Low-cost Supports for Amine Sorbents: Biochars, Silicas and Metal-organic frameworks (hybrid approaches)

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Amine Sorbent Support Evolution and Objectives

The evolution of amine sorbent supports has been a critical area of research in carbon capture and storage (CCS) technologies. Initially, the focus was on high-surface-area materials like activated carbons and zeolites. However, these traditional supports often suffered from high production costs and limited CO2 adsorption capacity.

In recent years, the development of low-cost supports for amine sorbents has gained significant attention. This shift is driven by the need for more economically viable and sustainable CCS solutions. Biochars, derived from biomass pyrolysis, have emerged as promising candidates due to their low cost, high surface area, and renewable nature. The evolution of biochar-based supports has seen improvements in their porosity and surface functionalization to enhance amine loading and CO2 capture performance.

Silica-based materials have also undergone substantial development. From simple silica gels to more advanced mesoporous silicas, these supports offer excellent stability and high surface areas. The evolution of silica supports has focused on optimizing pore structures and surface chemistry to maximize amine loading and CO2 adsorption efficiency.

Metal-organic frameworks (MOFs) represent a more recent advancement in amine sorbent supports. These highly porous materials offer unprecedented surface areas and tunable pore structures. The evolution of MOFs as supports has involved developing more stable frameworks and incorporating amine functionalities directly into the MOF structure.

The latest trend in amine sorbent support development is the exploration of hybrid approaches. These combine the advantages of different support materials to create synergistic effects. For instance, biochar-silica composites aim to combine the low cost of biochars with the high surface area of silicas. Similarly, MOF-silica hybrids seek to merge the high porosity of MOFs with the stability of silicas.

The primary objectives of current research in this field are multifaceted. Firstly, there is a strong focus on further reducing the cost of supports while maintaining or improving their CO2 capture performance. This involves optimizing production processes and exploring new precursor materials. Secondly, researchers aim to enhance the stability and regeneration capacity of amine-loaded supports to increase their operational lifespan. Thirdly, there is a push towards developing supports that can maintain high CO2 adsorption capacities under realistic flue gas conditions, including the presence of moisture and other contaminants.

Another key objective is to improve the kinetics of CO2 adsorption and desorption, which is crucial for practical applications. This involves tailoring the pore structure and surface chemistry of supports to facilitate rapid mass transfer. Additionally, there is growing interest in developing multifunctional supports that can simultaneously capture CO2 and other pollutants, thereby increasing the overall efficiency of flue gas treatment systems.

In recent years, the development of low-cost supports for amine sorbents has gained significant attention. This shift is driven by the need for more economically viable and sustainable CCS solutions. Biochars, derived from biomass pyrolysis, have emerged as promising candidates due to their low cost, high surface area, and renewable nature. The evolution of biochar-based supports has seen improvements in their porosity and surface functionalization to enhance amine loading and CO2 capture performance.

Silica-based materials have also undergone substantial development. From simple silica gels to more advanced mesoporous silicas, these supports offer excellent stability and high surface areas. The evolution of silica supports has focused on optimizing pore structures and surface chemistry to maximize amine loading and CO2 adsorption efficiency.

Metal-organic frameworks (MOFs) represent a more recent advancement in amine sorbent supports. These highly porous materials offer unprecedented surface areas and tunable pore structures. The evolution of MOFs as supports has involved developing more stable frameworks and incorporating amine functionalities directly into the MOF structure.

The latest trend in amine sorbent support development is the exploration of hybrid approaches. These combine the advantages of different support materials to create synergistic effects. For instance, biochar-silica composites aim to combine the low cost of biochars with the high surface area of silicas. Similarly, MOF-silica hybrids seek to merge the high porosity of MOFs with the stability of silicas.

The primary objectives of current research in this field are multifaceted. Firstly, there is a strong focus on further reducing the cost of supports while maintaining or improving their CO2 capture performance. This involves optimizing production processes and exploring new precursor materials. Secondly, researchers aim to enhance the stability and regeneration capacity of amine-loaded supports to increase their operational lifespan. Thirdly, there is a push towards developing supports that can maintain high CO2 adsorption capacities under realistic flue gas conditions, including the presence of moisture and other contaminants.

Another key objective is to improve the kinetics of CO2 adsorption and desorption, which is crucial for practical applications. This involves tailoring the pore structure and surface chemistry of supports to facilitate rapid mass transfer. Additionally, there is growing interest in developing multifunctional supports that can simultaneously capture CO2 and other pollutants, thereby increasing the overall efficiency of flue gas treatment systems.

Market Analysis for Low-Cost Carbon Capture Solutions

The market for low-cost carbon capture solutions is experiencing significant growth, driven by increasing global awareness of climate change and the urgent need to reduce greenhouse gas emissions. The carbon capture and storage (CCS) market is projected to expand rapidly in the coming years, with a particular focus on cost-effective technologies that can be widely implemented across various industries.

Amine-based sorbents have emerged as a promising technology for carbon capture due to their high selectivity and capacity for CO2 absorption. However, the high cost of traditional supports for these sorbents has been a major barrier to widespread adoption. This has created a substantial market opportunity for low-cost support materials such as biochars, silicas, and metal-organic frameworks (MOFs).

The biochar market, in particular, is expected to see significant growth as it offers a sustainable and cost-effective solution for carbon capture. Derived from biomass waste, biochars not only provide an economical support for amine sorbents but also contribute to waste reduction and circular economy principles. This dual benefit is likely to drive increased demand across multiple sectors, including power generation, cement production, and chemical manufacturing.

Silica-based supports are also gaining traction in the market due to their abundance, low cost, and versatile properties. The global silica market is well-established, with a robust supply chain that can be leveraged for carbon capture applications. As research continues to improve the performance of silica supports for amine sorbents, their market share in the CCS sector is expected to grow substantially.

Metal-organic frameworks represent an innovative approach to carbon capture, offering high surface areas and tunable properties. While currently more expensive than biochars or silicas, ongoing research and development efforts are focused on reducing production costs and scaling up manufacturing processes. As these challenges are addressed, MOFs are poised to capture a significant portion of the market, particularly in applications requiring high-performance carbon capture.

The hybrid approaches combining different support materials are attracting considerable interest from both researchers and industry players. These innovative solutions aim to leverage the strengths of multiple materials, potentially offering superior performance at competitive costs. The market for hybrid carbon capture solutions is still in its early stages but shows promise for rapid growth as technology advances.

Geographically, North America and Europe are currently leading the market for low-cost carbon capture solutions, driven by stringent environmental regulations and substantial research funding. However, Asia-Pacific is expected to emerge as a key market in the near future, with China and India making significant investments in clean energy technologies to address their growing environmental concerns.

Amine-based sorbents have emerged as a promising technology for carbon capture due to their high selectivity and capacity for CO2 absorption. However, the high cost of traditional supports for these sorbents has been a major barrier to widespread adoption. This has created a substantial market opportunity for low-cost support materials such as biochars, silicas, and metal-organic frameworks (MOFs).

The biochar market, in particular, is expected to see significant growth as it offers a sustainable and cost-effective solution for carbon capture. Derived from biomass waste, biochars not only provide an economical support for amine sorbents but also contribute to waste reduction and circular economy principles. This dual benefit is likely to drive increased demand across multiple sectors, including power generation, cement production, and chemical manufacturing.

Silica-based supports are also gaining traction in the market due to their abundance, low cost, and versatile properties. The global silica market is well-established, with a robust supply chain that can be leveraged for carbon capture applications. As research continues to improve the performance of silica supports for amine sorbents, their market share in the CCS sector is expected to grow substantially.

Metal-organic frameworks represent an innovative approach to carbon capture, offering high surface areas and tunable properties. While currently more expensive than biochars or silicas, ongoing research and development efforts are focused on reducing production costs and scaling up manufacturing processes. As these challenges are addressed, MOFs are poised to capture a significant portion of the market, particularly in applications requiring high-performance carbon capture.

The hybrid approaches combining different support materials are attracting considerable interest from both researchers and industry players. These innovative solutions aim to leverage the strengths of multiple materials, potentially offering superior performance at competitive costs. The market for hybrid carbon capture solutions is still in its early stages but shows promise for rapid growth as technology advances.

Geographically, North America and Europe are currently leading the market for low-cost carbon capture solutions, driven by stringent environmental regulations and substantial research funding. However, Asia-Pacific is expected to emerge as a key market in the near future, with China and India making significant investments in clean energy technologies to address their growing environmental concerns.

Current Challenges in Amine Sorbent Support Materials

The development of efficient and cost-effective amine sorbent support materials faces several significant challenges. One of the primary issues is the trade-off between surface area and mechanical strength. While high surface area is crucial for maximizing CO2 adsorption capacity, it often comes at the expense of structural integrity, leading to potential degradation and reduced lifespan of the sorbent material.

Another challenge lies in the thermal and chemical stability of support materials. Amine sorbents are typically subjected to repeated adsorption-desorption cycles at elevated temperatures, which can cause thermal degradation of both the amine and the support structure. This degradation can lead to a decrease in CO2 capture efficiency over time and potentially result in the release of harmful byproducts.

The issue of amine leaching presents a significant hurdle in the development of stable sorbent materials. Many support structures struggle to maintain a strong bond with the amine groups, leading to gradual loss of the active component during cycling. This not only reduces the overall CO2 capture capacity but also raises environmental concerns due to potential amine emissions.

Cost-effectiveness remains a critical challenge in the widespread adoption of amine sorbent technologies. Many high-performance support materials, such as certain metal-organic frameworks (MOFs), are expensive to synthesize at scale. Finding a balance between performance and economic viability is crucial for the commercial implementation of these technologies.

The scalability of support material production poses another significant challenge. While many promising materials show excellent performance at the laboratory scale, translating these results to industrial-scale production often proves difficult. Issues such as batch-to-batch consistency, quality control, and process optimization need to be addressed to ensure reliable large-scale manufacturing.

Water stability is a crucial factor that often limits the applicability of certain support materials. Many adsorbents, particularly some MOFs, are sensitive to moisture, which can lead to structural degradation and loss of performance in real-world conditions where flue gases contain significant amounts of water vapor.

Lastly, the environmental impact of support material production and disposal remains a concern. Developing sustainable synthesis routes and ensuring the recyclability or safe disposal of spent sorbents are important considerations that need to be addressed to make these technologies truly environmentally friendly.

Another challenge lies in the thermal and chemical stability of support materials. Amine sorbents are typically subjected to repeated adsorption-desorption cycles at elevated temperatures, which can cause thermal degradation of both the amine and the support structure. This degradation can lead to a decrease in CO2 capture efficiency over time and potentially result in the release of harmful byproducts.

The issue of amine leaching presents a significant hurdle in the development of stable sorbent materials. Many support structures struggle to maintain a strong bond with the amine groups, leading to gradual loss of the active component during cycling. This not only reduces the overall CO2 capture capacity but also raises environmental concerns due to potential amine emissions.

Cost-effectiveness remains a critical challenge in the widespread adoption of amine sorbent technologies. Many high-performance support materials, such as certain metal-organic frameworks (MOFs), are expensive to synthesize at scale. Finding a balance between performance and economic viability is crucial for the commercial implementation of these technologies.

The scalability of support material production poses another significant challenge. While many promising materials show excellent performance at the laboratory scale, translating these results to industrial-scale production often proves difficult. Issues such as batch-to-batch consistency, quality control, and process optimization need to be addressed to ensure reliable large-scale manufacturing.

Water stability is a crucial factor that often limits the applicability of certain support materials. Many adsorbents, particularly some MOFs, are sensitive to moisture, which can lead to structural degradation and loss of performance in real-world conditions where flue gases contain significant amounts of water vapor.

Lastly, the environmental impact of support material production and disposal remains a concern. Developing sustainable synthesis routes and ensuring the recyclability or safe disposal of spent sorbents are important considerations that need to be addressed to make these technologies truly environmentally friendly.

Existing Low-Cost Support Solutions for Amine Sorbents

01 Cost-effective amine sorbent production methods

Various methods have been developed to produce amine sorbents more cost-effectively. These include optimizing synthesis processes, using cheaper raw materials, and improving manufacturing techniques to reduce energy consumption and waste. Such advancements help lower the overall cost of amine sorbents while maintaining their effectiveness in carbon capture applications.- Cost-effective amine sorbent production methods: Various methods have been developed to produce amine sorbents more cost-effectively. These include optimizing synthesis processes, using cheaper raw materials, and improving manufacturing techniques to reduce energy consumption and waste. Such advancements help lower the overall cost of amine sorbents while maintaining their effectiveness in carbon capture applications.

- Regeneration and reuse of amine sorbents: Techniques for regenerating and reusing amine sorbents have been developed to extend their lifespan and reduce long-term costs. These methods involve efficient desorption processes, thermal regeneration, and chemical treatments to restore the sorbent's capacity. By increasing the number of use cycles, the overall cost per unit of CO2 captured can be significantly reduced.

- Novel amine sorbent materials: Research has led to the development of new amine sorbent materials with improved performance and lower costs. These include hybrid materials, supported amine sorbents, and novel polymer-based sorbents. These materials often exhibit higher CO2 capacity, better selectivity, and improved stability, potentially reducing the amount of sorbent needed and lowering overall costs.

- Process optimization for cost reduction: Various process optimizations have been implemented to reduce the cost of using amine sorbents in carbon capture. These include improving heat integration, enhancing mass transfer, and optimizing operating conditions. Such improvements can lead to reduced energy consumption, increased capture efficiency, and lower overall operational costs.

- Alternative low-cost precursors for amine sorbents: Researchers have explored the use of alternative, low-cost precursors for synthesizing amine sorbents. These include waste materials, biomass-derived compounds, and industrial by-products. By utilizing these cheaper starting materials, the production costs of amine sorbents can be significantly reduced without compromising their performance in carbon capture applications.

02 Regeneration and reuse of amine sorbents

Techniques for regenerating and reusing amine sorbents have been developed to extend their lifespan and reduce long-term costs. These methods involve efficient desorption processes, thermal regeneration, and chemical treatments that restore the sorbent's capacity for multiple cycles of use. By increasing the number of times a sorbent can be used, the overall cost per unit of carbon captured is significantly reduced.Expand Specific Solutions03 Novel amine sorbent materials with improved cost-efficiency

Research has led to the development of new amine sorbent materials that offer improved cost-efficiency. These materials may have higher CO2 absorption capacities, faster kinetics, or better stability, allowing for more efficient carbon capture with less material. Some novel sorbents also exhibit lower regeneration energy requirements, further reducing operational costs.Expand Specific Solutions04 Process optimization for cost reduction in amine sorbent systems

Various process optimizations have been implemented to reduce costs in amine sorbent systems. These include improvements in heat integration, pressure swing adsorption techniques, and advanced control strategies. Such optimizations aim to minimize energy consumption, reduce equipment size, and increase overall system efficiency, thereby lowering both capital and operational expenses.Expand Specific Solutions05 Low-cost support materials for amine sorbents

The use of low-cost support materials for amine sorbents has been explored to reduce overall costs. These supports may include readily available materials such as activated carbon, silica, or polymeric substrates. By utilizing cheaper support materials without compromising the sorbent's performance, the total cost of amine sorbents can be significantly reduced while maintaining their effectiveness in carbon capture applications.Expand Specific Solutions

Key Players in Amine Sorbent Support Development

The research on low-cost supports for amine sorbents is in an early development stage, with a growing market driven by increasing focus on carbon capture technologies. The global market for carbon capture and storage is projected to reach $7 billion by 2026, indicating significant growth potential. Technologically, the field is still evolving, with various approaches being explored. Key players like The Regents of the University of California, ExxonMobil, and Climeworks AG are at the forefront, developing innovative solutions. Academic institutions such as Zhejiang University and Georgia Tech are contributing fundamental research, while companies like FUJIFILM Corp. and Climeworks AG are working on commercialization. The involvement of diverse entities suggests a competitive landscape with ample room for technological advancements.

The Regents of the University of California

Technical Solution: The University of California has developed a novel approach using biochars as low-cost supports for amine sorbents in CO2 capture. Their research focuses on producing biochars from agricultural waste materials, which are then functionalized with amine groups. This method has shown promising results, with CO2 adsorption capacities reaching up to 2.5 mmol/g under simulated flue gas conditions[1]. The university has also explored the use of mesoporous silica supports, demonstrating enhanced CO2 capture performance when combined with polyethyleneimine (PEI)[2]. Additionally, they have investigated metal-organic frameworks (MOFs) as potential supports, particularly focusing on zirconium-based MOFs that exhibit high stability and tunable pore structures[3].

Strengths: Utilization of waste materials for biochar production, reducing costs and environmental impact. High CO2 adsorption capacity. Weaknesses: Potential variability in biochar properties depending on feedstock. Scalability challenges for large-scale implementation.

ExxonMobil Technology & Engineering Co.

Technical Solution: ExxonMobil has developed a proprietary technology called Molten Amine Process (MAP) for CO2 capture, which utilizes low-cost supports. While not specifically focused on biochars or MOFs, their approach involves using a mixture of low molecular weight amines supported on porous materials. This process operates at elevated temperatures, allowing for efficient CO2 capture and release. The company claims that their technology can reduce the cost of carbon capture by up to 25% compared to conventional amine scrubbing methods[4]. ExxonMobil has also explored the use of mesoporous silica supports in combination with various amine compounds to enhance CO2 adsorption capacity and kinetics[5].

Strengths: Potential for significant cost reduction in carbon capture. Efficient CO2 capture and release at elevated temperatures. Weaknesses: Limited public information on specific support materials used. Potential energy requirements for maintaining elevated temperatures.

Innovative Approaches in Biochar, Silica, and MOF Supports

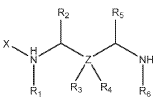

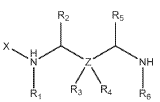

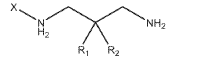

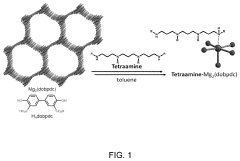

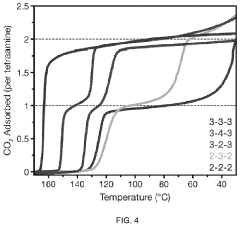

Amine-appended metal-organic frameworks exhibiting a new adsorption mechanism for carbon dioxide separations

PatentWO2018152438A1

Innovation

- A unique class of adsorbents is developed by appending substituted 1,3-propanediamines to metal-organic frameworks, which enables effective CO2 capture at low partial pressures (approximately 15 mbar at 40 °C) and regeneration at moderate temperatures (95-100 °C) with low energy, utilizing a mixed adsorption mechanism involving ammonium carbamate chains and carbamic acid pairs.

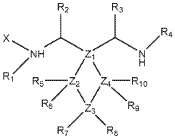

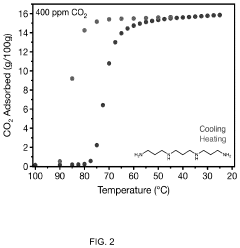

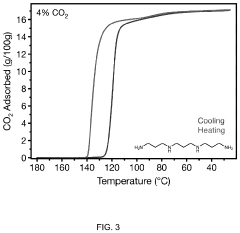

Metal-organic frameworks for carbon dioxide capture

PatentActiveUS11872537B2

Innovation

- Development of tetraamine-functionalized metal-organic frameworks that exhibit step-shaped CO2 adsorption profiles, maintaining adsorption in humid conditions and stability under steam regeneration, enabling greater than 90% CO2 capture from various sources including natural gas flue gases.

Environmental Impact of Low-Cost Sorbent Supports

The environmental impact of low-cost sorbent supports is a critical consideration in the development and implementation of amine-based carbon capture technologies. Biochars, silicas, and metal-organic frameworks (MOFs) have emerged as promising candidates for cost-effective and environmentally friendly sorbent supports. These materials offer potential advantages in terms of sustainability, resource efficiency, and reduced environmental footprint compared to traditional supports.

Biochars, derived from biomass pyrolysis, present a particularly attractive option from an environmental perspective. The production of biochars can utilize agricultural waste or other renewable biomass sources, effectively upcycling materials that might otherwise be discarded. This process not only reduces waste but also sequesters carbon, potentially creating a negative carbon footprint when considering the entire life cycle of the sorbent support.

Silica-based supports, while often derived from non-renewable sources, can be synthesized using relatively low-energy processes. Recent advancements in green chemistry have led to the development of silica production methods that utilize bio-based precursors or waste materials, further improving their environmental profile. Additionally, the high stability and potential for regeneration of silica supports contribute to their overall sustainability in carbon capture applications.

Metal-organic frameworks offer a unique balance of customizability and potential environmental benefits. The modular nature of MOFs allows for the incorporation of bio-based linkers or environmentally benign metal centers, reducing the reliance on scarce or toxic materials. However, the synthesis of MOFs often involves the use of organic solvents, which can pose environmental challenges if not properly managed or recycled.

When assessing the environmental impact of these low-cost supports, it is crucial to consider the entire life cycle, from raw material extraction to end-of-life disposal or recycling. Factors such as energy consumption during production, water usage, emissions of volatile organic compounds, and the potential for material recovery and reuse all play significant roles in determining the overall environmental footprint.

The durability and regeneration capacity of the sorbent supports also contribute to their long-term environmental impact. Materials that can withstand multiple adsorption-desorption cycles without significant degradation reduce the need for frequent replacement, thereby minimizing waste generation and resource consumption over time.

Furthermore, the integration of these low-cost supports into existing industrial processes must be evaluated for potential synergies or conflicts with other environmental initiatives. For instance, the use of biochar-based supports could align well with efforts to promote circular economy principles in the agricultural sector, while silica supports might find synergies with waste management strategies in the mining industry.

In conclusion, the environmental impact of low-cost sorbent supports for amine-based carbon capture is multifaceted and requires careful consideration of various factors throughout their life cycle. While biochars, silicas, and MOFs offer promising environmental benefits, ongoing research and development efforts should focus on further optimizing their production processes, enhancing their durability, and exploring innovative approaches to minimize their ecological footprint.

Biochars, derived from biomass pyrolysis, present a particularly attractive option from an environmental perspective. The production of biochars can utilize agricultural waste or other renewable biomass sources, effectively upcycling materials that might otherwise be discarded. This process not only reduces waste but also sequesters carbon, potentially creating a negative carbon footprint when considering the entire life cycle of the sorbent support.

Silica-based supports, while often derived from non-renewable sources, can be synthesized using relatively low-energy processes. Recent advancements in green chemistry have led to the development of silica production methods that utilize bio-based precursors or waste materials, further improving their environmental profile. Additionally, the high stability and potential for regeneration of silica supports contribute to their overall sustainability in carbon capture applications.

Metal-organic frameworks offer a unique balance of customizability and potential environmental benefits. The modular nature of MOFs allows for the incorporation of bio-based linkers or environmentally benign metal centers, reducing the reliance on scarce or toxic materials. However, the synthesis of MOFs often involves the use of organic solvents, which can pose environmental challenges if not properly managed or recycled.

When assessing the environmental impact of these low-cost supports, it is crucial to consider the entire life cycle, from raw material extraction to end-of-life disposal or recycling. Factors such as energy consumption during production, water usage, emissions of volatile organic compounds, and the potential for material recovery and reuse all play significant roles in determining the overall environmental footprint.

The durability and regeneration capacity of the sorbent supports also contribute to their long-term environmental impact. Materials that can withstand multiple adsorption-desorption cycles without significant degradation reduce the need for frequent replacement, thereby minimizing waste generation and resource consumption over time.

Furthermore, the integration of these low-cost supports into existing industrial processes must be evaluated for potential synergies or conflicts with other environmental initiatives. For instance, the use of biochar-based supports could align well with efforts to promote circular economy principles in the agricultural sector, while silica supports might find synergies with waste management strategies in the mining industry.

In conclusion, the environmental impact of low-cost sorbent supports for amine-based carbon capture is multifaceted and requires careful consideration of various factors throughout their life cycle. While biochars, silicas, and MOFs offer promising environmental benefits, ongoing research and development efforts should focus on further optimizing their production processes, enhancing their durability, and exploring innovative approaches to minimize their ecological footprint.

Scalability and Industrial Application Potential

The scalability and industrial application potential of low-cost supports for amine sorbents, including biochars, silicas, and metal-organic frameworks (MOFs), are significant factors in determining their viability for large-scale carbon capture and storage (CCS) applications. These materials show promise in addressing the cost and efficiency challenges associated with traditional amine-based sorbents.

Biochars, derived from biomass pyrolysis, offer excellent scalability due to their abundant and renewable feedstock sources. The production process is relatively simple and can be easily scaled up to meet industrial demands. However, the variability in biochar properties depending on the source material and production conditions may pose challenges for consistent performance in industrial settings.

Silica-based supports benefit from well-established manufacturing processes in the chemical industry. Their production can be readily scaled to meet large-scale requirements, and their uniform properties make them attractive for industrial applications. The main challenge lies in reducing production costs to make them competitive with other low-cost alternatives.

Metal-organic frameworks present a more complex scalability scenario. While they offer exceptional surface areas and tunable properties, their synthesis often involves costly precursors and multi-step processes. Recent advancements in continuous flow synthesis and mechanochemical methods show promise for scaling up MOF production, but further optimization is needed to achieve industrial-scale manufacturing.

Hybrid approaches combining these materials may offer the best potential for industrial applications. By leveraging the strengths of each support type, hybrid sorbents can potentially overcome individual limitations and provide optimized performance. For instance, biochar-silica composites could combine the low cost and renewability of biochars with the uniform properties of silicas.

The industrial application potential of these low-cost supports extends beyond CCS. They show promise in various sectors, including gas separation, water treatment, and catalysis. This versatility enhances their economic viability and market potential, potentially driving further research and development efforts.

To fully realize the industrial potential of these materials, several challenges must be addressed. These include optimizing large-scale production processes, ensuring consistent quality and performance, and developing efficient regeneration methods. Additionally, integrating these materials into existing industrial infrastructure and processes will require careful engineering and potentially significant capital investments.

In conclusion, while low-cost supports for amine sorbents show considerable promise for scalability and industrial applications, continued research and development efforts are necessary to overcome existing challenges and fully exploit their potential in CCS and other industrial sectors.

Biochars, derived from biomass pyrolysis, offer excellent scalability due to their abundant and renewable feedstock sources. The production process is relatively simple and can be easily scaled up to meet industrial demands. However, the variability in biochar properties depending on the source material and production conditions may pose challenges for consistent performance in industrial settings.

Silica-based supports benefit from well-established manufacturing processes in the chemical industry. Their production can be readily scaled to meet large-scale requirements, and their uniform properties make them attractive for industrial applications. The main challenge lies in reducing production costs to make them competitive with other low-cost alternatives.

Metal-organic frameworks present a more complex scalability scenario. While they offer exceptional surface areas and tunable properties, their synthesis often involves costly precursors and multi-step processes. Recent advancements in continuous flow synthesis and mechanochemical methods show promise for scaling up MOF production, but further optimization is needed to achieve industrial-scale manufacturing.

Hybrid approaches combining these materials may offer the best potential for industrial applications. By leveraging the strengths of each support type, hybrid sorbents can potentially overcome individual limitations and provide optimized performance. For instance, biochar-silica composites could combine the low cost and renewability of biochars with the uniform properties of silicas.

The industrial application potential of these low-cost supports extends beyond CCS. They show promise in various sectors, including gas separation, water treatment, and catalysis. This versatility enhances their economic viability and market potential, potentially driving further research and development efforts.

To fully realize the industrial potential of these materials, several challenges must be addressed. These include optimizing large-scale production processes, ensuring consistent quality and performance, and developing efficient regeneration methods. Additionally, integrating these materials into existing industrial infrastructure and processes will require careful engineering and potentially significant capital investments.

In conclusion, while low-cost supports for amine sorbents show considerable promise for scalability and industrial applications, continued research and development efforts are necessary to overcome existing challenges and fully exploit their potential in CCS and other industrial sectors.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!