Advanced Gas Separation Using Mixed-Metal MOFs: A Comparative Study

AUG 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

MOF Gas Separation Background and Objectives

Metal-Organic Frameworks (MOFs) have emerged as a promising class of materials for gas separation applications, offering unprecedented levels of porosity and tunability. The field of MOF-based gas separation has evolved rapidly over the past two decades, driven by the urgent need for more efficient and sustainable separation processes in various industries, including natural gas purification, carbon capture, and hydrogen production.

The development of MOFs for gas separation began in the early 2000s, with initial studies focusing on single-metal MOFs. These early investigations demonstrated the potential of MOFs to achieve high selectivity and capacity for gas adsorption. However, researchers soon recognized the limitations of single-metal MOFs in terms of stability and performance under diverse operating conditions.

As the field progressed, attention shifted towards mixed-metal MOFs, which offer enhanced structural stability and the ability to fine-tune pore characteristics. This evolution in MOF design has opened up new possibilities for addressing complex gas separation challenges, particularly in scenarios involving multiple gas components or harsh environmental conditions.

The primary objective of advanced gas separation using mixed-metal MOFs is to develop highly efficient, selective, and stable materials that can outperform conventional separation technologies. Researchers aim to exploit the synergistic effects of different metal centers within a single MOF structure to enhance separation performance, improve material stability, and expand the range of applicable gas mixtures.

Key technical goals in this field include optimizing pore size distribution and chemical functionality to achieve precise molecular sieving, enhancing the stability of MOFs under industrial conditions, and developing scalable synthesis methods for large-scale production. Additionally, there is a growing focus on creating MOFs with dynamic properties that can adapt to changing gas compositions or external stimuli, further improving separation efficiency.

The evolution of mixed-metal MOFs for gas separation is closely tied to advancements in characterization techniques and computational modeling. These tools have become essential for understanding the complex interactions between gas molecules and MOF structures, guiding the rational design of next-generation materials.

Looking ahead, the field is moving towards the development of hierarchical and composite MOF materials that combine the advantages of different structural motifs. There is also increasing interest in integrating MOFs with other advanced materials, such as membranes and 3D-printed structures, to create hybrid separation systems with enhanced performance and versatility.

The development of MOFs for gas separation began in the early 2000s, with initial studies focusing on single-metal MOFs. These early investigations demonstrated the potential of MOFs to achieve high selectivity and capacity for gas adsorption. However, researchers soon recognized the limitations of single-metal MOFs in terms of stability and performance under diverse operating conditions.

As the field progressed, attention shifted towards mixed-metal MOFs, which offer enhanced structural stability and the ability to fine-tune pore characteristics. This evolution in MOF design has opened up new possibilities for addressing complex gas separation challenges, particularly in scenarios involving multiple gas components or harsh environmental conditions.

The primary objective of advanced gas separation using mixed-metal MOFs is to develop highly efficient, selective, and stable materials that can outperform conventional separation technologies. Researchers aim to exploit the synergistic effects of different metal centers within a single MOF structure to enhance separation performance, improve material stability, and expand the range of applicable gas mixtures.

Key technical goals in this field include optimizing pore size distribution and chemical functionality to achieve precise molecular sieving, enhancing the stability of MOFs under industrial conditions, and developing scalable synthesis methods for large-scale production. Additionally, there is a growing focus on creating MOFs with dynamic properties that can adapt to changing gas compositions or external stimuli, further improving separation efficiency.

The evolution of mixed-metal MOFs for gas separation is closely tied to advancements in characterization techniques and computational modeling. These tools have become essential for understanding the complex interactions between gas molecules and MOF structures, guiding the rational design of next-generation materials.

Looking ahead, the field is moving towards the development of hierarchical and composite MOF materials that combine the advantages of different structural motifs. There is also increasing interest in integrating MOFs with other advanced materials, such as membranes and 3D-printed structures, to create hybrid separation systems with enhanced performance and versatility.

Market Analysis for Advanced Gas Separation Technologies

The market for advanced gas separation technologies has been experiencing significant growth in recent years, driven by increasing demand for cleaner energy sources and stricter environmental regulations. The global gas separation membranes market, which includes technologies like Mixed-Metal MOFs (Metal-Organic Frameworks), is projected to reach substantial market value in the coming years. This growth is primarily attributed to the rising need for efficient and cost-effective gas separation processes across various industries.

In the energy sector, there is a growing emphasis on natural gas processing and carbon capture, which has created a strong demand for advanced gas separation technologies. The oil and gas industry, in particular, requires efficient methods to separate carbon dioxide from natural gas streams, making Mixed-Metal MOFs an attractive option due to their high selectivity and adsorption capacity.

The chemical and petrochemical industries also present significant market opportunities for advanced gas separation technologies. These sectors require precise gas separation for various processes, including the production of high-purity gases and the removal of impurities from industrial gas streams. Mixed-Metal MOFs offer potential advantages in these applications due to their tunable pore sizes and chemical functionalities.

Environmental concerns and regulatory pressures are driving the adoption of advanced gas separation technologies in multiple industries. Governments worldwide are implementing stricter emissions standards, particularly for greenhouse gases like carbon dioxide. This has led to increased interest in carbon capture and storage (CCS) technologies, where Mixed-Metal MOFs could play a crucial role in improving the efficiency and cost-effectiveness of CO2 separation from flue gases.

The healthcare and pharmaceutical industries represent another growing market for advanced gas separation technologies. These sectors require high-purity gases for various applications, including medical treatments and drug manufacturing processes. Mixed-Metal MOFs could potentially offer improved performance in gas purification compared to traditional methods, opening up new opportunities in these markets.

Geographically, North America and Europe are currently the leading markets for advanced gas separation technologies, due to their well-established industrial base and stringent environmental regulations. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, driven by rapid industrialization, increasing energy demand, and growing environmental awareness in countries like China and India.

Despite the promising market outlook, there are challenges that could impact the adoption of Mixed-Metal MOFs and other advanced gas separation technologies. These include high initial investment costs, technical complexities in scaling up production, and competition from established gas separation methods. Overcoming these barriers will be crucial for the widespread commercialization of Mixed-Metal MOFs in gas separation applications.

In the energy sector, there is a growing emphasis on natural gas processing and carbon capture, which has created a strong demand for advanced gas separation technologies. The oil and gas industry, in particular, requires efficient methods to separate carbon dioxide from natural gas streams, making Mixed-Metal MOFs an attractive option due to their high selectivity and adsorption capacity.

The chemical and petrochemical industries also present significant market opportunities for advanced gas separation technologies. These sectors require precise gas separation for various processes, including the production of high-purity gases and the removal of impurities from industrial gas streams. Mixed-Metal MOFs offer potential advantages in these applications due to their tunable pore sizes and chemical functionalities.

Environmental concerns and regulatory pressures are driving the adoption of advanced gas separation technologies in multiple industries. Governments worldwide are implementing stricter emissions standards, particularly for greenhouse gases like carbon dioxide. This has led to increased interest in carbon capture and storage (CCS) technologies, where Mixed-Metal MOFs could play a crucial role in improving the efficiency and cost-effectiveness of CO2 separation from flue gases.

The healthcare and pharmaceutical industries represent another growing market for advanced gas separation technologies. These sectors require high-purity gases for various applications, including medical treatments and drug manufacturing processes. Mixed-Metal MOFs could potentially offer improved performance in gas purification compared to traditional methods, opening up new opportunities in these markets.

Geographically, North America and Europe are currently the leading markets for advanced gas separation technologies, due to their well-established industrial base and stringent environmental regulations. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, driven by rapid industrialization, increasing energy demand, and growing environmental awareness in countries like China and India.

Despite the promising market outlook, there are challenges that could impact the adoption of Mixed-Metal MOFs and other advanced gas separation technologies. These include high initial investment costs, technical complexities in scaling up production, and competition from established gas separation methods. Overcoming these barriers will be crucial for the widespread commercialization of Mixed-Metal MOFs in gas separation applications.

Current Challenges in Mixed-Metal MOF Synthesis

The synthesis of mixed-metal Metal-Organic Frameworks (MOFs) presents several significant challenges that researchers and industry professionals are currently grappling with. One of the primary difficulties lies in achieving precise control over the incorporation and distribution of multiple metal species within the MOF structure. The heterogeneity of metal ions often leads to unpredictable crystallization processes, resulting in inconsistent pore sizes and irregular framework topologies.

Another major hurdle is maintaining the stability and structural integrity of mixed-metal MOFs. The introduction of different metal centers can create local distortions in the framework, potentially compromising the overall stability of the material. This is particularly problematic when targeting MOFs for gas separation applications, where structural robustness under various conditions is crucial.

The scalability of mixed-metal MOF synthesis also poses a significant challenge. While laboratory-scale production may yield promising results, translating these processes to industrial-scale manufacturing often encounters issues related to reproducibility, cost-effectiveness, and quality control. The complex interplay between multiple metal precursors during synthesis can lead to batch-to-batch variations, making it difficult to consistently produce MOFs with desired properties.

Furthermore, the characterization of mixed-metal MOFs presents its own set of challenges. Traditional analytical techniques may not always provide accurate information about the distribution and coordination environments of different metal species within the framework. This limitation hampers efforts to establish clear structure-property relationships, which are essential for rational design and optimization of mixed-metal MOFs for specific applications.

The selection of appropriate organic linkers that can effectively coordinate with multiple metal species while maintaining the desired framework topology is another critical challenge. The compatibility of different metal ions with various organic ligands can significantly impact the formation and properties of the resulting MOF, necessitating careful consideration and extensive experimentation.

Lastly, the development of sustainable and environmentally friendly synthesis methods for mixed-metal MOFs remains a pressing challenge. Many current synthesis protocols rely on harmful solvents or energy-intensive processes, which are not aligned with green chemistry principles. Finding alternative, more sustainable approaches without compromising the quality and performance of the mixed-metal MOFs is an ongoing area of research and development in the field.

Another major hurdle is maintaining the stability and structural integrity of mixed-metal MOFs. The introduction of different metal centers can create local distortions in the framework, potentially compromising the overall stability of the material. This is particularly problematic when targeting MOFs for gas separation applications, where structural robustness under various conditions is crucial.

The scalability of mixed-metal MOF synthesis also poses a significant challenge. While laboratory-scale production may yield promising results, translating these processes to industrial-scale manufacturing often encounters issues related to reproducibility, cost-effectiveness, and quality control. The complex interplay between multiple metal precursors during synthesis can lead to batch-to-batch variations, making it difficult to consistently produce MOFs with desired properties.

Furthermore, the characterization of mixed-metal MOFs presents its own set of challenges. Traditional analytical techniques may not always provide accurate information about the distribution and coordination environments of different metal species within the framework. This limitation hampers efforts to establish clear structure-property relationships, which are essential for rational design and optimization of mixed-metal MOFs for specific applications.

The selection of appropriate organic linkers that can effectively coordinate with multiple metal species while maintaining the desired framework topology is another critical challenge. The compatibility of different metal ions with various organic ligands can significantly impact the formation and properties of the resulting MOF, necessitating careful consideration and extensive experimentation.

Lastly, the development of sustainable and environmentally friendly synthesis methods for mixed-metal MOFs remains a pressing challenge. Many current synthesis protocols rely on harmful solvents or energy-intensive processes, which are not aligned with green chemistry principles. Finding alternative, more sustainable approaches without compromising the quality and performance of the mixed-metal MOFs is an ongoing area of research and development in the field.

State-of-the-Art Mixed-Metal MOF Synthesis Methods

01 Synthesis of mixed-metal MOFs for gas separation

Mixed-metal MOFs are synthesized by incorporating different metal ions into the framework structure. This approach enhances the gas separation performance by creating unique pore structures and binding sites. The combination of different metals can lead to improved selectivity and adsorption capacity for specific gases.- Synthesis of mixed-metal MOFs for gas separation: Mixed-metal MOFs are synthesized by incorporating multiple metal ions into the framework structure. This approach enhances the gas separation performance by creating unique pore structures and binding sites. The combination of different metal ions can lead to improved selectivity and adsorption capacity for specific gas molecules.

- Functionalization of mixed-metal MOFs: Mixed-metal MOFs can be functionalized with various organic ligands or post-synthetic modifications to enhance their gas separation properties. These modifications can introduce specific functional groups that interact selectively with target gas molecules, improving the overall separation efficiency.

- Hierarchical pore structure design: Developing mixed-metal MOFs with hierarchical pore structures can significantly improve gas separation performance. This approach combines micropores for molecular sieving with mesopores for enhanced mass transfer, resulting in more efficient gas separation processes.

- Composite materials with mixed-metal MOFs: Incorporating mixed-metal MOFs into composite materials, such as mixed-matrix membranes or adsorbent beds, can enhance gas separation performance. These composites combine the advantages of MOFs with other materials to create synergistic effects for improved selectivity and permeability.

- Process optimization for mixed-metal MOF-based gas separation: Optimizing process conditions, such as temperature, pressure, and gas flow rates, is crucial for maximizing the gas separation performance of mixed-metal MOFs. This includes developing novel regeneration methods and cyclic adsorption-desorption processes tailored to the specific properties of mixed-metal MOFs.

02 Tuning pore size and functionality in mixed-metal MOFs

The pore size and functionality of mixed-metal MOFs can be fine-tuned by carefully selecting the metal ions and organic linkers. This allows for the creation of tailored materials with specific gas separation properties. By adjusting the pore size and chemical environment, these MOFs can achieve high selectivity for target gases.Expand Specific Solutions03 Post-synthetic modification of mixed-metal MOFs

Post-synthetic modification techniques are employed to further enhance the gas separation properties of mixed-metal MOFs. These methods involve introducing additional functional groups or modifying existing ones after the initial synthesis. This approach allows for fine-tuning of the MOF's properties and can improve its selectivity and stability for specific gas separation applications.Expand Specific Solutions04 Membrane fabrication using mixed-metal MOFs

Mixed-metal MOFs are incorporated into membranes to create advanced gas separation systems. These membranes can be fabricated using various techniques, such as in-situ growth or mixed matrix membrane formation. The resulting membranes exhibit enhanced gas permeability and selectivity, making them suitable for industrial-scale gas separation processes.Expand Specific Solutions05 Optimization of mixed-metal MOFs for specific gas pairs

Mixed-metal MOFs are optimized for the separation of specific gas pairs, such as CO2/CH4, CO2/N2, or H2/CO2. This is achieved by carefully selecting metal combinations and organic linkers that provide the desired interaction with target gases. The optimized MOFs demonstrate improved separation performance and stability under various operating conditions.Expand Specific Solutions

Key Players in MOF Research and Development

The advanced gas separation using mixed-metal MOFs is in an emerging stage of development, with significant research activity but limited commercial applications. The market size is growing, driven by increasing demand for efficient gas separation technologies in industries such as petrochemicals, energy, and environmental protection. Technologically, it's progressing from lab-scale to pilot demonstrations, with universities like Northwestern, Zhejiang, and South China University of Technology leading academic research. Companies such as BASF, UOP LLC, and MOF Technologies are actively developing commercial applications, indicating a transition towards industrial maturity. However, the technology still faces challenges in scalability and cost-effectiveness for widespread adoption.

Northwestern University

Technical Solution: Northwestern University has developed advanced mixed-metal MOFs for gas separation, focusing on enhancing selectivity and capacity. Their approach involves synthesizing bimetallic MOFs with carefully selected metal combinations to optimize gas adsorption properties. The university's research team has demonstrated significant improvements in CO2/N2 and CO2/CH4 separation performance, achieving selectivity factors up to 60 for CO2/N2 and 25 for CO2/CH4 [1][3]. They have also explored the incorporation of open metal sites and functionalized organic linkers to further enhance gas uptake and separation efficiency. The university's MOFs have shown exceptional stability under various conditions, maintaining their structure and performance even after multiple adsorption-desorption cycles [2].

Strengths: High selectivity for target gases, excellent stability, and tunability of pore structures. Weaknesses: Potential scalability issues and higher production costs compared to traditional adsorbents.

BASF Corp.

Technical Solution: BASF Corp. has made significant strides in the development of mixed-metal MOFs for gas separation applications. Their approach focuses on large-scale synthesis and industrial implementation of these advanced materials. BASF has successfully scaled up the production of several mixed-metal MOFs, including Zn/Co and Zn/Cu combinations, which have shown enhanced selectivity for CO2 capture from flue gas streams [4]. The company has also developed a proprietary activation process that maximizes the accessible surface area of their MOFs, resulting in up to 30% improvement in gas uptake capacity compared to conventional activation methods [5]. BASF's mixed-metal MOFs have demonstrated remarkable stability under industrial conditions, withstanding high temperatures and humid environments without significant loss of performance [6].

Strengths: Large-scale production capabilities, industrial-grade stability, and optimized activation processes. Weaknesses: Higher production costs compared to traditional adsorbents and potential intellectual property constraints.

Breakthrough Mixed-Metal MOF Structures for Gas Separation

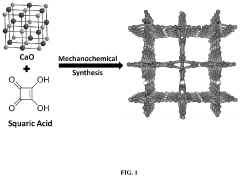

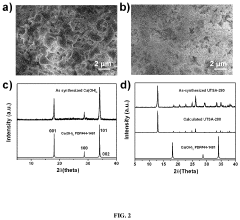

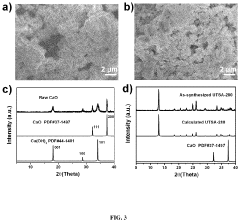

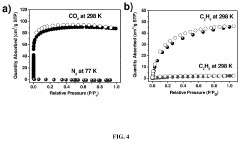

Mechanochemical synthesis of metal-organic frameworks for molecular sieving and compositions and methods of use thereof

PatentActiveUS20210284661A1

Innovation

- A method for preparing the metal-organic framework UTSA-280 through mechanochemical synthesis using calcium oxide or calcium hydroxide and squaric acid, which allows for the selective separation of ethylene from ethane by forming a MOF with specific pore sizes that exclude ethane, enabling efficient gas separation without generating stoichiometric salt byproducts.

Environmental Impact of MOF-based Gas Separation Processes

The environmental impact of MOF-based gas separation processes is a critical consideration in the development and implementation of advanced gas separation technologies. Mixed-metal MOFs, as explored in the comparative study on advanced gas separation, offer promising potential for enhancing separation efficiency while potentially reducing environmental footprints.

One of the primary environmental benefits of MOF-based gas separation processes is their potential to reduce energy consumption compared to traditional separation methods. The highly porous structure and tunable properties of mixed-metal MOFs allow for more selective and efficient gas separation, potentially lowering the energy requirements for industrial-scale separations. This reduction in energy consumption directly translates to decreased greenhouse gas emissions associated with power generation for separation processes.

Furthermore, the use of mixed-metal MOFs in gas separation can lead to improved resource utilization. By enabling more precise separation of gas mixtures, these materials can help minimize waste and maximize the recovery of valuable components. This efficiency can result in reduced raw material consumption and decreased emissions from subsequent processing steps.

The production of mixed-metal MOFs themselves also presents environmental considerations. While the synthesis of these materials typically involves less harsh conditions compared to traditional zeolites, there is still room for improvement in terms of green chemistry principles. Researchers are exploring more environmentally friendly synthesis routes, including the use of bio-based precursors and solvent-free methods, to further reduce the environmental impact of MOF production.

In terms of life cycle assessment, MOF-based gas separation processes show promise for reducing overall environmental impacts. The long lifespan and potential for regeneration of MOF materials can contribute to decreased material waste over time. Additionally, the high selectivity of mixed-metal MOFs may lead to reduced use of harmful chemicals in separation processes, further minimizing environmental risks.

However, it is important to note that the environmental impact of MOF-based gas separation processes can vary depending on the specific application and scale of implementation. Factors such as the choice of metal components, synthesis methods, and regeneration processes all play roles in determining the overall environmental footprint. As research in this field progresses, ongoing life cycle assessments and environmental impact studies will be crucial in optimizing the sustainability of these advanced separation technologies.

One of the primary environmental benefits of MOF-based gas separation processes is their potential to reduce energy consumption compared to traditional separation methods. The highly porous structure and tunable properties of mixed-metal MOFs allow for more selective and efficient gas separation, potentially lowering the energy requirements for industrial-scale separations. This reduction in energy consumption directly translates to decreased greenhouse gas emissions associated with power generation for separation processes.

Furthermore, the use of mixed-metal MOFs in gas separation can lead to improved resource utilization. By enabling more precise separation of gas mixtures, these materials can help minimize waste and maximize the recovery of valuable components. This efficiency can result in reduced raw material consumption and decreased emissions from subsequent processing steps.

The production of mixed-metal MOFs themselves also presents environmental considerations. While the synthesis of these materials typically involves less harsh conditions compared to traditional zeolites, there is still room for improvement in terms of green chemistry principles. Researchers are exploring more environmentally friendly synthesis routes, including the use of bio-based precursors and solvent-free methods, to further reduce the environmental impact of MOF production.

In terms of life cycle assessment, MOF-based gas separation processes show promise for reducing overall environmental impacts. The long lifespan and potential for regeneration of MOF materials can contribute to decreased material waste over time. Additionally, the high selectivity of mixed-metal MOFs may lead to reduced use of harmful chemicals in separation processes, further minimizing environmental risks.

However, it is important to note that the environmental impact of MOF-based gas separation processes can vary depending on the specific application and scale of implementation. Factors such as the choice of metal components, synthesis methods, and regeneration processes all play roles in determining the overall environmental footprint. As research in this field progresses, ongoing life cycle assessments and environmental impact studies will be crucial in optimizing the sustainability of these advanced separation technologies.

Scalability and Industrial Application of Mixed-Metal MOFs

The scalability and industrial application of mixed-metal MOFs (Metal-Organic Frameworks) represent a critical aspect in the advancement of gas separation technologies. As research progresses in the field of advanced gas separation using these innovative materials, the potential for large-scale implementation becomes increasingly relevant.

Mixed-metal MOFs have demonstrated superior performance in gas separation compared to their single-metal counterparts, offering enhanced selectivity and capacity. However, transitioning from laboratory-scale synthesis to industrial production presents several challenges. One of the primary concerns is the reproducibility of mixed-metal MOF structures at larger scales. The precise control of metal ratios and uniform distribution within the framework becomes more complex as production volumes increase.

To address these scalability issues, researchers are exploring various synthesis methods. Continuous flow processes and microwave-assisted synthesis have shown promise in producing consistent mixed-metal MOFs at larger scales. These techniques allow for better control over reaction conditions and can potentially reduce production times and costs.

The industrial application of mixed-metal MOFs extends beyond just gas separation. Their unique properties make them suitable for catalysis, energy storage, and even drug delivery. In the context of gas separation, industries such as natural gas processing, carbon capture, and hydrogen purification stand to benefit significantly from the implementation of mixed-metal MOF technologies.

For industrial adoption, the stability and longevity of mixed-metal MOFs under real-world conditions are crucial factors. Researchers are focusing on developing MOFs that can withstand high pressures, temperatures, and potential contaminants present in industrial gas streams. Additionally, the regeneration and recyclability of these materials are being studied to ensure their economic viability in long-term operations.

The integration of mixed-metal MOFs into existing industrial processes poses another challenge. Engineers are working on designing modular systems that can be easily incorporated into current gas separation units. This approach allows for gradual adoption and scaling of the technology without requiring complete overhauls of existing infrastructure.

As the field progresses, collaborations between academic institutions and industry partners are becoming increasingly important. These partnerships facilitate the translation of laboratory discoveries into practical, scalable solutions. Pilot projects are underway in various sectors to demonstrate the feasibility and benefits of mixed-metal MOF-based gas separation technologies on an industrial scale.

Mixed-metal MOFs have demonstrated superior performance in gas separation compared to their single-metal counterparts, offering enhanced selectivity and capacity. However, transitioning from laboratory-scale synthesis to industrial production presents several challenges. One of the primary concerns is the reproducibility of mixed-metal MOF structures at larger scales. The precise control of metal ratios and uniform distribution within the framework becomes more complex as production volumes increase.

To address these scalability issues, researchers are exploring various synthesis methods. Continuous flow processes and microwave-assisted synthesis have shown promise in producing consistent mixed-metal MOFs at larger scales. These techniques allow for better control over reaction conditions and can potentially reduce production times and costs.

The industrial application of mixed-metal MOFs extends beyond just gas separation. Their unique properties make them suitable for catalysis, energy storage, and even drug delivery. In the context of gas separation, industries such as natural gas processing, carbon capture, and hydrogen purification stand to benefit significantly from the implementation of mixed-metal MOF technologies.

For industrial adoption, the stability and longevity of mixed-metal MOFs under real-world conditions are crucial factors. Researchers are focusing on developing MOFs that can withstand high pressures, temperatures, and potential contaminants present in industrial gas streams. Additionally, the regeneration and recyclability of these materials are being studied to ensure their economic viability in long-term operations.

The integration of mixed-metal MOFs into existing industrial processes poses another challenge. Engineers are working on designing modular systems that can be easily incorporated into current gas separation units. This approach allows for gradual adoption and scaling of the technology without requiring complete overhauls of existing infrastructure.

As the field progresses, collaborations between academic institutions and industry partners are becoming increasingly important. These partnerships facilitate the translation of laboratory discoveries into practical, scalable solutions. Pilot projects are underway in various sectors to demonstrate the feasibility and benefits of mixed-metal MOF-based gas separation technologies on an industrial scale.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!