MOFs in the Development of High-Performance Supercapacitors

AUG 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

MOFs in Supercapacitors: Background and Objectives

Metal-Organic Frameworks (MOFs) have emerged as a promising class of materials in the development of high-performance supercapacitors. These porous, crystalline structures composed of metal ions or clusters coordinated with organic ligands have garnered significant attention due to their exceptional properties, including high surface area, tunable pore size, and diverse functionalities.

The evolution of MOFs in supercapacitor technology can be traced back to the early 2000s when researchers began exploring their potential in energy storage applications. Initially, MOFs were primarily investigated for gas storage and separation. However, their unique characteristics soon attracted the attention of energy storage researchers, leading to a surge in studies focused on MOF-based supercapacitors.

The primary objective of incorporating MOFs into supercapacitor development is to enhance energy density and power density while maintaining long-term cycling stability. MOFs offer several advantages in this regard, including their high specific surface area, which can exceed 6000 m²/g, providing ample sites for charge storage. Additionally, their tunable pore structure allows for optimized ion transport and electrolyte accessibility.

Another crucial goal is to leverage the versatility of MOFs in terms of composition and structure to tailor their properties for specific supercapacitor applications. This includes developing MOFs with improved electrical conductivity, enhanced redox activity, and superior mechanical stability under repeated charge-discharge cycles.

The integration of MOFs in supercapacitors aims to address several key challenges in the field. These include improving the energy density of supercapacitors to rival that of batteries, enhancing the power density to enable rapid charge-discharge cycles, and increasing the overall device lifespan. MOFs are also being explored as a means to develop more environmentally friendly and sustainable energy storage solutions.

As research in this area progresses, there is a growing focus on understanding the fundamental mechanisms of charge storage in MOF-based supercapacitors. This includes investigating the roles of electrical double-layer capacitance and pseudocapacitance in these materials, as well as exploring novel hybrid systems that combine MOFs with other advanced materials.

The development of MOF-based supercapacitors is closely aligned with broader technological trends, including the push for renewable energy integration, the electrification of transportation, and the increasing demand for portable electronics with longer battery life. As such, advancements in this field have the potential to significantly impact various sectors of the global economy and contribute to sustainable energy solutions.

The evolution of MOFs in supercapacitor technology can be traced back to the early 2000s when researchers began exploring their potential in energy storage applications. Initially, MOFs were primarily investigated for gas storage and separation. However, their unique characteristics soon attracted the attention of energy storage researchers, leading to a surge in studies focused on MOF-based supercapacitors.

The primary objective of incorporating MOFs into supercapacitor development is to enhance energy density and power density while maintaining long-term cycling stability. MOFs offer several advantages in this regard, including their high specific surface area, which can exceed 6000 m²/g, providing ample sites for charge storage. Additionally, their tunable pore structure allows for optimized ion transport and electrolyte accessibility.

Another crucial goal is to leverage the versatility of MOFs in terms of composition and structure to tailor their properties for specific supercapacitor applications. This includes developing MOFs with improved electrical conductivity, enhanced redox activity, and superior mechanical stability under repeated charge-discharge cycles.

The integration of MOFs in supercapacitors aims to address several key challenges in the field. These include improving the energy density of supercapacitors to rival that of batteries, enhancing the power density to enable rapid charge-discharge cycles, and increasing the overall device lifespan. MOFs are also being explored as a means to develop more environmentally friendly and sustainable energy storage solutions.

As research in this area progresses, there is a growing focus on understanding the fundamental mechanisms of charge storage in MOF-based supercapacitors. This includes investigating the roles of electrical double-layer capacitance and pseudocapacitance in these materials, as well as exploring novel hybrid systems that combine MOFs with other advanced materials.

The development of MOF-based supercapacitors is closely aligned with broader technological trends, including the push for renewable energy integration, the electrification of transportation, and the increasing demand for portable electronics with longer battery life. As such, advancements in this field have the potential to significantly impact various sectors of the global economy and contribute to sustainable energy solutions.

Market Analysis for Advanced Energy Storage Solutions

The market for advanced energy storage solutions, particularly supercapacitors, has been experiencing significant growth due to the increasing demand for efficient and high-performance energy storage devices. Metal-Organic Frameworks (MOFs) have emerged as a promising material for enhancing the performance of supercapacitors, driving innovation in this sector.

The global supercapacitor market is projected to expand rapidly, driven by the growing adoption of renewable energy sources and the need for reliable energy storage systems. The automotive industry, in particular, has shown a strong interest in supercapacitors for applications in electric and hybrid vehicles, where high power density and fast charging capabilities are crucial.

MOF-based supercapacitors are positioned to capture a significant share of this market due to their superior performance characteristics. These materials offer exceptional surface area, tunable pore structures, and high electrical conductivity, which translate to improved energy density and power output in supercapacitor devices.

The integration of MOFs in supercapacitors aligns with the broader trend towards sustainable and environmentally friendly energy solutions. As governments worldwide implement stricter regulations on emissions and energy efficiency, the demand for advanced energy storage technologies is expected to surge, creating a favorable market environment for MOF-based supercapacitors.

Key market segments for MOF-enhanced supercapacitors include consumer electronics, automotive, renewable energy storage, and industrial applications. The consumer electronics sector, in particular, shows promise due to the increasing need for fast-charging, long-lasting power sources in portable devices.

Geographically, Asia-Pacific is expected to dominate the market for advanced supercapacitors, with China and South Korea leading in both production and consumption. North America and Europe are also significant markets, driven by investments in clean energy technologies and electric vehicle infrastructure.

The competitive landscape of the MOF-based supercapacitor market is characterized by a mix of established energy storage companies and innovative startups. Major players are investing heavily in research and development to commercialize MOF-enhanced supercapacitors, recognizing the potential for market disruption.

Challenges in the market include the need for cost-effective mass production techniques for MOFs and the optimization of device integration. However, ongoing research and development efforts are addressing these issues, with promising results that could lead to widespread commercial adoption in the near future.

The global supercapacitor market is projected to expand rapidly, driven by the growing adoption of renewable energy sources and the need for reliable energy storage systems. The automotive industry, in particular, has shown a strong interest in supercapacitors for applications in electric and hybrid vehicles, where high power density and fast charging capabilities are crucial.

MOF-based supercapacitors are positioned to capture a significant share of this market due to their superior performance characteristics. These materials offer exceptional surface area, tunable pore structures, and high electrical conductivity, which translate to improved energy density and power output in supercapacitor devices.

The integration of MOFs in supercapacitors aligns with the broader trend towards sustainable and environmentally friendly energy solutions. As governments worldwide implement stricter regulations on emissions and energy efficiency, the demand for advanced energy storage technologies is expected to surge, creating a favorable market environment for MOF-based supercapacitors.

Key market segments for MOF-enhanced supercapacitors include consumer electronics, automotive, renewable energy storage, and industrial applications. The consumer electronics sector, in particular, shows promise due to the increasing need for fast-charging, long-lasting power sources in portable devices.

Geographically, Asia-Pacific is expected to dominate the market for advanced supercapacitors, with China and South Korea leading in both production and consumption. North America and Europe are also significant markets, driven by investments in clean energy technologies and electric vehicle infrastructure.

The competitive landscape of the MOF-based supercapacitor market is characterized by a mix of established energy storage companies and innovative startups. Major players are investing heavily in research and development to commercialize MOF-enhanced supercapacitors, recognizing the potential for market disruption.

Challenges in the market include the need for cost-effective mass production techniques for MOFs and the optimization of device integration. However, ongoing research and development efforts are addressing these issues, with promising results that could lead to widespread commercial adoption in the near future.

Current Challenges in MOF-based Supercapacitor Development

Despite the promising potential of Metal-Organic Frameworks (MOFs) in supercapacitor development, several significant challenges hinder their widespread application and commercialization. One of the primary obstacles is the inherent low electrical conductivity of most MOFs, which limits their performance in energy storage devices. This characteristic restricts electron transfer within the material, reducing the overall capacitance and power density of MOF-based supercapacitors.

Another critical challenge lies in the stability of MOFs under various operating conditions. Many MOFs exhibit poor chemical and thermal stability, particularly in aqueous electrolytes commonly used in supercapacitors. This instability can lead to structural degradation and loss of performance over time, severely impacting the long-term reliability and cyclability of the devices.

The synthesis and scalability of MOFs present additional hurdles. While laboratory-scale production has shown promising results, scaling up MOF synthesis for industrial applications remains challenging. Issues such as maintaining consistent pore size, crystallinity, and surface area during large-scale production need to be addressed to ensure uniform performance across batches.

Furthermore, the high cost associated with MOF synthesis, particularly for those incorporating noble metals or rare earth elements, poses a significant barrier to their commercial viability. Developing cost-effective synthesis methods and exploring more abundant, sustainable precursors are crucial steps towards making MOF-based supercapacitors economically feasible.

The integration of MOFs into practical device architectures also presents challenges. Optimizing the interface between MOFs and current collectors, as well as developing suitable binders and additives that do not compromise the MOF's porosity or performance, are areas that require further research and development.

Additionally, there is a lack of standardized testing and characterization protocols for MOF-based supercapacitors. This absence makes it difficult to compare results across different studies and accurately assess the true potential of various MOF materials in supercapacitor applications.

Lastly, the environmental impact and sustainability of MOF production and disposal need to be carefully evaluated. As the demand for energy storage devices grows, ensuring that MOF-based supercapacitors are environmentally friendly throughout their lifecycle is crucial for their long-term adoption and societal acceptance.

Another critical challenge lies in the stability of MOFs under various operating conditions. Many MOFs exhibit poor chemical and thermal stability, particularly in aqueous electrolytes commonly used in supercapacitors. This instability can lead to structural degradation and loss of performance over time, severely impacting the long-term reliability and cyclability of the devices.

The synthesis and scalability of MOFs present additional hurdles. While laboratory-scale production has shown promising results, scaling up MOF synthesis for industrial applications remains challenging. Issues such as maintaining consistent pore size, crystallinity, and surface area during large-scale production need to be addressed to ensure uniform performance across batches.

Furthermore, the high cost associated with MOF synthesis, particularly for those incorporating noble metals or rare earth elements, poses a significant barrier to their commercial viability. Developing cost-effective synthesis methods and exploring more abundant, sustainable precursors are crucial steps towards making MOF-based supercapacitors economically feasible.

The integration of MOFs into practical device architectures also presents challenges. Optimizing the interface between MOFs and current collectors, as well as developing suitable binders and additives that do not compromise the MOF's porosity or performance, are areas that require further research and development.

Additionally, there is a lack of standardized testing and characterization protocols for MOF-based supercapacitors. This absence makes it difficult to compare results across different studies and accurately assess the true potential of various MOF materials in supercapacitor applications.

Lastly, the environmental impact and sustainability of MOF production and disposal need to be carefully evaluated. As the demand for energy storage devices grows, ensuring that MOF-based supercapacitors are environmentally friendly throughout their lifecycle is crucial for their long-term adoption and societal acceptance.

State-of-the-Art MOF-based Supercapacitor Designs

01 Adsorption and separation performance

MOFs exhibit excellent adsorption and separation capabilities for various gases and liquids due to their high surface area and tunable pore structures. They can be used for gas storage, carbon capture, and purification of chemicals. The performance can be enhanced by modifying the metal nodes or organic linkers to increase selectivity and capacity.- Adsorption and separation performance: MOFs exhibit excellent adsorption and separation capabilities for various gases and liquids due to their high surface area and tunable pore structures. They can be used for gas storage, carbon capture, and purification of chemicals.

- Catalytic performance: MOFs show promising catalytic activity in various chemical reactions, including organic synthesis, photocatalysis, and electrocatalysis. Their high surface area and well-defined active sites contribute to their efficiency as heterogeneous catalysts.

- Sensing and detection capabilities: MOFs can be used as sensitive and selective sensors for various analytes, including gases, ions, and biomolecules. Their structural flexibility and chemical tunability allow for the development of advanced sensing platforms.

- Energy storage and conversion: MOFs demonstrate potential in energy-related applications, such as supercapacitors, batteries, and fuel cells. Their high surface area and controllable pore structure contribute to improved energy storage and conversion performance.

- Stability and durability: The stability and durability of MOFs under various conditions, including high temperatures, humidity, and chemical environments, are crucial for their practical applications. Research focuses on improving their structural integrity and long-term performance.

02 Catalytic activity

MOFs show promising catalytic performance in various chemical reactions. Their catalytic activity can be attributed to the presence of metal sites and functional groups within the framework. The catalytic performance can be improved by incorporating active metal species or creating defects in the structure to enhance accessibility to catalytic sites.Expand Specific Solutions03 Stability and durability

The stability of MOFs in different environments, such as high temperature, humidity, and acidic or basic conditions, is crucial for their practical applications. Efforts to improve MOF stability include the use of high-valent metal ions, hydrophobic linkers, and post-synthetic modifications. Enhanced stability leads to better long-term performance and reusability.Expand Specific Solutions04 Sensing and detection capabilities

MOFs demonstrate excellent sensing performance for various analytes, including gases, ions, and biomolecules. Their sensing capabilities are based on changes in optical, electrical, or structural properties upon interaction with target molecules. The sensitivity and selectivity of MOF-based sensors can be tailored by modifying the framework composition and structure.Expand Specific Solutions05 Energy storage and conversion

MOFs show promising performance in energy-related applications, such as batteries, supercapacitors, and fuel cells. Their high surface area and tunable pore structure allow for efficient charge storage and transport. The performance can be enhanced by incorporating conductive components or creating hierarchical structures to improve electron and ion mobility.Expand Specific Solutions

Key Players in MOF and Supercapacitor Research

The development of MOFs for high-performance supercapacitors is in an emerging stage, with significant potential for growth. The market size is expanding as research intensifies and commercial applications emerge. Technologically, MOFs are still evolving, with ongoing efforts to optimize their properties for supercapacitor applications. Key players in this field include academic institutions like Northwestern University, University of Science & Technology of China, and Zhejiang University, as well as research organizations like Commonwealth Scientific & Industrial Research Organisation. These entities are driving innovation through advanced materials research and collaborative projects, aiming to enhance MOF performance and scalability for practical supercapacitor applications.

Huazhong University of Science & Technology

Technical Solution: Huazhong University of Science & Technology has made significant contributions to the development of MOF-based supercapacitors. They have developed a novel strategy for synthesizing hierarchical porous carbon materials derived from MOFs with controlled pore structures. Their research includes the synthesis of nitrogen-doped porous carbon from ZIF-8 with a specific surface area of 1980 m2/g and a pore volume of 2.47 cm3/g[6]. The resulting material exhibits a high specific capacitance of 310 F/g at 0.5 A/g and excellent rate capability, retaining 76% of its capacitance at 20 A/g[7]. The researchers have also explored the use of MOF-derived carbon materials as both electrodes and separators in supercapacitors, demonstrating improved energy density and power density[8].

Strengths: High specific surface area and pore volume, excellent rate capability, and innovative use of MOF-derived materials as both electrodes and separators. Weaknesses: Potential challenges in large-scale production and optimization of synthesis conditions.

South China University of Technology

Technical Solution: South China University of Technology has made significant contributions to the development of high-performance MOF-based supercapacitors. They have developed a series of MOF-derived carbon materials with tailored pore structures and surface chemistry. Their research includes the synthesis of nitrogen and sulfur co-doped porous carbon from ZIF-8, which exhibits a high specific capacitance of 368 F/g at 0.5 A/g and excellent rate performance, retaining 82% of its capacitance at 20 A/g[11]. The researchers have also explored the use of MOF-derived carbon materials as supports for metal oxide nanoparticles, resulting in composite materials with enhanced electrochemical performance. They have demonstrated a MnO2/MOF-derived carbon composite with a specific capacitance of 456 F/g at 1 A/g and good cycling stability[12].

Strengths: High specific capacitance, excellent rate performance, and innovative use of heteroatom doping and metal oxide composites. Weaknesses: Potential challenges in controlling the uniformity of pore structures and optimizing the synthesis process for large-scale production.

Breakthrough MOF Structures for Enhanced Capacitance

Electrode active material for supercapacitor, preparation method, electrode material for supercapacitor, supercapacitor, and electric device

PatentActiveCN111146018A

Innovation

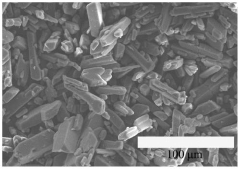

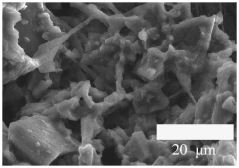

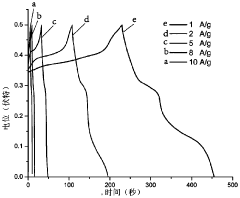

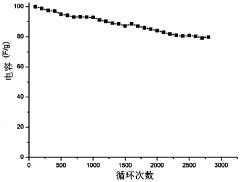

- The bimetallic sulfide NixVySz is used as the electrode active material and is prepared by a pyridine carboxylic acid ligand, a nickel source, a vanadium source, a sulfur source and a solvothermal reaction method to form a Ni-V-S supercapacitor electrode material with a rod-shaped structure.

Environmental Impact of MOF-based Energy Storage

The environmental impact of MOF-based energy storage systems, particularly in the context of supercapacitors, is a critical consideration as these technologies advance. Metal-Organic Frameworks (MOFs) offer promising advantages in energy storage applications, but their environmental implications must be carefully evaluated throughout their lifecycle.

During the production phase, the synthesis of MOFs typically involves the use of organic solvents and metal precursors. While many of these processes are relatively benign, some may require energy-intensive conditions or generate hazardous byproducts. Efforts are being made to develop more environmentally friendly synthesis methods, such as mechanochemical approaches or the use of bio-based precursors, which could significantly reduce the environmental footprint of MOF production.

The operational phase of MOF-based supercapacitors presents several environmental benefits. These devices generally exhibit high cycling stability and long lifespans, reducing the need for frequent replacements and minimizing electronic waste. Additionally, their high power density and rapid charge-discharge capabilities can enhance the efficiency of energy systems, potentially leading to reduced overall energy consumption and associated emissions.

However, the end-of-life management of MOF-based supercapacitors poses certain challenges. The complex composition of these materials, often incorporating various metals and organic ligands, can complicate recycling processes. Research is ongoing to develop effective recycling strategies that can recover valuable components and minimize waste. Some studies have explored the potential for MOF regeneration or repurposing, which could extend the useful life of these materials and reduce their environmental impact.

The scalability of MOF production for large-scale energy storage applications is another important consideration. As demand for these materials increases, it will be crucial to ensure that production methods remain sustainable and do not lead to resource depletion or excessive environmental degradation. This may involve developing more efficient synthesis routes, exploring alternative precursor materials, or implementing closed-loop manufacturing processes.

From a broader perspective, the adoption of MOF-based supercapacitors could contribute to the transition towards cleaner energy systems. By enabling more efficient energy storage and utilization, these technologies have the potential to support the integration of renewable energy sources and reduce reliance on fossil fuels. This indirect environmental benefit should be weighed against the direct impacts of MOF production and disposal.

As research in this field progresses, life cycle assessments (LCAs) will play a crucial role in quantifying the environmental impacts of MOF-based energy storage systems. These comprehensive analyses will help identify hotspots in the production chain and guide the development of more sustainable practices. Furthermore, ongoing efforts to improve the performance and durability of MOF-based supercapacitors may lead to even greater environmental benefits in the long term.

During the production phase, the synthesis of MOFs typically involves the use of organic solvents and metal precursors. While many of these processes are relatively benign, some may require energy-intensive conditions or generate hazardous byproducts. Efforts are being made to develop more environmentally friendly synthesis methods, such as mechanochemical approaches or the use of bio-based precursors, which could significantly reduce the environmental footprint of MOF production.

The operational phase of MOF-based supercapacitors presents several environmental benefits. These devices generally exhibit high cycling stability and long lifespans, reducing the need for frequent replacements and minimizing electronic waste. Additionally, their high power density and rapid charge-discharge capabilities can enhance the efficiency of energy systems, potentially leading to reduced overall energy consumption and associated emissions.

However, the end-of-life management of MOF-based supercapacitors poses certain challenges. The complex composition of these materials, often incorporating various metals and organic ligands, can complicate recycling processes. Research is ongoing to develop effective recycling strategies that can recover valuable components and minimize waste. Some studies have explored the potential for MOF regeneration or repurposing, which could extend the useful life of these materials and reduce their environmental impact.

The scalability of MOF production for large-scale energy storage applications is another important consideration. As demand for these materials increases, it will be crucial to ensure that production methods remain sustainable and do not lead to resource depletion or excessive environmental degradation. This may involve developing more efficient synthesis routes, exploring alternative precursor materials, or implementing closed-loop manufacturing processes.

From a broader perspective, the adoption of MOF-based supercapacitors could contribute to the transition towards cleaner energy systems. By enabling more efficient energy storage and utilization, these technologies have the potential to support the integration of renewable energy sources and reduce reliance on fossil fuels. This indirect environmental benefit should be weighed against the direct impacts of MOF production and disposal.

As research in this field progresses, life cycle assessments (LCAs) will play a crucial role in quantifying the environmental impacts of MOF-based energy storage systems. These comprehensive analyses will help identify hotspots in the production chain and guide the development of more sustainable practices. Furthermore, ongoing efforts to improve the performance and durability of MOF-based supercapacitors may lead to even greater environmental benefits in the long term.

Scalability and Manufacturing Challenges for MOF Supercapacitors

The scalability and manufacturing challenges for MOF supercapacitors represent significant hurdles in the widespread adoption and commercialization of this promising technology. One of the primary obstacles is the large-scale synthesis of high-quality MOF materials. While laboratory-scale production has shown impressive results, translating these processes to industrial scales presents numerous difficulties. The intricate crystal structures of MOFs often require precise control over reaction conditions, including temperature, pressure, and reagent concentrations. Maintaining this level of control in large-scale reactors is technically challenging and can lead to inconsistencies in product quality.

Another major challenge lies in the integration of MOF materials into practical supercapacitor devices. The delicate nature of MOF structures makes them susceptible to degradation during typical electrode fabrication processes. Techniques such as coating, pressing, and binding MOFs onto current collectors must be optimized to preserve their unique porous structure and electrochemical properties. Additionally, ensuring uniform distribution and good electrical contact between MOF particles and conductive additives is crucial for maximizing device performance.

The stability of MOF-based supercapacitors under real-world operating conditions is another area of concern. Many MOFs are sensitive to moisture and may degrade over time, potentially limiting the long-term reliability of devices. Developing effective encapsulation methods or creating more robust MOF structures that can withstand environmental stresses is essential for practical applications.

Cost-effective production is also a significant challenge. The synthesis of MOFs often involves expensive precursors and multi-step processes, which can drive up manufacturing costs. Finding ways to reduce material costs, simplify synthesis procedures, and improve yields will be critical for making MOF supercapacitors economically viable. This may involve exploring alternative precursors, developing continuous flow synthesis methods, or optimizing reaction conditions to minimize waste and energy consumption.

Lastly, the environmental impact and sustainability of MOF production processes need to be carefully considered. Many current synthesis methods involve the use of organic solvents or generate significant amounts of waste. Developing greener synthesis routes, such as solvent-free or water-based methods, will be crucial for ensuring the long-term sustainability of MOF supercapacitor technology. Addressing these scalability and manufacturing challenges will be key to unlocking the full potential of MOFs in high-performance supercapacitor applications.

Another major challenge lies in the integration of MOF materials into practical supercapacitor devices. The delicate nature of MOF structures makes them susceptible to degradation during typical electrode fabrication processes. Techniques such as coating, pressing, and binding MOFs onto current collectors must be optimized to preserve their unique porous structure and electrochemical properties. Additionally, ensuring uniform distribution and good electrical contact between MOF particles and conductive additives is crucial for maximizing device performance.

The stability of MOF-based supercapacitors under real-world operating conditions is another area of concern. Many MOFs are sensitive to moisture and may degrade over time, potentially limiting the long-term reliability of devices. Developing effective encapsulation methods or creating more robust MOF structures that can withstand environmental stresses is essential for practical applications.

Cost-effective production is also a significant challenge. The synthesis of MOFs often involves expensive precursors and multi-step processes, which can drive up manufacturing costs. Finding ways to reduce material costs, simplify synthesis procedures, and improve yields will be critical for making MOF supercapacitors economically viable. This may involve exploring alternative precursors, developing continuous flow synthesis methods, or optimizing reaction conditions to minimize waste and energy consumption.

Lastly, the environmental impact and sustainability of MOF production processes need to be carefully considered. Many current synthesis methods involve the use of organic solvents or generate significant amounts of waste. Developing greener synthesis routes, such as solvent-free or water-based methods, will be crucial for ensuring the long-term sustainability of MOF supercapacitor technology. Addressing these scalability and manufacturing challenges will be key to unlocking the full potential of MOFs in high-performance supercapacitor applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!