High-Pressure Gas Storage in Robust MOF Frameworks

AUG 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

MOF Gas Storage Evolution

The evolution of Metal-Organic Frameworks (MOFs) for gas storage has been a remarkable journey in materials science. Initially developed in the late 1990s, MOFs quickly gained attention for their exceptional porosity and tunable structures, making them ideal candidates for gas storage applications.

In the early 2000s, researchers focused on synthesizing MOFs with high surface areas and pore volumes. The breakthrough came with the development of MOF-5, which demonstrated unprecedented surface area and hydrogen uptake capacity. This discovery sparked intense research into MOFs for hydrogen storage, aligning with the growing interest in hydrogen as a clean energy carrier.

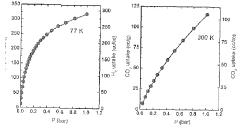

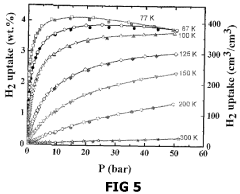

As the field progressed, scientists began exploring MOFs for storing other gases, particularly methane and carbon dioxide. The mid-2000s saw the emergence of flexible MOFs, capable of structural changes upon gas adsorption, further enhancing storage capacities. This period also witnessed the development of computational methods to predict and design MOFs with optimal properties for specific gas storage applications.

The late 2000s and early 2010s marked a shift towards creating more robust MOFs capable of withstanding high pressures. This was crucial for practical applications in gas storage, especially for vehicular natural gas tanks. Researchers focused on strengthening MOF frameworks through strategies such as interpenetration and the incorporation of robust organic linkers.

In recent years, the focus has expanded to include the scalable synthesis of MOFs and their integration into composite materials. This has led to the development of MOF-based pellets and monoliths suitable for high-pressure gas storage systems. Additionally, there has been growing interest in multicomponent gas storage, where MOFs are designed to selectively store and separate gas mixtures.

The latest advancements in MOF gas storage involve the use of defect engineering and post-synthetic modifications to enhance storage capacities and material stability. Researchers are also exploring the potential of flexible MOFs that can adapt their pore sizes and shapes in response to external stimuli, optimizing gas uptake and release.

Throughout this evolution, the overarching goal has remained consistent: to develop MOFs capable of storing larger quantities of gas at lower pressures and with improved stability. The progress in this field has been driven by advancements in synthetic chemistry, characterization techniques, and computational modeling, all contributing to the design of increasingly efficient and robust MOF frameworks for high-pressure gas storage applications.

In the early 2000s, researchers focused on synthesizing MOFs with high surface areas and pore volumes. The breakthrough came with the development of MOF-5, which demonstrated unprecedented surface area and hydrogen uptake capacity. This discovery sparked intense research into MOFs for hydrogen storage, aligning with the growing interest in hydrogen as a clean energy carrier.

As the field progressed, scientists began exploring MOFs for storing other gases, particularly methane and carbon dioxide. The mid-2000s saw the emergence of flexible MOFs, capable of structural changes upon gas adsorption, further enhancing storage capacities. This period also witnessed the development of computational methods to predict and design MOFs with optimal properties for specific gas storage applications.

The late 2000s and early 2010s marked a shift towards creating more robust MOFs capable of withstanding high pressures. This was crucial for practical applications in gas storage, especially for vehicular natural gas tanks. Researchers focused on strengthening MOF frameworks through strategies such as interpenetration and the incorporation of robust organic linkers.

In recent years, the focus has expanded to include the scalable synthesis of MOFs and their integration into composite materials. This has led to the development of MOF-based pellets and monoliths suitable for high-pressure gas storage systems. Additionally, there has been growing interest in multicomponent gas storage, where MOFs are designed to selectively store and separate gas mixtures.

The latest advancements in MOF gas storage involve the use of defect engineering and post-synthetic modifications to enhance storage capacities and material stability. Researchers are also exploring the potential of flexible MOFs that can adapt their pore sizes and shapes in response to external stimuli, optimizing gas uptake and release.

Throughout this evolution, the overarching goal has remained consistent: to develop MOFs capable of storing larger quantities of gas at lower pressures and with improved stability. The progress in this field has been driven by advancements in synthetic chemistry, characterization techniques, and computational modeling, all contributing to the design of increasingly efficient and robust MOF frameworks for high-pressure gas storage applications.

Market Demand Analysis

The market demand for high-pressure gas storage in robust MOF frameworks has been steadily increasing across various industries. This growth is primarily driven by the rising need for efficient and safe storage solutions for gases such as hydrogen, methane, and carbon dioxide. The automotive sector, particularly in the development of hydrogen fuel cell vehicles, has emerged as a significant driver of this demand. As countries worldwide push for cleaner energy alternatives, the market for hydrogen storage solutions is expected to expand rapidly.

In the energy sector, the transition towards renewable sources has created a substantial demand for advanced gas storage technologies. MOF frameworks offer promising solutions for grid-scale energy storage, enabling the integration of intermittent renewable energy sources into existing power systems. This application is particularly crucial in regions with high renewable energy penetration, where efficient storage mechanisms are essential for maintaining grid stability.

The industrial gas market, encompassing sectors such as chemicals, pharmaceuticals, and electronics, also contributes significantly to the demand for high-pressure gas storage solutions. These industries require advanced storage technologies for various processes, including gas separation, purification, and on-demand supply. MOF frameworks, with their high surface area and tunable pore structures, present attractive options for these applications.

Environmental concerns and regulatory pressures have further bolstered the market demand. As governments worldwide implement stricter emissions regulations, industries are seeking innovative solutions for carbon capture and storage. MOF-based systems have shown potential in this area, offering efficient and cost-effective means of capturing and storing greenhouse gases.

The medical and healthcare sectors represent another growing market for high-pressure gas storage in MOF frameworks. Applications in medical gas storage, drug delivery systems, and diagnostic tools are driving research and development in this field. The ability of MOFs to store and release gases in a controlled manner makes them particularly valuable in these sensitive applications.

Despite the promising outlook, challenges remain in scaling up MOF production and integrating these materials into existing infrastructure. The market demand is tempered by factors such as high initial costs, the need for specialized manufacturing processes, and competition from established storage technologies. However, ongoing research and development efforts are addressing these challenges, potentially unlocking new market opportunities and applications for MOF-based gas storage solutions.

In the energy sector, the transition towards renewable sources has created a substantial demand for advanced gas storage technologies. MOF frameworks offer promising solutions for grid-scale energy storage, enabling the integration of intermittent renewable energy sources into existing power systems. This application is particularly crucial in regions with high renewable energy penetration, where efficient storage mechanisms are essential for maintaining grid stability.

The industrial gas market, encompassing sectors such as chemicals, pharmaceuticals, and electronics, also contributes significantly to the demand for high-pressure gas storage solutions. These industries require advanced storage technologies for various processes, including gas separation, purification, and on-demand supply. MOF frameworks, with their high surface area and tunable pore structures, present attractive options for these applications.

Environmental concerns and regulatory pressures have further bolstered the market demand. As governments worldwide implement stricter emissions regulations, industries are seeking innovative solutions for carbon capture and storage. MOF-based systems have shown potential in this area, offering efficient and cost-effective means of capturing and storing greenhouse gases.

The medical and healthcare sectors represent another growing market for high-pressure gas storage in MOF frameworks. Applications in medical gas storage, drug delivery systems, and diagnostic tools are driving research and development in this field. The ability of MOFs to store and release gases in a controlled manner makes them particularly valuable in these sensitive applications.

Despite the promising outlook, challenges remain in scaling up MOF production and integrating these materials into existing infrastructure. The market demand is tempered by factors such as high initial costs, the need for specialized manufacturing processes, and competition from established storage technologies. However, ongoing research and development efforts are addressing these challenges, potentially unlocking new market opportunities and applications for MOF-based gas storage solutions.

Current MOF Challenges

Metal-Organic Frameworks (MOFs) have emerged as promising materials for high-pressure gas storage applications due to their exceptional porosity and tunable properties. However, several challenges currently hinder their widespread adoption and practical implementation in industrial settings.

One of the primary challenges facing MOFs is their limited stability under extreme conditions. Many MOFs exhibit structural degradation when exposed to high pressures, elevated temperatures, or harsh chemical environments. This instability compromises their performance and longevity in real-world applications, particularly in high-pressure gas storage scenarios where materials must withstand significant mechanical stress.

Another significant hurdle is the scalability of MOF synthesis. While laboratory-scale production has been well-established, scaling up to industrial quantities while maintaining consistent quality and properties remains a formidable challenge. The complex synthesis procedures and the high cost of precursor materials further complicate large-scale manufacturing efforts.

The mechanical properties of MOFs also present a considerable challenge. Many MOFs exhibit poor mechanical strength and are prone to collapse under high pressures, limiting their practical use in gas storage applications. Enhancing the mechanical robustness of MOFs without compromising their porosity and gas uptake capacity is a critical area of ongoing research.

Additionally, the long-term cycling stability of MOFs in gas storage applications is a concern. Repeated adsorption and desorption cycles can lead to gradual degradation of the MOF structure, reducing its storage capacity and overall performance over time. Developing MOFs that maintain their structural integrity and functional properties over thousands of cycles remains a significant challenge.

The selectivity of MOFs for specific gases in mixed gas environments is another area requiring improvement. While MOFs have shown promise in separating gas mixtures, achieving high selectivity for target gases while maintaining high storage capacity is still a challenge, particularly in complex industrial gas streams.

Furthermore, the integration of MOFs into practical storage systems poses engineering challenges. Issues such as heat management during rapid gas adsorption and desorption, as well as the development of efficient packing methods to maximize volumetric storage capacity, need to be addressed for successful implementation in real-world applications.

Lastly, the environmental impact and sustainability of MOF production and use are growing concerns. Developing green synthesis methods, utilizing renewable precursors, and ensuring the recyclability of MOFs at the end of their lifecycle are crucial challenges that need to be addressed to make MOFs a truly sustainable solution for high-pressure gas storage.

One of the primary challenges facing MOFs is their limited stability under extreme conditions. Many MOFs exhibit structural degradation when exposed to high pressures, elevated temperatures, or harsh chemical environments. This instability compromises their performance and longevity in real-world applications, particularly in high-pressure gas storage scenarios where materials must withstand significant mechanical stress.

Another significant hurdle is the scalability of MOF synthesis. While laboratory-scale production has been well-established, scaling up to industrial quantities while maintaining consistent quality and properties remains a formidable challenge. The complex synthesis procedures and the high cost of precursor materials further complicate large-scale manufacturing efforts.

The mechanical properties of MOFs also present a considerable challenge. Many MOFs exhibit poor mechanical strength and are prone to collapse under high pressures, limiting their practical use in gas storage applications. Enhancing the mechanical robustness of MOFs without compromising their porosity and gas uptake capacity is a critical area of ongoing research.

Additionally, the long-term cycling stability of MOFs in gas storage applications is a concern. Repeated adsorption and desorption cycles can lead to gradual degradation of the MOF structure, reducing its storage capacity and overall performance over time. Developing MOFs that maintain their structural integrity and functional properties over thousands of cycles remains a significant challenge.

The selectivity of MOFs for specific gases in mixed gas environments is another area requiring improvement. While MOFs have shown promise in separating gas mixtures, achieving high selectivity for target gases while maintaining high storage capacity is still a challenge, particularly in complex industrial gas streams.

Furthermore, the integration of MOFs into practical storage systems poses engineering challenges. Issues such as heat management during rapid gas adsorption and desorption, as well as the development of efficient packing methods to maximize volumetric storage capacity, need to be addressed for successful implementation in real-world applications.

Lastly, the environmental impact and sustainability of MOF production and use are growing concerns. Developing green synthesis methods, utilizing renewable precursors, and ensuring the recyclability of MOFs at the end of their lifecycle are crucial challenges that need to be addressed to make MOFs a truly sustainable solution for high-pressure gas storage.

High-Pressure MOF Solutions

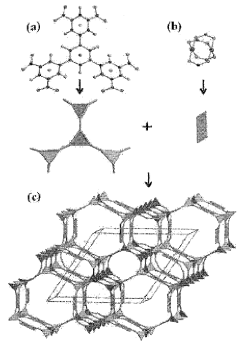

01 MOF structure optimization for enhanced gas storage

Optimizing the structure of Metal-Organic Frameworks (MOFs) can significantly improve their gas storage capacity. This includes tailoring pore sizes, increasing surface area, and modifying the metal nodes or organic linkers to enhance gas adsorption properties. Advanced synthesis techniques and post-synthetic modifications can be employed to create MOFs with higher storage capacities for various gases.- MOF structure optimization for enhanced gas storage: Optimizing the structure of Metal-Organic Frameworks (MOFs) can significantly improve their gas storage capacity. This includes tailoring pore sizes, increasing surface area, and modifying the metal nodes or organic linkers to enhance gas adsorption properties. Advanced synthesis techniques and post-synthetic modifications can be employed to create MOFs with superior gas storage capabilities.

- Functionalization of MOFs for selective gas adsorption: Functionalizing MOFs with specific chemical groups or incorporating guest molecules can enhance their selectivity and capacity for particular gases. This approach allows for the design of MOFs tailored for specific gas storage applications, such as hydrogen storage for fuel cells or carbon dioxide capture for environmental purposes.

- Composite MOF materials for improved gas storage: Developing composite materials that combine MOFs with other porous materials or nanoparticles can lead to synergistic effects, enhancing overall gas storage capacity. These composites can overcome limitations of individual components and offer improved stability, adsorption kinetics, and storage densities.

- Flexible MOFs for pressure-responsive gas storage: Designing flexible or 'breathing' MOFs that can change their structure in response to external stimuli, such as pressure or temperature, allows for dynamic gas storage capabilities. These materials can adapt their pore sizes and shapes to accommodate varying amounts of gas under different conditions, potentially increasing overall storage capacity.

- Scale-up and industrial application of MOFs for gas storage: Addressing challenges in large-scale synthesis and implementation of MOFs for practical gas storage applications is crucial. This includes developing cost-effective production methods, improving the mechanical and chemical stability of MOFs, and designing efficient gas storage systems that can be integrated into various industrial processes and energy applications.

02 Functionalization of MOFs for selective gas adsorption

Functionalizing MOFs with specific chemical groups or incorporating guest molecules can enhance their selectivity and affinity for particular gases. This approach allows for the development of MOFs tailored for specific gas storage applications, such as hydrogen storage for fuel cells or carbon dioxide capture for environmental purposes.Expand Specific Solutions03 Composite MOF materials for improved gas storage

Creating composite materials by combining MOFs with other materials such as polymers, carbon nanotubes, or graphene can lead to synergistic effects that enhance gas storage capacity. These composites often exhibit improved mechanical stability, thermal conductivity, and gas uptake compared to pure MOF structures.Expand Specific Solutions04 Hierarchical and defect-engineered MOFs for gas storage

Developing MOFs with hierarchical pore structures or intentionally introduced defects can significantly increase gas storage capacity. These approaches create additional adsorption sites and improve gas diffusion within the framework, leading to enhanced overall storage performance.Expand Specific Solutions05 In-situ characterization and modeling of MOF gas storage

Utilizing advanced in-situ characterization techniques and computational modeling to understand gas adsorption mechanisms in MOFs can guide the design of more efficient gas storage materials. This approach allows for the prediction of gas storage properties and the rational design of MOFs with optimized performance for specific gas storage applications.Expand Specific Solutions

Key MOF Industry Players

The high-pressure gas storage in robust MOF frameworks technology is in an early development stage, with significant potential for growth. The market size is expanding as industries seek more efficient and sustainable gas storage solutions. While the technology shows promise, it is still evolving towards full commercial maturity. Key players like China Petroleum & Chemical Corp., BASF Corp., and Air Liquide SA are investing in research and development to advance MOF-based gas storage systems. Universities and research institutions, including the University of Michigan and Beijing University of Technology, are also contributing to technological advancements. The competitive landscape is characterized by a mix of established chemical companies and innovative research entities, all striving to optimize MOF frameworks for high-pressure gas storage applications.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has made significant strides in developing robust MOF frameworks for high-pressure natural gas storage. Their research focuses on creating MOFs with high methane storage capacity and stability under cyclic adsorption-desorption processes. Sinopec's proprietary MOF materials, such as JLU-Liu48, have demonstrated exceptional methane uptake of up to 263 cm3/cm3 at 65 bar and room temperature [5]. The company has also developed novel synthesis methods, including microwave-assisted and mechanochemical approaches, to produce MOFs with enhanced thermal and mechanical stability. Sinopec has successfully implemented these materials in pilot-scale natural gas storage systems, demonstrating their potential for practical applications in the energy sector [6].

Strengths: High methane storage capacity at moderate pressures; Enhanced stability for cyclic operations; Successful implementation in pilot-scale systems. Weaknesses: Limited data on long-term stability under real-world conditions; Potential challenges in large-scale production.

The Regents of the University of Michigan

Technical Solution: The University of Michigan has been at the forefront of MOF research for high-pressure gas storage applications. Their work has focused on developing novel MOF structures with exceptional stability and gas uptake capacities. One of their notable achievements is the development of NU-1501-Al, a MOF with an ultrahigh surface area of 7,310 m2/g and a record-breaking methane storage capacity of 262 cm3/cm3 at 100 bar [7]. The university's research team has also pioneered the use of computational screening methods to predict and design MOFs with optimal properties for specific gas storage applications. Additionally, they have made significant progress in enhancing the mechanical stability of MOFs through the incorporation of interpenetrated networks and mixed-metal nodes, resulting in frameworks that can withstand pressures up to 10,000 atm [8].

Strengths: Cutting-edge research in MOF design and synthesis; Record-breaking gas storage capacities; Advanced computational methods for MOF prediction. Weaknesses: Focus primarily on fundamental research rather than commercial applications; Potential challenges in scaling up novel MOF synthesis methods.

Innovative MOF Structures

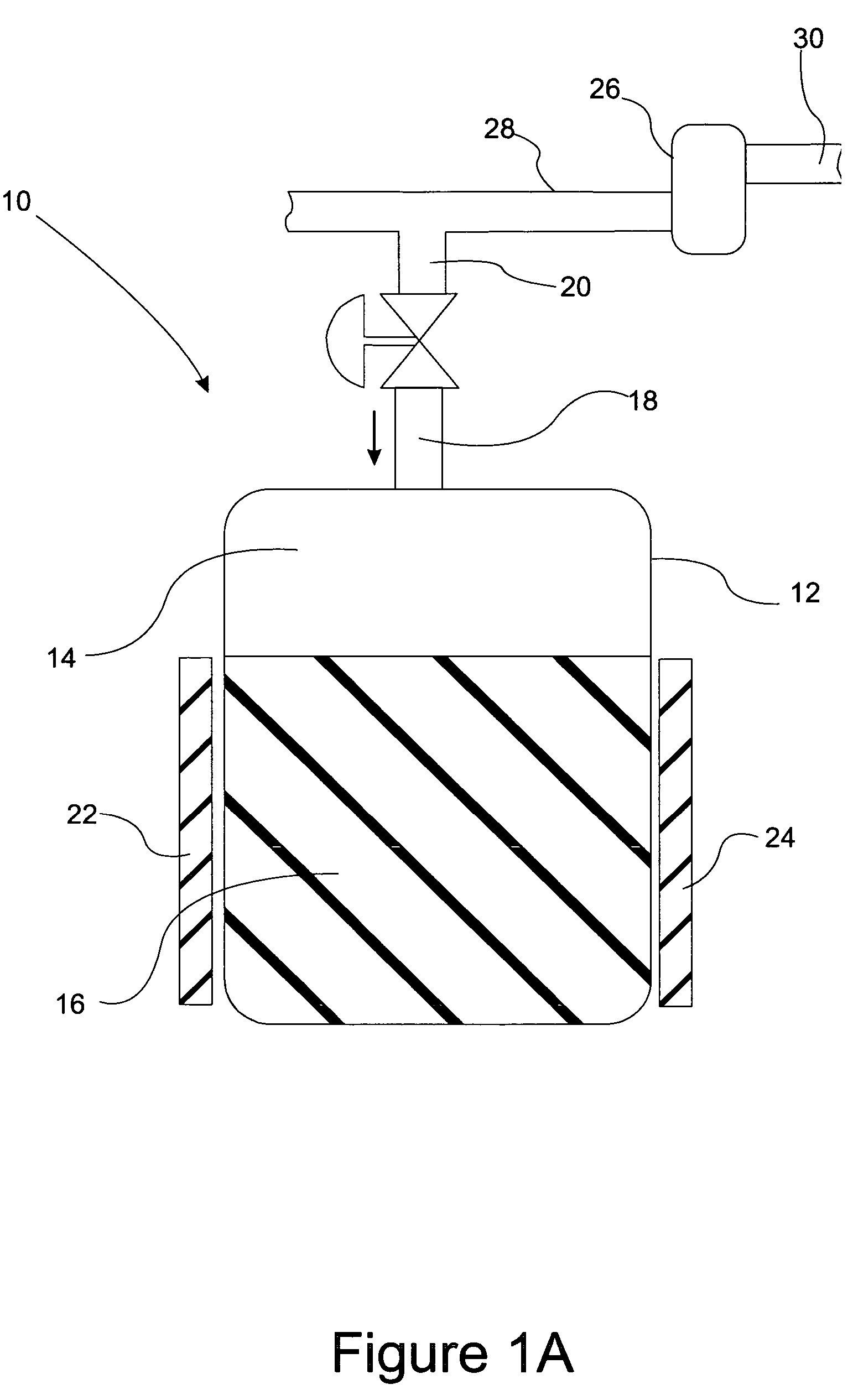

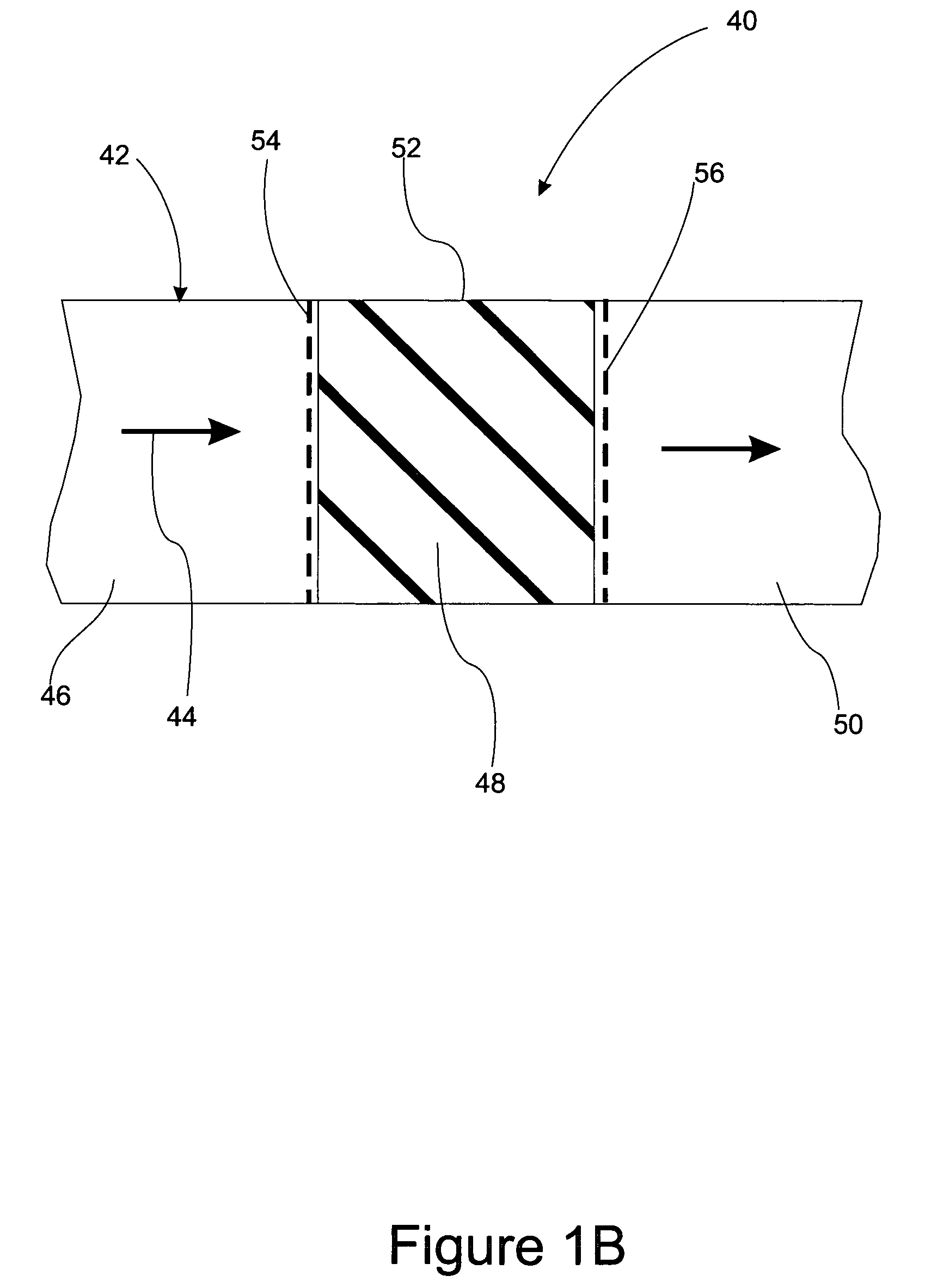

A metal organic framework with optimized open metal sites and pore spaces for high methane storage at room termerature

PatentInactiveIN8044DELNP2013A

Innovation

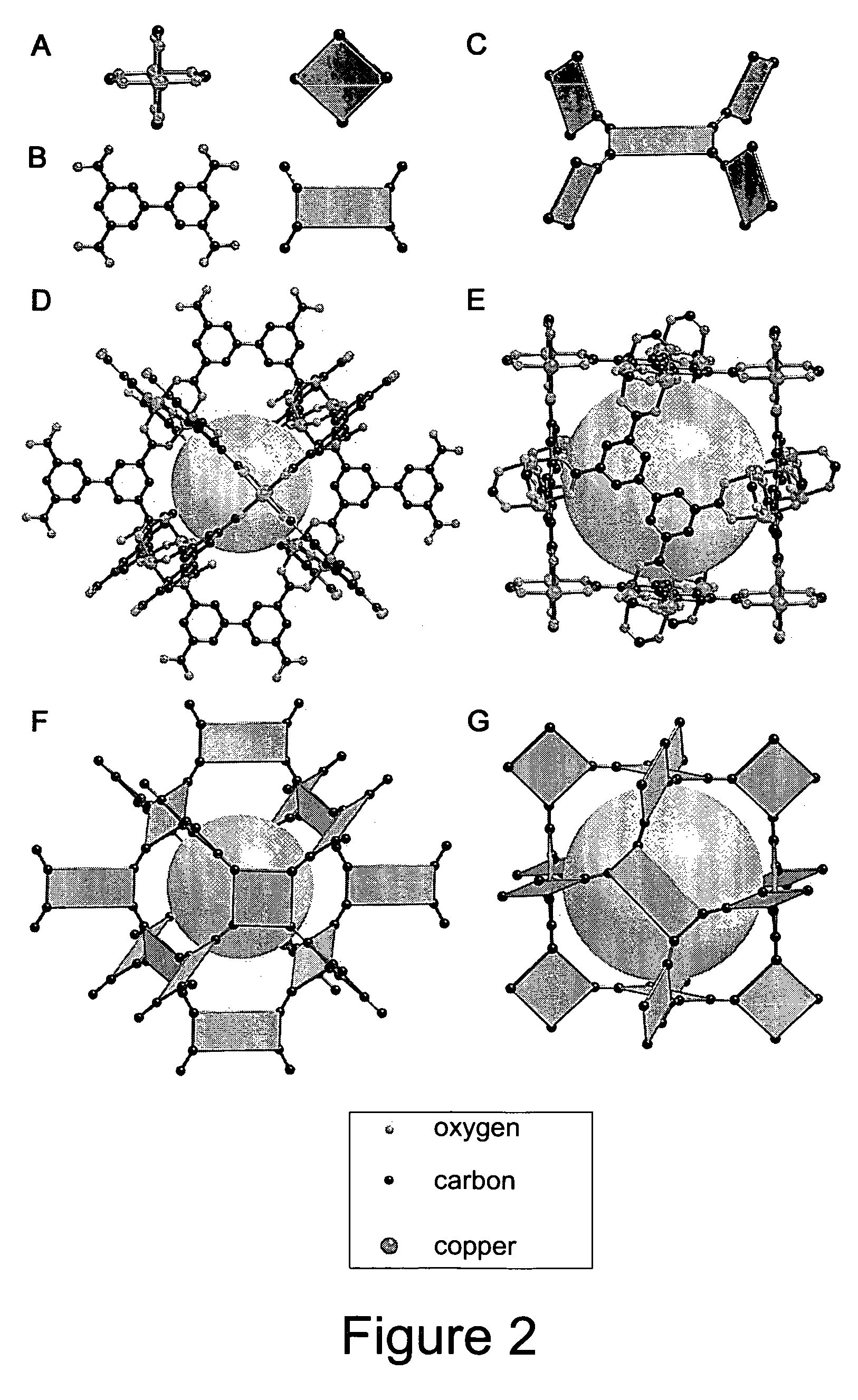

- A novel metal-organic framework, UTSA-20, is synthesized using a 3,3',3",5,5',5"-benzene-1,3,5-triyl-hexabenzoate and copper, forming a microporous framework with open copper sites and channel-like pore spaces, optimized through a solvothermal reaction process, enhancing methane storage density and volumetric capacity at room temperature and 35 bar.

High gas adsorption metal-organic framework

PatentInactiveUS7662746B2

Innovation

- A metal-organic framework with metal clusters and charged multidentate linking ligands that expose open metal sites for hydrogen and gas storage, allowing for high-capacity adsorption and reversible carbon dioxide uptake.

Safety Regulations

Safety regulations play a crucial role in the development and implementation of high-pressure gas storage systems using robust Metal-Organic Framework (MOF) frameworks. These regulations are designed to ensure the safe handling, storage, and transportation of compressed gases, which are essential for various industries and applications.

The primary focus of safety regulations in this field is to prevent potential hazards associated with high-pressure gas storage, such as leaks, explosions, and structural failures. Regulatory bodies, such as the Occupational Safety and Health Administration (OSHA) and the Department of Transportation (DOT), have established comprehensive guidelines for the design, construction, and operation of high-pressure gas storage systems.

One of the key aspects of these regulations is the requirement for rigorous testing and certification of MOF-based storage systems. This includes pressure testing to ensure the structural integrity of the storage vessels and their ability to withstand the high pressures involved. Additionally, safety regulations mandate the use of appropriate pressure relief devices to prevent over-pressurization and potential catastrophic failures.

Material compatibility is another critical consideration addressed by safety regulations. MOF frameworks must be carefully evaluated for their chemical stability and resistance to degradation when exposed to the stored gases. This is particularly important for corrosive or reactive gases that may compromise the structural integrity of the storage system over time.

Safety regulations also emphasize the importance of proper monitoring and control systems. These include pressure sensors, temperature monitors, and gas detection systems to alert operators to potential leaks or abnormal conditions. Regular inspections and maintenance procedures are mandated to ensure the ongoing safety and reliability of high-pressure gas storage systems.

Training and certification requirements for personnel involved in the handling and operation of high-pressure gas storage systems are also outlined in safety regulations. This ensures that operators are knowledgeable about the potential risks and proper procedures for safe operation and emergency response.

Furthermore, safety regulations address the need for appropriate ventilation and fire suppression systems in areas where high-pressure gas storage systems are located. This is crucial for minimizing the risk of gas accumulation and potential ignition sources.

As the field of high-pressure gas storage in robust MOF frameworks continues to advance, safety regulations are expected to evolve to address new challenges and technologies. This may include specific guidelines for the use of novel MOF materials, advanced monitoring technologies, and improved risk assessment methodologies.

The primary focus of safety regulations in this field is to prevent potential hazards associated with high-pressure gas storage, such as leaks, explosions, and structural failures. Regulatory bodies, such as the Occupational Safety and Health Administration (OSHA) and the Department of Transportation (DOT), have established comprehensive guidelines for the design, construction, and operation of high-pressure gas storage systems.

One of the key aspects of these regulations is the requirement for rigorous testing and certification of MOF-based storage systems. This includes pressure testing to ensure the structural integrity of the storage vessels and their ability to withstand the high pressures involved. Additionally, safety regulations mandate the use of appropriate pressure relief devices to prevent over-pressurization and potential catastrophic failures.

Material compatibility is another critical consideration addressed by safety regulations. MOF frameworks must be carefully evaluated for their chemical stability and resistance to degradation when exposed to the stored gases. This is particularly important for corrosive or reactive gases that may compromise the structural integrity of the storage system over time.

Safety regulations also emphasize the importance of proper monitoring and control systems. These include pressure sensors, temperature monitors, and gas detection systems to alert operators to potential leaks or abnormal conditions. Regular inspections and maintenance procedures are mandated to ensure the ongoing safety and reliability of high-pressure gas storage systems.

Training and certification requirements for personnel involved in the handling and operation of high-pressure gas storage systems are also outlined in safety regulations. This ensures that operators are knowledgeable about the potential risks and proper procedures for safe operation and emergency response.

Furthermore, safety regulations address the need for appropriate ventilation and fire suppression systems in areas where high-pressure gas storage systems are located. This is crucial for minimizing the risk of gas accumulation and potential ignition sources.

As the field of high-pressure gas storage in robust MOF frameworks continues to advance, safety regulations are expected to evolve to address new challenges and technologies. This may include specific guidelines for the use of novel MOF materials, advanced monitoring technologies, and improved risk assessment methodologies.

Environmental Impact

The environmental impact of high-pressure gas storage in robust MOF frameworks is a critical consideration in the development and implementation of this technology. MOFs, or Metal-Organic Frameworks, offer promising solutions for efficient gas storage, but their production and use have both positive and negative environmental implications.

One of the primary environmental benefits of MOF-based gas storage is the potential reduction in greenhouse gas emissions. By enabling more efficient storage of gases like hydrogen and methane, MOFs can contribute to the transition towards cleaner energy sources. This technology could play a crucial role in reducing the carbon footprint of transportation and industrial sectors, which are significant contributors to global emissions.

However, the production of MOFs can have environmental drawbacks. The synthesis of these materials often involves the use of solvents and metal precursors, which may have negative environmental impacts if not properly managed. The energy-intensive nature of some MOF production processes also raises concerns about their overall environmental footprint. Researchers are actively working on developing more sustainable synthesis methods to mitigate these issues.

The durability and recyclability of MOF frameworks are important factors in assessing their long-term environmental impact. Robust MOFs that can withstand high pressures and multiple adsorption-desorption cycles can significantly reduce material waste and the need for frequent replacements. This longevity can offset the initial environmental costs associated with their production.

Another environmental consideration is the potential for MOFs to contribute to resource conservation. By improving the efficiency of gas storage, these materials can reduce the need for large-scale storage infrastructure, potentially leading to less land use and resource consumption. This aspect is particularly relevant in urban areas where space is at a premium.

The end-of-life management of MOFs is an area that requires careful attention. While many MOFs can be recycled or repurposed, proper disposal methods need to be developed to prevent potential environmental contamination. Research into biodegradable MOFs and environmentally friendly disposal techniques is ongoing to address these concerns.

In conclusion, while high-pressure gas storage in robust MOF frameworks presents significant environmental benefits, particularly in terms of emissions reduction and energy efficiency, it is crucial to consider and mitigate the potential negative impacts associated with their production and disposal. Ongoing research and development efforts are focused on enhancing the environmental sustainability of MOF technologies throughout their lifecycle.

One of the primary environmental benefits of MOF-based gas storage is the potential reduction in greenhouse gas emissions. By enabling more efficient storage of gases like hydrogen and methane, MOFs can contribute to the transition towards cleaner energy sources. This technology could play a crucial role in reducing the carbon footprint of transportation and industrial sectors, which are significant contributors to global emissions.

However, the production of MOFs can have environmental drawbacks. The synthesis of these materials often involves the use of solvents and metal precursors, which may have negative environmental impacts if not properly managed. The energy-intensive nature of some MOF production processes also raises concerns about their overall environmental footprint. Researchers are actively working on developing more sustainable synthesis methods to mitigate these issues.

The durability and recyclability of MOF frameworks are important factors in assessing their long-term environmental impact. Robust MOFs that can withstand high pressures and multiple adsorption-desorption cycles can significantly reduce material waste and the need for frequent replacements. This longevity can offset the initial environmental costs associated with their production.

Another environmental consideration is the potential for MOFs to contribute to resource conservation. By improving the efficiency of gas storage, these materials can reduce the need for large-scale storage infrastructure, potentially leading to less land use and resource consumption. This aspect is particularly relevant in urban areas where space is at a premium.

The end-of-life management of MOFs is an area that requires careful attention. While many MOFs can be recycled or repurposed, proper disposal methods need to be developed to prevent potential environmental contamination. Research into biodegradable MOFs and environmentally friendly disposal techniques is ongoing to address these concerns.

In conclusion, while high-pressure gas storage in robust MOF frameworks presents significant environmental benefits, particularly in terms of emissions reduction and energy efficiency, it is crucial to consider and mitigate the potential negative impacts associated with their production and disposal. Ongoing research and development efforts are focused on enhancing the environmental sustainability of MOF technologies throughout their lifecycle.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!