Solid Amine Sorbent vs Liquid Amine Capture: Energy, Kinetics and Scale-Up Comparison

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

CO2 Capture Evolution

Carbon dioxide capture technology has undergone significant evolution since its inception in the 1930s. Initially developed for natural gas processing, CO2 capture has expanded its application to address global climate change concerns. The technology's progression can be traced through several key phases, each marked by advancements in efficiency, cost-effectiveness, and environmental impact.

In the early stages, absorption using aqueous amine solutions, particularly monoethanolamine (MEA), dominated the field. This liquid-based capture method proved effective but energy-intensive, prompting research into alternative sorbents and processes. The 1990s saw increased interest in CO2 capture for emissions reduction, leading to significant improvements in liquid amine technologies and the exploration of solid sorbents.

The turn of the millennium brought a shift towards more sustainable and efficient capture methods. Researchers began investigating advanced liquid amines with lower regeneration energy requirements and higher CO2 loading capacities. Concurrently, solid amine sorbents emerged as a promising alternative, offering potential advantages in energy efficiency and operational flexibility.

Recent years have witnessed a convergence of efforts to compare and optimize both liquid and solid amine-based capture systems. The focus has been on enhancing energy efficiency, improving kinetics, and addressing scale-up challenges. Liquid amine systems have seen advancements in solvent formulations and process configurations, while solid amine sorbents have progressed in material design and contactor technology.

The comparison between solid amine sorbents and liquid amine capture has become a central theme in current research. Energy consumption, a critical factor in CO2 capture economics, has been scrutinized for both technologies. Kinetics studies have aimed to understand and improve the rate of CO2 absorption and desorption, crucial for practical implementation. Scale-up considerations have gained prominence as researchers and industry stakeholders seek to bridge the gap between laboratory success and commercial viability.

As the field progresses, hybrid systems combining elements of both solid and liquid technologies are emerging, promising to leverage the strengths of each approach. The evolution of CO2 capture technology continues to be driven by the urgent need for cost-effective, energy-efficient solutions to mitigate greenhouse gas emissions and combat climate change.

In the early stages, absorption using aqueous amine solutions, particularly monoethanolamine (MEA), dominated the field. This liquid-based capture method proved effective but energy-intensive, prompting research into alternative sorbents and processes. The 1990s saw increased interest in CO2 capture for emissions reduction, leading to significant improvements in liquid amine technologies and the exploration of solid sorbents.

The turn of the millennium brought a shift towards more sustainable and efficient capture methods. Researchers began investigating advanced liquid amines with lower regeneration energy requirements and higher CO2 loading capacities. Concurrently, solid amine sorbents emerged as a promising alternative, offering potential advantages in energy efficiency and operational flexibility.

Recent years have witnessed a convergence of efforts to compare and optimize both liquid and solid amine-based capture systems. The focus has been on enhancing energy efficiency, improving kinetics, and addressing scale-up challenges. Liquid amine systems have seen advancements in solvent formulations and process configurations, while solid amine sorbents have progressed in material design and contactor technology.

The comparison between solid amine sorbents and liquid amine capture has become a central theme in current research. Energy consumption, a critical factor in CO2 capture economics, has been scrutinized for both technologies. Kinetics studies have aimed to understand and improve the rate of CO2 absorption and desorption, crucial for practical implementation. Scale-up considerations have gained prominence as researchers and industry stakeholders seek to bridge the gap between laboratory success and commercial viability.

As the field progresses, hybrid systems combining elements of both solid and liquid technologies are emerging, promising to leverage the strengths of each approach. The evolution of CO2 capture technology continues to be driven by the urgent need for cost-effective, energy-efficient solutions to mitigate greenhouse gas emissions and combat climate change.

Market for CO2 Capture

The market for CO2 capture technologies has been experiencing significant growth in recent years, driven by increasing global concerns over climate change and the urgent need to reduce greenhouse gas emissions. This market encompasses various industries, including power generation, oil and gas, chemical manufacturing, and cement production, all of which are major contributors to CO2 emissions.

The global CO2 capture market is projected to expand rapidly in the coming years, with estimates suggesting a compound annual growth rate (CAGR) of over 20% between 2021 and 2026. This growth is primarily fueled by stringent environmental regulations, government initiatives to promote clean energy, and corporate commitments to achieve net-zero emissions targets.

In terms of regional distribution, North America and Europe currently dominate the CO2 capture market, owing to their advanced technological infrastructure and supportive regulatory frameworks. However, the Asia-Pacific region is expected to witness the fastest growth, driven by rapid industrialization and increasing environmental awareness in countries like China and India.

The market for CO2 capture technologies can be segmented based on technology type, with post-combustion capture, pre-combustion capture, and oxy-fuel combustion being the primary categories. Among these, post-combustion capture technologies, including both liquid and solid amine-based systems, hold the largest market share due to their compatibility with existing infrastructure and relative ease of implementation.

Liquid amine-based capture systems have traditionally dominated the market, particularly in large-scale applications. However, solid amine sorbents are gaining traction due to their potential advantages in energy efficiency and operational flexibility. The comparison between solid amine sorbents and liquid amine capture systems in terms of energy requirements, kinetics, and scale-up potential is becoming increasingly relevant as the market evolves.

Key market players in the CO2 capture industry include multinational corporations such as Mitsubishi Heavy Industries, Fluor Corporation, and Aker Solutions, as well as specialized technology providers like Carbon Engineering and Climeworks. These companies are actively investing in research and development to improve the efficiency and cost-effectiveness of their capture technologies.

The market demand for CO2 capture solutions is further bolstered by the growing interest in carbon utilization and storage (CCUS) projects. These initiatives aim to not only capture CO2 but also repurpose it for various industrial applications or safely store it underground, creating additional value streams and environmental benefits.

The global CO2 capture market is projected to expand rapidly in the coming years, with estimates suggesting a compound annual growth rate (CAGR) of over 20% between 2021 and 2026. This growth is primarily fueled by stringent environmental regulations, government initiatives to promote clean energy, and corporate commitments to achieve net-zero emissions targets.

In terms of regional distribution, North America and Europe currently dominate the CO2 capture market, owing to their advanced technological infrastructure and supportive regulatory frameworks. However, the Asia-Pacific region is expected to witness the fastest growth, driven by rapid industrialization and increasing environmental awareness in countries like China and India.

The market for CO2 capture technologies can be segmented based on technology type, with post-combustion capture, pre-combustion capture, and oxy-fuel combustion being the primary categories. Among these, post-combustion capture technologies, including both liquid and solid amine-based systems, hold the largest market share due to their compatibility with existing infrastructure and relative ease of implementation.

Liquid amine-based capture systems have traditionally dominated the market, particularly in large-scale applications. However, solid amine sorbents are gaining traction due to their potential advantages in energy efficiency and operational flexibility. The comparison between solid amine sorbents and liquid amine capture systems in terms of energy requirements, kinetics, and scale-up potential is becoming increasingly relevant as the market evolves.

Key market players in the CO2 capture industry include multinational corporations such as Mitsubishi Heavy Industries, Fluor Corporation, and Aker Solutions, as well as specialized technology providers like Carbon Engineering and Climeworks. These companies are actively investing in research and development to improve the efficiency and cost-effectiveness of their capture technologies.

The market demand for CO2 capture solutions is further bolstered by the growing interest in carbon utilization and storage (CCUS) projects. These initiatives aim to not only capture CO2 but also repurpose it for various industrial applications or safely store it underground, creating additional value streams and environmental benefits.

Amine Sorbent Challenges

The development of amine sorbents for carbon capture faces several significant challenges that hinder their widespread adoption and efficiency. One of the primary issues is the energy intensity of the regeneration process. Both solid and liquid amine sorbents require substantial energy input to release the captured CO2, which can significantly reduce the overall efficiency of the carbon capture system. This high energy demand not only increases operational costs but also potentially offsets some of the environmental benefits of carbon capture.

Another critical challenge is the degradation of amine sorbents over time. Exposure to flue gas contaminants, thermal stress during regeneration cycles, and oxidative degradation can lead to a decrease in CO2 absorption capacity and selectivity. This degradation necessitates frequent replacement or regeneration of the sorbent material, adding to the operational complexity and cost of carbon capture systems.

Scale-up issues present a formidable obstacle in the transition from laboratory-scale experiments to industrial-scale applications. The behavior of amine sorbents can differ significantly when scaled up, particularly in terms of mass transfer limitations, heat management, and pressure drop across large absorption columns. These factors can lead to reduced efficiency and increased operational challenges in large-scale carbon capture plants.

Kinetics of CO2 absorption and desorption also pose challenges, especially for solid amine sorbents. While liquid amines generally offer faster absorption rates due to their homogeneous nature, solid sorbents often struggle with slower kinetics, which can limit their effectiveness in rapid cycling systems. Improving the kinetics without compromising other performance aspects remains a key area of research.

The environmental impact of amine sorbents is another concern. Potential emissions of amine degradation products, such as nitrosamines and nitramines, raise health and environmental safety issues. Addressing these concerns requires the development of more stable sorbents and improved emission control strategies.

Lastly, the cost-effectiveness of amine sorbent systems compared to other carbon capture technologies remains a significant challenge. The high capital costs associated with implementing amine-based capture systems, coupled with ongoing operational expenses, make it difficult to achieve economic viability without substantial policy support or technological breakthroughs. Balancing performance improvements with cost reductions is crucial for the widespread adoption of amine sorbent technologies in carbon capture applications.

Another critical challenge is the degradation of amine sorbents over time. Exposure to flue gas contaminants, thermal stress during regeneration cycles, and oxidative degradation can lead to a decrease in CO2 absorption capacity and selectivity. This degradation necessitates frequent replacement or regeneration of the sorbent material, adding to the operational complexity and cost of carbon capture systems.

Scale-up issues present a formidable obstacle in the transition from laboratory-scale experiments to industrial-scale applications. The behavior of amine sorbents can differ significantly when scaled up, particularly in terms of mass transfer limitations, heat management, and pressure drop across large absorption columns. These factors can lead to reduced efficiency and increased operational challenges in large-scale carbon capture plants.

Kinetics of CO2 absorption and desorption also pose challenges, especially for solid amine sorbents. While liquid amines generally offer faster absorption rates due to their homogeneous nature, solid sorbents often struggle with slower kinetics, which can limit their effectiveness in rapid cycling systems. Improving the kinetics without compromising other performance aspects remains a key area of research.

The environmental impact of amine sorbents is another concern. Potential emissions of amine degradation products, such as nitrosamines and nitramines, raise health and environmental safety issues. Addressing these concerns requires the development of more stable sorbents and improved emission control strategies.

Lastly, the cost-effectiveness of amine sorbent systems compared to other carbon capture technologies remains a significant challenge. The high capital costs associated with implementing amine-based capture systems, coupled with ongoing operational expenses, make it difficult to achieve economic viability without substantial policy support or technological breakthroughs. Balancing performance improvements with cost reductions is crucial for the widespread adoption of amine sorbent technologies in carbon capture applications.

Solid vs Liquid Amines

01 Energy-efficient amine-based carbon capture systems

Advanced amine-based carbon capture technologies focus on improving energy efficiency through optimized process designs, heat integration, and novel solvents. These systems aim to reduce the energy penalty associated with carbon capture, making the process more economically viable for large-scale applications.- Energy-efficient amine-based carbon capture systems: Advanced amine-based carbon capture technologies focus on improving energy efficiency through optimized process designs, heat integration, and novel solvents. These systems aim to reduce the energy penalty associated with carbon capture, making the process more economically viable for large-scale implementation.

- Enhanced capture kinetics in amine-based systems: Research efforts are directed towards improving the capture kinetics of amine-based carbon capture technologies. This includes developing new amine formulations, exploring additives to enhance reaction rates, and optimizing process conditions to achieve faster CO2 absorption and desorption cycles.

- Scale-up potential and industrial implementation: Amine-based carbon capture technologies are being adapted for large-scale industrial applications. This involves addressing challenges related to equipment sizing, process integration, and operational stability to ensure successful deployment in power plants and other CO2-intensive industries.

- Novel amine solvents and blends for improved performance: Researchers are developing new amine solvents and blends to enhance the overall performance of carbon capture systems. These novel formulations aim to increase CO2 absorption capacity, reduce degradation, and minimize corrosion issues, leading to more efficient and cost-effective capture processes.

- Process intensification and hybrid systems: Innovative approaches to amine-based carbon capture involve process intensification techniques and the development of hybrid systems. These advancements combine amine absorption with other technologies such as membranes or cryogenic separation, aiming to achieve higher capture efficiencies and reduced energy consumption.

02 Enhanced capture kinetics in amine-based systems

Research on improving capture kinetics in amine-based carbon capture technologies involves developing new amine formulations, utilizing additives, and optimizing reactor designs. These advancements aim to increase CO2 absorption rates and overall system efficiency, enabling faster and more effective carbon capture processes.Expand Specific Solutions03 Scale-up potential and industrial implementation

Efforts to enhance the scale-up potential of amine-based carbon capture technologies focus on addressing challenges related to equipment sizing, process integration, and operational stability. Innovations in this area aim to facilitate the transition from pilot-scale to full-scale industrial implementation, ensuring reliable and cost-effective carbon capture solutions.Expand Specific Solutions04 Novel amine solvents and blends for improved performance

Development of new amine solvents and blends aims to enhance carbon capture performance by improving CO2 absorption capacity, reducing regeneration energy, and minimizing solvent degradation. These novel formulations contribute to increased energy efficiency and improved overall system performance in amine-based carbon capture technologies.Expand Specific Solutions05 Process intensification and hybrid systems

Innovative approaches to process intensification and hybrid systems in amine-based carbon capture technologies aim to combine multiple unit operations, integrate alternative capture methods, or incorporate advanced materials. These developments seek to enhance energy efficiency, improve capture kinetics, and increase the overall effectiveness of carbon capture processes.Expand Specific Solutions

Key CO2 Capture Players

The competition in solid amine sorbent vs liquid amine capture technology is in a growth phase, with increasing market size driven by global carbon reduction initiatives. The market is characterized by a mix of established energy companies and innovative startups, indicating moderate technological maturity. Key players like ExxonMobil, Saudi Aramco, and Climeworks are investing heavily in research and development, while universities such as Tsinghua and Wyoming are contributing to technological advancements. The involvement of diverse entities, from oil majors to specialized carbon capture firms, suggests a competitive landscape with potential for significant breakthroughs in energy efficiency and scalability of carbon capture solutions.

ExxonMobil Technology & Engineering Co.

Technical Solution: ExxonMobil has developed a proprietary Controlled Freeze Zone (CFZ) technology for carbon capture. This process involves cooling the flue gas to temperatures below -100°F, causing CO2 to freeze and separate from other gases. The frozen CO2 is then melted and pressurized for storage or utilization. The CFZ technology can achieve up to 90% CO2 capture efficiency[1]. In addition to CFZ, ExxonMobil is also researching advanced amine-based solvents that can potentially reduce the energy requirements for CO2 capture by up to 30% compared to conventional amine processes[2].

Strengths: High capture efficiency, potential for significant energy savings. Weaknesses: High capital costs for cryogenic equipment, energy-intensive freezing process.

Climeworks AG

Technical Solution: Climeworks has developed a Direct Air Capture (DAC) technology using solid amine sorbents. Their modular CO2 collectors use a cyclic adsorption-desorption process. During adsorption, air is drawn into the collector with a fan, and CO2 is captured on the surface of the amine-functionalized filter material. For regeneration, the collector is heated to 80-100°C, releasing high-purity CO2[3]. Climeworks' latest DAC plant, Orca in Iceland, has a capture capacity of 4,000 tons of CO2 per year[4]. The company is continuously improving its technology, aiming to reduce energy consumption and costs.

Strengths: Modular and scalable design, can capture CO2 directly from ambient air. Weaknesses: Currently high costs, energy-intensive regeneration process.

Amine Sorbent Innovations

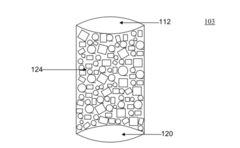

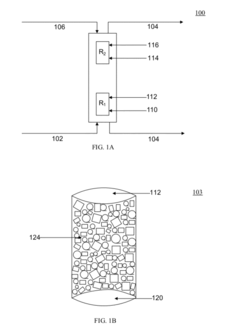

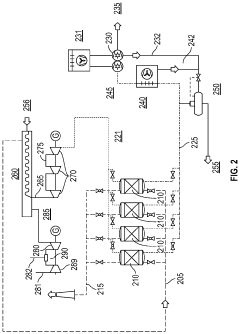

Bi-Directional Reactor and Supported Monoethenalamine for CO2 Separation

PatentActiveUS20120288429A1

Innovation

- A bi-directional reactor system utilizing a supported monoethanolamine (MEA) sorbent with a macroporous substrate, allowing for the recycling of the sorbent material and minimizing energy requirements by eliminating the need for water evaporation during regeneration, and using a non-aqueous sorbent that is less corrosive and easier to handle.

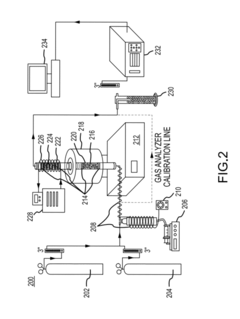

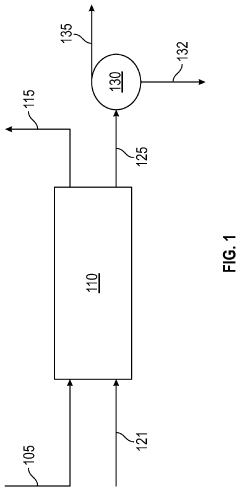

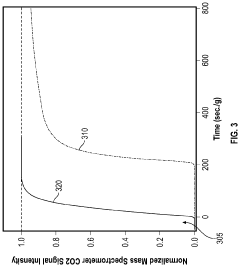

Bed regeneration using low value steam

PatentPendingUS20220233996A1

Innovation

- A method using low-temperature steam at pressures below 50 kPa to desorb CO2 from a sorbent bed, combined with a liquid ring pump to produce a high-purity CO2 stream, reducing energy consumption and waste heat generation.

Techno-economic Analysis

The techno-economic analysis of solid amine sorbents versus liquid amine capture for CO2 removal is crucial for determining the most cost-effective and efficient solution for carbon capture and storage (CCS) applications. This analysis encompasses various factors, including capital expenditure (CAPEX), operational expenditure (OPEX), energy requirements, and overall process efficiency.

Solid amine sorbents have shown promising results in terms of energy efficiency and operational costs. The regeneration energy for solid sorbents is typically lower than that of liquid amine systems, potentially reducing the overall energy penalty of the capture process. Additionally, solid sorbents often exhibit faster kinetics, allowing for quicker CO2 absorption and desorption cycles. This can lead to smaller equipment sizes and lower capital costs.

However, the scale-up of solid sorbent systems presents unique challenges. The handling and transport of solid materials in large-scale operations can be more complex and costly compared to liquid systems. Factors such as attrition, agglomeration, and pressure drop across packed beds must be carefully considered in the design and operation of solid sorbent systems.

Liquid amine capture, on the other hand, benefits from decades of industrial experience and established large-scale operations. The technology is well-understood, and there are numerous commercial installations worldwide. This maturity translates to lower technological risks and potentially more predictable costs. However, liquid amine systems typically have higher regeneration energy requirements, which can significantly impact operational costs, especially in regions with high energy prices.

When comparing the two technologies, it is essential to consider the specific application and scale of the CCS project. For smaller-scale applications or those with stringent space constraints, solid sorbents may offer advantages due to their potentially smaller footprint and lower energy requirements. In contrast, liquid amine systems may be more suitable for very large-scale operations where the handling of solid materials could become prohibitively complex.

The economic analysis must also account for the lifespan and degradation rates of the sorbents or solvents. Solid sorbents may have longer lifespans and lower degradation rates compared to liquid amines, potentially reducing replacement costs over time. However, the production costs of advanced solid sorbents could be higher than those of conventional liquid amines, impacting the initial investment.

Ultimately, the techno-economic comparison between solid amine sorbents and liquid amine capture systems must be conducted on a case-by-case basis, considering factors such as plant size, location, energy costs, and environmental regulations. As research in solid sorbents continues to advance, their economic competitiveness is likely to improve, potentially shifting the balance in their favor for a wider range of applications in the future.

Solid amine sorbents have shown promising results in terms of energy efficiency and operational costs. The regeneration energy for solid sorbents is typically lower than that of liquid amine systems, potentially reducing the overall energy penalty of the capture process. Additionally, solid sorbents often exhibit faster kinetics, allowing for quicker CO2 absorption and desorption cycles. This can lead to smaller equipment sizes and lower capital costs.

However, the scale-up of solid sorbent systems presents unique challenges. The handling and transport of solid materials in large-scale operations can be more complex and costly compared to liquid systems. Factors such as attrition, agglomeration, and pressure drop across packed beds must be carefully considered in the design and operation of solid sorbent systems.

Liquid amine capture, on the other hand, benefits from decades of industrial experience and established large-scale operations. The technology is well-understood, and there are numerous commercial installations worldwide. This maturity translates to lower technological risks and potentially more predictable costs. However, liquid amine systems typically have higher regeneration energy requirements, which can significantly impact operational costs, especially in regions with high energy prices.

When comparing the two technologies, it is essential to consider the specific application and scale of the CCS project. For smaller-scale applications or those with stringent space constraints, solid sorbents may offer advantages due to their potentially smaller footprint and lower energy requirements. In contrast, liquid amine systems may be more suitable for very large-scale operations where the handling of solid materials could become prohibitively complex.

The economic analysis must also account for the lifespan and degradation rates of the sorbents or solvents. Solid sorbents may have longer lifespans and lower degradation rates compared to liquid amines, potentially reducing replacement costs over time. However, the production costs of advanced solid sorbents could be higher than those of conventional liquid amines, impacting the initial investment.

Ultimately, the techno-economic comparison between solid amine sorbents and liquid amine capture systems must be conducted on a case-by-case basis, considering factors such as plant size, location, energy costs, and environmental regulations. As research in solid sorbents continues to advance, their economic competitiveness is likely to improve, potentially shifting the balance in their favor for a wider range of applications in the future.

Environmental Impact

The environmental impact of carbon capture technologies, particularly in the comparison between solid amine sorbents and liquid amine capture systems, is a critical consideration in their development and implementation. Both methods aim to reduce greenhouse gas emissions, but their environmental footprints differ significantly.

Liquid amine capture systems, while effective, often raise concerns due to their potential for amine emissions. These emissions can lead to the formation of nitrosamines and nitramines in the atmosphere, which are known carcinogens. Additionally, the degradation of liquid amines can produce harmful byproducts that may contaminate water sources if not properly managed. The energy-intensive regeneration process of liquid amine systems also contributes to their overall environmental impact.

In contrast, solid amine sorbents generally exhibit a more favorable environmental profile. They typically have lower volatility, reducing the risk of amine emissions. The solid nature of these sorbents also minimizes the potential for spills and leaks, which can be a significant environmental hazard with liquid systems. Furthermore, solid amine sorbents often require less energy for regeneration, potentially reducing the overall carbon footprint of the capture process.

However, the production and disposal of solid amine sorbents present their own environmental challenges. The manufacturing process may involve energy-intensive steps and the use of potentially harmful chemicals. At the end of their lifecycle, these sorbents must be disposed of or recycled properly to prevent environmental contamination.

Scale-up considerations also play a role in the environmental impact assessment. Liquid amine systems have been implemented at large scales, allowing for optimized processes and established waste management protocols. Solid amine sorbents, being a relatively newer technology, may face unforeseen environmental challenges as they are scaled up to industrial levels.

Water consumption is another crucial factor. Liquid amine systems typically require significant amounts of water for cooling and process operations, potentially straining local water resources. Solid amine sorbents generally have lower water requirements, which can be particularly advantageous in water-scarce regions.

Land use and biodiversity impacts should also be considered. The infrastructure required for both technologies can lead to habitat disruption, but the extent may vary depending on the specific implementation and location. Solid amine systems might offer more flexibility in terms of plant design and footprint, potentially reducing land use impacts.

In conclusion, while both solid amine sorbents and liquid amine capture systems aim to mitigate climate change, their environmental impacts differ across various dimensions. A comprehensive life cycle assessment is essential to fully understand and compare the environmental implications of these technologies as they evolve and are implemented at larger scales.

Liquid amine capture systems, while effective, often raise concerns due to their potential for amine emissions. These emissions can lead to the formation of nitrosamines and nitramines in the atmosphere, which are known carcinogens. Additionally, the degradation of liquid amines can produce harmful byproducts that may contaminate water sources if not properly managed. The energy-intensive regeneration process of liquid amine systems also contributes to their overall environmental impact.

In contrast, solid amine sorbents generally exhibit a more favorable environmental profile. They typically have lower volatility, reducing the risk of amine emissions. The solid nature of these sorbents also minimizes the potential for spills and leaks, which can be a significant environmental hazard with liquid systems. Furthermore, solid amine sorbents often require less energy for regeneration, potentially reducing the overall carbon footprint of the capture process.

However, the production and disposal of solid amine sorbents present their own environmental challenges. The manufacturing process may involve energy-intensive steps and the use of potentially harmful chemicals. At the end of their lifecycle, these sorbents must be disposed of or recycled properly to prevent environmental contamination.

Scale-up considerations also play a role in the environmental impact assessment. Liquid amine systems have been implemented at large scales, allowing for optimized processes and established waste management protocols. Solid amine sorbents, being a relatively newer technology, may face unforeseen environmental challenges as they are scaled up to industrial levels.

Water consumption is another crucial factor. Liquid amine systems typically require significant amounts of water for cooling and process operations, potentially straining local water resources. Solid amine sorbents generally have lower water requirements, which can be particularly advantageous in water-scarce regions.

Land use and biodiversity impacts should also be considered. The infrastructure required for both technologies can lead to habitat disruption, but the extent may vary depending on the specific implementation and location. Solid amine systems might offer more flexibility in terms of plant design and footprint, potentially reducing land use impacts.

In conclusion, while both solid amine sorbents and liquid amine capture systems aim to mitigate climate change, their environmental impacts differ across various dimensions. A comprehensive life cycle assessment is essential to fully understand and compare the environmental implications of these technologies as they evolve and are implemented at larger scales.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!