for assessing progress towards large-scale atmospheric carbon removal. This standardization effort will ultimately contribute to the development of more efficient and cost-effective DAC technologies, supporting global efforts to mitigate climate change.

Capture Energy per kg CO2 is a critical measure of the energy efficiency of the DAC process. It quantifies the amount of energy required to capture one kilogram of CO2 from the atmosphere. This metric should be reported in units of kWh/kg CO2 and should include all energy inputs, such as thermal energy for regeneration and electrical energy for fans and pumps. Standardizing this metric allows for direct comparison between different sorbent technologies and helps identify the most energy-efficient solutions.

Cycle Life is an essential indicator of the sorbent's durability and longevity. It represents the number of adsorption-desorption cycles a sorbent can undergo before its performance degrades significantly. This metric should be reported as the number of cycles completed before the sorbent's CO2 capture capacity drops below a specified threshold (e.g., 80% of its initial capacity). Standardizing the reporting of Cycle Life enables better assessment of the long-term economic viability of different sorbent technologies.

Throughput is a measure of the sorbent's productivity, indicating the amount of CO2 captured per unit of time. This metric should be reported in kg CO2/day or tons CO2/year, considering the sorbent's capture capacity, cycle time, and regeneration efficiency. Standardizing throughput reporting allows for a clear comparison of the capture rates achievable by different sorbent technologies, which is crucial for scaling up DAC operations.

To ensure consistent and comparable reporting of these KPIs, it is essential to establish standardized testing protocols and conditions. These should include specifications for temperature, pressure, humidity, and CO2 concentration during testing. Additionally, the reporting should include details on the sorbent material, its preparation method, and any pre-treatment processes used.

Implementing a standardized reporting framework for DAC sorbent KPIs will facilitate more accurate comparisons between different technologies, accelerate innovation in the field, and provide clearer benchmarks for assessing progress towards large-scale atmospheric carbon removal. This standardization effort will ultimately contribute to the development of more efficient and cost-effective DAC technologies, supporting global efforts to mitigate climate change.

Environmental Impact Assessment

The environmental impact assessment of Direct Air Capture (DAC) sorbents is crucial for evaluating their overall sustainability and potential for large-scale implementation. When considering the key performance indicators (KPIs) of capture energy per kg CO2, cycle life, and throughput, it is essential to examine their broader environmental implications.

The capture energy per kg CO2 directly correlates with the carbon footprint of the DAC process. Lower energy requirements for CO2 capture translate to reduced greenhouse gas emissions associated with the energy production needed to power the DAC systems. This is particularly important when considering the life cycle assessment of DAC technologies, as the energy source used can significantly influence the net environmental benefit of the carbon removal process.

Cycle life of DAC sorbents plays a critical role in determining the long-term environmental impact of these systems. Sorbents with higher cycle life reduce the frequency of replacement, thereby minimizing waste generation and the environmental costs associated with manufacturing and disposing of spent materials. Additionally, extended cycle life contributes to the overall efficiency of the DAC process, potentially reducing the cumulative energy consumption and associated emissions over the system's operational lifetime.

Throughput, or the amount of CO2 captured per unit time, affects the land use requirements and overall efficiency of DAC installations. Higher throughput can lead to more compact systems, potentially reducing the environmental footprint in terms of land use and material requirements for infrastructure. However, it is crucial to balance increased throughput with energy efficiency to ensure that the environmental benefits are not offset by higher energy demands.

The environmental impact assessment must also consider the production and disposal of DAC sorbents. The manufacturing process of these materials may involve energy-intensive steps or the use of environmentally sensitive chemicals. Therefore, it is essential to evaluate the entire life cycle of the sorbents, from raw material extraction to end-of-life management, to gain a comprehensive understanding of their environmental implications.

Water consumption is another critical factor in the environmental assessment of DAC technologies. Some sorbent-based systems may require significant amounts of water for regeneration or cooling processes. In water-stressed regions, this could lead to competition with other essential water uses, potentially impacting local ecosystems and communities.

Lastly, the environmental impact assessment should consider the potential for unintended consequences. For instance, the large-scale deployment of DAC technologies could alter local air quality or microclimates. It is crucial to conduct thorough studies on the potential impacts on biodiversity, air circulation patterns, and local temperature variations to ensure that the implementation of DAC systems does not inadvertently harm the surrounding environment.

The capture energy per kg CO2 directly correlates with the carbon footprint of the DAC process. Lower energy requirements for CO2 capture translate to reduced greenhouse gas emissions associated with the energy production needed to power the DAC systems. This is particularly important when considering the life cycle assessment of DAC technologies, as the energy source used can significantly influence the net environmental benefit of the carbon removal process.

Cycle life of DAC sorbents plays a critical role in determining the long-term environmental impact of these systems. Sorbents with higher cycle life reduce the frequency of replacement, thereby minimizing waste generation and the environmental costs associated with manufacturing and disposing of spent materials. Additionally, extended cycle life contributes to the overall efficiency of the DAC process, potentially reducing the cumulative energy consumption and associated emissions over the system's operational lifetime.

Throughput, or the amount of CO2 captured per unit time, affects the land use requirements and overall efficiency of DAC installations. Higher throughput can lead to more compact systems, potentially reducing the environmental footprint in terms of land use and material requirements for infrastructure. However, it is crucial to balance increased throughput with energy efficiency to ensure that the environmental benefits are not offset by higher energy demands.

The environmental impact assessment must also consider the production and disposal of DAC sorbents. The manufacturing process of these materials may involve energy-intensive steps or the use of environmentally sensitive chemicals. Therefore, it is essential to evaluate the entire life cycle of the sorbents, from raw material extraction to end-of-life management, to gain a comprehensive understanding of their environmental implications.

Water consumption is another critical factor in the environmental assessment of DAC technologies. Some sorbent-based systems may require significant amounts of water for regeneration or cooling processes. In water-stressed regions, this could lead to competition with other essential water uses, potentially impacting local ecosystems and communities.

Lastly, the environmental impact assessment should consider the potential for unintended consequences. For instance, the large-scale deployment of DAC technologies could alter local air quality or microclimates. It is crucial to conduct thorough studies on the potential impacts on biodiversity, air circulation patterns, and local temperature variations to ensure that the implementation of DAC systems does not inadvertently harm the surrounding environment.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!