Long-Term Cycling Tests for DAC Sorbents: Designing Accelerated Aging Protocols

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DAC Sorbent Evolution

The evolution of Direct Air Capture (DAC) sorbents has been a critical aspect of advancing carbon dioxide removal technologies. Initially, DAC systems primarily utilized liquid solvents, such as aqueous solutions of alkali and alkaline earth metals. These early sorbents were effective but energy-intensive, requiring significant heat for regeneration.

As research progressed, solid sorbents emerged as promising alternatives. Amine-functionalized materials, including supported amine sorbents and metal-organic frameworks (MOFs), gained attention due to their lower regeneration energy requirements and potential for higher CO2 selectivity. These materials underwent continuous refinement to improve their CO2 capture capacity and stability under repeated adsorption-desorption cycles.

The development of moisture-resistant sorbents marked a significant milestone in DAC sorbent evolution. Early solid sorbents often suffered from performance degradation in the presence of water vapor, a common component in ambient air. Researchers focused on creating hydrophobic or moisture-tolerant materials to overcome this challenge, leading to more robust and efficient DAC systems.

Another key advancement was the creation of sorbents with enhanced kinetics. Fast adsorption and desorption rates became crucial for improving the overall efficiency of DAC processes. This led to the exploration of novel material structures, such as hierarchical porous materials and nanostructured sorbents, which offered improved mass transfer properties and faster CO2 uptake.

The pursuit of low-cost, scalable sorbents has been a consistent theme in DAC sorbent evolution. Researchers have investigated abundant, naturally occurring materials like zeolites and modified clays as potential sorbents. These efforts aim to reduce the overall cost of DAC technology and make it more economically viable for large-scale deployment.

Recent developments have focused on creating multifunctional sorbents that not only capture CO2 but also facilitate its conversion into valuable products. This approach, known as carbon capture and utilization (CCU), aims to offset the costs associated with DAC by producing marketable chemicals or fuels from the captured CO2.

The latest frontier in DAC sorbent evolution involves the development of materials with exceptional long-term stability. As DAC systems are expected to operate continuously for extended periods, sorbents that can maintain their performance over thousands of cycles are crucial. This has led to increased emphasis on accelerated aging protocols and long-term cycling tests to evaluate and improve sorbent durability under realistic operating conditions.

As research progressed, solid sorbents emerged as promising alternatives. Amine-functionalized materials, including supported amine sorbents and metal-organic frameworks (MOFs), gained attention due to their lower regeneration energy requirements and potential for higher CO2 selectivity. These materials underwent continuous refinement to improve their CO2 capture capacity and stability under repeated adsorption-desorption cycles.

The development of moisture-resistant sorbents marked a significant milestone in DAC sorbent evolution. Early solid sorbents often suffered from performance degradation in the presence of water vapor, a common component in ambient air. Researchers focused on creating hydrophobic or moisture-tolerant materials to overcome this challenge, leading to more robust and efficient DAC systems.

Another key advancement was the creation of sorbents with enhanced kinetics. Fast adsorption and desorption rates became crucial for improving the overall efficiency of DAC processes. This led to the exploration of novel material structures, such as hierarchical porous materials and nanostructured sorbents, which offered improved mass transfer properties and faster CO2 uptake.

The pursuit of low-cost, scalable sorbents has been a consistent theme in DAC sorbent evolution. Researchers have investigated abundant, naturally occurring materials like zeolites and modified clays as potential sorbents. These efforts aim to reduce the overall cost of DAC technology and make it more economically viable for large-scale deployment.

Recent developments have focused on creating multifunctional sorbents that not only capture CO2 but also facilitate its conversion into valuable products. This approach, known as carbon capture and utilization (CCU), aims to offset the costs associated with DAC by producing marketable chemicals or fuels from the captured CO2.

The latest frontier in DAC sorbent evolution involves the development of materials with exceptional long-term stability. As DAC systems are expected to operate continuously for extended periods, sorbents that can maintain their performance over thousands of cycles are crucial. This has led to increased emphasis on accelerated aging protocols and long-term cycling tests to evaluate and improve sorbent durability under realistic operating conditions.

Market for CO2 Capture

The market for CO2 capture technologies, particularly Direct Air Capture (DAC), has been experiencing significant growth in recent years. This expansion is driven by increasing global awareness of climate change and the urgent need to reduce greenhouse gas emissions. The potential market for DAC is vast, as it addresses the challenge of removing CO2 directly from the atmosphere, complementing efforts to reduce emissions at the source.

Several factors contribute to the growing demand for DAC technologies. Firstly, many countries and organizations have set ambitious carbon neutrality targets, creating a need for negative emissions technologies to offset residual emissions from hard-to-abate sectors. Secondly, the voluntary carbon market has been expanding rapidly, with companies seeking high-quality carbon removal credits to meet their sustainability goals.

The market for DAC is still in its early stages, with only a handful of companies operating pilot plants or small-scale commercial facilities. However, the potential for growth is substantial. Estimates suggest that the DAC market could reach several billion dollars by 2030, with projections for even more significant expansion in the following decades as the technology matures and costs decrease.

Key market segments for DAC include the energy sector, where captured CO2 can be used for enhanced oil recovery or converted into synthetic fuels. The industrial sector also presents opportunities, with applications in the production of carbon-neutral or carbon-negative materials. Additionally, there is growing interest from the agricultural sector in using captured CO2 for greenhouse enrichment and the food and beverage industry for carbonation processes.

The market landscape is characterized by a mix of established companies and innovative startups. Major players are investing heavily in research and development to improve the efficiency and cost-effectiveness of their DAC technologies. Partnerships between technology providers, industrial users, and governments are becoming increasingly common, driving further market growth and technology adoption.

Despite the promising outlook, several challenges remain for the DAC market. The high cost of current technologies is a significant barrier to widespread adoption. However, ongoing research and development efforts, including those focused on improving sorbent materials and designing accelerated aging protocols, are expected to drive down costs over time. Additionally, supportive policy frameworks and financial incentives will play a crucial role in accelerating market growth and technology deployment.

Several factors contribute to the growing demand for DAC technologies. Firstly, many countries and organizations have set ambitious carbon neutrality targets, creating a need for negative emissions technologies to offset residual emissions from hard-to-abate sectors. Secondly, the voluntary carbon market has been expanding rapidly, with companies seeking high-quality carbon removal credits to meet their sustainability goals.

The market for DAC is still in its early stages, with only a handful of companies operating pilot plants or small-scale commercial facilities. However, the potential for growth is substantial. Estimates suggest that the DAC market could reach several billion dollars by 2030, with projections for even more significant expansion in the following decades as the technology matures and costs decrease.

Key market segments for DAC include the energy sector, where captured CO2 can be used for enhanced oil recovery or converted into synthetic fuels. The industrial sector also presents opportunities, with applications in the production of carbon-neutral or carbon-negative materials. Additionally, there is growing interest from the agricultural sector in using captured CO2 for greenhouse enrichment and the food and beverage industry for carbonation processes.

The market landscape is characterized by a mix of established companies and innovative startups. Major players are investing heavily in research and development to improve the efficiency and cost-effectiveness of their DAC technologies. Partnerships between technology providers, industrial users, and governments are becoming increasingly common, driving further market growth and technology adoption.

Despite the promising outlook, several challenges remain for the DAC market. The high cost of current technologies is a significant barrier to widespread adoption. However, ongoing research and development efforts, including those focused on improving sorbent materials and designing accelerated aging protocols, are expected to drive down costs over time. Additionally, supportive policy frameworks and financial incentives will play a crucial role in accelerating market growth and technology deployment.

DAC Sorbent Challenges

Direct air capture (DAC) sorbents face significant challenges in long-term cycling tests and accelerated aging protocols. The primary issue lies in the harsh operating conditions these materials must endure over extended periods. DAC sorbents are exposed to atmospheric contaminants, temperature fluctuations, and humidity variations, which can lead to degradation and loss of performance over time.

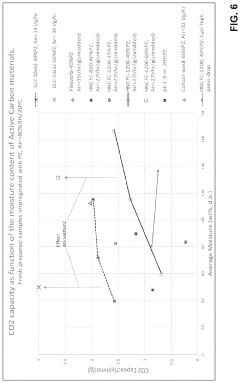

One of the main challenges is the development of sorbents that can maintain their CO2 capture capacity and selectivity over thousands of cycles. The repeated adsorption and desorption processes can cause structural changes in the sorbent materials, leading to a decrease in surface area and pore volume. This degradation directly impacts the sorbent's ability to efficiently capture CO2 from ambient air.

Another significant challenge is the design of accelerated aging protocols that accurately simulate long-term exposure conditions. These protocols must account for various environmental factors, including temperature swings, moisture levels, and the presence of atmospheric pollutants. Creating a test environment that realistically represents years of operational wear in a compressed timeframe is crucial for predicting sorbent longevity and performance.

The presence of trace contaminants in the air, such as SOx, NOx, and particulate matter, poses additional challenges for DAC sorbents. These impurities can accumulate on the sorbent surface over time, leading to poisoning and reduced CO2 capture efficiency. Developing sorbents that are resistant to these contaminants or designing effective regeneration methods is essential for long-term viability.

Thermal stability is another critical factor in DAC sorbent performance. The materials must withstand repeated temperature swings during the adsorption-desorption cycles without losing their structural integrity or capture properties. This thermal cycling can lead to sintering, phase changes, or other forms of degradation that compromise the sorbent's effectiveness over time.

Moisture management presents a unique challenge for DAC sorbents. While some moisture can be beneficial for certain sorbent types, excessive humidity can compete with CO2 for adsorption sites or cause structural changes in the material. Designing sorbents that can maintain optimal performance across a range of humidity levels is crucial for real-world applications.

Lastly, the mechanical stability of DAC sorbents is a significant concern. The materials must withstand physical stresses from handling, gas flow, and pressure changes without breaking down or generating excessive fines. Developing sorbents with high mechanical strength and attrition resistance is essential for ensuring long-term operational reliability in DAC systems.

One of the main challenges is the development of sorbents that can maintain their CO2 capture capacity and selectivity over thousands of cycles. The repeated adsorption and desorption processes can cause structural changes in the sorbent materials, leading to a decrease in surface area and pore volume. This degradation directly impacts the sorbent's ability to efficiently capture CO2 from ambient air.

Another significant challenge is the design of accelerated aging protocols that accurately simulate long-term exposure conditions. These protocols must account for various environmental factors, including temperature swings, moisture levels, and the presence of atmospheric pollutants. Creating a test environment that realistically represents years of operational wear in a compressed timeframe is crucial for predicting sorbent longevity and performance.

The presence of trace contaminants in the air, such as SOx, NOx, and particulate matter, poses additional challenges for DAC sorbents. These impurities can accumulate on the sorbent surface over time, leading to poisoning and reduced CO2 capture efficiency. Developing sorbents that are resistant to these contaminants or designing effective regeneration methods is essential for long-term viability.

Thermal stability is another critical factor in DAC sorbent performance. The materials must withstand repeated temperature swings during the adsorption-desorption cycles without losing their structural integrity or capture properties. This thermal cycling can lead to sintering, phase changes, or other forms of degradation that compromise the sorbent's effectiveness over time.

Moisture management presents a unique challenge for DAC sorbents. While some moisture can be beneficial for certain sorbent types, excessive humidity can compete with CO2 for adsorption sites or cause structural changes in the material. Designing sorbents that can maintain optimal performance across a range of humidity levels is crucial for real-world applications.

Lastly, the mechanical stability of DAC sorbents is a significant concern. The materials must withstand physical stresses from handling, gas flow, and pressure changes without breaking down or generating excessive fines. Developing sorbents with high mechanical strength and attrition resistance is essential for ensuring long-term operational reliability in DAC systems.

Current Aging Protocols

01 Adsorption and regeneration cycles of DAC sorbents

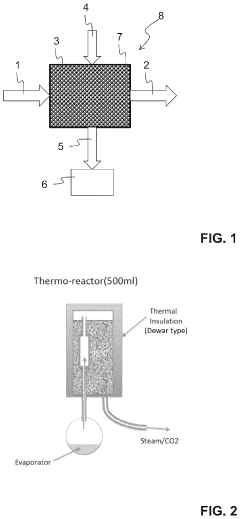

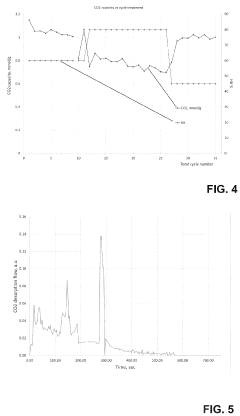

Direct Air Capture (DAC) sorbents undergo repeated cycles of adsorption and regeneration to capture CO2 from ambient air. The cycling performance of these sorbents is crucial for the efficiency and longevity of DAC systems. Factors affecting cycling performance include sorbent stability, regeneration conditions, and operational parameters.- Adsorption and regeneration cycles of DAC sorbents: Direct air capture (DAC) sorbents undergo repeated cycles of adsorption and regeneration to capture CO2 from ambient air. The cycling performance of these sorbents is crucial for the efficiency and longevity of DAC systems. Factors affecting cycling performance include sorbent stability, regeneration conditions, and adsorption capacity retention over multiple cycles.

- Sorbent material composition and structure: The composition and structure of DAC sorbents play a significant role in their cycling performance. Advanced materials, such as metal-organic frameworks (MOFs), amine-functionalized silica, and polymer-based sorbents, are designed to withstand repeated cycling while maintaining high CO2 capture capacity. Optimizing pore size, surface area, and functional groups can enhance the sorbent's durability and efficiency.

- Regeneration techniques and energy efficiency: Efficient regeneration of DAC sorbents is critical for maintaining cycling performance. Various techniques, including temperature swing adsorption (TSA), pressure swing adsorption (PSA), and vacuum swing adsorption (VSA), are employed to desorb captured CO2 and prepare the sorbent for the next cycle. Improving the energy efficiency of these processes is key to enhancing overall system performance.

- Monitoring and control systems for DAC performance: Advanced monitoring and control systems are essential for optimizing the cycling performance of DAC sorbents. These systems track key parameters such as adsorption capacity, regeneration efficiency, and sorbent degradation over time. Real-time data analysis and adaptive control strategies help maintain optimal operating conditions and extend the lifespan of sorbent materials.

- Sorbent degradation and lifetime extension strategies: Mitigating sorbent degradation is crucial for maintaining long-term cycling performance in DAC systems. Strategies to extend sorbent lifetime include developing more robust materials, optimizing operating conditions to minimize thermal and chemical stress, and implementing regeneration protocols that preserve sorbent integrity. Additionally, techniques for in-situ sorbent rejuvenation and partial replacement can help maintain system efficiency over extended periods.

02 Sorbent material composition and structure

The composition and structure of DAC sorbents play a significant role in their cycling performance. Innovative materials and designs are developed to enhance CO2 capture capacity, selectivity, and durability over multiple cycles. These may include novel porous structures, functionalized surfaces, or composite materials.Expand Specific Solutions03 Regeneration techniques for DAC sorbents

Various regeneration techniques are employed to desorb captured CO2 and prepare the sorbent for the next adsorption cycle. These may include temperature swing adsorption (TSA), pressure swing adsorption (PSA), or combinations thereof. The choice and optimization of regeneration methods significantly impact the overall cycling performance of DAC systems.Expand Specific Solutions04 Monitoring and control systems for DAC performance

Advanced monitoring and control systems are developed to optimize the cycling performance of DAC sorbents. These systems may include sensors, data analytics, and automated control mechanisms to adjust operational parameters in real-time, ensuring optimal adsorption and regeneration conditions throughout multiple cycles.Expand Specific Solutions05 Sorbent degradation and lifetime extension strategies

The long-term cycling performance of DAC sorbents is affected by degradation mechanisms such as chemical aging, physical attrition, and contamination. Strategies to extend sorbent lifetime and maintain performance over numerous cycles are developed, including in-situ regeneration techniques, protective coatings, and sorbent replenishment methods.Expand Specific Solutions

Key DAC Technology Players

The development of long-term cycling tests for Direct Air Capture (DAC) sorbents is in its early stages, reflecting the nascent nature of the DAC industry. The market size is growing but still relatively small, with increasing interest from both public and private sectors. Technologically, the field is rapidly evolving, with companies like W. L. Gore & Associates and The Regents of the University of California leading research efforts. These organizations, along with academic institutions such as Albert Einstein College of Medicine and École Polytechnique Fédérale de Lausanne, are driving innovation in sorbent materials and testing protocols. The competitive landscape is characterized by a mix of established industrial players and emerging startups, all striving to improve the efficiency and longevity of DAC sorbents.

The Regents of the University of California

Technical Solution: The University of California has developed a comprehensive accelerated aging protocol for DAC sorbents that focuses on replicating the effects of long-term exposure to atmospheric pollutants and varying environmental conditions. Their approach utilizes a series of environmental chambers that can simulate a range of temperature, humidity, and atmospheric composition scenarios[7]. The protocol includes exposure to trace amounts of SOx, NOx, and other potential contaminants found in ambient air. UC researchers have also incorporated cyclic mechanical stress testing to simulate the physical wear experienced by sorbents in industrial-scale DAC systems[8]. Their method employs advanced characterization techniques such as solid-state nuclear magnetic resonance (NMR) spectroscopy and scanning electron microscopy (SEM) to analyze changes in sorbent structure and surface properties over time[9].

Strengths: Comprehensive simulation of environmental factors and mechanical stress, detailed structural analysis capabilities. Weaknesses: Complex and potentially costly setup required for accurate simulation of multiple environmental factors.

Xi'an Thermal Power Research Institute Co., Ltd.

Technical Solution: Xi'an Thermal Power Research Institute has developed an accelerated aging protocol specifically tailored for high-temperature DAC sorbents used in power plant applications. Their method focuses on simulating the harsh conditions experienced by sorbents in flue gas environments. The protocol involves exposing sorbents to simulated flue gas streams with controlled levels of CO2, SOx, NOx, and particulate matter at elevated temperatures[10]. They utilize a pilot-scale testing facility that can operate continuously for extended periods, allowing for long-duration cycling tests. The institute's approach also incorporates periodic sorbent regeneration cycles using steam or vacuum swing processes to assess the impact of repeated regeneration on long-term performance[11]. Advanced analytical techniques such as X-ray photoelectron spectroscopy (XPS) and mercury porosimetry are employed to characterize changes in sorbent surface chemistry and pore structure over time[12].

Strengths: Specialized focus on high-temperature applications, realistic simulation of flue gas conditions, comprehensive regeneration cycle testing. Weaknesses: May be less applicable to ambient air DAC systems, potentially limited to specific types of high-temperature sorbents.

Innovative Aging Methods

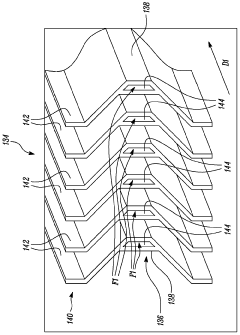

Improved materials for direct air capture and uses thereof

PatentPendingUS20240001281A1

Innovation

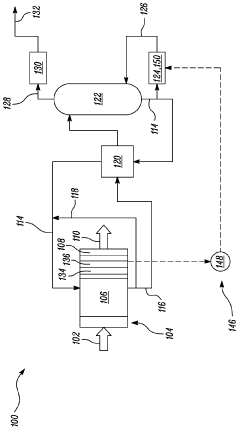

- The use of a high nitrogen-containing aromatic secondary amine, such as piperazine, combined with a water-retaining and porous support material, allows for efficient CO2 capture and desorption, even at high water vapor pressures, through cyclic adsorption/desorption processes using a sorbent material impregnated with a secondary cycloaliphatic or aromatic amine compound.

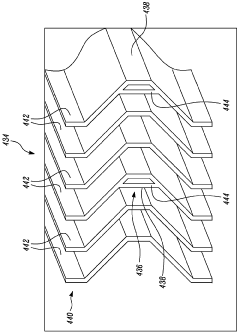

Direct air capture system and method

PatentPendingGB2624212A

Innovation

- Incorporating a mist eliminator and a cooling device in a heat exchange relationship to capture drift/droplets and reduce the temperature of the airflow, thereby reducing evaporation rates and water loss, with optional integration of a refrigeration circuit and heat exchangers to optimize energy use and capture waste heat for further processing.

Regulatory Framework

The regulatory framework surrounding long-term cycling tests for Direct Air Capture (DAC) sorbents and the design of accelerated aging protocols is still in its nascent stages. As DAC technology continues to evolve, policymakers and regulatory bodies are working to establish guidelines that ensure the safety, efficacy, and environmental sustainability of these systems.

Currently, there is no unified global regulatory framework specifically tailored to DAC sorbents and their long-term performance. However, existing regulations in related fields, such as air quality control and carbon capture and storage (CCS), provide a foundation for developing DAC-specific guidelines. The Environmental Protection Agency (EPA) in the United States, for instance, has regulations in place for CCS under the Clean Air Act, which may inform future DAC regulations.

In the European Union, the Carbon Capture and Storage Directive (Directive 2009/31/EC) establishes a legal framework for the environmentally safe geological storage of CO2. While this directive does not directly address DAC sorbents, it sets precedents for carbon capture technologies that could be adapted for DAC applications.

The development of accelerated aging protocols for DAC sorbents falls under the broader category of materials testing and qualification. Organizations such as ASTM International and the International Organization for Standardization (ISO) play crucial roles in establishing standardized testing methods. These organizations are likely to be involved in creating specific standards for DAC sorbent testing as the technology matures.

Regulatory considerations for DAC sorbents must address several key aspects, including environmental impact, safety, and performance reliability. Long-term cycling tests and accelerated aging protocols will need to demonstrate that sorbents can maintain their efficacy over extended periods without releasing harmful substances or degrading in ways that could compromise the overall DAC system performance.

As the field progresses, it is anticipated that regulatory bodies will collaborate with academic institutions, industry stakeholders, and environmental organizations to develop comprehensive guidelines. These guidelines will likely cover aspects such as minimum performance standards, testing durations, acceptable degradation rates, and safety thresholds for various sorbent materials used in DAC systems.

The regulatory landscape will also need to address the disposal or recycling of spent DAC sorbents, considering their potential environmental impact and the principles of circular economy. This aspect of regulation will be crucial in ensuring the long-term sustainability of DAC technologies.

Currently, there is no unified global regulatory framework specifically tailored to DAC sorbents and their long-term performance. However, existing regulations in related fields, such as air quality control and carbon capture and storage (CCS), provide a foundation for developing DAC-specific guidelines. The Environmental Protection Agency (EPA) in the United States, for instance, has regulations in place for CCS under the Clean Air Act, which may inform future DAC regulations.

In the European Union, the Carbon Capture and Storage Directive (Directive 2009/31/EC) establishes a legal framework for the environmentally safe geological storage of CO2. While this directive does not directly address DAC sorbents, it sets precedents for carbon capture technologies that could be adapted for DAC applications.

The development of accelerated aging protocols for DAC sorbents falls under the broader category of materials testing and qualification. Organizations such as ASTM International and the International Organization for Standardization (ISO) play crucial roles in establishing standardized testing methods. These organizations are likely to be involved in creating specific standards for DAC sorbent testing as the technology matures.

Regulatory considerations for DAC sorbents must address several key aspects, including environmental impact, safety, and performance reliability. Long-term cycling tests and accelerated aging protocols will need to demonstrate that sorbents can maintain their efficacy over extended periods without releasing harmful substances or degrading in ways that could compromise the overall DAC system performance.

As the field progresses, it is anticipated that regulatory bodies will collaborate with academic institutions, industry stakeholders, and environmental organizations to develop comprehensive guidelines. These guidelines will likely cover aspects such as minimum performance standards, testing durations, acceptable degradation rates, and safety thresholds for various sorbent materials used in DAC systems.

The regulatory landscape will also need to address the disposal or recycling of spent DAC sorbents, considering their potential environmental impact and the principles of circular economy. This aspect of regulation will be crucial in ensuring the long-term sustainability of DAC technologies.

Environmental Impact

The environmental impact of long-term cycling tests for Direct Air Capture (DAC) sorbents is a critical consideration in the development of accelerated aging protocols. These tests, designed to simulate years of operational wear in a compressed timeframe, can have both direct and indirect environmental consequences that must be carefully evaluated and mitigated.

One of the primary environmental concerns is the energy consumption associated with accelerated aging protocols. These tests often require continuous operation of equipment, potentially for weeks or months, to simulate long-term cycling. The energy demand for such intensive testing can be substantial, contributing to increased carbon emissions if not sourced from renewable energy. To address this, researchers and facilities conducting these tests should prioritize the use of clean energy sources and implement energy-efficient practices throughout the testing process.

Water usage is another significant environmental factor to consider. Many DAC sorbents require moisture for optimal performance, and accelerated aging protocols may involve repeated hydration and dehydration cycles. This can lead to substantial water consumption, particularly in areas where water resources are already strained. Implementing water recycling systems and optimizing test protocols to minimize water usage can help mitigate this impact.

The production and disposal of sorbent materials used in these tests also have environmental implications. Accelerated aging may require larger quantities of sorbent materials than would be used in normal operational conditions, potentially leading to increased resource extraction and manufacturing-related emissions. Additionally, the disposal or recycling of used sorbents after testing must be carefully managed to prevent environmental contamination. Developing protocols for the safe handling and disposal of test materials is essential to minimize ecological harm.

Chemical emissions during the testing process present another environmental concern. Some sorbents may release volatile organic compounds (VOCs) or other potentially harmful substances during cycling, especially under the stress of accelerated aging conditions. Proper ventilation systems and emission control measures must be implemented to prevent these substances from entering the environment and potentially affecting local air quality or ecosystems.

The development of accelerated aging protocols also offers opportunities for environmental benefits. By accurately simulating long-term performance in a shorter timeframe, these tests can lead to the more rapid development and deployment of efficient DAC technologies. This, in turn, can accelerate the implementation of carbon removal strategies, contributing to global efforts to mitigate climate change. Furthermore, insights gained from these tests can inform the design of more durable and environmentally friendly sorbent materials, reducing the overall environmental footprint of DAC operations in the long term.

To fully assess and minimize the environmental impact of long-term cycling tests, life cycle assessments (LCAs) should be conducted. These assessments can provide a comprehensive view of the environmental implications throughout the entire testing process, from material sourcing to waste management. By identifying areas of significant environmental impact, researchers can refine their protocols to be more sustainable without compromising the validity and usefulness of the accelerated aging tests.

One of the primary environmental concerns is the energy consumption associated with accelerated aging protocols. These tests often require continuous operation of equipment, potentially for weeks or months, to simulate long-term cycling. The energy demand for such intensive testing can be substantial, contributing to increased carbon emissions if not sourced from renewable energy. To address this, researchers and facilities conducting these tests should prioritize the use of clean energy sources and implement energy-efficient practices throughout the testing process.

Water usage is another significant environmental factor to consider. Many DAC sorbents require moisture for optimal performance, and accelerated aging protocols may involve repeated hydration and dehydration cycles. This can lead to substantial water consumption, particularly in areas where water resources are already strained. Implementing water recycling systems and optimizing test protocols to minimize water usage can help mitigate this impact.

The production and disposal of sorbent materials used in these tests also have environmental implications. Accelerated aging may require larger quantities of sorbent materials than would be used in normal operational conditions, potentially leading to increased resource extraction and manufacturing-related emissions. Additionally, the disposal or recycling of used sorbents after testing must be carefully managed to prevent environmental contamination. Developing protocols for the safe handling and disposal of test materials is essential to minimize ecological harm.

Chemical emissions during the testing process present another environmental concern. Some sorbents may release volatile organic compounds (VOCs) or other potentially harmful substances during cycling, especially under the stress of accelerated aging conditions. Proper ventilation systems and emission control measures must be implemented to prevent these substances from entering the environment and potentially affecting local air quality or ecosystems.

The development of accelerated aging protocols also offers opportunities for environmental benefits. By accurately simulating long-term performance in a shorter timeframe, these tests can lead to the more rapid development and deployment of efficient DAC technologies. This, in turn, can accelerate the implementation of carbon removal strategies, contributing to global efforts to mitigate climate change. Furthermore, insights gained from these tests can inform the design of more durable and environmentally friendly sorbent materials, reducing the overall environmental footprint of DAC operations in the long term.

To fully assess and minimize the environmental impact of long-term cycling tests, life cycle assessments (LCAs) should be conducted. These assessments can provide a comprehensive view of the environmental implications throughout the entire testing process, from material sourcing to waste management. By identifying areas of significant environmental impact, researchers can refine their protocols to be more sustainable without compromising the validity and usefulness of the accelerated aging tests.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!