How to Scale Sorbent Synthesis from Lab to Pilot: Quality Controls and Cost Drivers

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Sorbent Synthesis Scale-up Background and Objectives

Sorbent synthesis has emerged as a critical technology in various industrial applications, particularly in environmental remediation, gas separation, and energy storage. The journey from laboratory-scale synthesis to pilot-scale production represents a significant challenge in the commercialization of sorbent materials. This scale-up process is crucial for bridging the gap between academic research and industrial implementation, ultimately determining the feasibility and economic viability of sorbent technologies.

The evolution of sorbent synthesis techniques has been driven by the increasing demand for high-performance materials with tailored properties. Over the past decades, researchers have developed a wide array of synthesis methods, ranging from traditional sol-gel processes to advanced templating techniques. These advancements have led to the creation of sorbents with enhanced surface areas, controlled pore structures, and specific functionalities, catering to diverse applications across industries.

As the field progresses, the focus has shifted towards addressing the challenges associated with scaling up these laboratory-developed synthesis methods. The primary objective of this scale-up process is to maintain the desirable properties and performance of sorbents while increasing production volume and efficiency. This transition is critical for meeting the growing industrial demand and reducing production costs, ultimately facilitating the widespread adoption of sorbent technologies.

Quality control emerges as a paramount concern in the scale-up process. Ensuring consistent product quality across larger batch sizes presents unique challenges, as minor variations in synthesis parameters can significantly impact the final product's properties. Establishing robust quality control measures is essential for maintaining the sorbent's performance characteristics, such as adsorption capacity, selectivity, and regeneration efficiency, at the pilot scale.

Simultaneously, understanding and optimizing cost drivers become crucial aspects of the scale-up process. The economic viability of sorbent production at larger scales depends on various factors, including raw material costs, energy consumption, equipment requirements, and process efficiency. Identifying and addressing these cost drivers is essential for developing economically competitive sorbent materials that can successfully transition from the laboratory to industrial applications.

The objectives of this technical research report are multifaceted. Firstly, it aims to provide a comprehensive overview of the current state of sorbent synthesis scale-up technologies, highlighting key advancements and persistent challenges. Secondly, the report seeks to identify critical quality control parameters and methodologies that ensure consistent sorbent performance during scale-up. Lastly, it intends to analyze the primary cost drivers in the scale-up process and explore potential strategies for cost optimization without compromising product quality.

The evolution of sorbent synthesis techniques has been driven by the increasing demand for high-performance materials with tailored properties. Over the past decades, researchers have developed a wide array of synthesis methods, ranging from traditional sol-gel processes to advanced templating techniques. These advancements have led to the creation of sorbents with enhanced surface areas, controlled pore structures, and specific functionalities, catering to diverse applications across industries.

As the field progresses, the focus has shifted towards addressing the challenges associated with scaling up these laboratory-developed synthesis methods. The primary objective of this scale-up process is to maintain the desirable properties and performance of sorbents while increasing production volume and efficiency. This transition is critical for meeting the growing industrial demand and reducing production costs, ultimately facilitating the widespread adoption of sorbent technologies.

Quality control emerges as a paramount concern in the scale-up process. Ensuring consistent product quality across larger batch sizes presents unique challenges, as minor variations in synthesis parameters can significantly impact the final product's properties. Establishing robust quality control measures is essential for maintaining the sorbent's performance characteristics, such as adsorption capacity, selectivity, and regeneration efficiency, at the pilot scale.

Simultaneously, understanding and optimizing cost drivers become crucial aspects of the scale-up process. The economic viability of sorbent production at larger scales depends on various factors, including raw material costs, energy consumption, equipment requirements, and process efficiency. Identifying and addressing these cost drivers is essential for developing economically competitive sorbent materials that can successfully transition from the laboratory to industrial applications.

The objectives of this technical research report are multifaceted. Firstly, it aims to provide a comprehensive overview of the current state of sorbent synthesis scale-up technologies, highlighting key advancements and persistent challenges. Secondly, the report seeks to identify critical quality control parameters and methodologies that ensure consistent sorbent performance during scale-up. Lastly, it intends to analyze the primary cost drivers in the scale-up process and explore potential strategies for cost optimization without compromising product quality.

Industrial Demand for Large-scale Sorbent Production

The industrial demand for large-scale sorbent production has been steadily increasing in recent years, driven by various factors across multiple sectors. In the environmental sector, stringent regulations on air and water pollution control have led to a surge in demand for high-performance sorbents capable of removing contaminants efficiently. Industries such as power generation, chemical manufacturing, and wastewater treatment are actively seeking advanced sorbent materials to meet these regulatory requirements.

The energy sector, particularly in carbon capture and storage (CCS) applications, has emerged as a significant driver for large-scale sorbent production. As global efforts to mitigate climate change intensify, the need for effective CO2 capture technologies has become paramount. This has resulted in a growing market for specialized sorbents designed for post-combustion carbon capture, pre-combustion capture, and direct air capture systems.

In the pharmaceutical and biotechnology industries, the demand for high-purity sorbents has been rising due to the increasing complexity of drug manufacturing processes and the need for more efficient purification techniques. Large-scale production of sorbents is crucial to meet the stringent quality standards required in these sectors, where even minor impurities can have significant impacts on product efficacy and safety.

The electronics industry has also contributed to the growing demand for large-scale sorbent production. As electronic devices become more sophisticated and miniaturized, the need for ultra-pure materials in manufacturing processes has increased. Sorbents play a critical role in removing trace contaminants from gases and liquids used in semiconductor fabrication and other high-tech manufacturing processes.

Market analysis indicates that the global sorbent market is expected to grow substantially in the coming years. This growth is attributed to the expanding industrial applications, technological advancements in sorbent materials, and the increasing focus on sustainability across various sectors. The Asia-Pacific region, in particular, is projected to witness significant growth in sorbent demand due to rapid industrialization and stringent environmental regulations in countries like China and India.

To meet this growing industrial demand, there is a pressing need for scaling up sorbent synthesis from laboratory to pilot scale. This transition presents several challenges, including maintaining consistent product quality, optimizing production processes, and managing cost drivers effectively. As a result, research and development efforts are increasingly focused on developing scalable synthesis methods that can produce high-performance sorbents in large quantities while maintaining cost-effectiveness and quality control.

The energy sector, particularly in carbon capture and storage (CCS) applications, has emerged as a significant driver for large-scale sorbent production. As global efforts to mitigate climate change intensify, the need for effective CO2 capture technologies has become paramount. This has resulted in a growing market for specialized sorbents designed for post-combustion carbon capture, pre-combustion capture, and direct air capture systems.

In the pharmaceutical and biotechnology industries, the demand for high-purity sorbents has been rising due to the increasing complexity of drug manufacturing processes and the need for more efficient purification techniques. Large-scale production of sorbents is crucial to meet the stringent quality standards required in these sectors, where even minor impurities can have significant impacts on product efficacy and safety.

The electronics industry has also contributed to the growing demand for large-scale sorbent production. As electronic devices become more sophisticated and miniaturized, the need for ultra-pure materials in manufacturing processes has increased. Sorbents play a critical role in removing trace contaminants from gases and liquids used in semiconductor fabrication and other high-tech manufacturing processes.

Market analysis indicates that the global sorbent market is expected to grow substantially in the coming years. This growth is attributed to the expanding industrial applications, technological advancements in sorbent materials, and the increasing focus on sustainability across various sectors. The Asia-Pacific region, in particular, is projected to witness significant growth in sorbent demand due to rapid industrialization and stringent environmental regulations in countries like China and India.

To meet this growing industrial demand, there is a pressing need for scaling up sorbent synthesis from laboratory to pilot scale. This transition presents several challenges, including maintaining consistent product quality, optimizing production processes, and managing cost drivers effectively. As a result, research and development efforts are increasingly focused on developing scalable synthesis methods that can produce high-performance sorbents in large quantities while maintaining cost-effectiveness and quality control.

Current Challenges in Sorbent Synthesis Scale-up

The scale-up of sorbent synthesis from laboratory to pilot scale presents several significant challenges that must be addressed to ensure successful commercialization. One of the primary obstacles is maintaining consistent product quality across different production scales. The precise control of reaction conditions, such as temperature, pressure, and mixing, becomes increasingly difficult as batch sizes increase. This can lead to variations in particle size distribution, surface area, and pore structure, which are critical parameters for sorbent performance.

Another major challenge is the optimization of production processes to minimize costs while maximizing yield and quality. As production scales up, the economics of raw materials, energy consumption, and equipment utilization become more critical. Identifying cost drivers and implementing efficient resource management strategies are essential for commercial viability.

The selection and design of appropriate equipment for larger-scale production pose additional challenges. Laboratory equipment often cannot be directly scaled up due to differences in heat transfer, mass transfer, and mixing dynamics. Engineers must carefully consider factors such as reactor design, agitation systems, and heat exchange capabilities to ensure that the scaled-up process closely mimics the laboratory conditions that produced the desired sorbent properties.

Quality control and characterization methods also need to be adapted for larger batch sizes. Sampling techniques and analytical procedures that work well for small-scale production may not be suitable or cost-effective for pilot-scale operations. Developing robust and rapid quality assessment methods is crucial for maintaining consistent product specifications and meeting regulatory requirements.

Environmental and safety considerations become more pronounced at larger scales. The handling of larger quantities of potentially hazardous materials, management of waste streams, and implementation of safety protocols all require careful planning and investment. Regulatory compliance and obtaining necessary permits can also be time-consuming and complex processes that need to be addressed early in the scale-up journey.

Lastly, the challenge of knowledge transfer from research and development teams to production personnel is often underestimated. Ensuring that the nuances of the synthesis process are fully understood and can be replicated by operators at the pilot scale is critical for maintaining product quality and consistency. This often requires the development of detailed standard operating procedures and comprehensive training programs.

Another major challenge is the optimization of production processes to minimize costs while maximizing yield and quality. As production scales up, the economics of raw materials, energy consumption, and equipment utilization become more critical. Identifying cost drivers and implementing efficient resource management strategies are essential for commercial viability.

The selection and design of appropriate equipment for larger-scale production pose additional challenges. Laboratory equipment often cannot be directly scaled up due to differences in heat transfer, mass transfer, and mixing dynamics. Engineers must carefully consider factors such as reactor design, agitation systems, and heat exchange capabilities to ensure that the scaled-up process closely mimics the laboratory conditions that produced the desired sorbent properties.

Quality control and characterization methods also need to be adapted for larger batch sizes. Sampling techniques and analytical procedures that work well for small-scale production may not be suitable or cost-effective for pilot-scale operations. Developing robust and rapid quality assessment methods is crucial for maintaining consistent product specifications and meeting regulatory requirements.

Environmental and safety considerations become more pronounced at larger scales. The handling of larger quantities of potentially hazardous materials, management of waste streams, and implementation of safety protocols all require careful planning and investment. Regulatory compliance and obtaining necessary permits can also be time-consuming and complex processes that need to be addressed early in the scale-up journey.

Lastly, the challenge of knowledge transfer from research and development teams to production personnel is often underestimated. Ensuring that the nuances of the synthesis process are fully understood and can be replicated by operators at the pilot scale is critical for maintaining product quality and consistency. This often requires the development of detailed standard operating procedures and comprehensive training programs.

Existing Scale-up Strategies for Sorbent Synthesis

01 Large-scale sorbent synthesis methods

Various techniques for scaling up sorbent synthesis, including continuous flow processes, reactor design optimization, and batch size increases. These methods aim to improve production efficiency and maintain consistent quality in large-scale manufacturing of sorbent materials.- Large-scale sorbent synthesis methods: Various techniques for scaling up sorbent production, including continuous flow processes, spray drying, and fluidized bed reactors. These methods allow for increased production capacity while maintaining consistent quality and properties of the sorbents.

- Optimization of sorbent particle size and morphology: Techniques for controlling and optimizing the particle size distribution and morphology of sorbents during synthesis. This includes methods for producing nano-sized particles, hierarchical structures, and specific shapes to enhance adsorption capacity and kinetics.

- Novel precursor materials for sorbent synthesis: Exploration of new raw materials and precursors for sorbent synthesis, including waste products, biomass-derived materials, and synthetic compounds. These novel precursors can lead to sorbents with improved properties or reduced production costs.

- Green synthesis approaches for sorbents: Development of environmentally friendly synthesis methods for sorbents, including low-temperature processes, solvent-free techniques, and the use of renewable resources. These approaches aim to reduce the environmental impact of sorbent production while maintaining or improving performance.

- Post-synthesis modification techniques: Methods for modifying sorbents after initial synthesis to enhance their properties, such as surface functionalization, impregnation with active components, and thermal or chemical treatments. These techniques allow for fine-tuning of sorbent characteristics for specific applications.

02 Novel sorbent materials and compositions

Development of new sorbent materials with enhanced properties, such as improved adsorption capacity, selectivity, and regeneration capabilities. This includes the synthesis of composite materials, functionalized adsorbents, and nanostructured sorbents for various applications.Expand Specific Solutions03 Sorbent synthesis process optimization

Strategies for optimizing sorbent synthesis processes, including parameter control, precursor selection, and reaction condition adjustments. These optimizations aim to improve yield, reduce costs, and enhance the overall quality of the synthesized sorbents.Expand Specific Solutions04 Environmentally friendly sorbent production

Development of green synthesis methods for sorbents, focusing on reducing environmental impact, using sustainable precursors, and minimizing waste generation. These approaches aim to create more eco-friendly production processes for sorbent materials.Expand Specific Solutions05 Characterization and quality control of scaled-up sorbents

Techniques and methodologies for characterizing and ensuring the quality of sorbents produced at larger scales. This includes the development of analytical methods, in-process controls, and standardization procedures to maintain consistent performance across batches.Expand Specific Solutions

Key Players in Sorbent Manufacturing Industry

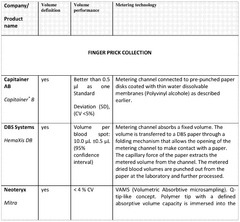

The scaling of sorbent synthesis from lab to pilot scale presents a competitive landscape in a maturing industry with significant market potential. The technology's maturity varies among key players, with established companies like Rohm & Haas Co., UOP LLC, and ExxonMobil Technology & Engineering Co. leading in industrial applications. Academic institutions such as MIT, Tsinghua University, and EPFL contribute cutting-edge research. Emerging players like Capitainer AB and Nirrin Bioprocess Analytics, Inc. focus on innovative approaches. The market is driven by increasing environmental regulations and demand for efficient separation processes, with a growing emphasis on quality control and cost optimization in large-scale production.

UOP LLC

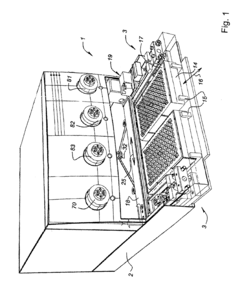

Technical Solution: UOP LLC, a Honeywell company, has developed advanced sorbent synthesis techniques for scaling up from lab to pilot. Their approach involves a continuous flow reactor system that allows for precise control of reaction conditions and particle size distribution[1]. The company utilizes in-situ characterization techniques to monitor sorbent properties during synthesis, enabling real-time adjustments to maintain quality[3]. UOP's process incorporates automated quality control measures, including online particle size analysis and surface area measurements, to ensure consistent sorbent characteristics throughout scale-up[5]. To address cost drivers, UOP has implemented a modular design for their pilot-scale reactors, allowing for easy capacity expansion and reducing capital expenditure[7].

Strengths: Precise control over synthesis conditions, real-time quality monitoring, and modular scalability. Weaknesses: Potentially higher initial investment costs and complexity in process control systems.

Arkema France SA

Technical Solution: Arkema has developed a scalable sorbent synthesis process focusing on polymer-based adsorbents. Their approach utilizes a suspension polymerization technique that allows for precise control over particle size distribution and porosity[1]. The company has implemented an automated quality control system that incorporates online particle size analysis, surface area measurements, and pore size distribution characterization to ensure consistent sorbent properties during scale-up[3]. Arkema's process includes a novel post-synthesis modification step that enhances sorbent selectivity and capacity without significantly increasing production costs[5]. To address energy consumption as a major cost driver, the company has developed an innovative heat integration system that recovers and reuses thermal energy throughout the synthesis process[7]. Additionally, Arkema has explored the use of renewable monomers and sustainable crosslinking agents to reduce the environmental impact and raw material costs of large-scale sorbent production[9].

Strengths: Precise control over particle properties, enhanced sorbent performance through post-synthesis modification, and energy-efficient process. Weaknesses: Potential limitations in the types of sorbents that can be produced using polymer-based approaches.

Critical Quality Control Parameters in Scale-up

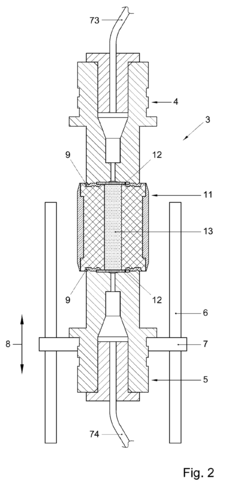

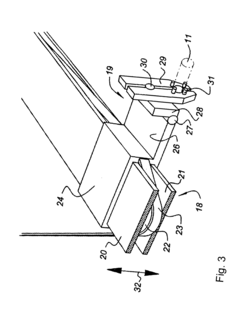

Flow through cartridge for selecting an analyte online with high performance liquid chromatography

PatentInactiveEP2278325A1

Innovation

- A cartridge design featuring a core of a stiffer polymeric material surrounding the passage, with sealing rings of a more flexible polymeric material, and enhanced clamping forces to maintain a hermetic seal, allowing resistance to pressures up to 100 MPa and temperatures up to 100°C without leakage.

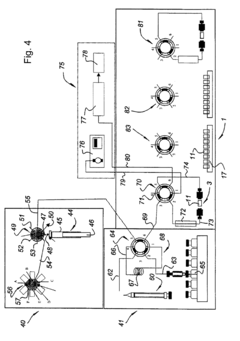

Simplified quantitative analysis using substrates with pre-loaded standards

PatentWO2024151786A1

Innovation

- A method and device utilizing pre-loaded stable isotope labeled internal standards on a substrate, allowing immediate mixing with the bio-sample before extraction, enabling near 100% recovery and improved reproducibility by using a microfluidic device with a substrate like a cotton disk pre-loaded with internal standards, facilitating precise quantitation through mass spectrometry.

Environmental Impact Assessment of Large-scale Production

The environmental impact of scaling up sorbent synthesis from laboratory to pilot scale is a critical consideration in the development of sustainable production processes. As production volumes increase, the potential for environmental consequences grows proportionally. A comprehensive environmental impact assessment is essential to identify, evaluate, and mitigate potential risks associated with large-scale sorbent production.

One of the primary concerns in scaling up sorbent synthesis is the increased consumption of raw materials and energy. The production of sorbents often involves energy-intensive processes, such as high-temperature calcination or chemical activation. As production scales up, the energy demand rises significantly, potentially leading to increased greenhouse gas emissions if not managed properly. Additionally, the extraction and processing of raw materials for sorbent production may have substantial environmental impacts, including habitat disruption, water pollution, and soil degradation.

Water usage and wastewater generation are also important factors to consider in large-scale sorbent production. Many synthesis processes require substantial amounts of water for washing, rinsing, and cooling. The increased water demand may strain local water resources, particularly in water-scarce regions. Furthermore, the generation of wastewater containing chemical residues, heavy metals, or other pollutants necessitates proper treatment and disposal to prevent contamination of water bodies and ecosystems.

Air emissions from large-scale sorbent production facilities can have significant environmental implications. Depending on the synthesis method and precursor materials used, various pollutants such as particulate matter, volatile organic compounds (VOCs), and acid gases may be released. These emissions can contribute to local air quality degradation, potentially affecting human health and surrounding ecosystems. Implementing effective air pollution control technologies and monitoring systems is crucial to minimize these impacts.

The disposal of waste materials generated during sorbent production is another environmental concern that becomes more pronounced at larger scales. Solid waste, including off-specification products, spent catalysts, and packaging materials, requires proper management to prevent soil and groundwater contamination. Developing efficient recycling and waste reduction strategies can help mitigate these impacts and promote a more circular production approach.

To address these environmental challenges, it is essential to implement sustainable production practices and technologies. This may include adopting cleaner production techniques, optimizing resource efficiency, and incorporating renewable energy sources into the production process. Life cycle assessment (LCA) methodologies can be employed to evaluate the environmental footprint of sorbent production across its entire life cycle, from raw material extraction to end-of-life disposal or recycling. By identifying hotspots of environmental impact, LCA can guide the development of more sustainable production strategies and inform decision-making processes.

One of the primary concerns in scaling up sorbent synthesis is the increased consumption of raw materials and energy. The production of sorbents often involves energy-intensive processes, such as high-temperature calcination or chemical activation. As production scales up, the energy demand rises significantly, potentially leading to increased greenhouse gas emissions if not managed properly. Additionally, the extraction and processing of raw materials for sorbent production may have substantial environmental impacts, including habitat disruption, water pollution, and soil degradation.

Water usage and wastewater generation are also important factors to consider in large-scale sorbent production. Many synthesis processes require substantial amounts of water for washing, rinsing, and cooling. The increased water demand may strain local water resources, particularly in water-scarce regions. Furthermore, the generation of wastewater containing chemical residues, heavy metals, or other pollutants necessitates proper treatment and disposal to prevent contamination of water bodies and ecosystems.

Air emissions from large-scale sorbent production facilities can have significant environmental implications. Depending on the synthesis method and precursor materials used, various pollutants such as particulate matter, volatile organic compounds (VOCs), and acid gases may be released. These emissions can contribute to local air quality degradation, potentially affecting human health and surrounding ecosystems. Implementing effective air pollution control technologies and monitoring systems is crucial to minimize these impacts.

The disposal of waste materials generated during sorbent production is another environmental concern that becomes more pronounced at larger scales. Solid waste, including off-specification products, spent catalysts, and packaging materials, requires proper management to prevent soil and groundwater contamination. Developing efficient recycling and waste reduction strategies can help mitigate these impacts and promote a more circular production approach.

To address these environmental challenges, it is essential to implement sustainable production practices and technologies. This may include adopting cleaner production techniques, optimizing resource efficiency, and incorporating renewable energy sources into the production process. Life cycle assessment (LCA) methodologies can be employed to evaluate the environmental footprint of sorbent production across its entire life cycle, from raw material extraction to end-of-life disposal or recycling. By identifying hotspots of environmental impact, LCA can guide the development of more sustainable production strategies and inform decision-making processes.

Regulatory Compliance in Industrial Sorbent Manufacturing

Regulatory compliance is a critical aspect of industrial sorbent manufacturing, particularly when scaling up from laboratory to pilot production. As the production scale increases, manufacturers must navigate a complex landscape of regulations to ensure product safety, environmental protection, and quality standards.

One of the primary regulatory bodies overseeing sorbent manufacturing is the Environmental Protection Agency (EPA). The EPA sets guidelines for the production, use, and disposal of sorbents, especially those used in environmental remediation. Manufacturers must adhere to the Toxic Substances Control Act (TSCA) regulations, which govern the production and use of chemical substances. This includes maintaining detailed records of chemical inventories, conducting safety assessments, and reporting any new chemical substances.

Occupational Safety and Health Administration (OSHA) regulations also play a crucial role in sorbent manufacturing. These regulations focus on worker safety and health, requiring manufacturers to implement proper handling procedures, provide adequate personal protective equipment, and maintain a safe working environment. As production scales up, ensuring compliance with OSHA standards becomes increasingly complex, necessitating robust safety management systems.

Quality control regulations, such as those outlined by the International Organization for Standardization (ISO), are essential for maintaining product consistency and reliability. ISO 9001 certification, which specifies requirements for quality management systems, is often sought by sorbent manufacturers to demonstrate their commitment to quality and regulatory compliance. This certification becomes particularly important when scaling up production, as it helps ensure that quality standards are maintained across larger batches.

For sorbents used in specific industries, additional regulatory requirements may apply. For instance, sorbents used in food and pharmaceutical applications must comply with Food and Drug Administration (FDA) regulations. This includes adherence to Good Manufacturing Practices (GMP) and obtaining necessary approvals for food contact materials.

Environmental regulations also play a significant role in sorbent manufacturing. The Clean Air Act and Clean Water Act impose restrictions on emissions and effluents from manufacturing processes. As production scales up, manufacturers must invest in appropriate pollution control technologies and obtain necessary permits to ensure compliance with these environmental regulations.

Internationally, manufacturers must navigate varying regulatory landscapes when exporting sorbents. The European Union's Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulation, for example, imposes strict requirements on chemical substances entering the EU market. Compliance with such international regulations is crucial for manufacturers looking to expand their market reach.

One of the primary regulatory bodies overseeing sorbent manufacturing is the Environmental Protection Agency (EPA). The EPA sets guidelines for the production, use, and disposal of sorbents, especially those used in environmental remediation. Manufacturers must adhere to the Toxic Substances Control Act (TSCA) regulations, which govern the production and use of chemical substances. This includes maintaining detailed records of chemical inventories, conducting safety assessments, and reporting any new chemical substances.

Occupational Safety and Health Administration (OSHA) regulations also play a crucial role in sorbent manufacturing. These regulations focus on worker safety and health, requiring manufacturers to implement proper handling procedures, provide adequate personal protective equipment, and maintain a safe working environment. As production scales up, ensuring compliance with OSHA standards becomes increasingly complex, necessitating robust safety management systems.

Quality control regulations, such as those outlined by the International Organization for Standardization (ISO), are essential for maintaining product consistency and reliability. ISO 9001 certification, which specifies requirements for quality management systems, is often sought by sorbent manufacturers to demonstrate their commitment to quality and regulatory compliance. This certification becomes particularly important when scaling up production, as it helps ensure that quality standards are maintained across larger batches.

For sorbents used in specific industries, additional regulatory requirements may apply. For instance, sorbents used in food and pharmaceutical applications must comply with Food and Drug Administration (FDA) regulations. This includes adherence to Good Manufacturing Practices (GMP) and obtaining necessary approvals for food contact materials.

Environmental regulations also play a significant role in sorbent manufacturing. The Clean Air Act and Clean Water Act impose restrictions on emissions and effluents from manufacturing processes. As production scales up, manufacturers must invest in appropriate pollution control technologies and obtain necessary permits to ensure compliance with these environmental regulations.

Internationally, manufacturers must navigate varying regulatory landscapes when exporting sorbents. The European Union's Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulation, for example, imposes strict requirements on chemical substances entering the EU market. Compliance with such international regulations is crucial for manufacturers looking to expand their market reach.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!