Sorbent Disposal & Recycling: Environmental Impact Assessment and Options

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Sorbent Technology Evolution and Objectives

Sorbent technology has evolved significantly over the past few decades, driven by the increasing need for effective pollution control and environmental remediation. The journey of sorbent materials began with simple, naturally occurring substances like activated carbon and zeolites. These early sorbents demonstrated remarkable capacity for adsorbing various pollutants but often lacked specificity and regeneration potential.

As environmental regulations became more stringent and industrial processes more complex, the demand for advanced sorbent materials grew. This led to the development of synthetic sorbents with enhanced properties, such as higher surface areas, improved selectivity, and greater stability under diverse conditions. Engineered nanomaterials emerged as a promising class of sorbents, offering unprecedented surface-to-volume ratios and tunable surface chemistries.

The evolution of sorbent technology has been closely tied to advancements in material science and nanotechnology. Researchers have explored various approaches to enhance sorbent performance, including surface modification, pore structure optimization, and the creation of composite materials. These efforts have resulted in sorbents capable of targeting specific contaminants with high efficiency, even in complex environmental matrices.

Recent years have seen a shift towards sustainable and bio-based sorbents, aligning with global efforts to reduce environmental impact. Agricultural waste products, industrial by-products, and other renewable resources are being repurposed as eco-friendly sorbent materials. This trend not only addresses waste management issues but also offers cost-effective alternatives to traditional synthetic sorbents.

The primary objectives of current sorbent technology research and development are multifaceted. Firstly, there is a focus on improving the adsorption capacity and selectivity of sorbents, particularly for emerging contaminants such as pharmaceuticals and microplastics. Secondly, researchers aim to enhance the regeneration and reusability of sorbents, addressing the critical issue of disposal and reducing the overall environmental footprint of sorption processes.

Another key objective is the development of multi-functional sorbents capable of simultaneous removal of diverse pollutants, streamlining treatment processes and reducing operational costs. Additionally, there is growing interest in smart sorbents that can respond to environmental stimuli, allowing for controlled release or capture of target substances.

As we look to the future, the goals of sorbent technology are increasingly aligned with circular economy principles. This includes not only the recycling and regeneration of spent sorbents but also the recovery of valuable resources from waste streams. The ultimate aim is to create closed-loop systems where sorbents play a central role in pollution control, resource recovery, and sustainable material management.

As environmental regulations became more stringent and industrial processes more complex, the demand for advanced sorbent materials grew. This led to the development of synthetic sorbents with enhanced properties, such as higher surface areas, improved selectivity, and greater stability under diverse conditions. Engineered nanomaterials emerged as a promising class of sorbents, offering unprecedented surface-to-volume ratios and tunable surface chemistries.

The evolution of sorbent technology has been closely tied to advancements in material science and nanotechnology. Researchers have explored various approaches to enhance sorbent performance, including surface modification, pore structure optimization, and the creation of composite materials. These efforts have resulted in sorbents capable of targeting specific contaminants with high efficiency, even in complex environmental matrices.

Recent years have seen a shift towards sustainable and bio-based sorbents, aligning with global efforts to reduce environmental impact. Agricultural waste products, industrial by-products, and other renewable resources are being repurposed as eco-friendly sorbent materials. This trend not only addresses waste management issues but also offers cost-effective alternatives to traditional synthetic sorbents.

The primary objectives of current sorbent technology research and development are multifaceted. Firstly, there is a focus on improving the adsorption capacity and selectivity of sorbents, particularly for emerging contaminants such as pharmaceuticals and microplastics. Secondly, researchers aim to enhance the regeneration and reusability of sorbents, addressing the critical issue of disposal and reducing the overall environmental footprint of sorption processes.

Another key objective is the development of multi-functional sorbents capable of simultaneous removal of diverse pollutants, streamlining treatment processes and reducing operational costs. Additionally, there is growing interest in smart sorbents that can respond to environmental stimuli, allowing for controlled release or capture of target substances.

As we look to the future, the goals of sorbent technology are increasingly aligned with circular economy principles. This includes not only the recycling and regeneration of spent sorbents but also the recovery of valuable resources from waste streams. The ultimate aim is to create closed-loop systems where sorbents play a central role in pollution control, resource recovery, and sustainable material management.

Market Analysis for Sorbent Disposal Solutions

The market for sorbent disposal solutions is experiencing significant growth driven by increasing environmental regulations and a growing focus on sustainable waste management practices. The global sorbent market, which includes materials used for spill control and cleanup, is projected to reach $9.7 billion by 2025, with a compound annual growth rate of 5.2% from 2020 to 2025. This growth is primarily attributed to the rising demand for effective spill management solutions across various industries, including oil and gas, chemicals, and manufacturing.

In the context of sorbent disposal and recycling, the market is witnessing a shift towards more environmentally friendly and cost-effective solutions. Traditional disposal methods, such as landfilling, are becoming less favorable due to their negative environmental impact and increasing costs. This has led to a growing demand for innovative disposal and recycling technologies that can minimize waste and recover valuable resources.

The oil and gas industry remains the largest consumer of sorbents, accounting for approximately 40% of the global market share. This sector's demand is driven by the need for effective spill cleanup solutions in offshore and onshore operations. However, other industries, such as chemicals, manufacturing, and healthcare, are also contributing to the market growth as they seek to improve their environmental performance and comply with stricter regulations.

Geographically, North America dominates the sorbent market, followed by Europe and Asia-Pacific. The United States, in particular, holds a significant market share due to its stringent environmental regulations and well-established oil and gas industry. However, emerging economies in Asia-Pacific, such as China and India, are expected to witness the highest growth rates in the coming years, driven by rapid industrialization and increasing environmental awareness.

The market for sorbent disposal solutions is characterized by a mix of established players and innovative startups. Key market players are focusing on developing advanced recycling technologies and biodegradable sorbents to gain a competitive edge. There is also a growing trend towards the development of reusable sorbents, which can significantly reduce disposal costs and environmental impact.

One of the key challenges facing the sorbent disposal market is the high cost associated with advanced recycling technologies. This has led to a demand for more cost-effective solutions that can balance environmental benefits with economic feasibility. Additionally, there is a growing need for standardized regulations and guidelines for sorbent disposal and recycling across different regions and industries.

In conclusion, the market for sorbent disposal solutions presents significant opportunities for growth and innovation. As environmental concerns continue to drive regulatory changes and corporate sustainability initiatives, the demand for effective and environmentally friendly sorbent disposal and recycling solutions is expected to increase. Companies that can develop cost-effective, sustainable technologies are likely to gain a significant competitive advantage in this evolving market landscape.

In the context of sorbent disposal and recycling, the market is witnessing a shift towards more environmentally friendly and cost-effective solutions. Traditional disposal methods, such as landfilling, are becoming less favorable due to their negative environmental impact and increasing costs. This has led to a growing demand for innovative disposal and recycling technologies that can minimize waste and recover valuable resources.

The oil and gas industry remains the largest consumer of sorbents, accounting for approximately 40% of the global market share. This sector's demand is driven by the need for effective spill cleanup solutions in offshore and onshore operations. However, other industries, such as chemicals, manufacturing, and healthcare, are also contributing to the market growth as they seek to improve their environmental performance and comply with stricter regulations.

Geographically, North America dominates the sorbent market, followed by Europe and Asia-Pacific. The United States, in particular, holds a significant market share due to its stringent environmental regulations and well-established oil and gas industry. However, emerging economies in Asia-Pacific, such as China and India, are expected to witness the highest growth rates in the coming years, driven by rapid industrialization and increasing environmental awareness.

The market for sorbent disposal solutions is characterized by a mix of established players and innovative startups. Key market players are focusing on developing advanced recycling technologies and biodegradable sorbents to gain a competitive edge. There is also a growing trend towards the development of reusable sorbents, which can significantly reduce disposal costs and environmental impact.

One of the key challenges facing the sorbent disposal market is the high cost associated with advanced recycling technologies. This has led to a demand for more cost-effective solutions that can balance environmental benefits with economic feasibility. Additionally, there is a growing need for standardized regulations and guidelines for sorbent disposal and recycling across different regions and industries.

In conclusion, the market for sorbent disposal solutions presents significant opportunities for growth and innovation. As environmental concerns continue to drive regulatory changes and corporate sustainability initiatives, the demand for effective and environmentally friendly sorbent disposal and recycling solutions is expected to increase. Companies that can develop cost-effective, sustainable technologies are likely to gain a significant competitive advantage in this evolving market landscape.

Current Challenges in Sorbent Disposal

The disposal of sorbents used in various industrial processes presents significant challenges in terms of environmental impact and resource management. One of the primary concerns is the potential for contamination of soil and groundwater. Many sorbents, particularly those used in oil spill cleanup or industrial wastewater treatment, can retain hazardous substances even after their primary use. When improperly disposed of, these contaminated sorbents can leach toxic compounds into the environment, posing risks to ecosystems and human health.

Another challenge lies in the sheer volume of sorbent materials requiring disposal. As industries expand and environmental regulations become more stringent, the use of sorbents in pollution control and cleanup operations has increased dramatically. This surge in usage has led to a corresponding increase in the amount of spent sorbents that need to be managed, putting pressure on existing waste management infrastructure and landfill capacity.

The diversity of sorbent materials further complicates disposal efforts. Sorbents can range from natural materials like clay and sawdust to synthetic polymers and activated carbon. Each type of sorbent may require different handling and disposal methods, making it difficult to implement standardized disposal protocols across industries. This variability also impacts the effectiveness of recycling efforts, as some sorbents may be more amenable to regeneration or repurposing than others.

Cost considerations present another significant hurdle in sorbent disposal. Proper treatment and disposal of contaminated sorbents can be expensive, particularly for materials classified as hazardous waste. These costs can be a substantial burden for businesses, potentially discouraging compliance with environmental regulations and promoting improper disposal practices.

The lack of widespread, efficient recycling technologies for many types of sorbents exacerbates the disposal problem. While some sorbents can be regenerated or repurposed, many end up in landfills or incinerators. This not only represents a loss of potentially valuable resources but also contributes to the overall environmental footprint of industrial operations.

Regulatory challenges also play a role in the complexities of sorbent disposal. Varying regulations across different regions and countries can create confusion and compliance difficulties for multinational corporations. Additionally, the classification of spent sorbents as hazardous or non-hazardous waste can be subject to interpretation, leading to inconsistencies in disposal practices.

Lastly, there is a growing concern about the long-term environmental impacts of certain sorbent materials, particularly synthetic polymers that do not biodegrade. The persistence of these materials in the environment, even after disposal, raises questions about their cumulative effects on ecosystems and the potential for microplastic pollution.

Another challenge lies in the sheer volume of sorbent materials requiring disposal. As industries expand and environmental regulations become more stringent, the use of sorbents in pollution control and cleanup operations has increased dramatically. This surge in usage has led to a corresponding increase in the amount of spent sorbents that need to be managed, putting pressure on existing waste management infrastructure and landfill capacity.

The diversity of sorbent materials further complicates disposal efforts. Sorbents can range from natural materials like clay and sawdust to synthetic polymers and activated carbon. Each type of sorbent may require different handling and disposal methods, making it difficult to implement standardized disposal protocols across industries. This variability also impacts the effectiveness of recycling efforts, as some sorbents may be more amenable to regeneration or repurposing than others.

Cost considerations present another significant hurdle in sorbent disposal. Proper treatment and disposal of contaminated sorbents can be expensive, particularly for materials classified as hazardous waste. These costs can be a substantial burden for businesses, potentially discouraging compliance with environmental regulations and promoting improper disposal practices.

The lack of widespread, efficient recycling technologies for many types of sorbents exacerbates the disposal problem. While some sorbents can be regenerated or repurposed, many end up in landfills or incinerators. This not only represents a loss of potentially valuable resources but also contributes to the overall environmental footprint of industrial operations.

Regulatory challenges also play a role in the complexities of sorbent disposal. Varying regulations across different regions and countries can create confusion and compliance difficulties for multinational corporations. Additionally, the classification of spent sorbents as hazardous or non-hazardous waste can be subject to interpretation, leading to inconsistencies in disposal practices.

Lastly, there is a growing concern about the long-term environmental impacts of certain sorbent materials, particularly synthetic polymers that do not biodegrade. The persistence of these materials in the environment, even after disposal, raises questions about their cumulative effects on ecosystems and the potential for microplastic pollution.

Existing Sorbent Disposal Techniques

01 Environmental impact assessment of sorbents

Sorbents are evaluated for their environmental impact through comprehensive assessments. These evaluations consider factors such as biodegradability, toxicity to aquatic life, and potential for bioaccumulation. The lifecycle analysis of sorbents, from production to disposal, is crucial in determining their overall environmental footprint.- Environmental impact assessment of sorbents: Sorbents are evaluated for their environmental impact through comprehensive assessments. These evaluations consider factors such as biodegradability, toxicity to aquatic life, and potential for bioaccumulation. The assessment process helps in selecting sorbents that are effective in their intended use while minimizing negative effects on ecosystems.

- Sustainable sorbent materials: Development of eco-friendly sorbent materials focuses on using renewable resources and biodegradable components. These sustainable sorbents are designed to effectively absorb target substances while decomposing naturally after use, reducing long-term environmental impact. Research in this area aims to balance performance with environmental responsibility.

- Life cycle analysis of sorbent products: Life cycle analysis is employed to assess the environmental impact of sorbents from production to disposal. This comprehensive approach considers energy consumption, resource depletion, and emissions throughout the sorbent's lifecycle. The analysis helps in identifying areas for improvement and guides the development of more environmentally friendly sorbent solutions.

- Sorbent disposal and recycling methods: Proper disposal and recycling of used sorbents are crucial for minimizing environmental impact. Innovative methods are being developed to regenerate spent sorbents, reducing waste and extending their useful life. Additionally, research focuses on creating sorbents that can be safely disposed of without causing harm to the environment or can be easily recycled into other products.

- Environmental monitoring of sorbent use: Continuous monitoring systems are implemented to assess the environmental impact of sorbents during their application. These systems track factors such as leaching of chemicals, changes in local ecosystems, and long-term effects on soil or water quality. The data collected helps in refining sorbent formulations and application methods to minimize negative environmental consequences.

02 Sustainable sorbent materials

Development of eco-friendly sorbent materials focuses on using renewable resources and biodegradable components. These sustainable sorbents aim to minimize environmental impact while maintaining high efficiency in their intended applications, such as water purification or oil spill cleanup.Expand Specific Solutions03 Sorbent disposal and recycling methods

Proper disposal and recycling of used sorbents are critical for reducing environmental impact. Advanced methods for regenerating spent sorbents and recovering valuable materials are being developed to minimize waste and promote circular economy principles in sorbent usage.Expand Specific Solutions04 Carbon footprint reduction in sorbent production

Efforts to reduce the carbon footprint associated with sorbent production include optimizing manufacturing processes, utilizing renewable energy sources, and developing low-energy synthesis methods. These initiatives aim to decrease greenhouse gas emissions and overall environmental impact of sorbent materials.Expand Specific Solutions05 Environmental monitoring and impact mitigation

Implementing robust environmental monitoring systems to assess the long-term effects of sorbent use in various applications. This includes developing strategies to mitigate any potential negative impacts on ecosystems and human health, ensuring responsible use of sorbent technologies in environmental remediation and industrial processes.Expand Specific Solutions

Key Players in Sorbent Recycling Industry

The sorbent disposal and recycling market is in a growth phase, driven by increasing environmental regulations and sustainability concerns. The global market size is expanding, with projections indicating significant growth in the coming years. Technologically, the field is advancing rapidly, with companies like Zhejiang University, China Petroleum & Chemical Corp., and Albemarle Corp. leading research and development efforts. These organizations are focusing on innovative recycling methods, environmentally-friendly disposal techniques, and the development of more efficient sorbent materials. The industry is seeing a shift towards circular economy principles, with emphasis on reducing waste and maximizing resource recovery. However, challenges remain in scaling up new technologies and ensuring cost-effectiveness across different applications and industries.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed an innovative approach to sorbent disposal and recycling, focusing on environmental impact reduction. Their method involves a multi-stage treatment process for spent sorbents, including thermal desorption, chemical washing, and biological remediation[1]. This integrated system allows for the recovery of valuable hydrocarbons while minimizing waste. The company has also implemented advanced monitoring techniques to assess the environmental impact of their disposal methods, using real-time data analytics to optimize the recycling process[3]. Sinopec's commitment to sustainability is evident in their recent investment in carbon capture technology, which can be applied to sorbent regeneration, further reducing the overall environmental footprint of their operations[5].

Strengths: Comprehensive approach combining multiple treatment technologies; Advanced monitoring and optimization capabilities; Integration with carbon capture technology. Weaknesses: High initial investment costs; Complexity of the multi-stage process may require specialized training and maintenance.

Albemarle Corp.

Technical Solution: Albemarle Corp. has pioneered a circular economy approach to sorbent disposal and recycling, particularly focusing on catalysts and adsorbents used in petrochemical processes. Their proprietary technology, known as ReNew™, allows for the regeneration and reuse of spent catalysts, significantly reducing waste and raw material consumption[2]. The process involves a combination of physical and chemical treatments, including acid leaching and thermal reactivation, which can restore up to 98% of the original catalyst activity[4]. Albemarle has also developed a life cycle assessment tool to quantify the environmental benefits of their recycling program, demonstrating up to 40% reduction in greenhouse gas emissions compared to traditional disposal methods[6]. Additionally, the company is exploring the use of artificial intelligence to predict optimal recycling schedules and maximize the lifespan of sorbents in industrial applications[8].

Strengths: High efficiency in catalyst regeneration; Comprehensive life cycle assessment capabilities; Integration of AI for predictive maintenance. Weaknesses: Process may be limited to specific types of catalysts and sorbents; Potential for chemical waste generation during regeneration process.

Innovative Sorbent Recycling Technologies

Process for disposing of environmentally harmful substances

PatentInactiveEP0652804A1

Innovation

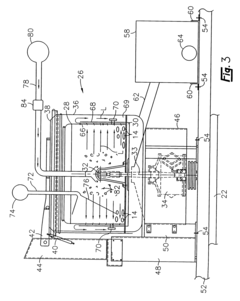

- A disposal method involving a moving bed reactor where heat is coupled into the system to facilitate desorption of toxins, allowing for on-site disposal and potential reuse or processing of the adsorbent, with a gas flow that enhances toxin concentration and destruction, thereby reducing environmental impact.

Recycling process and apparatus

PatentInactiveUS6383394B1

Innovation

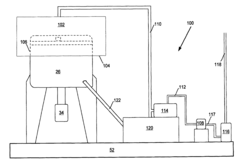

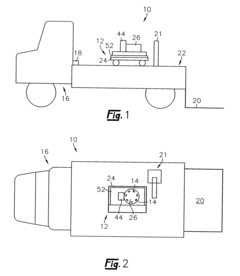

- A mobile centrifugal treatment system, comprising a self-balancing centrifuge mounted on a motor vehicle, which allows on-site recovery and reconditioning of sorbent materials by applying centrifugal forces to extract organic fluids and solvents, thereby rendering the materials non-hazardous and reusable, reducing the need for remote transportation and enabling on-site recycling.

Environmental Regulations on Sorbent Disposal

Environmental regulations on sorbent disposal have become increasingly stringent in recent years, reflecting growing concerns about the potential environmental impacts of improper handling and disposal of used sorbents. These regulations vary across different jurisdictions but generally aim to minimize the release of hazardous substances into the environment and protect human health.

In the United States, the Environmental Protection Agency (EPA) has established comprehensive guidelines for the management of spent sorbents under the Resource Conservation and Recovery Act (RCRA). The RCRA classifies spent sorbents as hazardous waste if they exhibit characteristics such as ignitability, corrosivity, reactivity, or toxicity. Generators of hazardous waste sorbents must comply with strict handling, storage, and disposal requirements, including obtaining EPA identification numbers and using licensed hazardous waste transporters and treatment, storage, and disposal facilities.

The European Union has implemented the Waste Framework Directive (2008/98/EC), which sets the basic concepts and definitions related to waste management. Under this directive, spent sorbents may be classified as hazardous waste depending on their properties and the substances they have absorbed. The directive emphasizes the waste hierarchy, promoting prevention, reuse, and recycling over disposal.

Many countries have adopted the Basel Convention on the Control of Transboundary Movements of Hazardous Wastes and Their Disposal, which regulates the international movement of hazardous wastes, including certain types of spent sorbents. This convention aims to prevent the transfer of hazardous wastes from developed to less developed countries.

Specific regulations often apply to different industries and types of sorbents. For example, the International Maritime Organization's MARPOL Convention addresses the disposal of oil-absorbent materials used in marine environments. Similarly, the aviation industry has specific guidelines for the disposal of sorbents used in fuel spill cleanup operations.

Regulatory trends indicate a move towards more sustainable practices in sorbent disposal. There is an increasing emphasis on extended producer responsibility, where manufacturers are required to take back and properly dispose of or recycle spent sorbents. Some jurisdictions are also implementing landfill bans for certain types of sorbents, encouraging the development of more environmentally friendly disposal and recycling methods.

Compliance with these regulations often requires detailed record-keeping, regular reporting, and implementation of best management practices. Penalties for non-compliance can be severe, including substantial fines and potential criminal charges for egregious violations.

In the United States, the Environmental Protection Agency (EPA) has established comprehensive guidelines for the management of spent sorbents under the Resource Conservation and Recovery Act (RCRA). The RCRA classifies spent sorbents as hazardous waste if they exhibit characteristics such as ignitability, corrosivity, reactivity, or toxicity. Generators of hazardous waste sorbents must comply with strict handling, storage, and disposal requirements, including obtaining EPA identification numbers and using licensed hazardous waste transporters and treatment, storage, and disposal facilities.

The European Union has implemented the Waste Framework Directive (2008/98/EC), which sets the basic concepts and definitions related to waste management. Under this directive, spent sorbents may be classified as hazardous waste depending on their properties and the substances they have absorbed. The directive emphasizes the waste hierarchy, promoting prevention, reuse, and recycling over disposal.

Many countries have adopted the Basel Convention on the Control of Transboundary Movements of Hazardous Wastes and Their Disposal, which regulates the international movement of hazardous wastes, including certain types of spent sorbents. This convention aims to prevent the transfer of hazardous wastes from developed to less developed countries.

Specific regulations often apply to different industries and types of sorbents. For example, the International Maritime Organization's MARPOL Convention addresses the disposal of oil-absorbent materials used in marine environments. Similarly, the aviation industry has specific guidelines for the disposal of sorbents used in fuel spill cleanup operations.

Regulatory trends indicate a move towards more sustainable practices in sorbent disposal. There is an increasing emphasis on extended producer responsibility, where manufacturers are required to take back and properly dispose of or recycle spent sorbents. Some jurisdictions are also implementing landfill bans for certain types of sorbents, encouraging the development of more environmentally friendly disposal and recycling methods.

Compliance with these regulations often requires detailed record-keeping, regular reporting, and implementation of best management practices. Penalties for non-compliance can be severe, including substantial fines and potential criminal charges for egregious violations.

Economic Viability of Sorbent Recycling Options

The economic viability of sorbent recycling options is a critical consideration in the overall assessment of sorbent disposal and recycling strategies. This analysis focuses on the financial aspects of various recycling methods, weighing the costs against potential benefits and market opportunities.

Recycling sorbents can offer significant cost savings compared to continuous disposal and replacement. The primary economic drivers include reduced raw material costs, decreased waste management expenses, and potential revenue from recycled products. However, the viability of recycling depends on several factors, including the type of sorbent, contamination levels, and available recycling technologies.

For activated carbon, a common sorbent in industrial applications, thermal reactivation has shown promising economic returns. This process can restore up to 95% of the original adsorption capacity, significantly extending the sorbent's lifespan. The initial investment in reactivation facilities can be substantial, but operational costs are often lower than purchasing new activated carbon, especially for large-scale operations.

Chemical regeneration methods, while less energy-intensive than thermal processes, may have varying economic outcomes depending on the chemicals used and the resulting by-products. In some cases, the regenerated sorbent may have reduced capacity, impacting its long-term economic value. However, advancements in chemical regeneration techniques are improving efficiency and reducing costs.

The economic feasibility of biological regeneration is still being explored. While potentially more environmentally friendly, the slower regeneration rates and specialized equipment requirements can impact its cost-effectiveness. As research progresses, biological methods may become more economically competitive, particularly for specific contaminants and industries.

Market demand for recycled sorbents plays a crucial role in economic viability. Industries with high sorbent usage, such as water treatment and air purification, offer significant potential for recycled products. However, quality concerns and regulatory requirements can influence market acceptance and pricing.

Transportation costs are a significant factor in the economics of sorbent recycling. Centralized recycling facilities may benefit from economies of scale but face higher logistics expenses. On-site recycling systems, while potentially more capital-intensive, can reduce transportation costs and offer quicker turnaround times.

The economic landscape of sorbent recycling is also shaped by regulatory policies. Stricter waste disposal regulations and landfill taxes can make recycling more attractive financially. Additionally, government incentives for sustainable practices may further improve the economic viability of recycling options.

In conclusion, while sorbent recycling can offer substantial economic benefits, its viability varies depending on the specific context, technology, and market conditions. A thorough cost-benefit analysis, considering both short-term expenses and long-term savings, is essential for determining the most economically sound approach to sorbent management.

Recycling sorbents can offer significant cost savings compared to continuous disposal and replacement. The primary economic drivers include reduced raw material costs, decreased waste management expenses, and potential revenue from recycled products. However, the viability of recycling depends on several factors, including the type of sorbent, contamination levels, and available recycling technologies.

For activated carbon, a common sorbent in industrial applications, thermal reactivation has shown promising economic returns. This process can restore up to 95% of the original adsorption capacity, significantly extending the sorbent's lifespan. The initial investment in reactivation facilities can be substantial, but operational costs are often lower than purchasing new activated carbon, especially for large-scale operations.

Chemical regeneration methods, while less energy-intensive than thermal processes, may have varying economic outcomes depending on the chemicals used and the resulting by-products. In some cases, the regenerated sorbent may have reduced capacity, impacting its long-term economic value. However, advancements in chemical regeneration techniques are improving efficiency and reducing costs.

The economic feasibility of biological regeneration is still being explored. While potentially more environmentally friendly, the slower regeneration rates and specialized equipment requirements can impact its cost-effectiveness. As research progresses, biological methods may become more economically competitive, particularly for specific contaminants and industries.

Market demand for recycled sorbents plays a crucial role in economic viability. Industries with high sorbent usage, such as water treatment and air purification, offer significant potential for recycled products. However, quality concerns and regulatory requirements can influence market acceptance and pricing.

Transportation costs are a significant factor in the economics of sorbent recycling. Centralized recycling facilities may benefit from economies of scale but face higher logistics expenses. On-site recycling systems, while potentially more capital-intensive, can reduce transportation costs and offer quicker turnaround times.

The economic landscape of sorbent recycling is also shaped by regulatory policies. Stricter waste disposal regulations and landfill taxes can make recycling more attractive financially. Additionally, government incentives for sustainable practices may further improve the economic viability of recycling options.

In conclusion, while sorbent recycling can offer substantial economic benefits, its viability varies depending on the specific context, technology, and market conditions. A thorough cost-benefit analysis, considering both short-term expenses and long-term savings, is essential for determining the most economically sound approach to sorbent management.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!