Sorbent Pelletization & Attrition Resistance: Test Protocols and Binder Selection

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Sorbent Pelletization Background and Objectives

Sorbent pelletization has emerged as a critical technology in various industrial applications, particularly in environmental remediation and gas purification processes. The development of this technology can be traced back to the mid-20th century when the need for efficient and cost-effective methods to remove contaminants from gas streams became increasingly apparent. Over the years, sorbent pelletization has evolved significantly, driven by advancements in material science and engineering.

The primary objective of sorbent pelletization is to create highly effective, durable, and easily manageable sorbent materials capable of capturing and retaining specific target substances from gas or liquid streams. This process involves transforming powdered or granular sorbent materials into uniform, spherical pellets with enhanced physical and chemical properties. The pelletization technique offers numerous advantages, including improved handling characteristics, reduced pressure drop in fixed-bed applications, and increased surface area for adsorption.

As environmental regulations have become more stringent and industrial processes more complex, the demand for advanced sorbent materials has grown exponentially. This has led to a surge in research and development efforts focused on optimizing sorbent pelletization techniques and enhancing the performance of the resulting pellets. Key areas of focus include improving the mechanical strength of pellets to withstand attrition, increasing their adsorption capacity, and enhancing their selectivity for specific target compounds.

The evolution of sorbent pelletization technology has been marked by several significant milestones. These include the development of novel binder materials, the introduction of advanced pelletization equipment, and the implementation of innovative pellet formation techniques. Each of these advancements has contributed to the overall improvement of sorbent performance and durability, enabling more efficient and cost-effective industrial applications.

Looking ahead, the field of sorbent pelletization continues to face several challenges and opportunities. One of the primary objectives is to develop sorbent pellets with superior attrition resistance while maintaining high adsorption capacity. This goal necessitates a comprehensive understanding of the relationship between pellet composition, structure, and performance. Additionally, there is a growing emphasis on developing environmentally friendly and sustainable sorbent materials, aligning with global efforts to reduce the environmental impact of industrial processes.

In conclusion, the background and objectives of sorbent pelletization research reflect a dynamic and evolving field with significant potential for further innovation. As industries continue to seek more efficient and sustainable solutions for gas purification and environmental remediation, the development of advanced sorbent pellets remains a critical area of focus, driving ongoing research and technological advancements in this domain.

The primary objective of sorbent pelletization is to create highly effective, durable, and easily manageable sorbent materials capable of capturing and retaining specific target substances from gas or liquid streams. This process involves transforming powdered or granular sorbent materials into uniform, spherical pellets with enhanced physical and chemical properties. The pelletization technique offers numerous advantages, including improved handling characteristics, reduced pressure drop in fixed-bed applications, and increased surface area for adsorption.

As environmental regulations have become more stringent and industrial processes more complex, the demand for advanced sorbent materials has grown exponentially. This has led to a surge in research and development efforts focused on optimizing sorbent pelletization techniques and enhancing the performance of the resulting pellets. Key areas of focus include improving the mechanical strength of pellets to withstand attrition, increasing their adsorption capacity, and enhancing their selectivity for specific target compounds.

The evolution of sorbent pelletization technology has been marked by several significant milestones. These include the development of novel binder materials, the introduction of advanced pelletization equipment, and the implementation of innovative pellet formation techniques. Each of these advancements has contributed to the overall improvement of sorbent performance and durability, enabling more efficient and cost-effective industrial applications.

Looking ahead, the field of sorbent pelletization continues to face several challenges and opportunities. One of the primary objectives is to develop sorbent pellets with superior attrition resistance while maintaining high adsorption capacity. This goal necessitates a comprehensive understanding of the relationship between pellet composition, structure, and performance. Additionally, there is a growing emphasis on developing environmentally friendly and sustainable sorbent materials, aligning with global efforts to reduce the environmental impact of industrial processes.

In conclusion, the background and objectives of sorbent pelletization research reflect a dynamic and evolving field with significant potential for further innovation. As industries continue to seek more efficient and sustainable solutions for gas purification and environmental remediation, the development of advanced sorbent pellets remains a critical area of focus, driving ongoing research and technological advancements in this domain.

Market Analysis for Attrition-Resistant Sorbents

The market for attrition-resistant sorbents has been experiencing significant growth in recent years, driven by increasing environmental regulations and the need for more efficient industrial processes. These specialized materials play a crucial role in various applications, including gas purification, carbon capture, and wastewater treatment.

In the gas purification sector, attrition-resistant sorbents are widely used in flue gas desulfurization systems, where they help remove sulfur dioxide and other pollutants from industrial emissions. The growing emphasis on reducing air pollution has led to a surge in demand for these materials, particularly in regions with stringent environmental regulations such as Europe and North America.

The carbon capture market is another key driver for attrition-resistant sorbents. As global efforts to combat climate change intensify, there is an increasing focus on developing efficient and cost-effective carbon capture technologies. Attrition-resistant sorbents are essential in this field, as they can withstand the harsh conditions of carbon capture processes while maintaining their effectiveness over multiple cycles.

In the wastewater treatment industry, attrition-resistant sorbents are utilized for removing contaminants from industrial and municipal wastewater. The growing awareness of water scarcity and the need for water reuse has led to increased investments in advanced water treatment technologies, further boosting the demand for these specialized materials.

The market for attrition-resistant sorbents is highly competitive, with several key players dominating the industry. These companies are continuously investing in research and development to improve the performance and durability of their products. The focus is on developing sorbents with higher attrition resistance, increased adsorption capacity, and improved regeneration capabilities.

Geographically, North America and Europe are the largest markets for attrition-resistant sorbents, primarily due to stringent environmental regulations and a well-established industrial base. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, driven by rapid industrialization, increasing environmental concerns, and government initiatives to reduce pollution.

The market is also influenced by technological advancements in sorbent manufacturing processes. Innovations in pelletization techniques and binder selection are crucial for developing sorbents with enhanced attrition resistance. This has led to increased collaboration between academic institutions and industry players to develop novel materials and production methods.

In the gas purification sector, attrition-resistant sorbents are widely used in flue gas desulfurization systems, where they help remove sulfur dioxide and other pollutants from industrial emissions. The growing emphasis on reducing air pollution has led to a surge in demand for these materials, particularly in regions with stringent environmental regulations such as Europe and North America.

The carbon capture market is another key driver for attrition-resistant sorbents. As global efforts to combat climate change intensify, there is an increasing focus on developing efficient and cost-effective carbon capture technologies. Attrition-resistant sorbents are essential in this field, as they can withstand the harsh conditions of carbon capture processes while maintaining their effectiveness over multiple cycles.

In the wastewater treatment industry, attrition-resistant sorbents are utilized for removing contaminants from industrial and municipal wastewater. The growing awareness of water scarcity and the need for water reuse has led to increased investments in advanced water treatment technologies, further boosting the demand for these specialized materials.

The market for attrition-resistant sorbents is highly competitive, with several key players dominating the industry. These companies are continuously investing in research and development to improve the performance and durability of their products. The focus is on developing sorbents with higher attrition resistance, increased adsorption capacity, and improved regeneration capabilities.

Geographically, North America and Europe are the largest markets for attrition-resistant sorbents, primarily due to stringent environmental regulations and a well-established industrial base. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, driven by rapid industrialization, increasing environmental concerns, and government initiatives to reduce pollution.

The market is also influenced by technological advancements in sorbent manufacturing processes. Innovations in pelletization techniques and binder selection are crucial for developing sorbents with enhanced attrition resistance. This has led to increased collaboration between academic institutions and industry players to develop novel materials and production methods.

Current Challenges in Sorbent Pelletization

Sorbent pelletization faces several significant challenges that hinder its widespread adoption and efficiency in various applications. One of the primary issues is achieving consistent pellet size and shape distribution. The pelletization process often results in a wide range of particle sizes, which can negatively impact the overall performance of the sorbent system. Uniformity in pellet size is crucial for ensuring even flow rates, predictable pressure drops, and consistent adsorption capacities.

Another major challenge lies in maintaining the structural integrity of the pellets during handling, transportation, and use. Sorbent pellets are subjected to various mechanical stresses, including compression, impact, and abrasion. These forces can lead to pellet breakage, attrition, and the generation of fines, which not only reduces the effective surface area for adsorption but also causes operational issues such as clogging and increased pressure drop in fixed-bed systems.

The selection of appropriate binders presents a complex challenge in sorbent pelletization. While binders are essential for improving the mechanical strength of pellets, they can also adversely affect the adsorption properties of the sorbent material. Finding the right balance between pellet strength and adsorption capacity is a delicate task that requires extensive research and optimization.

Environmental factors, such as humidity and temperature fluctuations, pose additional challenges to sorbent pellet stability. Many sorbent materials are hygroscopic, making them susceptible to moisture-induced degradation. This can lead to changes in pellet structure, reduced mechanical strength, and altered adsorption characteristics over time.

Scalability of the pelletization process is another significant hurdle. Laboratory-scale pelletization techniques often do not translate directly to industrial-scale production. Achieving consistent quality and properties in large-scale manufacturing while maintaining cost-effectiveness remains a challenge for many sorbent materials.

The development of standardized test protocols for evaluating pellet attrition resistance is an ongoing challenge in the field. The lack of universally accepted methods for assessing pellet durability makes it difficult to compare different sorbent formulations and pelletization techniques across studies and applications.

Lastly, the increasing demand for sustainable and environmentally friendly materials adds another layer of complexity to sorbent pelletization. There is a growing need to develop pelletization processes and binder systems that are not only effective but also align with green chemistry principles and circular economy concepts.

Another major challenge lies in maintaining the structural integrity of the pellets during handling, transportation, and use. Sorbent pellets are subjected to various mechanical stresses, including compression, impact, and abrasion. These forces can lead to pellet breakage, attrition, and the generation of fines, which not only reduces the effective surface area for adsorption but also causes operational issues such as clogging and increased pressure drop in fixed-bed systems.

The selection of appropriate binders presents a complex challenge in sorbent pelletization. While binders are essential for improving the mechanical strength of pellets, they can also adversely affect the adsorption properties of the sorbent material. Finding the right balance between pellet strength and adsorption capacity is a delicate task that requires extensive research and optimization.

Environmental factors, such as humidity and temperature fluctuations, pose additional challenges to sorbent pellet stability. Many sorbent materials are hygroscopic, making them susceptible to moisture-induced degradation. This can lead to changes in pellet structure, reduced mechanical strength, and altered adsorption characteristics over time.

Scalability of the pelletization process is another significant hurdle. Laboratory-scale pelletization techniques often do not translate directly to industrial-scale production. Achieving consistent quality and properties in large-scale manufacturing while maintaining cost-effectiveness remains a challenge for many sorbent materials.

The development of standardized test protocols for evaluating pellet attrition resistance is an ongoing challenge in the field. The lack of universally accepted methods for assessing pellet durability makes it difficult to compare different sorbent formulations and pelletization techniques across studies and applications.

Lastly, the increasing demand for sustainable and environmentally friendly materials adds another layer of complexity to sorbent pelletization. There is a growing need to develop pelletization processes and binder systems that are not only effective but also align with green chemistry principles and circular economy concepts.

Existing Test Protocols for Attrition Resistance

01 Binder composition for improved attrition resistance

Incorporating specific binder compositions into sorbent pellets can significantly enhance their attrition resistance. These binders, which may include clay minerals, organic polymers, or inorganic compounds, help to strengthen the pellet structure and reduce particle breakdown during handling and use. The choice and proportion of binder materials can be optimized to achieve the desired balance between attrition resistance and other pellet properties.- Binder composition for improved attrition resistance: Incorporating specific binder compositions into sorbent pellets can significantly enhance their attrition resistance. These binders, such as clay minerals, organic polymers, or inorganic compounds, help to strengthen the pellet structure and reduce particle breakdown during handling and use. The choice and proportion of binder materials are crucial for optimizing the pellet's mechanical strength while maintaining its sorbent properties.

- Heat treatment and calcination processes: Applying specific heat treatment and calcination processes to sorbent pellets can improve their attrition resistance. These thermal processes help to sinter the particles, creating stronger bonds between them and increasing the overall hardness of the pellets. The temperature, duration, and atmosphere of the heat treatment are key factors in achieving the desired balance between attrition resistance and sorbent capacity.

- Particle size distribution and pellet formation techniques: Optimizing the particle size distribution of the sorbent material and employing advanced pellet formation techniques can enhance attrition resistance. This includes using a combination of fine and coarse particles, as well as utilizing methods such as spray drying, extrusion, or granulation to create more uniform and denser pellets. The pellet shape and surface characteristics also play a role in improving resistance to mechanical stress.

- Surface modification and coating: Applying surface modifications or coatings to sorbent pellets can significantly improve their attrition resistance. These treatments can include the addition of hydrophobic agents, silane coupling agents, or polymer coatings that create a protective layer on the pellet surface. Such modifications not only enhance mechanical strength but can also improve the pellet's resistance to moisture and other environmental factors that may contribute to attrition.

- Composite materials and reinforcement additives: Incorporating composite materials or reinforcement additives into sorbent pellets can greatly enhance their attrition resistance. This approach involves combining the primary sorbent material with secondary components that provide structural support or act as reinforcing agents. Examples include the addition of fibers, nanoparticles, or other high-strength materials that can create a more robust pellet structure while maintaining or even improving sorbent properties.

02 Heat treatment and calcination processes

Applying specific heat treatment and calcination processes to sorbent pellets can improve their attrition resistance. These thermal processes can promote sintering, increase particle density, and strengthen inter-particle bonds. The temperature, duration, and atmosphere of the heat treatment can be carefully controlled to optimize the pellet's physical properties and attrition resistance without compromising its adsorption capacity.Expand Specific Solutions03 Particle size distribution and pellet formation techniques

Optimizing the particle size distribution of the raw materials and employing specific pellet formation techniques can enhance the attrition resistance of sorbent pellets. This may involve using a combination of fine and coarse particles, controlling the moisture content during pelletization, and applying appropriate pressure and shaping methods. These factors contribute to the overall strength and durability of the pellets.Expand Specific Solutions04 Surface modification and coating

Applying surface modifications or coatings to sorbent pellets can improve their attrition resistance. This may involve treating the pellet surface with chemical agents, polymers, or inorganic materials that enhance the pellet's hardness and resistance to abrasion. These surface treatments can create a protective layer without significantly affecting the pellet's adsorption properties.Expand Specific Solutions05 Composite materials and reinforcement additives

Incorporating composite materials or reinforcement additives into sorbent pellets can enhance their attrition resistance. This may involve adding fibers, nanoparticles, or other strengthening agents that improve the pellet's mechanical properties. These additives can be dispersed throughout the pellet matrix or concentrated in specific regions to provide targeted reinforcement.Expand Specific Solutions

Key Players in Sorbent Manufacturing

The research on sorbent pelletization and attrition resistance is in a developing stage, with growing market potential driven by environmental regulations and industrial applications. The global market for advanced sorbent materials is expanding, estimated to reach several billion dollars by 2025. Technologically, the field is progressing rapidly, with companies like Carbonxt, Inc. and Multisorb Technologies leading innovations in custom activated carbon solutions and active packaging technology. Other key players such as 3M Innovative Properties Co. and Henkel AG & Co. KGaA are contributing to advancements in adhesive technologies and functional coatings, which may have applications in sorbent development. The involvement of research institutions like the University of Florida and Fraunhofer-Gesellschaft indicates ongoing efforts to improve test protocols and binder selection for enhanced sorbent performance.

3M Innovative Properties Co.

Technical Solution: 3M's research on sorbent pelletization and attrition resistance leverages their expertise in adhesive technologies and material science. The company has developed a proprietary binder system that creates strong inter-particle bonds within sorbent pellets while maintaining porosity. Their approach involves a careful balance of binder chemistry and pelletization process parameters to optimize both mechanical strength and adsorption performance[5]. 3M's test protocols include advanced imaging techniques to analyze pellet microstructure and predict long-term stability. The company also employs computational modeling to simulate pellet behavior under various stress conditions, allowing for rapid iteration and optimization of formulations[6]. Binder selection at 3M focuses on versatile polymeric compounds that can be tailored to specific sorbent materials and end-use requirements.

Strengths: Advanced material science capabilities, innovative testing methods, and customizable binder systems. Weaknesses: Potentially higher costs associated with proprietary technologies and extensive R&D processes.

Carbonxt, Inc.

Technical Solution: Carbonxt specializes in developing advanced sorbent technologies for environmental applications. Their research on sorbent pelletization focuses on creating high-performance activated carbon pellets with enhanced attrition resistance. The company employs a proprietary binding process that utilizes eco-friendly binders to form durable pellets capable of withstanding harsh industrial conditions. Their test protocols involve rigorous attrition testing, including drum tests and fluidized bed simulations, to ensure pellet integrity under various operational scenarios[1]. Carbonxt's binder selection process emphasizes the use of organic compounds that not only improve pellet strength but also maintain or enhance the sorbent's adsorption capacity[3].

Strengths: Expertise in activated carbon technology, focus on eco-friendly binders, and comprehensive testing protocols. Weaknesses: Potentially higher production costs due to specialized binders and extensive testing procedures.

Innovative Binder Technologies

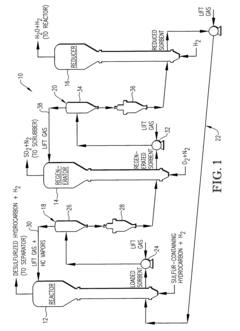

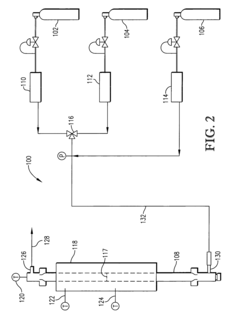

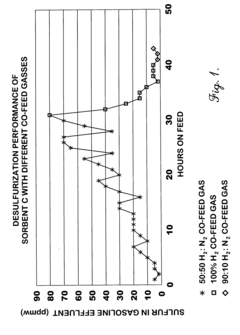

Desulfurization sorbent

PatentInactiveUS7371707B2

Innovation

- A sorbent composition is developed by treating expanded perlite with an acid and combining it with a zinc source and a promoter metal, which is then calcined and reduced to create a sorbent with enhanced attrition resistance and minimal hydrogen consumption, maintaining the octane number during sulfur removal.

Desulfurization and novel sorbent for the same

PatentInactiveUS20050266989A1

Innovation

- A sorbent composition is developed by admixing a zinc source and an aluminum source, controlling the pH, and incorporating a promoter metal, followed by calcination and reduction, which enhances attrition resistance and minimizes hydrogen consumption while maintaining octane levels.

Environmental Impact of Sorbent Production

The production of sorbent materials for environmental applications, while beneficial for pollution control, can have significant environmental impacts throughout its lifecycle. The manufacturing process often involves energy-intensive steps, including mining of raw materials, processing, and pelletization, which contribute to greenhouse gas emissions and resource depletion. The choice of binders and additives in sorbent production can also introduce potential environmental hazards if not properly managed.

Water consumption is a notable concern in sorbent production, particularly during the pelletization process. Large volumes of water may be required for mixing and shaping the sorbent materials, potentially straining local water resources in water-scarce regions. Additionally, wastewater generated during production may contain contaminants that require treatment before discharge, adding to the environmental footprint of the manufacturing process.

The mining and extraction of raw materials for sorbents, such as zeolites, activated carbon, or clay minerals, can lead to habitat disruption, soil erosion, and potential contamination of surrounding ecosystems. These activities may also result in the release of particulate matter and other pollutants into the air and water, affecting local air and water quality.

Transportation of raw materials and finished sorbent products contributes to the overall carbon footprint of sorbent production. The global nature of supply chains often necessitates long-distance shipping, increasing fuel consumption and associated emissions. Furthermore, the packaging materials used for sorbent products, often plastic-based, add to the waste stream and potential environmental pollution if not properly recycled or disposed of.

The disposal or regeneration of spent sorbents presents another environmental challenge. While some sorbents can be regenerated, extending their useful life, others may require disposal in landfills or through incineration. This can lead to soil and groundwater contamination if not managed properly, or contribute to air pollution in the case of incineration.

However, it is important to note that the environmental impacts of sorbent production must be weighed against the significant environmental benefits these materials provide in pollution control and remediation efforts. Advancements in green chemistry and sustainable manufacturing practices are continually being developed to mitigate the environmental impacts of sorbent production, including the use of bio-based binders, energy-efficient processing techniques, and closed-loop water systems.

Water consumption is a notable concern in sorbent production, particularly during the pelletization process. Large volumes of water may be required for mixing and shaping the sorbent materials, potentially straining local water resources in water-scarce regions. Additionally, wastewater generated during production may contain contaminants that require treatment before discharge, adding to the environmental footprint of the manufacturing process.

The mining and extraction of raw materials for sorbents, such as zeolites, activated carbon, or clay minerals, can lead to habitat disruption, soil erosion, and potential contamination of surrounding ecosystems. These activities may also result in the release of particulate matter and other pollutants into the air and water, affecting local air and water quality.

Transportation of raw materials and finished sorbent products contributes to the overall carbon footprint of sorbent production. The global nature of supply chains often necessitates long-distance shipping, increasing fuel consumption and associated emissions. Furthermore, the packaging materials used for sorbent products, often plastic-based, add to the waste stream and potential environmental pollution if not properly recycled or disposed of.

The disposal or regeneration of spent sorbents presents another environmental challenge. While some sorbents can be regenerated, extending their useful life, others may require disposal in landfills or through incineration. This can lead to soil and groundwater contamination if not managed properly, or contribute to air pollution in the case of incineration.

However, it is important to note that the environmental impacts of sorbent production must be weighed against the significant environmental benefits these materials provide in pollution control and remediation efforts. Advancements in green chemistry and sustainable manufacturing practices are continually being developed to mitigate the environmental impacts of sorbent production, including the use of bio-based binders, energy-efficient processing techniques, and closed-loop water systems.

Regulatory Framework for Sorbent Materials

The regulatory framework for sorbent materials plays a crucial role in ensuring the safety, efficacy, and environmental compatibility of these substances. In the context of pelletization and attrition resistance research, regulatory considerations are particularly important due to the potential applications in various industries, including environmental remediation, industrial processes, and consumer products.

At the international level, organizations such as the International Organization for Standardization (ISO) and the World Health Organization (WHO) provide guidelines and standards for sorbent materials. These guidelines often focus on quality control, performance metrics, and safety assessments. For instance, ISO 9001 standards may be applicable to the manufacturing processes of sorbent pellets, ensuring consistent quality and traceability.

In the United States, the Environmental Protection Agency (EPA) regulates sorbent materials used in environmental applications, such as oil spill cleanup or water treatment. The EPA's Spill Prevention, Control, and Countermeasure (SPCC) regulations outline requirements for oil sorbents, including performance criteria and disposal protocols. Additionally, the Occupational Safety and Health Administration (OSHA) sets standards for worker safety when handling sorbent materials in industrial settings.

The European Union has established the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation, which applies to sorbent materials and their components. REACH requires manufacturers and importers to assess and manage the risks associated with these substances, including potential environmental and health impacts. The European Chemicals Agency (ECHA) oversees the implementation of REACH and provides guidance on compliance.

Specific regulations may also apply to binders used in sorbent pelletization. For example, if food-grade binders are employed, they must comply with food safety regulations set by agencies such as the U.S. Food and Drug Administration (FDA) or the European Food Safety Authority (EFSA). These regulations ensure that the binders do not introduce harmful substances into the final product or compromise its intended function.

Test protocols for sorbent materials often need to adhere to standardized methods recognized by regulatory bodies. For instance, the American Society for Testing and Materials (ASTM) provides several standard test methods for evaluating sorbent performance, including ASTM F726 for oil spill sorbents and ASTM D2862 for activated carbon. Compliance with these standards can be essential for regulatory approval and market acceptance.

As research in sorbent pelletization and attrition resistance progresses, it is crucial to consider emerging regulations and anticipate future regulatory changes. This may include stricter environmental standards, increased focus on sustainable materials, or new requirements for lifecycle assessments of sorbent products. Staying informed about regulatory developments and engaging with relevant authorities can help ensure that research efforts align with current and future compliance requirements.

At the international level, organizations such as the International Organization for Standardization (ISO) and the World Health Organization (WHO) provide guidelines and standards for sorbent materials. These guidelines often focus on quality control, performance metrics, and safety assessments. For instance, ISO 9001 standards may be applicable to the manufacturing processes of sorbent pellets, ensuring consistent quality and traceability.

In the United States, the Environmental Protection Agency (EPA) regulates sorbent materials used in environmental applications, such as oil spill cleanup or water treatment. The EPA's Spill Prevention, Control, and Countermeasure (SPCC) regulations outline requirements for oil sorbents, including performance criteria and disposal protocols. Additionally, the Occupational Safety and Health Administration (OSHA) sets standards for worker safety when handling sorbent materials in industrial settings.

The European Union has established the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation, which applies to sorbent materials and their components. REACH requires manufacturers and importers to assess and manage the risks associated with these substances, including potential environmental and health impacts. The European Chemicals Agency (ECHA) oversees the implementation of REACH and provides guidance on compliance.

Specific regulations may also apply to binders used in sorbent pelletization. For example, if food-grade binders are employed, they must comply with food safety regulations set by agencies such as the U.S. Food and Drug Administration (FDA) or the European Food Safety Authority (EFSA). These regulations ensure that the binders do not introduce harmful substances into the final product or compromise its intended function.

Test protocols for sorbent materials often need to adhere to standardized methods recognized by regulatory bodies. For instance, the American Society for Testing and Materials (ASTM) provides several standard test methods for evaluating sorbent performance, including ASTM F726 for oil spill sorbents and ASTM D2862 for activated carbon. Compliance with these standards can be essential for regulatory approval and market acceptance.

As research in sorbent pelletization and attrition resistance progresses, it is crucial to consider emerging regulations and anticipate future regulatory changes. This may include stricter environmental standards, increased focus on sustainable materials, or new requirements for lifecycle assessments of sorbent products. Staying informed about regulatory developments and engaging with relevant authorities can help ensure that research efforts align with current and future compliance requirements.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!