Enhancement of Molecular Sieving in Pore-Engineered MOFs

AUG 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

MOF Sieving Background

Metal-Organic Frameworks (MOFs) have emerged as a revolutionary class of porous materials, garnering significant attention in the field of molecular sieving. These crystalline structures, composed of metal ions or clusters coordinated to organic ligands, offer unprecedented levels of porosity and surface area, making them ideal candidates for selective gas separation and purification processes.

The concept of molecular sieving in MOFs dates back to the early 2000s when researchers began exploring their potential for gas storage and separation. The unique ability of MOFs to be tailored at the molecular level, allowing for precise control over pore size and chemistry, has been a driving force behind their rapid development in the field of molecular sieving.

Over the past two decades, MOFs have demonstrated exceptional performance in various molecular sieving applications, including carbon capture, hydrogen purification, and hydrocarbon separation. Their success can be attributed to their highly ordered and tunable pore structures, which enable size-based and chemical-based selectivity for target molecules.

The evolution of MOF-based molecular sieving has been marked by several key milestones. Initially, research focused on developing MOFs with high surface areas and pore volumes. This was followed by efforts to create MOFs with specific pore sizes and shapes to enhance selectivity for particular molecules. More recently, attention has shifted towards engineering MOFs with multiple levels of porosity and functionalized pore surfaces to achieve more complex separation tasks.

One of the most significant advancements in MOF sieving technology has been the development of mixed-matrix membranes (MMMs) incorporating MOFs. These composite materials combine the high selectivity of MOFs with the processability of polymers, offering a practical solution for large-scale molecular sieving applications.

Despite the remarkable progress, challenges remain in the field of MOF-based molecular sieving. These include improving the stability of MOFs under harsh operating conditions, enhancing their selectivity for closely related molecules, and scaling up production for industrial applications. Addressing these challenges is crucial for the widespread adoption of MOF-based molecular sieving technologies.

As research in this field continues to advance, new frontiers are being explored. These include the development of stimuli-responsive MOFs that can dynamically adjust their pore characteristics, the integration of MOFs with other advanced materials for enhanced performance, and the application of artificial intelligence and machine learning techniques to predict and design optimal MOF structures for specific sieving tasks.

The concept of molecular sieving in MOFs dates back to the early 2000s when researchers began exploring their potential for gas storage and separation. The unique ability of MOFs to be tailored at the molecular level, allowing for precise control over pore size and chemistry, has been a driving force behind their rapid development in the field of molecular sieving.

Over the past two decades, MOFs have demonstrated exceptional performance in various molecular sieving applications, including carbon capture, hydrogen purification, and hydrocarbon separation. Their success can be attributed to their highly ordered and tunable pore structures, which enable size-based and chemical-based selectivity for target molecules.

The evolution of MOF-based molecular sieving has been marked by several key milestones. Initially, research focused on developing MOFs with high surface areas and pore volumes. This was followed by efforts to create MOFs with specific pore sizes and shapes to enhance selectivity for particular molecules. More recently, attention has shifted towards engineering MOFs with multiple levels of porosity and functionalized pore surfaces to achieve more complex separation tasks.

One of the most significant advancements in MOF sieving technology has been the development of mixed-matrix membranes (MMMs) incorporating MOFs. These composite materials combine the high selectivity of MOFs with the processability of polymers, offering a practical solution for large-scale molecular sieving applications.

Despite the remarkable progress, challenges remain in the field of MOF-based molecular sieving. These include improving the stability of MOFs under harsh operating conditions, enhancing their selectivity for closely related molecules, and scaling up production for industrial applications. Addressing these challenges is crucial for the widespread adoption of MOF-based molecular sieving technologies.

As research in this field continues to advance, new frontiers are being explored. These include the development of stimuli-responsive MOFs that can dynamically adjust their pore characteristics, the integration of MOFs with other advanced materials for enhanced performance, and the application of artificial intelligence and machine learning techniques to predict and design optimal MOF structures for specific sieving tasks.

Market Analysis MOFs

The market for Metal-Organic Frameworks (MOFs) has been experiencing significant growth in recent years, driven by their unique properties and diverse applications. The global MOF market was valued at approximately $70 million in 2020 and is projected to reach $200 million by 2025, with a compound annual growth rate (CAGR) of over 20%. This rapid expansion is primarily attributed to the increasing demand for advanced materials in various industries, including gas storage, separation, catalysis, and sensing.

The gas separation and storage segment currently dominates the MOF market, accounting for nearly 40% of the total market share. This is largely due to the growing need for efficient carbon capture and storage solutions, as well as the rising demand for clean energy alternatives such as hydrogen storage. The catalysis segment is also showing promising growth, with applications in chemical synthesis, environmental remediation, and fuel cell technology.

Geographically, North America and Europe are the leading markets for MOFs, collectively accounting for over 60% of the global market share. This dominance is attributed to the presence of major research institutions, technological advancements, and substantial investments in R&D activities. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, driven by rapid industrialization, increasing environmental concerns, and government initiatives to promote clean energy technologies.

The enhancement of molecular sieving in pore-engineered MOFs is expected to further expand market opportunities, particularly in the gas separation and purification sectors. This advancement could lead to more efficient and cost-effective separation processes, potentially disrupting traditional separation technologies such as cryogenic distillation and pressure swing adsorption.

Key market players in the MOF industry include BASF SE, MOF Technologies Ltd, NuMat Technologies, and Strem Chemicals, Inc. These companies are actively investing in research and development to improve MOF performance and scalability. The market is also witnessing an increasing number of collaborations between academic institutions and industry partners, aimed at accelerating the commercialization of MOF-based technologies.

Despite the promising growth prospects, challenges such as high production costs and scalability issues continue to hinder widespread adoption. However, ongoing research in pore engineering and synthesis methods is expected to address these challenges, potentially leading to broader market penetration and new application areas for MOFs in the near future.

The gas separation and storage segment currently dominates the MOF market, accounting for nearly 40% of the total market share. This is largely due to the growing need for efficient carbon capture and storage solutions, as well as the rising demand for clean energy alternatives such as hydrogen storage. The catalysis segment is also showing promising growth, with applications in chemical synthesis, environmental remediation, and fuel cell technology.

Geographically, North America and Europe are the leading markets for MOFs, collectively accounting for over 60% of the global market share. This dominance is attributed to the presence of major research institutions, technological advancements, and substantial investments in R&D activities. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, driven by rapid industrialization, increasing environmental concerns, and government initiatives to promote clean energy technologies.

The enhancement of molecular sieving in pore-engineered MOFs is expected to further expand market opportunities, particularly in the gas separation and purification sectors. This advancement could lead to more efficient and cost-effective separation processes, potentially disrupting traditional separation technologies such as cryogenic distillation and pressure swing adsorption.

Key market players in the MOF industry include BASF SE, MOF Technologies Ltd, NuMat Technologies, and Strem Chemicals, Inc. These companies are actively investing in research and development to improve MOF performance and scalability. The market is also witnessing an increasing number of collaborations between academic institutions and industry partners, aimed at accelerating the commercialization of MOF-based technologies.

Despite the promising growth prospects, challenges such as high production costs and scalability issues continue to hinder widespread adoption. However, ongoing research in pore engineering and synthesis methods is expected to address these challenges, potentially leading to broader market penetration and new application areas for MOFs in the near future.

MOF Pore Engineering

Metal-Organic Frameworks (MOFs) have emerged as a promising class of porous materials with diverse applications in gas storage, separation, catalysis, and sensing. The ability to engineer the pore structure of MOFs at the molecular level has opened up new avenues for enhancing their performance in various applications, particularly in molecular sieving.

Pore engineering in MOFs involves the deliberate modification of pore size, shape, and functionality to achieve desired properties. This can be accomplished through various strategies, including ligand design, post-synthetic modification, and the incorporation of functional groups or nanoparticles within the pores. The primary goal of pore engineering is to optimize the selectivity and efficiency of molecular sieving processes.

One of the key approaches in MOF pore engineering is the use of extended organic linkers to create larger pores while maintaining structural stability. This strategy has led to the development of ultra-high porosity MOFs with exceptional surface areas and gas storage capacities. However, controlling pore size distribution and preventing interpenetration remain significant challenges in this approach.

Another important aspect of pore engineering is the introduction of functional groups within the pores to enhance selectivity and affinity towards specific molecules. This can be achieved through the use of functionalized organic linkers during synthesis or through post-synthetic modification techniques. The strategic placement of functional groups can create specific binding sites or alter the electronic properties of the pore surface, leading to improved molecular recognition and separation performance.

The development of hierarchical pore structures in MOFs has also gained significant attention in recent years. By combining micropores with meso- and macropores, these materials can overcome diffusion limitations and provide enhanced mass transport properties. This approach has shown great promise in catalysis and large molecule separations.

Defect engineering has emerged as a powerful tool for tailoring the pore structure of MOFs. Controlled introduction of defects, such as missing linkers or nodes, can create additional porosity and active sites within the framework. This strategy has been successfully employed to enhance gas uptake and catalytic activity in various MOF systems.

Recent advances in computational modeling and simulation techniques have greatly accelerated the design and optimization of pore-engineered MOFs. These tools allow researchers to predict the performance of hypothetical structures and guide experimental efforts towards the most promising candidates for specific applications.

In conclusion, pore engineering in MOFs represents a powerful approach for enhancing molecular sieving capabilities. By precisely controlling the size, shape, and chemical environment of the pores, researchers can develop highly selective and efficient materials for a wide range of separation and purification processes. As the field continues to advance, the integration of multiple engineering strategies and the development of novel characterization techniques will likely lead to even more sophisticated and high-performance MOF materials.

Pore engineering in MOFs involves the deliberate modification of pore size, shape, and functionality to achieve desired properties. This can be accomplished through various strategies, including ligand design, post-synthetic modification, and the incorporation of functional groups or nanoparticles within the pores. The primary goal of pore engineering is to optimize the selectivity and efficiency of molecular sieving processes.

One of the key approaches in MOF pore engineering is the use of extended organic linkers to create larger pores while maintaining structural stability. This strategy has led to the development of ultra-high porosity MOFs with exceptional surface areas and gas storage capacities. However, controlling pore size distribution and preventing interpenetration remain significant challenges in this approach.

Another important aspect of pore engineering is the introduction of functional groups within the pores to enhance selectivity and affinity towards specific molecules. This can be achieved through the use of functionalized organic linkers during synthesis or through post-synthetic modification techniques. The strategic placement of functional groups can create specific binding sites or alter the electronic properties of the pore surface, leading to improved molecular recognition and separation performance.

The development of hierarchical pore structures in MOFs has also gained significant attention in recent years. By combining micropores with meso- and macropores, these materials can overcome diffusion limitations and provide enhanced mass transport properties. This approach has shown great promise in catalysis and large molecule separations.

Defect engineering has emerged as a powerful tool for tailoring the pore structure of MOFs. Controlled introduction of defects, such as missing linkers or nodes, can create additional porosity and active sites within the framework. This strategy has been successfully employed to enhance gas uptake and catalytic activity in various MOF systems.

Recent advances in computational modeling and simulation techniques have greatly accelerated the design and optimization of pore-engineered MOFs. These tools allow researchers to predict the performance of hypothetical structures and guide experimental efforts towards the most promising candidates for specific applications.

In conclusion, pore engineering in MOFs represents a powerful approach for enhancing molecular sieving capabilities. By precisely controlling the size, shape, and chemical environment of the pores, researchers can develop highly selective and efficient materials for a wide range of separation and purification processes. As the field continues to advance, the integration of multiple engineering strategies and the development of novel characterization techniques will likely lead to even more sophisticated and high-performance MOF materials.

Current MOF Solutions

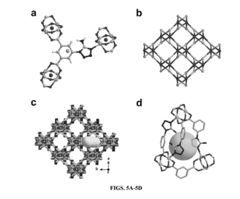

01 Synthesis and structure of MOFs for molecular sieving

Metal-Organic Frameworks (MOFs) are synthesized with specific structures and pore sizes to enable effective molecular sieving. The design and synthesis of these MOFs focus on creating uniform pore sizes and high surface areas to selectively separate molecules based on their size and shape.- Synthesis and structure of MOFs for molecular sieving: Metal-Organic Frameworks (MOFs) are synthesized with specific structures and pore sizes to enable effective molecular sieving. The design and fabrication of these MOFs focus on creating uniform pore distributions and tailored chemical functionalities to achieve selective separation of molecules based on size and chemical properties.

- Gas separation and purification using MOF-based molecular sieves: MOFs are utilized for gas separation and purification processes, leveraging their molecular sieving properties. These frameworks are particularly effective in separating gas mixtures, such as CO2 capture from flue gas, hydrogen purification, and natural gas upgrading, due to their high selectivity and adsorption capacity.

- Liquid-phase separations using MOF molecular sieves: MOF-based molecular sieves are applied in liquid-phase separations, including the purification of organic solvents, removal of contaminants from water, and separation of isomers or chiral molecules. The unique pore structures and chemical functionalities of MOFs enable highly selective separations in liquid media.

- Modification and functionalization of MOFs for enhanced molecular sieving: Researchers focus on modifying and functionalizing MOFs to enhance their molecular sieving performance. This includes post-synthetic modifications, incorporation of specific functional groups, and creation of composite materials to improve selectivity, stability, and efficiency in various separation processes.

- Application of MOF molecular sieves in membrane technologies: MOF-based molecular sieves are integrated into membrane technologies for advanced separation processes. These membranes combine the molecular sieving properties of MOFs with the continuous flow capabilities of membranes, offering high-performance solutions for gas and liquid separations in various industrial applications.

02 Gas separation and purification using MOF-based molecular sieves

MOFs are utilized for gas separation and purification processes, leveraging their molecular sieving properties. These frameworks can selectively adsorb and separate different gas molecules, making them valuable for applications such as carbon capture, hydrogen purification, and natural gas upgrading.Expand Specific Solutions03 Functionalization of MOFs for enhanced molecular sieving

MOFs are functionalized with specific chemical groups or modified post-synthesis to enhance their molecular sieving capabilities. These modifications can improve selectivity, stability, and efficiency in separating target molecules from mixtures.Expand Specific Solutions04 MOF-based membranes for molecular separation

MOF-based membranes are developed for continuous molecular separation processes. These membranes combine the molecular sieving properties of MOFs with the advantages of membrane technology, enabling efficient and selective separation of gases and liquids.Expand Specific Solutions05 Application of MOF molecular sieves in water treatment

MOF-based molecular sieves are applied in water treatment processes for the removal of contaminants and pollutants. The selective adsorption and separation capabilities of MOFs are utilized to purify water by removing specific molecules or ions from aqueous solutions.Expand Specific Solutions

Key MOF Developers

The enhancement of molecular sieving in pore-engineered MOFs is an emerging field in advanced materials science, currently in its growth phase. The market for these materials is expanding, driven by applications in gas separation, water purification, and energy storage. The technology's maturity varies among key players, with companies like UOP LLC and SABIC Global Technologies BV leading in industrial applications. Academic institutions such as the University of Liverpool and Monash University are advancing fundamental research. Collaborations between industry and academia, exemplified by partnerships involving the CNRS and Georgia Tech Research Corp., are accelerating innovation in this domain.

UOP LLC

Technical Solution: UOP LLC has developed advanced molecular sieving techniques for MOFs, focusing on pore engineering to enhance separation efficiency. Their approach involves precise control of pore size and shape through ligand functionalization and post-synthetic modification[1]. They have successfully created MOFs with tailored pore structures that exhibit improved selectivity for specific gas molecules, such as CO2 capture from flue gas streams[3]. UOP's technology also incorporates the use of mixed-matrix membranes, combining MOFs with polymeric materials to create highly permeable and selective separation systems[5].

Strengths: Industry-leading expertise in MOF synthesis and modification; extensive experience in industrial-scale implementation. Weaknesses: Potential high costs associated with complex MOF synthesis and scale-up challenges.

The Georgia Tech Research Corp.

Technical Solution: The Georgia Tech Research Corp. has pioneered innovative approaches to enhance molecular sieving in MOFs through advanced pore engineering techniques. Their research focuses on developing hierarchical pore structures within MOFs, combining micropores for selective molecular sieving with mesopores for improved mass transport[2]. They have successfully synthesized MOFs with controlled pore size distributions using template-directed synthesis methods and post-synthetic pore expansion techniques[4]. Additionally, their work includes the integration of functional groups within MOF pores to enhance selectivity and affinity for target molecules[6].

Strengths: Cutting-edge research in hierarchical pore structures; strong academic-industry collaborations. Weaknesses: Potential challenges in scaling up complex synthesis methods for industrial applications.

MOF Sieving Innovations

Microporous metal-organic frameworks for the removal of acetylene from ethylene

PatentActiveUS20180085733A1

Innovation

- Development of a specific MOF with a repeat unit [ML] where M is a divalent transition metal cation, such as copper, and L is a ligand with specific aromatic groups, which allows for selective sorption of acetylene over ethylene, achieving high selectivity and uptake capacity through tailored pore structure and functionalization.

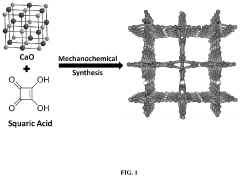

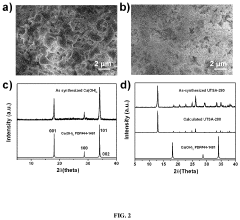

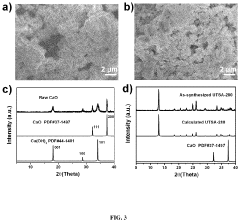

Mechanochemical synthesis of metal-organic frameworks for molecular sieving and compositions and methods of use thereof

PatentActiveUS20210284661A1

Innovation

- A method for preparing the metal-organic framework UTSA-280 through mechanochemical synthesis using calcium oxide or calcium hydroxide and squaric acid, which allows for the selective separation of ethylene from ethane by forming a MOF with specific pore sizes that exclude ethane, enabling efficient gas separation without generating stoichiometric salt byproducts.

Environmental Impact

The enhancement of molecular sieving in pore-engineered Metal-Organic Frameworks (MOFs) has significant environmental implications. These advanced materials offer promising solutions for various environmental challenges, particularly in the realm of gas separation and purification.

One of the primary environmental benefits of improved molecular sieving in MOFs is their potential for more efficient carbon capture and storage. As global efforts to mitigate climate change intensify, the ability to selectively capture CO2 from industrial emissions becomes increasingly crucial. Pore-engineered MOFs with enhanced molecular sieving properties can potentially achieve higher CO2 selectivity and capacity, leading to more effective greenhouse gas reduction strategies.

In the context of air purification, these advanced MOFs can contribute to improved indoor and outdoor air quality. Their ability to selectively filter out harmful pollutants, such as volatile organic compounds (VOCs) and particulate matter, can lead to the development of more efficient air filtration systems. This has far-reaching implications for public health, especially in urban environments where air pollution is a significant concern.

Water treatment is another area where enhanced molecular sieving in MOFs can make a substantial environmental impact. These materials can be engineered to remove specific contaminants from water, including heavy metals, organic pollutants, and even microplastics. The potential for developing more effective and energy-efficient water purification technologies using these advanced MOFs could help address global water scarcity issues and improve access to clean water in developing regions.

Furthermore, the application of these materials in industrial processes can lead to reduced energy consumption and waste generation. By enabling more precise separation of gases and liquids, pore-engineered MOFs can enhance the efficiency of various industrial processes, from petrochemical refining to pharmaceutical production. This increased efficiency translates to lower energy requirements and fewer byproducts, contributing to overall environmental sustainability in the industrial sector.

The development of these advanced MOFs also has implications for renewable energy technologies. For instance, in hydrogen fuel cells, improved gas separation capabilities can lead to more efficient hydrogen purification processes, potentially accelerating the adoption of hydrogen as a clean energy carrier. Similarly, in the field of natural gas purification, enhanced molecular sieving can result in cleaner burning fuels and reduced emissions from natural gas power plants.

However, it is important to consider the potential environmental impacts of MOF production and disposal. As research in this field progresses, attention must be given to developing sustainable synthesis methods and exploring the recyclability and end-of-life management of these materials to ensure their overall environmental benefit throughout their lifecycle.

One of the primary environmental benefits of improved molecular sieving in MOFs is their potential for more efficient carbon capture and storage. As global efforts to mitigate climate change intensify, the ability to selectively capture CO2 from industrial emissions becomes increasingly crucial. Pore-engineered MOFs with enhanced molecular sieving properties can potentially achieve higher CO2 selectivity and capacity, leading to more effective greenhouse gas reduction strategies.

In the context of air purification, these advanced MOFs can contribute to improved indoor and outdoor air quality. Their ability to selectively filter out harmful pollutants, such as volatile organic compounds (VOCs) and particulate matter, can lead to the development of more efficient air filtration systems. This has far-reaching implications for public health, especially in urban environments where air pollution is a significant concern.

Water treatment is another area where enhanced molecular sieving in MOFs can make a substantial environmental impact. These materials can be engineered to remove specific contaminants from water, including heavy metals, organic pollutants, and even microplastics. The potential for developing more effective and energy-efficient water purification technologies using these advanced MOFs could help address global water scarcity issues and improve access to clean water in developing regions.

Furthermore, the application of these materials in industrial processes can lead to reduced energy consumption and waste generation. By enabling more precise separation of gases and liquids, pore-engineered MOFs can enhance the efficiency of various industrial processes, from petrochemical refining to pharmaceutical production. This increased efficiency translates to lower energy requirements and fewer byproducts, contributing to overall environmental sustainability in the industrial sector.

The development of these advanced MOFs also has implications for renewable energy technologies. For instance, in hydrogen fuel cells, improved gas separation capabilities can lead to more efficient hydrogen purification processes, potentially accelerating the adoption of hydrogen as a clean energy carrier. Similarly, in the field of natural gas purification, enhanced molecular sieving can result in cleaner burning fuels and reduced emissions from natural gas power plants.

However, it is important to consider the potential environmental impacts of MOF production and disposal. As research in this field progresses, attention must be given to developing sustainable synthesis methods and exploring the recyclability and end-of-life management of these materials to ensure their overall environmental benefit throughout their lifecycle.

MOF Scalability

The scalability of Metal-Organic Frameworks (MOFs) is a critical factor in their potential for industrial applications, particularly in the context of enhancing molecular sieving through pore engineering. As research in MOF synthesis and modification continues to advance, the ability to produce these materials on a large scale becomes increasingly important.

One of the primary challenges in MOF scalability is maintaining the desired pore structure and properties during scale-up processes. Laboratory-scale synthesis methods often rely on precise control of reaction conditions, which can be difficult to replicate in industrial settings. However, recent developments in continuous flow synthesis and mechanochemical approaches have shown promise in addressing this issue.

Continuous flow synthesis methods allow for the production of MOFs in a more controlled and consistent manner. By precisely regulating reaction parameters such as temperature, pressure, and reagent concentrations, these techniques can produce MOFs with uniform pore sizes and structures at larger scales. This approach has been successfully demonstrated for several MOF types, including those with enhanced molecular sieving properties.

Mechanochemical synthesis, which involves the use of mechanical energy to drive chemical reactions, offers another avenue for scaling up MOF production. This solvent-free or solvent-reduced method can significantly reduce waste and energy consumption compared to traditional solution-based syntheses. Moreover, it has been shown to produce MOFs with comparable or even superior properties to those synthesized through conventional methods.

The development of modular and scalable reactor designs has also contributed to improved MOF scalability. These systems allow for easier scale-up from laboratory to pilot plant levels, maintaining the critical parameters necessary for producing high-quality, pore-engineered MOFs. Such reactors often incorporate in-line monitoring and control systems to ensure consistency across batches.

Despite these advancements, challenges remain in the large-scale production of MOFs with precisely engineered pores for molecular sieving applications. The cost of raw materials, particularly organic linkers, can be a limiting factor in industrial-scale production. Efforts to develop more cost-effective precursors and optimize synthesis routes are ongoing to address this issue.

Furthermore, post-synthetic modification techniques, which are often crucial for fine-tuning pore structures, must be adapted for large-scale processes. This includes developing efficient activation methods to remove guest molecules and solvents from MOF pores without compromising the framework integrity.

As research progresses, the focus on scalability is likely to intensify, driving innovations in synthesis methods, reactor designs, and process optimization. These developments will be crucial in bridging the gap between laboratory-scale discoveries and industrial-scale applications of pore-engineered MOFs for enhanced molecular sieving.

One of the primary challenges in MOF scalability is maintaining the desired pore structure and properties during scale-up processes. Laboratory-scale synthesis methods often rely on precise control of reaction conditions, which can be difficult to replicate in industrial settings. However, recent developments in continuous flow synthesis and mechanochemical approaches have shown promise in addressing this issue.

Continuous flow synthesis methods allow for the production of MOFs in a more controlled and consistent manner. By precisely regulating reaction parameters such as temperature, pressure, and reagent concentrations, these techniques can produce MOFs with uniform pore sizes and structures at larger scales. This approach has been successfully demonstrated for several MOF types, including those with enhanced molecular sieving properties.

Mechanochemical synthesis, which involves the use of mechanical energy to drive chemical reactions, offers another avenue for scaling up MOF production. This solvent-free or solvent-reduced method can significantly reduce waste and energy consumption compared to traditional solution-based syntheses. Moreover, it has been shown to produce MOFs with comparable or even superior properties to those synthesized through conventional methods.

The development of modular and scalable reactor designs has also contributed to improved MOF scalability. These systems allow for easier scale-up from laboratory to pilot plant levels, maintaining the critical parameters necessary for producing high-quality, pore-engineered MOFs. Such reactors often incorporate in-line monitoring and control systems to ensure consistency across batches.

Despite these advancements, challenges remain in the large-scale production of MOFs with precisely engineered pores for molecular sieving applications. The cost of raw materials, particularly organic linkers, can be a limiting factor in industrial-scale production. Efforts to develop more cost-effective precursors and optimize synthesis routes are ongoing to address this issue.

Furthermore, post-synthetic modification techniques, which are often crucial for fine-tuning pore structures, must be adapted for large-scale processes. This includes developing efficient activation methods to remove guest molecules and solvents from MOF pores without compromising the framework integrity.

As research progresses, the focus on scalability is likely to intensify, driving innovations in synthesis methods, reactor designs, and process optimization. These developments will be crucial in bridging the gap between laboratory-scale discoveries and industrial-scale applications of pore-engineered MOFs for enhanced molecular sieving.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!