How to Design Low-Energy Sorbent Regeneration Cycles for Direct Air Capture Plants

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DAC Technology Background and Objectives

Direct Air Capture (DAC) technology has emerged as a promising solution to combat climate change by removing carbon dioxide directly from the atmosphere. The development of DAC has its roots in the early 2000s, with significant advancements made in the past decade. As global efforts to reduce greenhouse gas emissions intensify, DAC has gained increasing attention as a potential tool to achieve negative emissions and mitigate the impacts of climate change.

The evolution of DAC technology has been driven by the urgent need to address rising atmospheric CO2 levels. Early DAC systems were energy-intensive and costly, limiting their practical application. However, continuous research and development have led to more efficient and economically viable designs. The primary goal of DAC technology is to capture CO2 from ambient air at a large scale while minimizing energy consumption and operational costs.

Current DAC systems primarily utilize two approaches: liquid solvent-based systems and solid sorbent-based systems. Both methods aim to selectively capture CO2 from the air and then release it in a concentrated form for storage or utilization. The regeneration of sorbents or solvents is a critical step in the DAC process, as it typically requires significant energy input, which can impact the overall efficiency and sustainability of the technology.

The specific technical objective addressed in this report is the design of low-energy sorbent regeneration cycles for DAC plants. This focus is crucial because the energy requirements for sorbent regeneration represent a substantial portion of the operational costs and environmental impact of DAC systems. By developing more efficient regeneration processes, it becomes possible to enhance the overall performance of DAC plants, reduce their carbon footprint, and improve their economic viability.

Achieving low-energy sorbent regeneration involves several key challenges. These include optimizing the sorbent material properties, improving heat management during the regeneration process, and developing novel cycle configurations that minimize energy waste. Additionally, there is a need to balance the trade-offs between capture efficiency, regeneration energy, and sorbent longevity to create sustainable and scalable DAC solutions.

As the technology continues to mature, the objectives for DAC systems extend beyond mere technical feasibility. There is a growing emphasis on developing DAC plants that are not only effective at capturing CO2 but also environmentally sustainable, economically competitive, and capable of integration with existing industrial processes or renewable energy sources. The pursuit of low-energy sorbent regeneration cycles aligns with these broader goals, potentially unlocking new possibilities for widespread DAC deployment and contributing significantly to global carbon reduction efforts.

The evolution of DAC technology has been driven by the urgent need to address rising atmospheric CO2 levels. Early DAC systems were energy-intensive and costly, limiting their practical application. However, continuous research and development have led to more efficient and economically viable designs. The primary goal of DAC technology is to capture CO2 from ambient air at a large scale while minimizing energy consumption and operational costs.

Current DAC systems primarily utilize two approaches: liquid solvent-based systems and solid sorbent-based systems. Both methods aim to selectively capture CO2 from the air and then release it in a concentrated form for storage or utilization. The regeneration of sorbents or solvents is a critical step in the DAC process, as it typically requires significant energy input, which can impact the overall efficiency and sustainability of the technology.

The specific technical objective addressed in this report is the design of low-energy sorbent regeneration cycles for DAC plants. This focus is crucial because the energy requirements for sorbent regeneration represent a substantial portion of the operational costs and environmental impact of DAC systems. By developing more efficient regeneration processes, it becomes possible to enhance the overall performance of DAC plants, reduce their carbon footprint, and improve their economic viability.

Achieving low-energy sorbent regeneration involves several key challenges. These include optimizing the sorbent material properties, improving heat management during the regeneration process, and developing novel cycle configurations that minimize energy waste. Additionally, there is a need to balance the trade-offs between capture efficiency, regeneration energy, and sorbent longevity to create sustainable and scalable DAC solutions.

As the technology continues to mature, the objectives for DAC systems extend beyond mere technical feasibility. There is a growing emphasis on developing DAC plants that are not only effective at capturing CO2 but also environmentally sustainable, economically competitive, and capable of integration with existing industrial processes or renewable energy sources. The pursuit of low-energy sorbent regeneration cycles aligns with these broader goals, potentially unlocking new possibilities for widespread DAC deployment and contributing significantly to global carbon reduction efforts.

Market Analysis for Carbon Capture Solutions

The carbon capture solutions market is experiencing significant growth, driven by increasing global efforts to combat climate change and reduce greenhouse gas emissions. Direct Air Capture (DAC) technology, particularly low-energy sorbent regeneration cycles, is emerging as a promising solution within this market.

The global carbon capture and storage market was valued at approximately $6.13 billion in 2020 and is projected to reach $11.85 billion by 2028, growing at a CAGR of 8.5% during the forecast period. This growth is primarily attributed to stringent government regulations, rising investments in carbon capture technologies, and increasing awareness of the need for carbon reduction.

Direct Air Capture, a subset of the broader carbon capture market, is gaining traction due to its potential to remove CO2 directly from the atmosphere. The DAC market is expected to grow from $135 million in 2021 to $1.6 billion by 2030, with a CAGR of 31.6%. This rapid growth is fueled by the increasing demand for negative emissions technologies to meet ambitious climate targets.

Low-energy sorbent regeneration cycles for DAC plants are particularly attractive due to their potential to significantly reduce operational costs and improve overall efficiency. The market for these advanced DAC technologies is expected to grow at an even faster rate than the general DAC market, as energy efficiency becomes a critical factor in large-scale deployment.

Key market drivers for low-energy sorbent regeneration cycles include the need for cost-effective carbon removal solutions, government incentives and carbon pricing mechanisms, and corporate commitments to achieve net-zero emissions. Additionally, the growing interest in carbon-neutral fuels and materials is creating new market opportunities for DAC technologies.

The market for carbon capture solutions, including DAC, is geographically diverse. North America currently leads the market, followed by Europe and Asia-Pacific. The United States, in particular, is expected to be a major market for DAC technologies, driven by supportive policies such as the 45Q tax credit for carbon sequestration.

Key players in the DAC market include Carbon Engineering, Climeworks, and Global Thermostat. These companies are actively developing and scaling up their technologies, with a focus on improving energy efficiency and reducing costs. The market is also seeing increased interest from major oil and gas companies, as well as technology giants, who are investing in and partnering with DAC startups.

Despite the promising growth prospects, the market for low-energy sorbent regeneration cycles in DAC plants faces challenges. These include high initial capital costs, the need for further technological advancements to improve efficiency, and the requirement for supportive policy frameworks to drive large-scale adoption. However, ongoing research and development efforts, coupled with increasing climate urgency, are expected to address these challenges and drive market growth in the coming years.

The global carbon capture and storage market was valued at approximately $6.13 billion in 2020 and is projected to reach $11.85 billion by 2028, growing at a CAGR of 8.5% during the forecast period. This growth is primarily attributed to stringent government regulations, rising investments in carbon capture technologies, and increasing awareness of the need for carbon reduction.

Direct Air Capture, a subset of the broader carbon capture market, is gaining traction due to its potential to remove CO2 directly from the atmosphere. The DAC market is expected to grow from $135 million in 2021 to $1.6 billion by 2030, with a CAGR of 31.6%. This rapid growth is fueled by the increasing demand for negative emissions technologies to meet ambitious climate targets.

Low-energy sorbent regeneration cycles for DAC plants are particularly attractive due to their potential to significantly reduce operational costs and improve overall efficiency. The market for these advanced DAC technologies is expected to grow at an even faster rate than the general DAC market, as energy efficiency becomes a critical factor in large-scale deployment.

Key market drivers for low-energy sorbent regeneration cycles include the need for cost-effective carbon removal solutions, government incentives and carbon pricing mechanisms, and corporate commitments to achieve net-zero emissions. Additionally, the growing interest in carbon-neutral fuels and materials is creating new market opportunities for DAC technologies.

The market for carbon capture solutions, including DAC, is geographically diverse. North America currently leads the market, followed by Europe and Asia-Pacific. The United States, in particular, is expected to be a major market for DAC technologies, driven by supportive policies such as the 45Q tax credit for carbon sequestration.

Key players in the DAC market include Carbon Engineering, Climeworks, and Global Thermostat. These companies are actively developing and scaling up their technologies, with a focus on improving energy efficiency and reducing costs. The market is also seeing increased interest from major oil and gas companies, as well as technology giants, who are investing in and partnering with DAC startups.

Despite the promising growth prospects, the market for low-energy sorbent regeneration cycles in DAC plants faces challenges. These include high initial capital costs, the need for further technological advancements to improve efficiency, and the requirement for supportive policy frameworks to drive large-scale adoption. However, ongoing research and development efforts, coupled with increasing climate urgency, are expected to address these challenges and drive market growth in the coming years.

Current Challenges in Sorbent Regeneration

Direct air capture (DAC) technology holds significant promise in combating climate change by removing CO2 directly from the atmosphere. However, the current sorbent regeneration processes in DAC plants face several critical challenges that hinder widespread adoption and efficiency.

One of the primary challenges is the high energy consumption associated with sorbent regeneration. The process of releasing captured CO2 from the sorbent material typically requires substantial thermal energy input, which can account for a significant portion of the overall energy demand in DAC operations. This high energy requirement not only increases operational costs but also potentially offsets the environmental benefits of carbon capture if the energy source is not renewable.

Another major challenge lies in the degradation of sorbent materials over multiple regeneration cycles. The repeated heating and cooling processes can lead to a gradual loss of CO2 capture capacity and structural integrity of the sorbents. This degradation necessitates frequent replacement of sorbent materials, increasing both the economic and environmental costs of DAC operations.

The kinetics of CO2 desorption during regeneration also present a significant challenge. Achieving rapid and complete release of captured CO2 while minimizing energy input is a delicate balance that current systems struggle to optimize. Slow desorption kinetics can lead to extended regeneration times, reducing the overall efficiency of the DAC process.

Water management during sorbent regeneration is another critical issue. Many sorbents used in DAC are sensitive to moisture, and the presence of water vapor can interfere with both CO2 capture and release processes. Efficiently managing water content in the system without incurring additional energy penalties remains a complex challenge.

Scale-up and integration of sorbent regeneration systems pose significant engineering challenges. As DAC plants increase in size to meet global carbon reduction targets, maintaining uniform heat distribution and flow dynamics in large-scale regeneration units becomes increasingly difficult. This can lead to inconsistent regeneration performance across the system, reducing overall efficiency.

The development of novel sorbent materials with improved regeneration characteristics is an ongoing challenge. Researchers are striving to create sorbents that require lower regeneration temperatures, exhibit faster desorption kinetics, and maintain stability over a greater number of cycles. However, balancing these properties with high CO2 capture capacity and selectivity remains a complex task.

Lastly, the environmental impact of the regeneration process itself needs careful consideration. The potential release of harmful byproducts or the use of environmentally detrimental regeneration agents must be minimized to ensure that the DAC technology remains a net positive for the environment.

One of the primary challenges is the high energy consumption associated with sorbent regeneration. The process of releasing captured CO2 from the sorbent material typically requires substantial thermal energy input, which can account for a significant portion of the overall energy demand in DAC operations. This high energy requirement not only increases operational costs but also potentially offsets the environmental benefits of carbon capture if the energy source is not renewable.

Another major challenge lies in the degradation of sorbent materials over multiple regeneration cycles. The repeated heating and cooling processes can lead to a gradual loss of CO2 capture capacity and structural integrity of the sorbents. This degradation necessitates frequent replacement of sorbent materials, increasing both the economic and environmental costs of DAC operations.

The kinetics of CO2 desorption during regeneration also present a significant challenge. Achieving rapid and complete release of captured CO2 while minimizing energy input is a delicate balance that current systems struggle to optimize. Slow desorption kinetics can lead to extended regeneration times, reducing the overall efficiency of the DAC process.

Water management during sorbent regeneration is another critical issue. Many sorbents used in DAC are sensitive to moisture, and the presence of water vapor can interfere with both CO2 capture and release processes. Efficiently managing water content in the system without incurring additional energy penalties remains a complex challenge.

Scale-up and integration of sorbent regeneration systems pose significant engineering challenges. As DAC plants increase in size to meet global carbon reduction targets, maintaining uniform heat distribution and flow dynamics in large-scale regeneration units becomes increasingly difficult. This can lead to inconsistent regeneration performance across the system, reducing overall efficiency.

The development of novel sorbent materials with improved regeneration characteristics is an ongoing challenge. Researchers are striving to create sorbents that require lower regeneration temperatures, exhibit faster desorption kinetics, and maintain stability over a greater number of cycles. However, balancing these properties with high CO2 capture capacity and selectivity remains a complex task.

Lastly, the environmental impact of the regeneration process itself needs careful consideration. The potential release of harmful byproducts or the use of environmentally detrimental regeneration agents must be minimized to ensure that the DAC technology remains a net positive for the environment.

Existing Low-Energy Regeneration Methods

01 Thermal regeneration techniques

Thermal regeneration is a common method for sorbent regeneration. It involves heating the sorbent to release adsorbed substances. This process can be energy-intensive, but various techniques are employed to optimize energy consumption, such as heat recovery systems and efficient heating methods. The choice of regeneration temperature and heating rate can significantly impact energy efficiency.- Thermal regeneration techniques: Thermal regeneration is a common method for sorbent regeneration, involving heating the sorbent to release adsorbed substances. This process can be energy-intensive, but various techniques are employed to optimize energy consumption, such as heat recovery systems and efficient heating methods. The choice of regeneration temperature and heating rate can significantly impact energy efficiency.

- Pressure Swing Adsorption (PSA) systems: Pressure Swing Adsorption is an energy-efficient method for sorbent regeneration, particularly for gas separation processes. It involves cycling between high and low pressure to adsorb and desorb gases. PSA systems can be designed with multiple beds to ensure continuous operation and optimize energy use through pressure equalization steps.

- Novel sorbent materials for improved regeneration: Development of advanced sorbent materials can significantly reduce energy consumption during regeneration cycles. These materials may have lower regeneration temperatures, faster kinetics, or higher capacity, leading to less frequent regeneration and lower overall energy use. Examples include metal-organic frameworks (MOFs) and functionalized carbon-based sorbents.

- Integration of renewable energy sources: Incorporating renewable energy sources, such as solar or waste heat, into sorbent regeneration processes can substantially reduce the net energy consumption. This approach is particularly beneficial for thermal regeneration methods, where the heat required can be partially or fully supplied by renewable sources, improving the overall sustainability of the process.

- Process optimization and control strategies: Advanced process control and optimization strategies play a crucial role in minimizing energy consumption during sorbent regeneration cycles. This includes real-time monitoring of sorbent performance, predictive modeling for optimal regeneration timing, and adaptive control systems that adjust regeneration parameters based on current process conditions and energy availability.

02 Pressure Swing Adsorption (PSA) systems

Pressure Swing Adsorption is an energy-efficient method for sorbent regeneration. It utilizes pressure changes to adsorb and desorb substances from the sorbent. PSA systems can be designed with multiple beds to allow for continuous operation and energy recovery. Optimizing cycle times and pressure levels can lead to reduced energy consumption in the regeneration process.Expand Specific Solutions03 Novel sorbent materials for improved regeneration

Development of advanced sorbent materials can significantly impact regeneration energy consumption. These materials may have lower regeneration temperatures, faster kinetics, or higher capacities, leading to more efficient regeneration cycles. Some novel sorbents incorporate nanostructures or composite materials to enhance their regeneration properties.Expand Specific Solutions04 Energy recovery and integration strategies

Implementing energy recovery systems and process integration strategies can substantially reduce the overall energy consumption of sorbent regeneration cycles. This may include heat integration between adsorption and desorption steps, waste heat utilization, and coupling with other processes to maximize energy efficiency. Advanced control systems can also optimize energy use across the regeneration cycle.Expand Specific Solutions05 Alternative regeneration methods

Exploring alternative regeneration methods can lead to reduced energy consumption. These may include electrochemical regeneration, microwave-assisted regeneration, or ultrasonic regeneration. Such methods can offer more targeted and efficient energy input for sorbent regeneration, potentially lowering overall energy requirements compared to conventional thermal methods.Expand Specific Solutions

Key Players in DAC Industry

The development of low-energy sorbent regeneration cycles for Direct Air Capture (DAC) plants is in its early stages, with the market still emerging and technology rapidly evolving. The global DAC market is projected to grow significantly, driven by increasing focus on carbon neutrality. Companies like Climeworks AG and Carba, Inc. are at the forefront, developing proprietary technologies for efficient carbon capture and storage. Academic institutions such as ETH Zurich and Arizona State University are contributing to research and innovation in this field. Established industrial players like Air Liquide SA and ExxonMobil are also investing in DAC technologies, leveraging their expertise in gas processing and large-scale operations. The competition is intensifying as various approaches to sorbent regeneration are being explored, with a focus on improving energy efficiency and scalability.

Climeworks AG

Technical Solution: Climeworks has developed a modular direct air capture (DAC) system using solid sorbents. Their approach focuses on low-energy regeneration through a temperature swing adsorption (TSA) process. The company utilizes waste heat from industrial processes or renewable energy sources to power the regeneration cycle, significantly reducing energy consumption. Climeworks' latest technology can capture CO2 at around 100 €/ton, with plans to reduce costs to 100-200 USD/ton by 2030[1]. Their modular design allows for easy scalability and integration with various heat sources, optimizing energy efficiency across different deployment scenarios[2].

Strengths: Modular design for scalability, utilization of waste heat, proven technology with multiple plants in operation. Weaknesses: Still relatively high energy requirements compared to theoretical minimums, limited to locations with available low-grade heat sources.

thyssenkrupp Industrial Solutions AG

Technical Solution: Thyssenkrupp has developed an advanced amine-based DAC technology focusing on energy-efficient sorbent regeneration. Their process utilizes a proprietary amine solution and a novel regeneration cycle that incorporates heat integration and multi-stage flash evaporation. This approach reduces the thermal energy required for sorbent regeneration by up to 50% compared to conventional amine scrubbing techniques[3]. The company's system is designed to operate with low-temperature heat sources (around 85-95°C), enabling the use of waste heat from industrial processes or low-grade geothermal energy[4].

Strengths: Significant reduction in regeneration energy, compatibility with low-grade heat sources, potential for integration with existing industrial infrastructure. Weaknesses: Liquid amine sorbents may have higher material costs and potential environmental concerns compared to solid sorbents.

Innovative Sorbent Materials for DAC

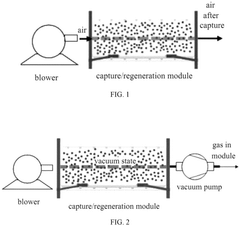

Direct air capturing method of carbon dioxide

PatentPendingEP4545168A1

Innovation

- A direct air capture method using an adsorbent prepared by mixing pulverized coal with a potassium carbonate solution, followed by activation to create a porous carbon material, and then combining this material with carbon nanotubes and an ionic liquid through carbonization. This adsorbent is used to capture CO2 from the air, with desorption and regeneration occurring at 105 to 110°C in a high vacuum state, and subsequent cooling with air for repeated cycles.

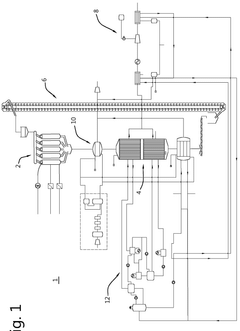

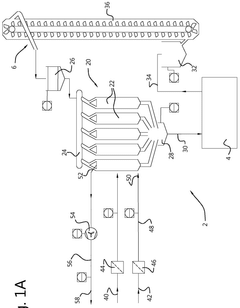

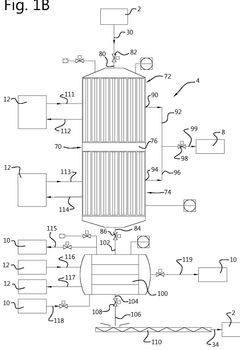

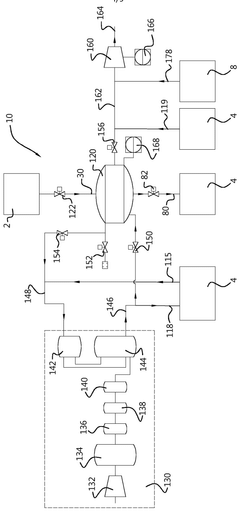

System and method for direct air capture

PatentWO2025141054A1

Innovation

- A system utilizing an adsorber section, regeneration section with multiple desorption stages at distinct temperature levels under vacuum, a transport section, and a heat recovery system with a two-stage heat pump assembly to optimize energy use, incorporating granular sorbent material and high-purity nitrogen purge to enhance adsorption efficiency.

Environmental Impact Assessment

The environmental impact assessment of low-energy sorbent regeneration cycles for Direct Air Capture (DAC) plants is crucial for evaluating the overall sustainability of this emerging carbon dioxide removal technology. These cycles aim to reduce the energy consumption associated with sorbent regeneration, which is a significant factor in the operational efficiency and environmental footprint of DAC plants.

One of the primary environmental benefits of implementing low-energy sorbent regeneration cycles is the potential reduction in greenhouse gas emissions associated with the energy required for the DAC process. By minimizing the energy input needed for regeneration, these cycles can significantly decrease the carbon footprint of DAC operations, enhancing their net carbon removal effectiveness.

Water consumption is another critical environmental consideration for DAC plants. Low-energy sorbent regeneration cycles may impact water usage patterns, potentially leading to reduced water requirements. This is particularly important in water-stressed regions where DAC plants might be deployed. The assessment should quantify changes in water consumption and evaluate the potential for water conservation or increased efficiency.

Land use and habitat disruption are additional factors to consider. While DAC plants generally have a smaller land footprint compared to other carbon capture technologies, the implementation of low-energy cycles might affect plant design and layout. The assessment should examine whether these cycles allow for more compact plant designs or if they require additional land for equipment or processes.

The production and disposal of sorbent materials used in these cycles also warrant careful environmental scrutiny. Low-energy regeneration may influence sorbent lifespan and replacement frequency, potentially reducing waste generation and the environmental impacts associated with sorbent manufacturing and disposal.

Air quality impacts, both positive and negative, should be evaluated. While DAC plants are designed to remove CO2 from the atmosphere, the processes involved in low-energy sorbent regeneration cycles may emit other air pollutants. The assessment should analyze potential emissions of particulate matter, volatile organic compounds, or other air contaminants, and compare these to conventional regeneration methods.

Noise pollution and visual impacts on the surrounding landscape are additional environmental considerations. The assessment should determine if low-energy cycles result in changes to noise levels or alter the visual profile of DAC plants, which could affect local ecosystems and communities.

Lastly, the life cycle assessment of low-energy sorbent regeneration cycles should be conducted, considering the environmental impacts from raw material extraction, manufacturing, operation, and end-of-life disposal. This comprehensive analysis will provide a holistic view of the environmental implications of implementing these innovative cycles in DAC plants.

One of the primary environmental benefits of implementing low-energy sorbent regeneration cycles is the potential reduction in greenhouse gas emissions associated with the energy required for the DAC process. By minimizing the energy input needed for regeneration, these cycles can significantly decrease the carbon footprint of DAC operations, enhancing their net carbon removal effectiveness.

Water consumption is another critical environmental consideration for DAC plants. Low-energy sorbent regeneration cycles may impact water usage patterns, potentially leading to reduced water requirements. This is particularly important in water-stressed regions where DAC plants might be deployed. The assessment should quantify changes in water consumption and evaluate the potential for water conservation or increased efficiency.

Land use and habitat disruption are additional factors to consider. While DAC plants generally have a smaller land footprint compared to other carbon capture technologies, the implementation of low-energy cycles might affect plant design and layout. The assessment should examine whether these cycles allow for more compact plant designs or if they require additional land for equipment or processes.

The production and disposal of sorbent materials used in these cycles also warrant careful environmental scrutiny. Low-energy regeneration may influence sorbent lifespan and replacement frequency, potentially reducing waste generation and the environmental impacts associated with sorbent manufacturing and disposal.

Air quality impacts, both positive and negative, should be evaluated. While DAC plants are designed to remove CO2 from the atmosphere, the processes involved in low-energy sorbent regeneration cycles may emit other air pollutants. The assessment should analyze potential emissions of particulate matter, volatile organic compounds, or other air contaminants, and compare these to conventional regeneration methods.

Noise pollution and visual impacts on the surrounding landscape are additional environmental considerations. The assessment should determine if low-energy cycles result in changes to noise levels or alter the visual profile of DAC plants, which could affect local ecosystems and communities.

Lastly, the life cycle assessment of low-energy sorbent regeneration cycles should be conducted, considering the environmental impacts from raw material extraction, manufacturing, operation, and end-of-life disposal. This comprehensive analysis will provide a holistic view of the environmental implications of implementing these innovative cycles in DAC plants.

Economic Viability of Low-Energy DAC

The economic viability of low-energy Direct Air Capture (DAC) plants is a critical factor in determining the feasibility and widespread adoption of this technology. As the global community seeks to mitigate climate change, DAC has emerged as a potential solution for removing carbon dioxide directly from the atmosphere. However, the high energy requirements and associated costs have been significant barriers to large-scale implementation.

Low-energy sorbent regeneration cycles offer a promising avenue for improving the economic viability of DAC plants. By reducing the energy input needed for the carbon capture process, these innovative designs can significantly lower operational costs. This, in turn, makes DAC more competitive with other carbon reduction strategies and increases its attractiveness to investors and policymakers.

One of the key economic advantages of low-energy DAC systems is the potential for reduced electricity consumption. Traditional DAC plants require substantial amounts of energy to heat the sorbent material and release captured CO2. By optimizing the regeneration cycle, low-energy designs can minimize this energy demand, leading to lower electricity bills and improved overall cost-effectiveness.

Furthermore, the reduced energy requirements of these systems can expand the range of suitable locations for DAC plants. Areas with access to low-cost renewable energy sources, such as solar or wind power, become particularly attractive for siting these facilities. This geographical flexibility can lead to additional cost savings through strategic placement and integration with existing energy infrastructure.

The economic benefits of low-energy DAC extend beyond operational costs. The reduced energy demand also translates to a smaller carbon footprint for the capture process itself, enhancing the net carbon removal efficiency. This improved efficiency can make low-energy DAC plants more appealing for carbon credit markets and increase their value in emissions trading schemes.

Additionally, as governments worldwide implement stricter carbon pricing mechanisms, the economic case for low-energy DAC becomes even stronger. The ability to capture and store or utilize CO2 at a lower cost positions these plants as increasingly competitive options for meeting emissions reduction targets and avoiding carbon taxes or penalties.

However, it is important to note that the economic viability of low-energy DAC plants also depends on factors beyond energy efficiency. The cost and availability of sorbent materials, the scale of operations, and the potential revenue streams from captured CO2 all play crucial roles in determining the overall economic feasibility of these systems.

Low-energy sorbent regeneration cycles offer a promising avenue for improving the economic viability of DAC plants. By reducing the energy input needed for the carbon capture process, these innovative designs can significantly lower operational costs. This, in turn, makes DAC more competitive with other carbon reduction strategies and increases its attractiveness to investors and policymakers.

One of the key economic advantages of low-energy DAC systems is the potential for reduced electricity consumption. Traditional DAC plants require substantial amounts of energy to heat the sorbent material and release captured CO2. By optimizing the regeneration cycle, low-energy designs can minimize this energy demand, leading to lower electricity bills and improved overall cost-effectiveness.

Furthermore, the reduced energy requirements of these systems can expand the range of suitable locations for DAC plants. Areas with access to low-cost renewable energy sources, such as solar or wind power, become particularly attractive for siting these facilities. This geographical flexibility can lead to additional cost savings through strategic placement and integration with existing energy infrastructure.

The economic benefits of low-energy DAC extend beyond operational costs. The reduced energy demand also translates to a smaller carbon footprint for the capture process itself, enhancing the net carbon removal efficiency. This improved efficiency can make low-energy DAC plants more appealing for carbon credit markets and increase their value in emissions trading schemes.

Additionally, as governments worldwide implement stricter carbon pricing mechanisms, the economic case for low-energy DAC becomes even stronger. The ability to capture and store or utilize CO2 at a lower cost positions these plants as increasingly competitive options for meeting emissions reduction targets and avoiding carbon taxes or penalties.

However, it is important to note that the economic viability of low-energy DAC plants also depends on factors beyond energy efficiency. The cost and availability of sorbent materials, the scale of operations, and the potential revenue streams from captured CO2 all play crucial roles in determining the overall economic feasibility of these systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!