How to Mitigate Sorbent Poisoning by Volatile Organic Compounds and Pollutants

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Sorbent Poisoning Background and Objectives

Sorbent poisoning by volatile organic compounds (VOCs) and pollutants has emerged as a significant challenge in various industrial and environmental applications. This phenomenon occurs when harmful substances adhere to the surface of sorbent materials, reducing their effectiveness in capturing target compounds. The issue has gained prominence due to the increasing focus on air and water purification, as well as the growing demand for efficient gas separation and storage technologies.

The evolution of sorbent technology can be traced back to the early 20th century, with significant advancements made in the development of activated carbon and zeolites. These materials have been widely used in applications ranging from water treatment to gas purification. However, as industrial processes have become more complex and environmental regulations more stringent, the limitations of traditional sorbents in dealing with diverse pollutants have become apparent.

Recent years have seen a surge in research aimed at understanding the mechanisms of sorbent poisoning and developing strategies to mitigate its effects. This renewed interest is driven by the need for more efficient and cost-effective solutions in environmental remediation, industrial gas separation, and energy storage applications. The primary objective in this field is to enhance the longevity and performance of sorbent materials in the presence of VOCs and other pollutants.

Key technological goals in addressing sorbent poisoning include developing materials with improved selectivity, increased resistance to poisoning, and enhanced regeneration capabilities. Researchers are exploring novel sorbent compositions, surface modifications, and hierarchical structures to achieve these objectives. Additionally, there is a growing emphasis on understanding the molecular-level interactions between sorbents and pollutants to design more effective mitigation strategies.

The pursuit of solutions to sorbent poisoning aligns with broader environmental and sustainability goals. As industries strive to reduce their carbon footprint and comply with stricter emissions standards, the demand for advanced sorbent technologies continues to grow. This has led to increased collaboration between academic institutions, research organizations, and industrial partners to accelerate innovation in this field.

Looking ahead, the trajectory of sorbent technology is expected to focus on developing "smart" materials that can adapt to changing environmental conditions and pollutant profiles. This may involve the integration of nanotechnology, advanced sensing capabilities, and even artificial intelligence to create more responsive and efficient sorbent systems. The ultimate aim is to create a new generation of sorbents that can maintain high performance over extended periods, even in the presence of complex mixtures of VOCs and pollutants.

The evolution of sorbent technology can be traced back to the early 20th century, with significant advancements made in the development of activated carbon and zeolites. These materials have been widely used in applications ranging from water treatment to gas purification. However, as industrial processes have become more complex and environmental regulations more stringent, the limitations of traditional sorbents in dealing with diverse pollutants have become apparent.

Recent years have seen a surge in research aimed at understanding the mechanisms of sorbent poisoning and developing strategies to mitigate its effects. This renewed interest is driven by the need for more efficient and cost-effective solutions in environmental remediation, industrial gas separation, and energy storage applications. The primary objective in this field is to enhance the longevity and performance of sorbent materials in the presence of VOCs and other pollutants.

Key technological goals in addressing sorbent poisoning include developing materials with improved selectivity, increased resistance to poisoning, and enhanced regeneration capabilities. Researchers are exploring novel sorbent compositions, surface modifications, and hierarchical structures to achieve these objectives. Additionally, there is a growing emphasis on understanding the molecular-level interactions between sorbents and pollutants to design more effective mitigation strategies.

The pursuit of solutions to sorbent poisoning aligns with broader environmental and sustainability goals. As industries strive to reduce their carbon footprint and comply with stricter emissions standards, the demand for advanced sorbent technologies continues to grow. This has led to increased collaboration between academic institutions, research organizations, and industrial partners to accelerate innovation in this field.

Looking ahead, the trajectory of sorbent technology is expected to focus on developing "smart" materials that can adapt to changing environmental conditions and pollutant profiles. This may involve the integration of nanotechnology, advanced sensing capabilities, and even artificial intelligence to create more responsive and efficient sorbent systems. The ultimate aim is to create a new generation of sorbents that can maintain high performance over extended periods, even in the presence of complex mixtures of VOCs and pollutants.

Market Analysis for VOC Mitigation Solutions

The market for Volatile Organic Compound (VOC) mitigation solutions has experienced significant growth in recent years, driven by increasing environmental regulations and growing awareness of the health risks associated with VOC exposure. The global VOC treatment market is projected to reach substantial value by 2025, with a compound annual growth rate exceeding 5% during the forecast period.

Industrial sectors, particularly chemical processing, petrochemicals, and manufacturing, represent the largest market segments for VOC mitigation solutions. These industries are under increasing pressure to reduce emissions and improve air quality, both for regulatory compliance and corporate social responsibility. The automotive and construction industries also contribute significantly to market demand, as they seek to reduce VOC emissions from paints, coatings, and adhesives.

Geographically, North America and Europe lead the market due to stringent environmental regulations and well-established industrial sectors. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, driven by rapid industrialization, urbanization, and increasing environmental concerns in countries like China and India.

The market for sorbent-based VOC mitigation technologies is particularly robust, as these solutions offer high efficiency and versatility across various applications. Activated carbon remains the most widely used sorbent material, valued for its high adsorption capacity and cost-effectiveness. However, the issue of sorbent poisoning by VOCs and other pollutants presents a significant challenge, driving demand for innovative solutions to extend sorbent life and improve overall system performance.

Emerging trends in the VOC mitigation market include the development of advanced sorbent materials with enhanced resistance to poisoning, such as modified activated carbons and synthetic zeolites. There is also growing interest in hybrid systems that combine multiple treatment technologies, such as adsorption with catalytic oxidation, to address a broader range of pollutants and improve overall efficiency.

The competitive landscape of the VOC mitigation market is characterized by a mix of large multinational corporations and specialized technology providers. Key players are investing heavily in research and development to address challenges like sorbent poisoning and to develop more efficient and cost-effective solutions. Collaborations between industry and academic institutions are also becoming more common, fostering innovation in materials science and process engineering.

Industrial sectors, particularly chemical processing, petrochemicals, and manufacturing, represent the largest market segments for VOC mitigation solutions. These industries are under increasing pressure to reduce emissions and improve air quality, both for regulatory compliance and corporate social responsibility. The automotive and construction industries also contribute significantly to market demand, as they seek to reduce VOC emissions from paints, coatings, and adhesives.

Geographically, North America and Europe lead the market due to stringent environmental regulations and well-established industrial sectors. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, driven by rapid industrialization, urbanization, and increasing environmental concerns in countries like China and India.

The market for sorbent-based VOC mitigation technologies is particularly robust, as these solutions offer high efficiency and versatility across various applications. Activated carbon remains the most widely used sorbent material, valued for its high adsorption capacity and cost-effectiveness. However, the issue of sorbent poisoning by VOCs and other pollutants presents a significant challenge, driving demand for innovative solutions to extend sorbent life and improve overall system performance.

Emerging trends in the VOC mitigation market include the development of advanced sorbent materials with enhanced resistance to poisoning, such as modified activated carbons and synthetic zeolites. There is also growing interest in hybrid systems that combine multiple treatment technologies, such as adsorption with catalytic oxidation, to address a broader range of pollutants and improve overall efficiency.

The competitive landscape of the VOC mitigation market is characterized by a mix of large multinational corporations and specialized technology providers. Key players are investing heavily in research and development to address challenges like sorbent poisoning and to develop more efficient and cost-effective solutions. Collaborations between industry and academic institutions are also becoming more common, fostering innovation in materials science and process engineering.

Current Challenges in Sorbent Poisoning Prevention

Sorbent poisoning by volatile organic compounds (VOCs) and pollutants presents significant challenges in various industrial applications, particularly in air and water purification systems. The primary issue lies in the gradual degradation of sorbent materials due to the accumulation of contaminants, which reduces their effectiveness and longevity. This phenomenon not only diminishes the overall efficiency of purification processes but also leads to increased operational costs and environmental concerns.

One of the main challenges in preventing sorbent poisoning is the diverse nature of VOCs and pollutants encountered in real-world scenarios. Different industrial processes and environmental conditions produce a wide array of contaminants, each with unique chemical properties and interactions with sorbent materials. This complexity makes it difficult to develop a one-size-fits-all solution for sorbent protection.

Another significant hurdle is the competitive adsorption between target compounds and poisoning agents. In many cases, the pollutants responsible for sorbent poisoning have a higher affinity for the sorbent surface than the intended adsorbates. This preferential adsorption can quickly lead to the occupation of active sites on the sorbent, rendering it less effective for its primary purpose.

The kinetics of poisoning processes also pose a challenge. Some contaminants may cause rapid poisoning, while others may have a more gradual effect over time. Understanding and predicting these kinetics is crucial for developing effective mitigation strategies, but it requires extensive research and long-term studies under various operating conditions.

Furthermore, the regeneration of poisoned sorbents presents its own set of challenges. Traditional regeneration methods may not be fully effective in removing strongly bound poisoning agents, leading to a progressive decline in sorbent performance over multiple cycles. Developing more efficient and cost-effective regeneration techniques is essential for extending the lifespan of sorbent materials and reducing waste.

The economic implications of sorbent poisoning are also a significant concern. The frequent replacement of poisoned sorbents can be costly, and the downtime associated with system maintenance can lead to production losses in industrial settings. Balancing the cost of implementing poisoning prevention measures against the potential savings from extended sorbent life is a complex optimization problem that requires careful consideration.

Lastly, the environmental impact of disposing of poisoned sorbents adds another layer of complexity to the challenge. Many sorbent materials, once contaminated, may be classified as hazardous waste, necessitating special handling and disposal procedures. Developing more sustainable sorbent materials and poisoning prevention techniques is crucial for minimizing the environmental footprint of purification processes.

One of the main challenges in preventing sorbent poisoning is the diverse nature of VOCs and pollutants encountered in real-world scenarios. Different industrial processes and environmental conditions produce a wide array of contaminants, each with unique chemical properties and interactions with sorbent materials. This complexity makes it difficult to develop a one-size-fits-all solution for sorbent protection.

Another significant hurdle is the competitive adsorption between target compounds and poisoning agents. In many cases, the pollutants responsible for sorbent poisoning have a higher affinity for the sorbent surface than the intended adsorbates. This preferential adsorption can quickly lead to the occupation of active sites on the sorbent, rendering it less effective for its primary purpose.

The kinetics of poisoning processes also pose a challenge. Some contaminants may cause rapid poisoning, while others may have a more gradual effect over time. Understanding and predicting these kinetics is crucial for developing effective mitigation strategies, but it requires extensive research and long-term studies under various operating conditions.

Furthermore, the regeneration of poisoned sorbents presents its own set of challenges. Traditional regeneration methods may not be fully effective in removing strongly bound poisoning agents, leading to a progressive decline in sorbent performance over multiple cycles. Developing more efficient and cost-effective regeneration techniques is essential for extending the lifespan of sorbent materials and reducing waste.

The economic implications of sorbent poisoning are also a significant concern. The frequent replacement of poisoned sorbents can be costly, and the downtime associated with system maintenance can lead to production losses in industrial settings. Balancing the cost of implementing poisoning prevention measures against the potential savings from extended sorbent life is a complex optimization problem that requires careful consideration.

Lastly, the environmental impact of disposing of poisoned sorbents adds another layer of complexity to the challenge. Many sorbent materials, once contaminated, may be classified as hazardous waste, necessitating special handling and disposal procedures. Developing more sustainable sorbent materials and poisoning prevention techniques is crucial for minimizing the environmental footprint of purification processes.

Existing Sorbent Poisoning Mitigation Strategies

01 Sorbent regeneration techniques

Various methods are employed to regenerate poisoned sorbents, including thermal treatment, chemical washing, and electrochemical processes. These techniques aim to remove contaminants and restore the sorbent's adsorption capacity, extending its useful life and reducing operational costs in industrial applications.- Sorbent regeneration techniques: Various methods are employed to regenerate poisoned sorbents, including thermal treatment, chemical washing, and electrochemical processes. These techniques aim to remove contaminants and restore the sorbent's adsorption capacity, extending its useful life and improving overall efficiency in gas purification systems.

- Novel sorbent materials resistant to poisoning: Development of advanced sorbent materials with enhanced resistance to poisoning, such as modified zeolites, metal-organic frameworks, and composite materials. These novel sorbents are designed to maintain their performance under challenging conditions and in the presence of common poisoning agents.

- Poisoning prevention strategies: Implementation of preventive measures to minimize sorbent poisoning, including pre-treatment of feed gases, optimized process conditions, and the use of guard beds. These strategies aim to extend sorbent life and maintain consistent performance in industrial applications.

- Monitoring and detection of sorbent poisoning: Development of advanced monitoring techniques and sensors to detect early signs of sorbent poisoning. These methods include real-time analysis of sorbent performance, predictive modeling, and the use of artificial intelligence to optimize sorbent replacement schedules and minimize operational disruptions.

- Selective poisoning for enhanced selectivity: Controlled poisoning of sorbents to enhance their selectivity for specific target molecules. This approach involves the deliberate modification of sorbent surfaces to improve their affinity for certain compounds while reducing unwanted adsorption, leading to more efficient separation processes in various industries.

02 Novel sorbent materials resistant to poisoning

Development of advanced sorbent materials with improved resistance to poisoning, such as modified zeolites, metal-organic frameworks, and nanostructured composites. These materials are designed to maintain their effectiveness in the presence of common poisoning agents, enhancing their longevity and performance in various applications.Expand Specific Solutions03 Monitoring and prevention of sorbent poisoning

Implementation of real-time monitoring systems and preventive measures to detect early signs of sorbent poisoning and mitigate its effects. This includes the use of sensors, predictive modeling, and process optimization techniques to maintain sorbent efficiency and reduce the risk of unexpected performance degradation.Expand Specific Solutions04 Selective poisoning for targeted applications

Utilization of controlled poisoning techniques to modify sorbent properties for specific applications. This approach involves intentionally introducing certain substances to alter the sorbent's selectivity or catalytic activity, enabling tailored performance in specialized industrial processes or environmental remediation efforts.Expand Specific Solutions05 Eco-friendly sorbent poisoning management

Development of environmentally sustainable methods for managing sorbent poisoning, including the use of bio-based regeneration agents, green chemistry approaches, and closed-loop recycling systems. These techniques aim to minimize the environmental impact of sorbent poisoning treatment while maintaining high performance standards.Expand Specific Solutions

Key Players in Sorbent and VOC Mitigation Industry

The market for mitigating sorbent poisoning by volatile organic compounds and pollutants is in a growth phase, driven by increasing environmental regulations and industrial demand for efficient pollution control. The global market size for air pollution control systems is projected to reach $98 billion by 2025. While the technology is relatively mature, ongoing research focuses on improving sorbent performance and longevity. Key players like Albemarle, Solvay, and BASF are developing advanced materials and solutions, while specialized companies such as CytoSorbents and Claros Technologies are innovating in niche applications. Academic institutions like Northwest A&F University and South China University of Technology are contributing to fundamental research in this field.

Battelle Energy Alliance LLC

Technical Solution: Battelle Energy Alliance has developed advanced sorbent materials and regeneration techniques to mitigate sorbent poisoning by volatile organic compounds (VOCs) and pollutants. Their approach involves using metal-organic frameworks (MOFs) with tailored pore sizes and functionalities to selectively adsorb target VOCs while resisting poisoning[1]. They have also implemented in-situ regeneration methods using thermal swing adsorption and pressure swing adsorption to extend sorbent lifetime and maintain performance[3]. Additionally, Battelle has explored the use of composite materials combining activated carbon with catalytic nanoparticles to simultaneously adsorb and degrade VOCs, reducing the impact of poisoning[5].

Strengths: Highly selective adsorption, extended sorbent lifetime, and potential for simultaneous adsorption and degradation. Weaknesses: Potentially higher cost of advanced materials and complexity of regeneration systems.

Albemarle Corp.

Technical Solution: Albemarle Corporation has developed a range of specialized sorbents and catalysts to address VOC and pollutant poisoning issues. Their approach focuses on creating highly stable zeolite-based materials with modified surface properties to enhance resistance to poisoning[2]. They have also introduced novel metal-impregnated activated carbon products that combine high adsorption capacity with catalytic activity to break down adsorbed pollutants[4]. Albemarle's research has led to the development of regenerable sorbents using steam treatment and chemical washing techniques to restore performance after exposure to poisoning agents[6]. Furthermore, they have explored the use of guard beds and pre-treatment systems to remove potential poisoning compounds before they reach the main sorbent bed, extending overall system lifetime[8].

Strengths: High stability materials, combined adsorption and catalytic capabilities, effective regeneration methods. Weaknesses: Potential for increased system complexity and higher initial costs.

Innovative Approaches to Sorbent Protection

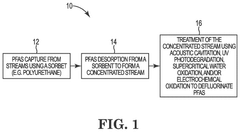

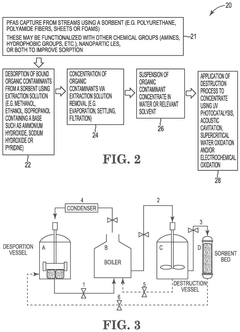

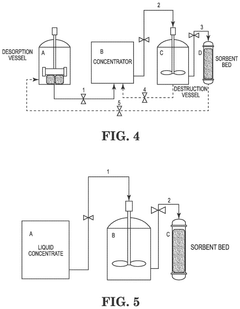

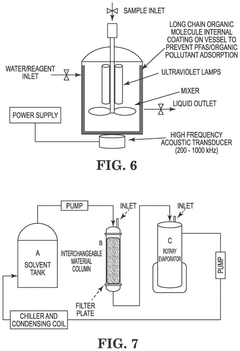

Sorbents and methods for the capture and defluorination of per and poly fluoroalkyl substances (PFAS)

PatentPendingUS20240336496A1

Innovation

- A sorbent system utilizing porous polymer materials with bound active chemical groups and nanoparticles, combined with desorption and destruction methods involving solvents and energy applications like acoustic cavitation, to capture and defluorinate PFAS effectively.

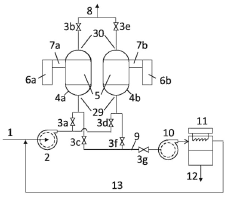

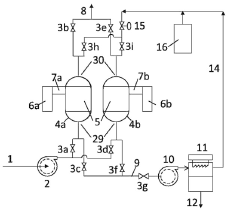

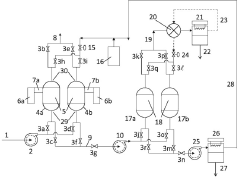

Method and apparatus for concentrating and recovering volatile organic compound

PatentInactiveJP2014014760A

Innovation

- The method employs adsorbents with adjusted silanol group densities to selectively absorb and desorb VOCs using microwaves, minimizing energy consumption and equipment size by controlling microwave output and temperature rise, and using vacuum or purge gases to enhance desorption efficiency.

Environmental Regulations Impact on Sorbent Technology

Environmental regulations have significantly shaped the development and implementation of sorbent technology in recent years. As governments worldwide intensify their efforts to combat air and water pollution, the demand for more efficient and environmentally friendly sorbent materials has increased dramatically. These regulations have spurred innovation in the field, driving researchers and manufacturers to develop sorbents that not only effectively capture volatile organic compounds (VOCs) and other pollutants but also comply with stringent environmental standards.

One of the primary impacts of environmental regulations on sorbent technology has been the push for more sustainable and less toxic materials. Traditional sorbents, such as activated carbon, while effective, often pose disposal challenges due to their potential to release captured pollutants back into the environment. As a result, there has been a shift towards developing bio-based sorbents and regenerable materials that can be safely disposed of or reused multiple times, reducing the overall environmental footprint of pollution control processes.

The implementation of stricter emission limits for industrial processes has also driven advancements in sorbent technology. Manufacturers are now required to achieve higher removal efficiencies for a broader range of pollutants, including those previously considered trace contaminants. This has led to the development of more specialized sorbents tailored to specific pollutants and industrial applications, as well as improved sorbent formulations that can simultaneously capture multiple types of contaminants.

Furthermore, environmental regulations have influenced the design of sorbent-based pollution control systems. There is an increasing emphasis on integrated approaches that combine sorbent technology with other treatment methods to achieve comprehensive pollutant removal. This has resulted in the development of multi-stage treatment systems that incorporate sorbents as a key component, often in conjunction with catalytic oxidation or membrane filtration technologies.

The regulatory focus on monitoring and reporting emissions has also impacted sorbent technology. There is a growing need for real-time monitoring of sorbent performance and breakthrough, leading to the integration of advanced sensors and control systems in sorbent-based pollution control equipment. This trend has facilitated more efficient sorbent utilization and timely replacement, ensuring consistent compliance with emission standards.

In conclusion, environmental regulations have been a significant driving force in the evolution of sorbent technology. They have not only spurred innovation in material science and engineering but also reshaped the approach to pollution control across various industries. As regulations continue to evolve, sorbent technology is expected to play an increasingly crucial role in meeting the global challenge of environmental protection.

One of the primary impacts of environmental regulations on sorbent technology has been the push for more sustainable and less toxic materials. Traditional sorbents, such as activated carbon, while effective, often pose disposal challenges due to their potential to release captured pollutants back into the environment. As a result, there has been a shift towards developing bio-based sorbents and regenerable materials that can be safely disposed of or reused multiple times, reducing the overall environmental footprint of pollution control processes.

The implementation of stricter emission limits for industrial processes has also driven advancements in sorbent technology. Manufacturers are now required to achieve higher removal efficiencies for a broader range of pollutants, including those previously considered trace contaminants. This has led to the development of more specialized sorbents tailored to specific pollutants and industrial applications, as well as improved sorbent formulations that can simultaneously capture multiple types of contaminants.

Furthermore, environmental regulations have influenced the design of sorbent-based pollution control systems. There is an increasing emphasis on integrated approaches that combine sorbent technology with other treatment methods to achieve comprehensive pollutant removal. This has resulted in the development of multi-stage treatment systems that incorporate sorbents as a key component, often in conjunction with catalytic oxidation or membrane filtration technologies.

The regulatory focus on monitoring and reporting emissions has also impacted sorbent technology. There is a growing need for real-time monitoring of sorbent performance and breakthrough, leading to the integration of advanced sensors and control systems in sorbent-based pollution control equipment. This trend has facilitated more efficient sorbent utilization and timely replacement, ensuring consistent compliance with emission standards.

In conclusion, environmental regulations have been a significant driving force in the evolution of sorbent technology. They have not only spurred innovation in material science and engineering but also reshaped the approach to pollution control across various industries. As regulations continue to evolve, sorbent technology is expected to play an increasingly crucial role in meeting the global challenge of environmental protection.

Economic Feasibility of Advanced Sorbent Solutions

The economic feasibility of advanced sorbent solutions for mitigating poisoning by volatile organic compounds (VOCs) and pollutants is a critical consideration for industries seeking to improve their environmental performance and operational efficiency. These solutions offer promising potential for reducing harmful emissions and extending the lifespan of sorbent materials, but their implementation must be carefully evaluated from a cost-benefit perspective.

Advanced sorbent technologies, such as engineered nanomaterials and functionalized adsorbents, have demonstrated superior performance in laboratory settings. However, scaling these solutions for industrial applications presents significant economic challenges. The production costs of these advanced materials are often substantially higher than traditional sorbents, which can impact the overall feasibility of their adoption.

One key factor in assessing economic viability is the potential for increased sorbent longevity. By effectively mitigating poisoning, advanced solutions can extend the operational life of sorbent materials, reducing replacement frequency and associated downtime costs. This extended lifespan must be weighed against the higher initial investment required for these sophisticated materials.

Energy consumption is another crucial aspect of economic feasibility. Some advanced sorbent solutions may require additional energy inputs for regeneration or activation processes. While these energy costs can be significant, they must be balanced against potential energy savings from improved efficiency and reduced waste treatment requirements.

The regulatory landscape plays a vital role in determining the economic attractiveness of advanced sorbent solutions. As environmental regulations become more stringent, the cost of non-compliance increases, making investments in superior pollution control technologies more justifiable. Companies may find that the long-term benefits of adopting these solutions outweigh the initial capital expenditure.

Market dynamics also influence the economic feasibility of advanced sorbents. As demand for these materials grows, economies of scale may lead to reduced production costs, making them more competitive with traditional options. Additionally, the potential for developing intellectual property and gaining a competitive edge in the market can provide significant economic incentives for early adopters of these technologies.

The integration of advanced sorbent solutions into existing industrial processes is a critical consideration. Retrofitting existing systems or designing new processes to accommodate these materials can incur substantial costs. However, the potential for improved process efficiency and reduced environmental liabilities may justify these expenses over the long term.

In conclusion, while advanced sorbent solutions show promise for mitigating VOC and pollutant poisoning, their economic feasibility depends on a complex interplay of factors. Industries must carefully evaluate the balance between higher initial costs and long-term operational benefits, considering regulatory pressures, market opportunities, and potential technological advancements that may further improve the cost-effectiveness of these solutions.

Advanced sorbent technologies, such as engineered nanomaterials and functionalized adsorbents, have demonstrated superior performance in laboratory settings. However, scaling these solutions for industrial applications presents significant economic challenges. The production costs of these advanced materials are often substantially higher than traditional sorbents, which can impact the overall feasibility of their adoption.

One key factor in assessing economic viability is the potential for increased sorbent longevity. By effectively mitigating poisoning, advanced solutions can extend the operational life of sorbent materials, reducing replacement frequency and associated downtime costs. This extended lifespan must be weighed against the higher initial investment required for these sophisticated materials.

Energy consumption is another crucial aspect of economic feasibility. Some advanced sorbent solutions may require additional energy inputs for regeneration or activation processes. While these energy costs can be significant, they must be balanced against potential energy savings from improved efficiency and reduced waste treatment requirements.

The regulatory landscape plays a vital role in determining the economic attractiveness of advanced sorbent solutions. As environmental regulations become more stringent, the cost of non-compliance increases, making investments in superior pollution control technologies more justifiable. Companies may find that the long-term benefits of adopting these solutions outweigh the initial capital expenditure.

Market dynamics also influence the economic feasibility of advanced sorbents. As demand for these materials grows, economies of scale may lead to reduced production costs, making them more competitive with traditional options. Additionally, the potential for developing intellectual property and gaining a competitive edge in the market can provide significant economic incentives for early adopters of these technologies.

The integration of advanced sorbent solutions into existing industrial processes is a critical consideration. Retrofitting existing systems or designing new processes to accommodate these materials can incur substantial costs. However, the potential for improved process efficiency and reduced environmental liabilities may justify these expenses over the long term.

In conclusion, while advanced sorbent solutions show promise for mitigating VOC and pollutant poisoning, their economic feasibility depends on a complex interplay of factors. Industries must carefully evaluate the balance between higher initial costs and long-term operational benefits, considering regulatory pressures, market opportunities, and potential technological advancements that may further improve the cost-effectiveness of these solutions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!