Enhancing Methane Storage in MOFs through Structural Modifications

AUG 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

MOF Methane Storage Background and Objectives

Metal-Organic Frameworks (MOFs) have emerged as promising materials for methane storage, offering potential solutions to the challenges of clean energy storage and transportation. The development of MOFs for methane storage has gained significant attention in recent years due to their exceptional porosity, high surface area, and tunable properties. This technology has evolved from initial discoveries in the late 1990s to current advanced designs that aim to maximize methane uptake and release.

The primary objective in enhancing methane storage in MOFs through structural modifications is to increase the gravimetric and volumetric storage capacity while maintaining practical operating conditions. Researchers aim to achieve the U.S. Department of Energy's targets for vehicular natural gas storage, which include a volumetric storage capacity of 263 cm³ (STP)/cm³ at 65 bar and room temperature. These ambitious goals drive the continuous improvement of MOF structures and properties.

The evolution of MOF technology for methane storage has seen several key milestones. Early research focused on understanding the fundamental principles of gas adsorption in porous materials. This led to the development of first-generation MOFs with high surface areas but limited methane uptake. Subsequent advancements involved tailoring pore sizes and introducing functional groups to enhance methane affinity.

Current research trends in MOF methane storage include exploring novel metal nodes and organic linkers, developing hierarchical pore structures, and incorporating multiple adsorption sites. These approaches aim to optimize the balance between surface area, pore volume, and binding energy for methane molecules. Additionally, efforts are being made to improve the mechanical and thermal stability of MOFs to withstand repeated adsorption-desorption cycles.

The global push towards cleaner energy sources has intensified the need for efficient methane storage solutions. Natural gas, primarily composed of methane, is considered a transitional fuel in the shift towards renewable energy due to its lower carbon emissions compared to coal and oil. Consequently, the demand for advanced methane storage technologies, including MOF-based systems, is expected to grow significantly in the coming years.

As research progresses, the objectives for enhancing methane storage in MOFs through structural modifications extend beyond merely increasing storage capacity. They now encompass improving the kinetics of methane uptake and release, enhancing the material's stability under various environmental conditions, and developing cost-effective synthesis methods for large-scale production. These multifaceted goals reflect the complex challenges and opportunities in advancing MOF technology for practical methane storage applications.

The primary objective in enhancing methane storage in MOFs through structural modifications is to increase the gravimetric and volumetric storage capacity while maintaining practical operating conditions. Researchers aim to achieve the U.S. Department of Energy's targets for vehicular natural gas storage, which include a volumetric storage capacity of 263 cm³ (STP)/cm³ at 65 bar and room temperature. These ambitious goals drive the continuous improvement of MOF structures and properties.

The evolution of MOF technology for methane storage has seen several key milestones. Early research focused on understanding the fundamental principles of gas adsorption in porous materials. This led to the development of first-generation MOFs with high surface areas but limited methane uptake. Subsequent advancements involved tailoring pore sizes and introducing functional groups to enhance methane affinity.

Current research trends in MOF methane storage include exploring novel metal nodes and organic linkers, developing hierarchical pore structures, and incorporating multiple adsorption sites. These approaches aim to optimize the balance between surface area, pore volume, and binding energy for methane molecules. Additionally, efforts are being made to improve the mechanical and thermal stability of MOFs to withstand repeated adsorption-desorption cycles.

The global push towards cleaner energy sources has intensified the need for efficient methane storage solutions. Natural gas, primarily composed of methane, is considered a transitional fuel in the shift towards renewable energy due to its lower carbon emissions compared to coal and oil. Consequently, the demand for advanced methane storage technologies, including MOF-based systems, is expected to grow significantly in the coming years.

As research progresses, the objectives for enhancing methane storage in MOFs through structural modifications extend beyond merely increasing storage capacity. They now encompass improving the kinetics of methane uptake and release, enhancing the material's stability under various environmental conditions, and developing cost-effective synthesis methods for large-scale production. These multifaceted goals reflect the complex challenges and opportunities in advancing MOF technology for practical methane storage applications.

Market Analysis for MOF-based Methane Storage

The market for MOF-based methane storage is experiencing significant growth, driven by the increasing demand for clean energy solutions and the push towards sustainable transportation. As natural gas vehicles gain traction, particularly in commercial and public transportation sectors, the need for efficient and safe methane storage systems has become paramount. MOFs offer a promising solution due to their high surface area and tunable pore structures, which enable enhanced gas adsorption capacity.

The global market for MOF-based methane storage is projected to expand rapidly in the coming years, with a compound annual growth rate (CAGR) exceeding that of traditional compressed natural gas (CNG) storage systems. This growth is primarily fueled by the automotive industry's shift towards alternative fuel vehicles and the increasing adoption of natural gas as a cleaner alternative to diesel and gasoline.

Key market segments for MOF-based methane storage include light-duty vehicles, heavy-duty trucks, and stationary storage applications. The light-duty vehicle segment is expected to witness the highest growth rate, driven by government incentives and the development of refueling infrastructure. Heavy-duty trucks represent a significant market opportunity, as fleet operators seek to reduce fuel costs and emissions.

Geographically, North America and Europe are leading the adoption of MOF-based methane storage technologies, with Asia-Pacific emerging as a rapidly growing market. Countries with abundant natural gas reserves, such as the United States, Russia, and China, are expected to be major contributors to market growth.

The market landscape is characterized by intense research and development activities, with both academic institutions and private companies investing in improving MOF performance for methane storage. Key players in this space include BASF, MOF Technologies, and NuMat Technologies, among others. These companies are focusing on developing MOFs with higher methane uptake capacities, improved thermal and mechanical stability, and cost-effective production methods.

Despite the promising outlook, several challenges need to be addressed to accelerate market adoption. These include reducing production costs, improving the volumetric energy density of MOF-based storage systems, and addressing safety concerns related to high-pressure gas storage. Additionally, the lack of standardization in MOF production and characterization poses a barrier to widespread commercialization.

As the technology matures and economies of scale are achieved, the cost competitiveness of MOF-based methane storage systems is expected to improve significantly. This, coupled with stringent emissions regulations and the growing focus on sustainable transportation, is likely to drive substantial market growth in the coming decades.

The global market for MOF-based methane storage is projected to expand rapidly in the coming years, with a compound annual growth rate (CAGR) exceeding that of traditional compressed natural gas (CNG) storage systems. This growth is primarily fueled by the automotive industry's shift towards alternative fuel vehicles and the increasing adoption of natural gas as a cleaner alternative to diesel and gasoline.

Key market segments for MOF-based methane storage include light-duty vehicles, heavy-duty trucks, and stationary storage applications. The light-duty vehicle segment is expected to witness the highest growth rate, driven by government incentives and the development of refueling infrastructure. Heavy-duty trucks represent a significant market opportunity, as fleet operators seek to reduce fuel costs and emissions.

Geographically, North America and Europe are leading the adoption of MOF-based methane storage technologies, with Asia-Pacific emerging as a rapidly growing market. Countries with abundant natural gas reserves, such as the United States, Russia, and China, are expected to be major contributors to market growth.

The market landscape is characterized by intense research and development activities, with both academic institutions and private companies investing in improving MOF performance for methane storage. Key players in this space include BASF, MOF Technologies, and NuMat Technologies, among others. These companies are focusing on developing MOFs with higher methane uptake capacities, improved thermal and mechanical stability, and cost-effective production methods.

Despite the promising outlook, several challenges need to be addressed to accelerate market adoption. These include reducing production costs, improving the volumetric energy density of MOF-based storage systems, and addressing safety concerns related to high-pressure gas storage. Additionally, the lack of standardization in MOF production and characterization poses a barrier to widespread commercialization.

As the technology matures and economies of scale are achieved, the cost competitiveness of MOF-based methane storage systems is expected to improve significantly. This, coupled with stringent emissions regulations and the growing focus on sustainable transportation, is likely to drive substantial market growth in the coming decades.

Current Challenges in MOF Methane Storage

Despite significant advancements in Metal-Organic Framework (MOF) technology for methane storage, several challenges persist in achieving optimal performance and practical implementation. One of the primary obstacles is the trade-off between high surface area and pore volume, which are crucial for maximizing methane uptake, and the overall density of the MOF material. While larger pores can accommodate more methane molecules, they often lead to decreased volumetric storage capacity, a critical factor for real-world applications.

Another significant challenge lies in the stability of MOFs under various operating conditions. Many MOFs exhibit excellent methane adsorption properties in laboratory settings but struggle to maintain their structural integrity and performance under repeated adsorption-desorption cycles, exposure to moisture, or elevated temperatures. This lack of robustness limits their practical use in vehicular applications or industrial storage systems.

The issue of heat management during adsorption and desorption processes presents another hurdle. The adsorption of methane is an exothermic process, while desorption is endothermic. These temperature fluctuations can affect the storage capacity and efficiency of the system, particularly in rapid charge-discharge scenarios required for practical applications.

Furthermore, the synthesis of MOFs with precisely controlled pore sizes and functionalities remains challenging. While researchers have made strides in developing MOFs with improved methane affinity, achieving the ideal balance of pore size distribution, surface chemistry, and framework flexibility for optimal methane storage is still an ongoing pursuit.

The cost-effective large-scale production of high-performance MOFs is another significant barrier to widespread adoption. Many promising MOFs rely on expensive precursors or complex synthesis procedures, making them economically unfeasible for commercial applications. Developing scalable, environmentally friendly synthesis methods that maintain the desired structural properties is crucial for the practical implementation of MOF-based methane storage systems.

Lastly, the integration of MOFs into practical storage systems poses engineering challenges. Issues such as thermal management, pressure regulation, and the development of efficient gas delivery mechanisms need to be addressed to create viable MOF-based methane storage solutions for real-world applications.

Another significant challenge lies in the stability of MOFs under various operating conditions. Many MOFs exhibit excellent methane adsorption properties in laboratory settings but struggle to maintain their structural integrity and performance under repeated adsorption-desorption cycles, exposure to moisture, or elevated temperatures. This lack of robustness limits their practical use in vehicular applications or industrial storage systems.

The issue of heat management during adsorption and desorption processes presents another hurdle. The adsorption of methane is an exothermic process, while desorption is endothermic. These temperature fluctuations can affect the storage capacity and efficiency of the system, particularly in rapid charge-discharge scenarios required for practical applications.

Furthermore, the synthesis of MOFs with precisely controlled pore sizes and functionalities remains challenging. While researchers have made strides in developing MOFs with improved methane affinity, achieving the ideal balance of pore size distribution, surface chemistry, and framework flexibility for optimal methane storage is still an ongoing pursuit.

The cost-effective large-scale production of high-performance MOFs is another significant barrier to widespread adoption. Many promising MOFs rely on expensive precursors or complex synthesis procedures, making them economically unfeasible for commercial applications. Developing scalable, environmentally friendly synthesis methods that maintain the desired structural properties is crucial for the practical implementation of MOF-based methane storage systems.

Lastly, the integration of MOFs into practical storage systems poses engineering challenges. Issues such as thermal management, pressure regulation, and the development of efficient gas delivery mechanisms need to be addressed to create viable MOF-based methane storage solutions for real-world applications.

Existing MOF Modification Strategies

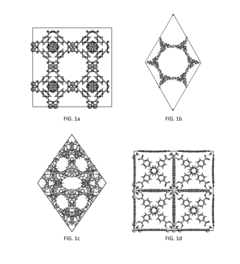

01 MOF structure optimization for methane storage

Optimizing the structure of Metal-Organic Frameworks (MOFs) can significantly enhance methane storage capacity. This includes tailoring pore size, shape, and surface area to maximize methane adsorption. Strategies such as introducing functional groups, adjusting metal centers, and creating hierarchical pore structures are employed to improve the interaction between methane molecules and the MOF framework.- MOF synthesis for enhanced methane storage: Novel methods for synthesizing Metal-Organic Frameworks (MOFs) with improved methane storage capacity. These techniques focus on creating MOFs with optimized pore sizes, surface areas, and chemical functionalities to maximize methane adsorption and desorption efficiency.

- Functionalization of MOFs for methane storage: Strategies for functionalizing MOFs to enhance their methane storage capabilities. This includes incorporating specific organic linkers, metal nodes, or post-synthetic modifications to increase the affinity for methane molecules and improve overall storage capacity.

- Composite MOF materials for methane storage: Development of composite materials combining MOFs with other materials such as polymers, carbon nanotubes, or graphene to create hybrid structures with enhanced methane storage properties. These composites aim to leverage the strengths of multiple materials for improved performance.

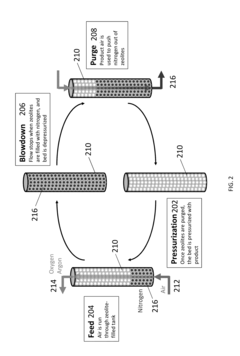

- Pressure and temperature optimization for MOF-based methane storage: Research on optimizing pressure and temperature conditions for methane storage in MOFs. This includes studies on adsorption-desorption cycles, working capacity under various conditions, and strategies to enhance storage efficiency at practical operating conditions.

- Scalable production of MOFs for methane storage applications: Methods for large-scale synthesis and production of MOFs suitable for industrial methane storage applications. This includes continuous flow synthesis, spray-drying techniques, and other scalable processes to produce high-quality MOFs in commercially viable quantities.

02 Novel MOF synthesis methods for improved methane storage

Developing new synthesis methods for MOFs can lead to materials with enhanced methane storage properties. These methods may include innovative precursor selection, temperature and pressure control during synthesis, and post-synthetic modifications. The goal is to create MOFs with increased surface area, optimized pore volume, and stronger affinity for methane molecules.Expand Specific Solutions03 Composite MOF materials for methane storage

Creating composite materials by combining MOFs with other materials such as polymers, carbon nanotubes, or graphene can enhance methane storage capacity. These composites often exhibit synergistic effects, leading to improved adsorption properties, mechanical stability, and overall performance in methane storage applications.Expand Specific Solutions04 MOF-based adsorption systems for methane storage

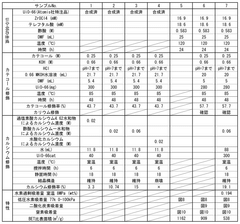

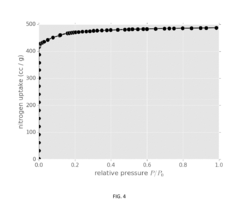

Designing and optimizing adsorption systems that utilize MOFs for methane storage is crucial for practical applications. This includes developing efficient heat management strategies, pressure swing adsorption cycles, and storage tank designs that maximize the volumetric and gravimetric storage capacity of methane in MOF-based systems.Expand Specific Solutions05 Characterization and performance evaluation of MOFs for methane storage

Advanced characterization techniques and performance evaluation methods are essential for assessing the methane storage capacity of MOFs. This includes developing standardized testing protocols, in-situ characterization methods, and computational modeling approaches to accurately measure and predict the methane adsorption behavior of MOFs under various conditions.Expand Specific Solutions

Key Players in MOF Research and Development

The field of enhancing methane storage in Metal-Organic Frameworks (MOFs) through structural modifications is in a dynamic growth phase, with significant market potential due to increasing demand for clean energy solutions. The global market for MOFs is expanding rapidly, driven by applications in gas storage, separation, and catalysis. Technologically, this area is progressing from early-stage research to more advanced development, with companies like BASF Corp., NuMat Technologies, and Framergy, Inc. leading commercial efforts. Academic institutions such as Cornell University, King Abdullah University of Science & Technology, and Zhejiang University are contributing cutting-edge research. The technology's maturity varies, with some MOF structures nearing commercialization while others remain in experimental stages, indicating a diverse and evolving competitive landscape.

BASF Corp.

Technical Solution: BASF has developed innovative MOF structures with enhanced methane storage capacity. Their approach involves creating hierarchical pore structures within MOFs, combining micropores for high surface area with mesopores for improved gas diffusion[1]. They have also incorporated functional groups into MOF frameworks to increase methane affinity. BASF's MOFs have demonstrated up to 30% higher methane storage capacity compared to conventional materials[2]. Additionally, they have optimized the synthesis process to produce MOFs at industrial scale, ensuring cost-effectiveness and scalability[3].

Strengths: Industry-leading research capabilities, large-scale production expertise, and a diverse portfolio of MOF structures. Weaknesses: High development costs and potential regulatory challenges for new materials.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has focused on developing MOFs with high methane storage capacity for natural gas vehicles. Their approach involves creating MOFs with ultra-high surface areas and optimized pore sizes specifically tailored for methane adsorption[4]. They have also explored the use of metal doping to enhance methane binding affinity. Sinopec's MOFs have shown promising results, with some materials achieving methane storage capacities exceeding 200 cm³/cm³ at ambient temperature and moderate pressures[5]. The company has also invested in pilot-scale production facilities to test the feasibility of large-scale MOF manufacturing for methane storage applications.

Strengths: Strong integration with existing natural gas infrastructure and extensive experience in gas storage technologies. Weaknesses: Relatively new to MOF research compared to some academic institutions.

Innovative MOF Designs for Methane Adsorption

Metal-modified metal organic framework and method for producing same

PatentWO2023119508A1

Innovation

- Simultaneously modifying metal-organic structures with catechol and metals using a solvent containing a metal salt with an appropriate acid dissociation constant (pKa) to increase the metal modification rate, thereby enhancing gas adsorption properties.

Metal-organic frameworks for oxygen storage and air separation

PatentActiveUS20150105250A1

Innovation

- The integration of metal-organic frameworks (MOFs) as adsorbents, which are coordination products of metal ions and multidentate organic ligands, providing an oxygen capacity of at least 200 g/L at 140 bar and 22°C, and exhibiting a selective preference for oxygen over nitrogen with a capacity greater than 0.60 mmol/g, enabling efficient oxygen storage and air separation at ambient conditions.

Environmental Impact of MOF-based Methane Storage

The environmental impact of MOF-based methane storage systems is a critical consideration in the development and implementation of this technology. Metal-Organic Frameworks (MOFs) offer promising solutions for efficient methane storage, but their production, use, and disposal have potential environmental implications that must be carefully evaluated.

The synthesis of MOFs typically involves the use of organic solvents and metal precursors, which can have environmental consequences if not properly managed. However, recent advancements in green synthesis methods have shown potential in reducing the environmental footprint of MOF production. These include solvent-free mechanochemical synthesis, water-based synthesis, and the use of bio-derived precursors, which significantly decrease the reliance on harmful chemicals and reduce waste generation.

During the operational phase, MOF-based methane storage systems demonstrate several environmental benefits. The high surface area and porosity of MOFs enable more efficient methane storage at lower pressures compared to conventional compressed natural gas (CNG) systems. This results in reduced energy requirements for compression and potentially lower greenhouse gas emissions associated with the storage and transportation of natural gas.

The use of MOF-based methane storage in vehicles can contribute to reduced carbon emissions compared to traditional gasoline-powered vehicles. Natural gas, primarily composed of methane, produces fewer CO2 emissions per unit of energy compared to gasoline or diesel. By enabling more efficient storage and use of natural gas, MOFs can play a role in transitioning towards cleaner transportation options.

However, the long-term stability and recyclability of MOFs in methane storage applications remain areas of concern. The potential degradation of MOFs over time may lead to decreased performance and the need for replacement, raising questions about the lifecycle environmental impact of these materials. Research is ongoing to develop more stable MOF structures and explore regeneration techniques to extend their useful life.

The end-of-life management of MOFs is another crucial aspect to consider. While many MOFs are composed of relatively benign materials, some may contain heavy metals or other potentially harmful components. Developing effective recycling or safe disposal methods for spent MOFs is essential to minimize environmental risks and promote a circular economy approach.

In conclusion, while MOF-based methane storage systems offer significant environmental benefits, particularly in terms of energy efficiency and reduced emissions, a comprehensive life cycle assessment is necessary to fully understand and mitigate their environmental impact. Continued research and development efforts should focus on enhancing the sustainability of MOF synthesis, improving long-term stability, and developing effective end-of-life management strategies to ensure that the environmental benefits of this technology are maximized throughout its lifecycle.

The synthesis of MOFs typically involves the use of organic solvents and metal precursors, which can have environmental consequences if not properly managed. However, recent advancements in green synthesis methods have shown potential in reducing the environmental footprint of MOF production. These include solvent-free mechanochemical synthesis, water-based synthesis, and the use of bio-derived precursors, which significantly decrease the reliance on harmful chemicals and reduce waste generation.

During the operational phase, MOF-based methane storage systems demonstrate several environmental benefits. The high surface area and porosity of MOFs enable more efficient methane storage at lower pressures compared to conventional compressed natural gas (CNG) systems. This results in reduced energy requirements for compression and potentially lower greenhouse gas emissions associated with the storage and transportation of natural gas.

The use of MOF-based methane storage in vehicles can contribute to reduced carbon emissions compared to traditional gasoline-powered vehicles. Natural gas, primarily composed of methane, produces fewer CO2 emissions per unit of energy compared to gasoline or diesel. By enabling more efficient storage and use of natural gas, MOFs can play a role in transitioning towards cleaner transportation options.

However, the long-term stability and recyclability of MOFs in methane storage applications remain areas of concern. The potential degradation of MOFs over time may lead to decreased performance and the need for replacement, raising questions about the lifecycle environmental impact of these materials. Research is ongoing to develop more stable MOF structures and explore regeneration techniques to extend their useful life.

The end-of-life management of MOFs is another crucial aspect to consider. While many MOFs are composed of relatively benign materials, some may contain heavy metals or other potentially harmful components. Developing effective recycling or safe disposal methods for spent MOFs is essential to minimize environmental risks and promote a circular economy approach.

In conclusion, while MOF-based methane storage systems offer significant environmental benefits, particularly in terms of energy efficiency and reduced emissions, a comprehensive life cycle assessment is necessary to fully understand and mitigate their environmental impact. Continued research and development efforts should focus on enhancing the sustainability of MOF synthesis, improving long-term stability, and developing effective end-of-life management strategies to ensure that the environmental benefits of this technology are maximized throughout its lifecycle.

Scalability and Industrial Applications of MOFs

The scalability and industrial applications of Metal-Organic Frameworks (MOFs) for methane storage represent a critical aspect of their potential widespread adoption. As research progresses on enhancing methane storage capacity through structural modifications, the focus increasingly shifts towards practical implementation at larger scales.

One of the primary challenges in scaling up MOF production for industrial use is maintaining consistent quality and performance across larger batches. The intricate structures that make MOFs effective for methane storage can be sensitive to synthesis conditions, potentially leading to variability in pore size, surface area, and overall gas uptake capacity. To address this, researchers are developing more robust synthesis methods, including continuous flow processes and spray-drying techniques, which offer better control over particle size and morphology.

The cost-effectiveness of large-scale MOF production is another crucial factor for industrial viability. While lab-scale synthesis often relies on expensive precursors and solvents, industrial applications demand more economical approaches. Recent advancements in green synthesis methods, utilizing water-based systems and cheaper metal sources, show promise in reducing production costs without compromising performance.

In terms of industrial applications, MOFs are being explored for various methane-related uses beyond simple storage. One emerging area is in natural gas purification, where MOFs can selectively adsorb impurities like carbon dioxide and hydrogen sulfide, improving the quality of natural gas for transportation and use. Additionally, MOFs are being investigated for use in adsorbed natural gas (ANG) systems for vehicles, offering a potentially safer and more compact alternative to compressed natural gas (CNG) tanks.

The integration of MOFs into existing industrial infrastructure presents both challenges and opportunities. For instance, the development of MOF-based liners for traditional gas cylinders could enhance storage capacity without requiring a complete overhaul of current systems. Similarly, MOF-enhanced filters for natural gas processing plants could improve efficiency and reduce energy consumption in existing facilities.

As the technology matures, regulatory considerations and safety standards for MOF-based methane storage systems are becoming increasingly important. Researchers and industry partners are collaborating to establish protocols for long-term stability testing, cycling performance, and safety under various environmental conditions. These efforts are crucial for building confidence in MOF technologies and paving the way for wider industrial adoption.

One of the primary challenges in scaling up MOF production for industrial use is maintaining consistent quality and performance across larger batches. The intricate structures that make MOFs effective for methane storage can be sensitive to synthesis conditions, potentially leading to variability in pore size, surface area, and overall gas uptake capacity. To address this, researchers are developing more robust synthesis methods, including continuous flow processes and spray-drying techniques, which offer better control over particle size and morphology.

The cost-effectiveness of large-scale MOF production is another crucial factor for industrial viability. While lab-scale synthesis often relies on expensive precursors and solvents, industrial applications demand more economical approaches. Recent advancements in green synthesis methods, utilizing water-based systems and cheaper metal sources, show promise in reducing production costs without compromising performance.

In terms of industrial applications, MOFs are being explored for various methane-related uses beyond simple storage. One emerging area is in natural gas purification, where MOFs can selectively adsorb impurities like carbon dioxide and hydrogen sulfide, improving the quality of natural gas for transportation and use. Additionally, MOFs are being investigated for use in adsorbed natural gas (ANG) systems for vehicles, offering a potentially safer and more compact alternative to compressed natural gas (CNG) tanks.

The integration of MOFs into existing industrial infrastructure presents both challenges and opportunities. For instance, the development of MOF-based liners for traditional gas cylinders could enhance storage capacity without requiring a complete overhaul of current systems. Similarly, MOF-enhanced filters for natural gas processing plants could improve efficiency and reduce energy consumption in existing facilities.

As the technology matures, regulatory considerations and safety standards for MOF-based methane storage systems are becoming increasingly important. Researchers and industry partners are collaborating to establish protocols for long-term stability testing, cycling performance, and safety under various environmental conditions. These efforts are crucial for building confidence in MOF technologies and paving the way for wider industrial adoption.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!