Nanoscale MOFs in Catalyzing Complex Reaction Pathways

AUG 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

MOF Catalysis Background

Metal-Organic Frameworks (MOFs) have emerged as a revolutionary class of porous materials, bridging the gap between organic and inorganic chemistry. These crystalline structures, composed of metal ions or clusters coordinated to organic ligands, have garnered significant attention in the field of catalysis over the past two decades. The unique properties of MOFs, including their high surface area, tunable pore size, and diverse chemical functionality, make them ideal candidates for catalyzing complex reaction pathways at the nanoscale.

The journey of MOFs in catalysis began in the early 2000s when researchers recognized their potential as heterogeneous catalysts. Initial studies focused on simple reactions, such as oxidations and reductions, but quickly expanded to more complex transformations. The ability to incorporate catalytically active sites within the MOF structure, either as part of the metal nodes or the organic linkers, opened up new possibilities for designing highly specific and efficient catalysts.

As the field progressed, researchers discovered that the confined spaces within MOF pores could create unique reaction environments, often leading to enhanced selectivity and reactivity compared to traditional catalysts. This confinement effect, coupled with the ability to precisely control the chemical environment around the active sites, has made MOFs particularly attractive for catalyzing complex, multi-step reactions.

The development of nanoscale MOFs further expanded their potential in catalysis. These materials, typically with dimensions below 100 nm, exhibit enhanced properties compared to their bulk counterparts. Nanoscale MOFs often display improved mass transfer characteristics, higher external surface areas, and unique size-dependent properties that can significantly influence their catalytic performance.

Recent years have seen a surge in research focused on utilizing nanoscale MOFs for catalyzing complex reaction pathways. These efforts have been driven by the need for more efficient and sustainable chemical processes in various industries, including pharmaceuticals, fine chemicals, and energy production. The ability of nanoscale MOFs to catalyze cascade reactions, where multiple transformations occur in a single pot, has been particularly noteworthy.

The background of MOF catalysis also encompasses significant advancements in characterization techniques and computational modeling. These tools have been crucial in understanding the intricate mechanisms of catalysis within MOF structures and guiding the design of next-generation catalysts. In-situ spectroscopic methods, for instance, have provided unprecedented insights into the dynamic behavior of MOFs during catalytic processes.

As we look to the future, the field of nanoscale MOFs in catalyzing complex reaction pathways continues to evolve rapidly. Researchers are exploring new frontiers, such as the integration of MOFs with other nanomaterials, the development of stimuli-responsive MOF catalysts, and the application of artificial intelligence in MOF design and optimization. These advancements promise to further expand the capabilities of MOFs in addressing some of the most challenging catalytic transformations in chemistry and materials science.

The journey of MOFs in catalysis began in the early 2000s when researchers recognized their potential as heterogeneous catalysts. Initial studies focused on simple reactions, such as oxidations and reductions, but quickly expanded to more complex transformations. The ability to incorporate catalytically active sites within the MOF structure, either as part of the metal nodes or the organic linkers, opened up new possibilities for designing highly specific and efficient catalysts.

As the field progressed, researchers discovered that the confined spaces within MOF pores could create unique reaction environments, often leading to enhanced selectivity and reactivity compared to traditional catalysts. This confinement effect, coupled with the ability to precisely control the chemical environment around the active sites, has made MOFs particularly attractive for catalyzing complex, multi-step reactions.

The development of nanoscale MOFs further expanded their potential in catalysis. These materials, typically with dimensions below 100 nm, exhibit enhanced properties compared to their bulk counterparts. Nanoscale MOFs often display improved mass transfer characteristics, higher external surface areas, and unique size-dependent properties that can significantly influence their catalytic performance.

Recent years have seen a surge in research focused on utilizing nanoscale MOFs for catalyzing complex reaction pathways. These efforts have been driven by the need for more efficient and sustainable chemical processes in various industries, including pharmaceuticals, fine chemicals, and energy production. The ability of nanoscale MOFs to catalyze cascade reactions, where multiple transformations occur in a single pot, has been particularly noteworthy.

The background of MOF catalysis also encompasses significant advancements in characterization techniques and computational modeling. These tools have been crucial in understanding the intricate mechanisms of catalysis within MOF structures and guiding the design of next-generation catalysts. In-situ spectroscopic methods, for instance, have provided unprecedented insights into the dynamic behavior of MOFs during catalytic processes.

As we look to the future, the field of nanoscale MOFs in catalyzing complex reaction pathways continues to evolve rapidly. Researchers are exploring new frontiers, such as the integration of MOFs with other nanomaterials, the development of stimuli-responsive MOF catalysts, and the application of artificial intelligence in MOF design and optimization. These advancements promise to further expand the capabilities of MOFs in addressing some of the most challenging catalytic transformations in chemistry and materials science.

Market Demand Analysis

The market demand for nanoscale Metal-Organic Frameworks (MOFs) in catalyzing complex reaction pathways has been steadily growing, driven by the increasing need for more efficient and sustainable chemical processes across various industries. The unique properties of nanoscale MOFs, including their high surface area, tunable pore size, and diverse chemical functionalities, make them particularly attractive for catalytic applications.

In the pharmaceutical sector, there is a significant demand for nanoscale MOFs to catalyze complex organic syntheses, enabling the production of novel drug compounds with improved efficiency and selectivity. This demand is fueled by the industry's constant pursuit of innovative therapies and the need to streamline drug discovery processes.

The petrochemical industry has also shown keen interest in nanoscale MOFs for catalyzing complex hydrocarbon transformations. As the industry faces pressure to reduce environmental impact and improve resource utilization, these advanced catalysts offer promising solutions for more efficient refining processes and the production of value-added chemicals from fossil resources.

Environmental applications represent another growing market for nanoscale MOFs in catalysis. There is an increasing demand for effective catalysts in air and water purification systems, as well as in the conversion of greenhouse gases into useful products. Nanoscale MOFs have demonstrated potential in these areas, particularly in the catalytic degradation of pollutants and CO2 conversion.

The fine chemicals industry is exploring nanoscale MOFs for catalyzing precision syntheses of specialty chemicals and advanced materials. The ability of these catalysts to facilitate complex, multi-step reactions with high selectivity aligns well with the industry's need for more sophisticated and efficient production methods.

In the emerging field of artificial photosynthesis and renewable energy, nanoscale MOFs are gaining attention for their potential in catalyzing water splitting and CO2 reduction reactions. This market segment is expected to grow significantly as research in sustainable energy technologies intensifies.

The global market for advanced catalysts, including nanoscale MOFs, is projected to expand at a compound annual growth rate (CAGR) of over 4% in the coming years. This growth is largely attributed to the increasing adoption of these materials in various industrial processes and the ongoing research into their catalytic properties.

However, challenges remain in scaling up the production of nanoscale MOFs and optimizing their performance for specific industrial applications. Addressing these challenges will be crucial for fully realizing the market potential of these advanced catalytic materials across different sectors.

In the pharmaceutical sector, there is a significant demand for nanoscale MOFs to catalyze complex organic syntheses, enabling the production of novel drug compounds with improved efficiency and selectivity. This demand is fueled by the industry's constant pursuit of innovative therapies and the need to streamline drug discovery processes.

The petrochemical industry has also shown keen interest in nanoscale MOFs for catalyzing complex hydrocarbon transformations. As the industry faces pressure to reduce environmental impact and improve resource utilization, these advanced catalysts offer promising solutions for more efficient refining processes and the production of value-added chemicals from fossil resources.

Environmental applications represent another growing market for nanoscale MOFs in catalysis. There is an increasing demand for effective catalysts in air and water purification systems, as well as in the conversion of greenhouse gases into useful products. Nanoscale MOFs have demonstrated potential in these areas, particularly in the catalytic degradation of pollutants and CO2 conversion.

The fine chemicals industry is exploring nanoscale MOFs for catalyzing precision syntheses of specialty chemicals and advanced materials. The ability of these catalysts to facilitate complex, multi-step reactions with high selectivity aligns well with the industry's need for more sophisticated and efficient production methods.

In the emerging field of artificial photosynthesis and renewable energy, nanoscale MOFs are gaining attention for their potential in catalyzing water splitting and CO2 reduction reactions. This market segment is expected to grow significantly as research in sustainable energy technologies intensifies.

The global market for advanced catalysts, including nanoscale MOFs, is projected to expand at a compound annual growth rate (CAGR) of over 4% in the coming years. This growth is largely attributed to the increasing adoption of these materials in various industrial processes and the ongoing research into their catalytic properties.

However, challenges remain in scaling up the production of nanoscale MOFs and optimizing their performance for specific industrial applications. Addressing these challenges will be crucial for fully realizing the market potential of these advanced catalytic materials across different sectors.

Nanoscale MOF Challenges

Nanoscale Metal-Organic Frameworks (MOFs) present several significant challenges in catalyzing complex reaction pathways. One of the primary obstacles is the precise control of pore size and structure at the nanoscale level. While MOFs offer exceptional tunability, achieving consistent and uniform pore dimensions across the entire framework remains difficult. This inconsistency can lead to variations in catalytic performance and selectivity, particularly when dealing with complex, multi-step reactions.

Another major challenge lies in maintaining the structural integrity of nanoscale MOFs under harsh reaction conditions. The high surface area and reduced particle size of these materials make them more susceptible to degradation, especially in the presence of reactive species or extreme temperatures. This instability can result in a loss of catalytic activity over time and limit the reusability of the MOF catalysts.

The integration of multiple catalytic sites within a single MOF structure poses yet another hurdle. Complex reaction pathways often require a sequence of different catalytic steps, each potentially needing a specific type of active site. Incorporating these diverse functionalities while maintaining the overall framework stability and preventing undesired interactions between different catalytic centers is a significant challenge in MOF design.

Mass transfer limitations also present a considerable obstacle in nanoscale MOF catalysis. Despite their high porosity, the intricate network of channels in MOFs can impede the efficient transport of reactants and products, particularly in liquid-phase reactions. This limitation can lead to reduced reaction rates and potentially alter the selectivity of complex reactions.

Furthermore, the characterization of catalytic processes within nanoscale MOFs remains challenging. Traditional spectroscopic and microscopic techniques often struggle to provide detailed, real-time information about the catalytic events occurring within the MOF pores. This lack of in-situ observation capabilities hinders the understanding of reaction mechanisms and the optimization of catalytic performance.

The scalability of nanoscale MOF synthesis for industrial applications is another significant challenge. While laboratory-scale production can yield high-quality materials, translating these processes to large-scale manufacturing while maintaining precise control over particle size, morphology, and catalytic properties is extremely difficult. This scalability issue presents a major barrier to the widespread adoption of nanoscale MOFs in industrial catalytic processes.

Lastly, the environmental impact and sustainability of nanoscale MOF catalysts must be carefully considered. The synthesis of these materials often involves the use of toxic solvents or metal precursors, raising concerns about their overall environmental footprint. Developing green synthesis methods and ensuring the safe disposal or recycling of spent MOF catalysts are crucial challenges that need to be addressed for their sustainable application in complex reaction catalysis.

Another major challenge lies in maintaining the structural integrity of nanoscale MOFs under harsh reaction conditions. The high surface area and reduced particle size of these materials make them more susceptible to degradation, especially in the presence of reactive species or extreme temperatures. This instability can result in a loss of catalytic activity over time and limit the reusability of the MOF catalysts.

The integration of multiple catalytic sites within a single MOF structure poses yet another hurdle. Complex reaction pathways often require a sequence of different catalytic steps, each potentially needing a specific type of active site. Incorporating these diverse functionalities while maintaining the overall framework stability and preventing undesired interactions between different catalytic centers is a significant challenge in MOF design.

Mass transfer limitations also present a considerable obstacle in nanoscale MOF catalysis. Despite their high porosity, the intricate network of channels in MOFs can impede the efficient transport of reactants and products, particularly in liquid-phase reactions. This limitation can lead to reduced reaction rates and potentially alter the selectivity of complex reactions.

Furthermore, the characterization of catalytic processes within nanoscale MOFs remains challenging. Traditional spectroscopic and microscopic techniques often struggle to provide detailed, real-time information about the catalytic events occurring within the MOF pores. This lack of in-situ observation capabilities hinders the understanding of reaction mechanisms and the optimization of catalytic performance.

The scalability of nanoscale MOF synthesis for industrial applications is another significant challenge. While laboratory-scale production can yield high-quality materials, translating these processes to large-scale manufacturing while maintaining precise control over particle size, morphology, and catalytic properties is extremely difficult. This scalability issue presents a major barrier to the widespread adoption of nanoscale MOFs in industrial catalytic processes.

Lastly, the environmental impact and sustainability of nanoscale MOF catalysts must be carefully considered. The synthesis of these materials often involves the use of toxic solvents or metal precursors, raising concerns about their overall environmental footprint. Developing green synthesis methods and ensuring the safe disposal or recycling of spent MOF catalysts are crucial challenges that need to be addressed for their sustainable application in complex reaction catalysis.

Current MOF Solutions

01 Synthesis and structure of nanoscale MOFs

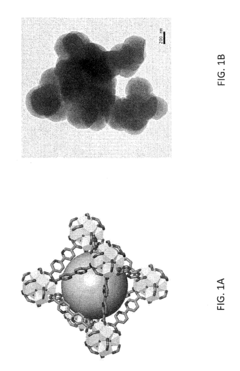

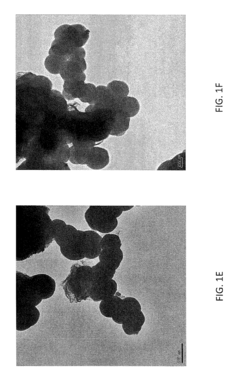

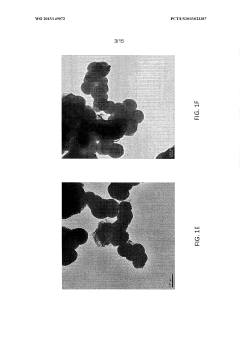

Nanoscale Metal-Organic Frameworks (MOFs) are synthesized using various methods to control their size, shape, and structure at the nanoscale level. These techniques include solvothermal synthesis, microwave-assisted synthesis, and template-directed growth. The resulting nanoscale MOFs exhibit unique properties due to their high surface area and tunable pore sizes.- Synthesis and fabrication of nanoscale MOFs: Various methods and techniques for synthesizing and fabricating nanoscale Metal-Organic Frameworks (MOFs) are explored. These processes aim to control the size, shape, and properties of MOFs at the nanoscale level, enabling their use in diverse applications such as gas storage, catalysis, and drug delivery.

- Applications of nanoscale MOFs in energy storage and conversion: Nanoscale MOFs are utilized in energy-related applications, including gas storage, fuel cells, and batteries. Their high surface area and tunable pore structures make them excellent candidates for improving energy storage capacity and efficiency in various devices.

- Nanoscale MOFs for environmental remediation and sensing: The use of nanoscale MOFs in environmental applications is explored, focusing on their potential for pollutant removal, water purification, and chemical sensing. Their high adsorption capacity and selectivity make them promising materials for detecting and removing contaminants from air and water.

- Functionalization and modification of nanoscale MOFs: Techniques for functionalizing and modifying nanoscale MOFs are developed to enhance their properties and expand their applications. This includes post-synthetic modifications, incorporation of functional groups, and creation of composite materials to tailor MOFs for specific uses.

- Characterization and modeling of nanoscale MOFs: Advanced characterization techniques and computational modeling approaches are employed to study the structure, properties, and behavior of nanoscale MOFs. These methods help in understanding the fundamental aspects of MOFs and guide the design of new materials with improved performance.

02 Applications of nanoscale MOFs in gas storage and separation

Nanoscale MOFs are utilized for efficient gas storage and separation due to their high porosity and selective adsorption properties. They are particularly effective in capturing and storing greenhouse gases, hydrogen storage for fuel cells, and separating gas mixtures in industrial processes.Expand Specific Solutions03 Nanoscale MOFs in catalysis and sensing

Nanoscale MOFs serve as efficient catalysts and sensors due to their high surface area and tunable chemical properties. They are used in various catalytic reactions, including organic transformations and electrochemical processes. Additionally, these materials are employed in chemical and biological sensing applications, offering high sensitivity and selectivity.Expand Specific Solutions04 Functionalization and modification of nanoscale MOFs

Nanoscale MOFs can be functionalized and modified to enhance their properties and expand their applications. This includes post-synthetic modification, incorporation of functional groups, and creation of composite materials. These modifications can improve stability, selectivity, and performance in various applications such as drug delivery and environmental remediation.Expand Specific Solutions05 Characterization and modeling of nanoscale MOFs

Advanced characterization techniques and computational modeling are employed to understand the structure, properties, and behavior of nanoscale MOFs. This includes the use of microscopy, spectroscopy, and diffraction methods for structural analysis, as well as molecular simulations to predict and optimize their performance in various applications.Expand Specific Solutions

Key MOF Industry Players

The field of nanoscale MOFs in catalyzing complex reaction pathways is in a rapidly evolving stage, with significant potential for growth. The market size is expanding as industries recognize the value of these advanced materials in enhancing catalytic processes. Technologically, the field is progressing from basic research to practical applications, with varying degrees of maturity across different sectors. Key players like Northwestern University, Sichuan University, and Jilin University are at the forefront of academic research, while companies such as Yissum Research Development Co. Ltd. and Hyundai Motor Co., Ltd. are exploring commercial applications. The involvement of diverse institutions globally indicates a competitive and collaborative landscape, driving innovation in this promising area of nanotechnology.

South China University of Technology

Technical Solution: South China University of Technology has made significant advancements in nanoscale MOFs for catalyzing complex reaction pathways. Their research focuses on developing highly efficient and selective MOF-based catalysts for various organic transformations. They have successfully synthesized a series of novel Zr-based MOFs with tailored pore structures and functionalities[1]. These MOFs exhibit exceptional catalytic performance in challenging reactions such as C-C bond formation and asymmetric synthesis. The university's team has also pioneered the use of in-situ characterization techniques to elucidate the reaction mechanisms within MOF pores, providing crucial insights for rational catalyst design[3]. Additionally, they have explored the integration of MOFs with other nanomaterials, such as graphene and metal nanoparticles, to create synergistic catalytic systems with enhanced activity and stability[5].

Strengths: Expertise in MOF synthesis and functionalization, advanced characterization capabilities, and innovative catalyst design. Weaknesses: Potential scalability issues for industrial applications and limited focus on catalyst recyclability.

Sun Yat-Sen University

Technical Solution: Sun Yat-Sen University has made substantial progress in the field of nanoscale MOFs for catalyzing complex reaction pathways. Their research team has developed a series of hierarchical MOFs with precisely controlled pore structures, enabling efficient mass transport and enhanced catalytic activity[2]. They have successfully applied these MOFs in challenging reactions such as CO2 conversion and biomass valorization. The university has also pioneered the use of post-synthetic modification techniques to introduce specific catalytic sites within MOF frameworks, allowing for tunable selectivity in multi-step reactions[4]. Furthermore, they have explored the integration of MOFs with enzymes to create bio-inspired catalytic systems capable of mimicking natural metabolic pathways[6]. Their recent work has focused on developing stimuli-responsive MOFs that can adapt their catalytic properties in response to external triggers, opening up new possibilities for smart catalytic processes.

Strengths: Expertise in hierarchical MOF synthesis, post-synthetic modification techniques, and bio-inspired catalytic systems. Weaknesses: Potential challenges in large-scale production and long-term stability of complex MOF structures.

Core MOF Innovations

Metal-organic frameworks containing nitrogen-donor ligands for efficient catalytic organic transformations

PatentActiveUS20170182486A1

Innovation

- The development of crystalline and porous metal-organic frameworks (MOFs) using nitrogen donor-based bridging ligands such as bipyridines, phenanthrolines, and salicylaldimines, which are complexed with metal sources like Zr, Hf, Zn, and Cu to create catalytically active sites, allowing for the catalysis of organic transformations like borylation, hydrogenation, and hydroboration.

Metal-organic frameworks containing nitrogen-donor ligands for efficient catalytic organic transformations

PatentWO2015149072A1

Innovation

- The development of metal-organic frameworks (MOFs) containing nitrogen donor-based bridging ligands, such as bipyridines, phenanthrolines, and salicylaldimines, which are used to create crystalline and porous MOFs by contacting nitrogen donor ligands with metal sources, allowing for post-synthetic metalation with catalysts like Ir, Pd, and Co to enhance catalytic activity and selectivity.

Green Chemistry Impact

The integration of nanoscale Metal-Organic Frameworks (MOFs) in catalyzing complex reaction pathways has significant implications for green chemistry. These advanced materials offer a unique platform for sustainable chemical processes, aligning with the principles of green chemistry by reducing waste, improving energy efficiency, and enhancing selectivity in chemical reactions.

Nanoscale MOFs contribute to greener chemical processes through their exceptional catalytic properties. Their high surface area and tunable pore structures allow for efficient mass transfer and selective molecular interactions, leading to improved reaction rates and reduced energy requirements. This efficiency translates to lower resource consumption and minimized waste generation, key objectives in green chemistry.

The versatility of MOFs in catalysis extends to various environmentally critical reactions. For instance, in CO2 conversion, nanoscale MOFs have shown promise in catalyzing the transformation of this greenhouse gas into value-added products, addressing both environmental concerns and resource utilization. Similarly, in water treatment applications, MOF-based catalysts have demonstrated effectiveness in degrading pollutants through advanced oxidation processes, offering a greener alternative to conventional treatment methods.

Furthermore, the modular nature of MOFs allows for the incorporation of multiple catalytic sites within a single framework. This feature enables cascade reactions to occur in one pot, reducing the need for intermediate separation steps and consequently minimizing solvent use and energy consumption. Such process intensification aligns perfectly with green chemistry principles, promoting atom economy and step efficiency.

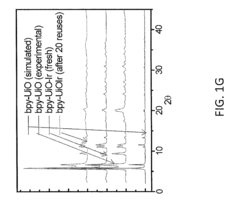

The recyclability of MOF catalysts also contributes significantly to their green chemistry impact. Many nanoscale MOFs can be easily recovered and reused multiple times without significant loss of catalytic activity. This characteristic not only reduces waste associated with single-use catalysts but also enhances the overall sustainability of chemical processes by extending the lifecycle of catalytic materials.

In the context of sustainable synthesis, MOFs themselves can be produced using green chemistry approaches. Methods such as mechanochemical synthesis or aqueous-based preparation techniques are being developed to reduce the environmental footprint of MOF production, further enhancing their credentials as green materials.

As research in this field progresses, the potential for nanoscale MOFs to revolutionize green chemistry continues to expand. Their ability to facilitate complex reaction pathways under milder conditions, coupled with their inherent sustainability features, positions them as key players in the transition towards more environmentally benign chemical processes. This alignment with green chemistry principles not only addresses current environmental challenges but also paves the way for innovative, sustainable technologies in the future.

Nanoscale MOFs contribute to greener chemical processes through their exceptional catalytic properties. Their high surface area and tunable pore structures allow for efficient mass transfer and selective molecular interactions, leading to improved reaction rates and reduced energy requirements. This efficiency translates to lower resource consumption and minimized waste generation, key objectives in green chemistry.

The versatility of MOFs in catalysis extends to various environmentally critical reactions. For instance, in CO2 conversion, nanoscale MOFs have shown promise in catalyzing the transformation of this greenhouse gas into value-added products, addressing both environmental concerns and resource utilization. Similarly, in water treatment applications, MOF-based catalysts have demonstrated effectiveness in degrading pollutants through advanced oxidation processes, offering a greener alternative to conventional treatment methods.

Furthermore, the modular nature of MOFs allows for the incorporation of multiple catalytic sites within a single framework. This feature enables cascade reactions to occur in one pot, reducing the need for intermediate separation steps and consequently minimizing solvent use and energy consumption. Such process intensification aligns perfectly with green chemistry principles, promoting atom economy and step efficiency.

The recyclability of MOF catalysts also contributes significantly to their green chemistry impact. Many nanoscale MOFs can be easily recovered and reused multiple times without significant loss of catalytic activity. This characteristic not only reduces waste associated with single-use catalysts but also enhances the overall sustainability of chemical processes by extending the lifecycle of catalytic materials.

In the context of sustainable synthesis, MOFs themselves can be produced using green chemistry approaches. Methods such as mechanochemical synthesis or aqueous-based preparation techniques are being developed to reduce the environmental footprint of MOF production, further enhancing their credentials as green materials.

As research in this field progresses, the potential for nanoscale MOFs to revolutionize green chemistry continues to expand. Their ability to facilitate complex reaction pathways under milder conditions, coupled with their inherent sustainability features, positions them as key players in the transition towards more environmentally benign chemical processes. This alignment with green chemistry principles not only addresses current environmental challenges but also paves the way for innovative, sustainable technologies in the future.

MOF Scalability Issues

The scalability of Metal-Organic Frameworks (MOFs) remains a significant challenge in their application for catalyzing complex reaction pathways at the nanoscale. While MOFs have shown tremendous potential in various catalytic processes, their large-scale production and implementation face several hurdles that need to be addressed for widespread industrial adoption.

One of the primary scalability issues is the synthesis of MOFs with consistent quality and properties at larger scales. Laboratory-scale synthesis methods often rely on precise control of reaction conditions, which becomes increasingly difficult to maintain in larger reactors. Variations in temperature, pressure, and reagent concentrations across larger volumes can lead to inconsistencies in crystal structure, porosity, and catalytic activity.

Another challenge lies in the cost-effective production of MOFs. Many MOFs require expensive organic linkers or metal precursors, making their large-scale synthesis economically unfeasible for certain applications. Additionally, the use of environmentally harmful solvents in traditional MOF synthesis methods poses sustainability concerns when scaling up production.

The stability of MOFs under industrial conditions is also a critical factor affecting their scalability. Many MOFs exhibit sensitivity to moisture, temperature, and chemical environments, which can lead to structural degradation and loss of catalytic activity over time. Developing MOFs with enhanced stability or protective strategies for existing MOFs is crucial for their long-term performance in industrial settings.

Post-synthesis processing and shaping of MOFs for practical applications present another scalability challenge. Many catalytic applications require MOFs to be formed into specific shapes or integrated into support structures, which can be difficult to achieve without compromising their unique properties. Techniques for large-scale extrusion, pelletization, or membrane formation of MOFs need further development.

Furthermore, the regeneration and recycling of MOFs in industrial processes pose significant challenges. Efficient methods for removing reaction products, regenerating catalytic sites, and maintaining structural integrity over multiple cycles are essential for the economic viability of MOF-based catalytic systems at scale.

Addressing these scalability issues requires a multidisciplinary approach, combining expertise in materials science, chemical engineering, and process optimization. Advances in continuous flow synthesis, solvent-free mechanochemical methods, and modular MOF design are promising directions for overcoming some of these challenges. Collaborative efforts between academia and industry will be crucial in bridging the gap between laboratory-scale discoveries and industrial-scale implementation of nanoscale MOFs in complex catalytic processes.

One of the primary scalability issues is the synthesis of MOFs with consistent quality and properties at larger scales. Laboratory-scale synthesis methods often rely on precise control of reaction conditions, which becomes increasingly difficult to maintain in larger reactors. Variations in temperature, pressure, and reagent concentrations across larger volumes can lead to inconsistencies in crystal structure, porosity, and catalytic activity.

Another challenge lies in the cost-effective production of MOFs. Many MOFs require expensive organic linkers or metal precursors, making their large-scale synthesis economically unfeasible for certain applications. Additionally, the use of environmentally harmful solvents in traditional MOF synthesis methods poses sustainability concerns when scaling up production.

The stability of MOFs under industrial conditions is also a critical factor affecting their scalability. Many MOFs exhibit sensitivity to moisture, temperature, and chemical environments, which can lead to structural degradation and loss of catalytic activity over time. Developing MOFs with enhanced stability or protective strategies for existing MOFs is crucial for their long-term performance in industrial settings.

Post-synthesis processing and shaping of MOFs for practical applications present another scalability challenge. Many catalytic applications require MOFs to be formed into specific shapes or integrated into support structures, which can be difficult to achieve without compromising their unique properties. Techniques for large-scale extrusion, pelletization, or membrane formation of MOFs need further development.

Furthermore, the regeneration and recycling of MOFs in industrial processes pose significant challenges. Efficient methods for removing reaction products, regenerating catalytic sites, and maintaining structural integrity over multiple cycles are essential for the economic viability of MOF-based catalytic systems at scale.

Addressing these scalability issues requires a multidisciplinary approach, combining expertise in materials science, chemical engineering, and process optimization. Advances in continuous flow synthesis, solvent-free mechanochemical methods, and modular MOF design are promising directions for overcoming some of these challenges. Collaborative efforts between academia and industry will be crucial in bridging the gap between laboratory-scale discoveries and industrial-scale implementation of nanoscale MOFs in complex catalytic processes.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!