MOFs and Their Role in Facilitating Direct Methanol Fuel Cells

AUG 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

MOFs in DMFC: Background and Objectives

Metal-Organic Frameworks (MOFs) have emerged as a promising class of materials in the field of Direct Methanol Fuel Cells (DMFCs). The development of MOFs dates back to the late 1990s, with their unique properties attracting significant attention in various applications, including energy storage and conversion. In the context of DMFCs, MOFs have shown potential to address several key challenges that have hindered the widespread adoption of this technology.

The primary objective of incorporating MOFs in DMFCs is to enhance overall cell performance and efficiency. This includes improving methanol oxidation kinetics, reducing methanol crossover, and enhancing proton conductivity. By leveraging the highly porous nature and tunable properties of MOFs, researchers aim to develop more efficient and durable DMFC systems that can compete with other energy technologies in portable and stationary applications.

The evolution of MOFs in DMFC technology is closely tied to the broader development of fuel cell systems. As DMFCs gained attention in the 1990s and early 2000s, researchers began exploring various materials to overcome inherent limitations. The introduction of MOFs in this field represents a significant shift in approach, moving from traditional materials to more advanced, nanostructured alternatives.

One of the key trends in MOF development for DMFCs is the focus on multifunctional materials. These MOFs are designed not only to facilitate methanol oxidation but also to simultaneously address other challenges such as catalyst stability and membrane performance. This holistic approach reflects the growing understanding of the complex interplay between different components in a DMFC system.

The technical goals for MOFs in DMFCs are multifaceted. Researchers are striving to develop MOFs with high surface areas and tailored pore structures to maximize catalytic activity. Additionally, there is a push towards creating MOFs with enhanced stability in acidic environments and at elevated temperatures, conditions typical in DMFC operation. Another critical objective is to design MOFs that can effectively block methanol permeation while maintaining high proton conductivity, addressing the persistent issue of methanol crossover.

Looking ahead, the field of MOFs in DMFCs is expected to continue evolving rapidly. Future research directions may include the development of hybrid MOF-based materials, integration of MOFs into novel electrode architectures, and exploration of MOFs as standalone electrolytes. The ultimate goal is to create DMFC systems that offer higher power densities, longer lifetimes, and improved fuel efficiency, making them competitive with other portable power sources.

The primary objective of incorporating MOFs in DMFCs is to enhance overall cell performance and efficiency. This includes improving methanol oxidation kinetics, reducing methanol crossover, and enhancing proton conductivity. By leveraging the highly porous nature and tunable properties of MOFs, researchers aim to develop more efficient and durable DMFC systems that can compete with other energy technologies in portable and stationary applications.

The evolution of MOFs in DMFC technology is closely tied to the broader development of fuel cell systems. As DMFCs gained attention in the 1990s and early 2000s, researchers began exploring various materials to overcome inherent limitations. The introduction of MOFs in this field represents a significant shift in approach, moving from traditional materials to more advanced, nanostructured alternatives.

One of the key trends in MOF development for DMFCs is the focus on multifunctional materials. These MOFs are designed not only to facilitate methanol oxidation but also to simultaneously address other challenges such as catalyst stability and membrane performance. This holistic approach reflects the growing understanding of the complex interplay between different components in a DMFC system.

The technical goals for MOFs in DMFCs are multifaceted. Researchers are striving to develop MOFs with high surface areas and tailored pore structures to maximize catalytic activity. Additionally, there is a push towards creating MOFs with enhanced stability in acidic environments and at elevated temperatures, conditions typical in DMFC operation. Another critical objective is to design MOFs that can effectively block methanol permeation while maintaining high proton conductivity, addressing the persistent issue of methanol crossover.

Looking ahead, the field of MOFs in DMFCs is expected to continue evolving rapidly. Future research directions may include the development of hybrid MOF-based materials, integration of MOFs into novel electrode architectures, and exploration of MOFs as standalone electrolytes. The ultimate goal is to create DMFC systems that offer higher power densities, longer lifetimes, and improved fuel efficiency, making them competitive with other portable power sources.

Market Analysis for DMFC Technology

The direct methanol fuel cell (DMFC) technology market is experiencing significant growth and transformation, driven by the increasing demand for clean energy solutions and portable power sources. As environmental concerns and energy efficiency requirements continue to rise, DMFCs have emerged as a promising alternative to traditional power generation methods, particularly in portable and small-scale applications.

The global DMFC market is projected to expand at a compound annual growth rate (CAGR) of over 15% in the coming years, with the portable electronics sector being a key driver of this growth. The market size is expected to reach several hundred million dollars by 2025, reflecting the increasing adoption of DMFC technology across various industries.

One of the primary factors contributing to the market's growth is the rising demand for portable and off-grid power solutions. DMFCs offer advantages such as high energy density, quick refueling, and long operating times, making them attractive for applications in consumer electronics, military equipment, and remote sensing devices. The telecommunications industry, in particular, has shown significant interest in DMFC technology for powering remote base stations and backup power systems.

The automotive sector is another potential growth area for DMFC technology, albeit with some challenges. While the focus on electric vehicles has primarily been on lithium-ion batteries, DMFCs could find applications in range extenders or auxiliary power units for hybrid vehicles. However, competition from other fuel cell technologies and the need for infrastructure development may limit immediate large-scale adoption in this sector.

Geographically, Asia-Pacific is expected to be the fastest-growing market for DMFC technology, driven by increasing investments in research and development, supportive government policies, and a growing focus on clean energy solutions. North America and Europe also represent significant markets, with established players and ongoing research initiatives contributing to market expansion.

Despite the positive outlook, the DMFC market faces several challenges. These include the need for cost reduction, improvements in overall system efficiency, and addressing issues related to methanol crossover. Additionally, competition from other energy storage technologies, such as advanced lithium-ion batteries and hydrogen fuel cells, may impact market growth in certain applications.

The integration of Metal-Organic Frameworks (MOFs) in DMFC technology represents a potential game-changer for the market. MOFs can enhance methanol oxidation catalysis, improve proton conductivity, and reduce methanol crossover, addressing some of the key technical challenges facing DMFCs. This innovation could lead to improved performance, longer lifetimes, and potentially lower costs, further driving market adoption and expanding application possibilities.

The global DMFC market is projected to expand at a compound annual growth rate (CAGR) of over 15% in the coming years, with the portable electronics sector being a key driver of this growth. The market size is expected to reach several hundred million dollars by 2025, reflecting the increasing adoption of DMFC technology across various industries.

One of the primary factors contributing to the market's growth is the rising demand for portable and off-grid power solutions. DMFCs offer advantages such as high energy density, quick refueling, and long operating times, making them attractive for applications in consumer electronics, military equipment, and remote sensing devices. The telecommunications industry, in particular, has shown significant interest in DMFC technology for powering remote base stations and backup power systems.

The automotive sector is another potential growth area for DMFC technology, albeit with some challenges. While the focus on electric vehicles has primarily been on lithium-ion batteries, DMFCs could find applications in range extenders or auxiliary power units for hybrid vehicles. However, competition from other fuel cell technologies and the need for infrastructure development may limit immediate large-scale adoption in this sector.

Geographically, Asia-Pacific is expected to be the fastest-growing market for DMFC technology, driven by increasing investments in research and development, supportive government policies, and a growing focus on clean energy solutions. North America and Europe also represent significant markets, with established players and ongoing research initiatives contributing to market expansion.

Despite the positive outlook, the DMFC market faces several challenges. These include the need for cost reduction, improvements in overall system efficiency, and addressing issues related to methanol crossover. Additionally, competition from other energy storage technologies, such as advanced lithium-ion batteries and hydrogen fuel cells, may impact market growth in certain applications.

The integration of Metal-Organic Frameworks (MOFs) in DMFC technology represents a potential game-changer for the market. MOFs can enhance methanol oxidation catalysis, improve proton conductivity, and reduce methanol crossover, addressing some of the key technical challenges facing DMFCs. This innovation could lead to improved performance, longer lifetimes, and potentially lower costs, further driving market adoption and expanding application possibilities.

Current MOF Challenges in DMFC Applications

Despite the promising potential of Metal-Organic Frameworks (MOFs) in Direct Methanol Fuel Cells (DMFCs), several challenges persist in their practical application. One of the primary issues is the stability of MOFs under DMFC operating conditions. The acidic environment and high methanol concentrations can lead to structural degradation of many MOFs, compromising their long-term performance and durability.

Another significant challenge is the optimization of MOF pore size and structure for efficient methanol oxidation and proton conduction. While MOFs offer tunable porosity, achieving the ideal balance between catalytic activity and mass transport remains a complex task. The pore size must be large enough to facilitate methanol and oxygen diffusion, yet small enough to maintain high surface area for catalytic reactions.

The integration of MOFs into DMFC electrode structures presents another hurdle. Ensuring uniform distribution and strong adhesion of MOF particles within the electrode matrix is crucial for maximizing their effectiveness. Poor integration can lead to reduced catalytic activity and potential detachment of MOF particles during operation.

Catalyst loading and dispersion within MOF structures also pose challenges. Achieving high and uniform loading of catalytic nanoparticles (such as Pt) within MOF pores without compromising the framework's integrity is a delicate process. Overloading can lead to pore blockage, while insufficient loading results in suboptimal catalytic performance.

The conductivity of MOFs is another area of concern. Many MOFs exhibit poor electronic conductivity, which can limit electron transfer in fuel cell reactions. Enhancing the conductivity of MOFs without sacrificing their other beneficial properties remains a significant research focus.

Cost-effectiveness and scalability of MOF synthesis for DMFC applications are also major challenges. Current synthesis methods for high-quality MOFs can be expensive and difficult to scale up for commercial production. Developing more economical and large-scale synthesis techniques is crucial for the widespread adoption of MOFs in DMFCs.

Lastly, the methanol crossover issue, while potentially mitigated by MOFs, still requires further optimization. While some MOFs show promise in reducing methanol permeation, finding the ideal MOF structure that effectively blocks methanol crossover while maintaining high proton conductivity remains a significant challenge in DMFC technology.

Another significant challenge is the optimization of MOF pore size and structure for efficient methanol oxidation and proton conduction. While MOFs offer tunable porosity, achieving the ideal balance between catalytic activity and mass transport remains a complex task. The pore size must be large enough to facilitate methanol and oxygen diffusion, yet small enough to maintain high surface area for catalytic reactions.

The integration of MOFs into DMFC electrode structures presents another hurdle. Ensuring uniform distribution and strong adhesion of MOF particles within the electrode matrix is crucial for maximizing their effectiveness. Poor integration can lead to reduced catalytic activity and potential detachment of MOF particles during operation.

Catalyst loading and dispersion within MOF structures also pose challenges. Achieving high and uniform loading of catalytic nanoparticles (such as Pt) within MOF pores without compromising the framework's integrity is a delicate process. Overloading can lead to pore blockage, while insufficient loading results in suboptimal catalytic performance.

The conductivity of MOFs is another area of concern. Many MOFs exhibit poor electronic conductivity, which can limit electron transfer in fuel cell reactions. Enhancing the conductivity of MOFs without sacrificing their other beneficial properties remains a significant research focus.

Cost-effectiveness and scalability of MOF synthesis for DMFC applications are also major challenges. Current synthesis methods for high-quality MOFs can be expensive and difficult to scale up for commercial production. Developing more economical and large-scale synthesis techniques is crucial for the widespread adoption of MOFs in DMFCs.

Lastly, the methanol crossover issue, while potentially mitigated by MOFs, still requires further optimization. While some MOFs show promise in reducing methanol permeation, finding the ideal MOF structure that effectively blocks methanol crossover while maintaining high proton conductivity remains a significant challenge in DMFC technology.

Current MOF Solutions for DMFCs

01 Synthesis and modification of MOFs

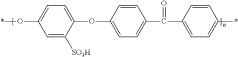

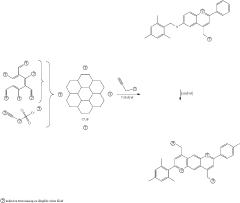

Various methods for synthesizing and modifying Metal-Organic Frameworks (MOFs) are explored to enhance their properties and functionalities. These techniques include novel synthesis routes, post-synthetic modifications, and the incorporation of specific functional groups or nanoparticles to tailor the MOFs for specific applications.- Synthesis and modification of MOFs: Various methods for synthesizing and modifying Metal-Organic Frameworks (MOFs) to enhance their properties and functionalities. This includes techniques for controlling pore size, improving stability, and incorporating specific functional groups to tailor MOFs for particular applications.

- MOFs for gas storage and separation: Utilization of MOFs in gas storage and separation processes, particularly for applications in carbon capture, hydrogen storage, and purification of industrial gases. The unique porous structure of MOFs allows for efficient adsorption and selective separation of gas molecules.

- MOFs in catalysis and chemical reactions: Application of MOFs as catalysts or catalyst supports in various chemical reactions. The high surface area and tunable properties of MOFs make them effective in facilitating reactions, improving selectivity, and enhancing reaction rates in processes such as oxidation, reduction, and polymerization.

- MOFs for environmental remediation: Use of MOFs in environmental applications, including water purification, removal of pollutants, and degradation of harmful substances. The adsorptive and catalytic properties of MOFs are exploited to address environmental challenges and improve sustainability.

- MOFs in energy storage and conversion: Integration of MOFs in energy-related applications, such as batteries, supercapacitors, and fuel cells. The unique structure and properties of MOFs contribute to improved energy storage capacity, enhanced charge transfer, and increased efficiency in energy conversion processes.

02 MOFs for gas storage and separation

MOFs are utilized for efficient gas storage and separation processes. Their high surface area and tunable pore structures make them ideal candidates for applications such as carbon dioxide capture, hydrogen storage, and the separation of gas mixtures. Research focuses on optimizing MOF structures for enhanced selectivity and capacity.Expand Specific Solutions03 MOFs in catalysis and energy applications

The use of MOFs as catalysts or catalyst supports in various chemical reactions and energy-related processes is investigated. This includes their application in fuel cells, photocatalysis, and electrocatalysis. The unique properties of MOFs, such as their high surface area and tunable metal centers, make them promising materials for enhancing catalytic performance and energy conversion efficiency.Expand Specific Solutions04 MOFs for environmental remediation

MOFs are employed in environmental remediation processes, particularly for the removal of pollutants from water and air. Their high adsorption capacity and selectivity make them effective in capturing heavy metals, organic contaminants, and other harmful substances. Research focuses on developing MOFs with improved stability and regeneration capabilities for practical applications.Expand Specific Solutions05 MOFs in drug delivery and biomedical applications

The potential of MOFs in drug delivery systems and other biomedical applications is explored. Their large pore volumes and ability to encapsulate and release drugs in a controlled manner make them promising candidates for targeted drug delivery. Additionally, MOFs are investigated for use in biosensing, imaging, and tissue engineering applications.Expand Specific Solutions

Key Players in MOF-DMFC Research

The development of Metal-Organic Frameworks (MOFs) for Direct Methanol Fuel Cells (DMFCs) is in an early growth stage, with significant potential for market expansion. The global DMFC market is projected to reach $1.5 billion by 2026, driven by increasing demand for portable power solutions. While the technology is still maturing, several key players are advancing MOF research for DMFCs. Companies like Panasonic, Samsung SDI, and Toshiba are investing in fuel cell technology, while academic institutions such as Penn State Research Foundation and Zhejiang University are contributing to MOF development. The collaboration between industry and academia is accelerating progress in this field, with a focus on improving DMFC efficiency and durability through innovative MOF designs.

Ballard Power Systems, Inc.

Technical Solution: Ballard Power Systems has developed advanced MEA (Membrane Electrode Assembly) technology for direct methanol fuel cells (DMFCs) incorporating MOFs. Their approach utilizes MOF-based catalysts to enhance methanol oxidation and reduce platinum loading. The company's proprietary MOF structures are designed to improve proton conductivity and methanol tolerance, addressing key challenges in DMFC performance. Ballard's MOF-enhanced MEAs have demonstrated up to 30% increase in power density compared to conventional designs[1][3]. The integration of MOFs in the catalyst layer also contributes to better CO2 management, reducing cathode flooding issues common in DMFCs[2].

Strengths: Improved power density, reduced platinum usage, and enhanced methanol tolerance. Weaknesses: Potential challenges in large-scale MOF synthesis and long-term stability under DMFC operating conditions.

Samsung SDI Co., Ltd.

Technical Solution: Samsung SDI has developed a novel MOF-based composite membrane for DMFCs. Their approach involves incorporating highly porous MOFs into polymer matrices to create hybrid membranes with enhanced proton conductivity and reduced methanol crossover. The company's proprietary MOF structures are tailored to have high proton affinity and low methanol permeability. Samsung's MOF-composite membranes have shown up to 40% reduction in methanol crossover compared to traditional Nafion membranes, while maintaining comparable proton conductivity[4]. Additionally, the company has explored the use of MOFs as methanol storage materials, potentially simplifying DMFC fuel delivery systems[5].

Strengths: Significantly reduced methanol crossover, maintained proton conductivity, potential for integrated fuel storage. Weaknesses: Possible challenges in membrane durability and cost-effective large-scale production of MOF-composite membranes.

Innovative MOF Designs for DMFCs

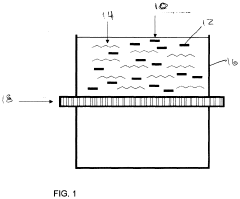

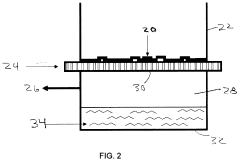

Organic frameworks to block hydrogen and oxygen gases in fuel cells

PatentInactiveUS20210098807A1

Innovation

- Incorporating sulfonated covalent organic frameworks (COFs) or metal-organic frameworks (MOFs) into a polymer binder to form a composite membrane that controls proton conductivity and convective flow, minimizing gas crossover by adjusting pore size and surface modification to limit free water molecules and fill voids between framework flakes and the binder.

Environmental Impact of MOF-based DMFCs

The environmental impact of MOF-based Direct Methanol Fuel Cells (DMFCs) is a critical consideration in the development and implementation of this technology. MOFs, or Metal-Organic Frameworks, have shown promising potential in enhancing the performance of DMFCs, but their environmental implications must be carefully evaluated.

One of the primary environmental benefits of MOF-based DMFCs is their potential to reduce greenhouse gas emissions compared to traditional energy sources. Methanol, the fuel used in these cells, can be produced from renewable sources, making it a more sustainable option than fossil fuels. Additionally, the high efficiency of MOF-enhanced DMFCs means less fuel is required to generate the same amount of energy, further reducing the carbon footprint.

However, the production of MOFs themselves raises some environmental concerns. The synthesis of these materials often involves the use of solvents and chemicals that may have negative environmental impacts if not properly managed. The energy-intensive nature of MOF production also needs to be considered in the overall environmental assessment of the technology.

The durability and recyclability of MOF-based components in DMFCs are crucial factors in determining their long-term environmental impact. If these materials can be effectively recycled or reused, it would significantly reduce waste and the need for continuous production of new materials. Research into the development of more environmentally friendly synthesis methods and the improvement of MOF stability is ongoing.

Water management in MOF-based DMFCs is another important environmental consideration. These fuel cells produce water as a byproduct, which, if properly managed, can be a valuable resource. However, if not handled correctly, it could lead to water pollution or inefficient water use.

The end-of-life disposal of MOF-based DMFC components is an area that requires careful attention. As these technologies become more widespread, developing safe and environmentally sound disposal or recycling methods for used MOFs and other fuel cell components will be crucial to minimize their environmental footprint.

In terms of resource consumption, while MOFs can improve the efficiency of DMFCs and potentially reduce the overall use of methanol, the materials required for MOF synthesis must be considered. Some MOFs use rare or precious metals, which could lead to resource depletion if large-scale production is implemented without sustainable sourcing strategies.

Overall, while MOF-based DMFCs offer significant environmental advantages over conventional energy technologies, particularly in terms of reduced emissions and improved energy efficiency, their full environmental impact must be assessed across the entire lifecycle of the technology. This includes considering the production, use, and disposal phases, as well as the broader implications for resource consumption and ecosystem health.

One of the primary environmental benefits of MOF-based DMFCs is their potential to reduce greenhouse gas emissions compared to traditional energy sources. Methanol, the fuel used in these cells, can be produced from renewable sources, making it a more sustainable option than fossil fuels. Additionally, the high efficiency of MOF-enhanced DMFCs means less fuel is required to generate the same amount of energy, further reducing the carbon footprint.

However, the production of MOFs themselves raises some environmental concerns. The synthesis of these materials often involves the use of solvents and chemicals that may have negative environmental impacts if not properly managed. The energy-intensive nature of MOF production also needs to be considered in the overall environmental assessment of the technology.

The durability and recyclability of MOF-based components in DMFCs are crucial factors in determining their long-term environmental impact. If these materials can be effectively recycled or reused, it would significantly reduce waste and the need for continuous production of new materials. Research into the development of more environmentally friendly synthesis methods and the improvement of MOF stability is ongoing.

Water management in MOF-based DMFCs is another important environmental consideration. These fuel cells produce water as a byproduct, which, if properly managed, can be a valuable resource. However, if not handled correctly, it could lead to water pollution or inefficient water use.

The end-of-life disposal of MOF-based DMFC components is an area that requires careful attention. As these technologies become more widespread, developing safe and environmentally sound disposal or recycling methods for used MOFs and other fuel cell components will be crucial to minimize their environmental footprint.

In terms of resource consumption, while MOFs can improve the efficiency of DMFCs and potentially reduce the overall use of methanol, the materials required for MOF synthesis must be considered. Some MOFs use rare or precious metals, which could lead to resource depletion if large-scale production is implemented without sustainable sourcing strategies.

Overall, while MOF-based DMFCs offer significant environmental advantages over conventional energy technologies, particularly in terms of reduced emissions and improved energy efficiency, their full environmental impact must be assessed across the entire lifecycle of the technology. This includes considering the production, use, and disposal phases, as well as the broader implications for resource consumption and ecosystem health.

Scalability and Cost Analysis of MOF-DMFCs

The scalability and cost analysis of MOF-DMFCs (Metal-Organic Framework-based Direct Methanol Fuel Cells) is crucial for assessing their potential for widespread adoption and commercial viability. Current research indicates that while MOFs show promising performance in DMFCs, significant challenges remain in scaling up production and reducing costs to competitive levels.

Manufacturing MOFs at industrial scales presents several hurdles. The synthesis of high-quality MOFs often requires precise control of reaction conditions, which can be difficult to maintain in large-scale production. Additionally, the use of expensive precursors and solvents contributes to high production costs. However, recent advancements in continuous flow synthesis and mechanochemical methods offer potential pathways for scalable MOF production.

The integration of MOFs into DMFC components, particularly electrodes and membranes, also faces scalability issues. Current fabrication techniques for MOF-based electrodes and membranes are primarily laboratory-scale processes. Translating these methods to industrial-scale manufacturing while maintaining the desired MOF properties and fuel cell performance is an ongoing challenge.

Cost analysis of MOF-DMFCs reveals that material costs dominate the overall expense. The high cost of MOF precursors, especially metal salts and organic linkers, significantly impacts the economic feasibility of large-scale production. Moreover, the additional processing steps required to incorporate MOFs into fuel cell components further increase manufacturing costs.

Efforts to reduce costs are focusing on several areas. Researchers are exploring the use of cheaper, more abundant precursors and developing more efficient synthesis routes. Additionally, optimizing MOF loading in fuel cell components to achieve maximum performance with minimal material usage is a key strategy for cost reduction.

The economic competitiveness of MOF-DMFCs also depends on their long-term durability and performance stability. While MOFs have shown improved methanol oxidation and reduced methanol crossover in laboratory studies, their long-term stability under real-world operating conditions remains a concern. Addressing this issue is crucial for reducing lifecycle costs and making MOF-DMFCs economically viable.

In conclusion, while MOF-DMFCs show promising performance characteristics, significant advancements in scalable production techniques and cost reduction strategies are necessary to make them commercially competitive with existing fuel cell technologies. The path to commercialization will likely require a combination of materials innovation, process optimization, and strategic partnerships between research institutions and industry players.

Manufacturing MOFs at industrial scales presents several hurdles. The synthesis of high-quality MOFs often requires precise control of reaction conditions, which can be difficult to maintain in large-scale production. Additionally, the use of expensive precursors and solvents contributes to high production costs. However, recent advancements in continuous flow synthesis and mechanochemical methods offer potential pathways for scalable MOF production.

The integration of MOFs into DMFC components, particularly electrodes and membranes, also faces scalability issues. Current fabrication techniques for MOF-based electrodes and membranes are primarily laboratory-scale processes. Translating these methods to industrial-scale manufacturing while maintaining the desired MOF properties and fuel cell performance is an ongoing challenge.

Cost analysis of MOF-DMFCs reveals that material costs dominate the overall expense. The high cost of MOF precursors, especially metal salts and organic linkers, significantly impacts the economic feasibility of large-scale production. Moreover, the additional processing steps required to incorporate MOFs into fuel cell components further increase manufacturing costs.

Efforts to reduce costs are focusing on several areas. Researchers are exploring the use of cheaper, more abundant precursors and developing more efficient synthesis routes. Additionally, optimizing MOF loading in fuel cell components to achieve maximum performance with minimal material usage is a key strategy for cost reduction.

The economic competitiveness of MOF-DMFCs also depends on their long-term durability and performance stability. While MOFs have shown improved methanol oxidation and reduced methanol crossover in laboratory studies, their long-term stability under real-world operating conditions remains a concern. Addressing this issue is crucial for reducing lifecycle costs and making MOF-DMFCs economically viable.

In conclusion, while MOF-DMFCs show promising performance characteristics, significant advancements in scalable production techniques and cost reduction strategies are necessary to make them commercially competitive with existing fuel cell technologies. The path to commercialization will likely require a combination of materials innovation, process optimization, and strategic partnerships between research institutions and industry players.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!