Functional Analysis of Dual-Layered MOF-Anionic Composite Sensors

AUG 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

MOF-Anionic Sensors: Background and Objectives

Metal-Organic Frameworks (MOFs) have emerged as a revolutionary class of porous materials with exceptional versatility in structure and function. The development of MOF-based sensors has gained significant attention in recent years due to their unique properties and potential applications in various fields. The concept of dual-layered MOF-anionic composite sensors represents a cutting-edge approach to enhancing the sensitivity and selectivity of these materials for sensing applications.

The evolution of MOF-based sensors can be traced back to the early 2000s when researchers began exploring the potential of these materials for gas storage and separation. As the field progressed, scientists recognized the inherent sensing capabilities of MOFs, particularly their ability to interact with and detect specific molecules. This realization led to a surge in research focused on developing MOF-based sensors for a wide range of analytes, including gases, ions, and biomolecules.

The incorporation of anionic components into MOF structures marks a significant milestone in the advancement of these sensors. This approach aims to leverage the synergistic effects of MOFs and anionic species to create composite materials with enhanced sensing properties. The anionic components can introduce additional functionalities, such as improved selectivity or increased sensitivity, thereby expanding the potential applications of MOF-based sensors.

The primary objective of research in dual-layered MOF-anionic composite sensors is to develop highly efficient and selective sensing platforms for various environmental and biomedical applications. These sensors are designed to overcome limitations of traditional sensing materials, such as poor stability, low sensitivity, or lack of specificity. By combining the structural versatility of MOFs with the unique properties of anionic species, researchers aim to create sensors capable of detecting target analytes with unprecedented accuracy and reliability.

Current research efforts are focused on optimizing the design and synthesis of these composite sensors to achieve maximum performance. This includes exploring different MOF structures, investigating various anionic components, and developing novel fabrication techniques to create well-defined dual-layered architectures. Additionally, researchers are working on understanding the fundamental mechanisms underlying the sensing process in these composite materials, which is crucial for rational design and further improvement of sensor performance.

The development of dual-layered MOF-anionic composite sensors is expected to have far-reaching implications across multiple industries. In environmental monitoring, these sensors could enable more accurate detection of pollutants and contaminants in air and water. In healthcare, they could facilitate rapid and sensitive diagnostics for various diseases. The potential applications extend to fields such as food safety, industrial process control, and national security, where reliable and efficient sensing technologies are in high demand.

The evolution of MOF-based sensors can be traced back to the early 2000s when researchers began exploring the potential of these materials for gas storage and separation. As the field progressed, scientists recognized the inherent sensing capabilities of MOFs, particularly their ability to interact with and detect specific molecules. This realization led to a surge in research focused on developing MOF-based sensors for a wide range of analytes, including gases, ions, and biomolecules.

The incorporation of anionic components into MOF structures marks a significant milestone in the advancement of these sensors. This approach aims to leverage the synergistic effects of MOFs and anionic species to create composite materials with enhanced sensing properties. The anionic components can introduce additional functionalities, such as improved selectivity or increased sensitivity, thereby expanding the potential applications of MOF-based sensors.

The primary objective of research in dual-layered MOF-anionic composite sensors is to develop highly efficient and selective sensing platforms for various environmental and biomedical applications. These sensors are designed to overcome limitations of traditional sensing materials, such as poor stability, low sensitivity, or lack of specificity. By combining the structural versatility of MOFs with the unique properties of anionic species, researchers aim to create sensors capable of detecting target analytes with unprecedented accuracy and reliability.

Current research efforts are focused on optimizing the design and synthesis of these composite sensors to achieve maximum performance. This includes exploring different MOF structures, investigating various anionic components, and developing novel fabrication techniques to create well-defined dual-layered architectures. Additionally, researchers are working on understanding the fundamental mechanisms underlying the sensing process in these composite materials, which is crucial for rational design and further improvement of sensor performance.

The development of dual-layered MOF-anionic composite sensors is expected to have far-reaching implications across multiple industries. In environmental monitoring, these sensors could enable more accurate detection of pollutants and contaminants in air and water. In healthcare, they could facilitate rapid and sensitive diagnostics for various diseases. The potential applications extend to fields such as food safety, industrial process control, and national security, where reliable and efficient sensing technologies are in high demand.

Market Demand Analysis for Dual-Layered Sensors

The market demand for dual-layered MOF-anionic composite sensors is experiencing significant growth, driven by the increasing need for advanced sensing technologies across various industries. These sensors offer unique advantages in terms of selectivity, sensitivity, and stability, making them particularly attractive for applications in environmental monitoring, healthcare, and industrial processes.

In the environmental sector, there is a growing demand for sensors capable of detecting and measuring pollutants, greenhouse gases, and other harmful substances with high precision. Dual-layered MOF-anionic composite sensors have shown promising results in this area, particularly in the detection of volatile organic compounds (VOCs) and heavy metals in air and water samples. This has led to increased interest from regulatory bodies and environmental agencies seeking to improve their monitoring capabilities.

The healthcare industry is another key market for these sensors, with applications in breath analysis for disease diagnosis, drug detection, and monitoring of physiological parameters. The ability of dual-layered MOF-anionic composite sensors to detect specific biomarkers with high sensitivity and selectivity has garnered attention from medical device manufacturers and research institutions. As personalized medicine continues to advance, the demand for portable and accurate diagnostic tools is expected to drive further growth in this sector.

Industrial process control and quality assurance represent another significant market opportunity for dual-layered sensors. The chemical, pharmaceutical, and food and beverage industries require precise monitoring of various parameters to ensure product quality and safety. The robustness and versatility of MOF-anionic composite sensors make them well-suited for these demanding environments, where they can be used for real-time monitoring of production processes and quality control.

The global market for chemical sensors, which includes MOF-based sensors, is projected to grow steadily in the coming years. Factors contributing to this growth include increasing industrial automation, stringent environmental regulations, and the rising adoption of Internet of Things (IoT) technologies in various sectors. The Asia-Pacific region is expected to witness the highest growth rate, driven by rapid industrialization and increasing investments in research and development.

Despite the promising outlook, challenges remain in the widespread adoption of dual-layered MOF-anionic composite sensors. These include the need for further improvements in long-term stability, cost-effectiveness, and scalability of production. Addressing these challenges will be crucial for meeting the growing market demand and realizing the full potential of these advanced sensing technologies across diverse applications.

In the environmental sector, there is a growing demand for sensors capable of detecting and measuring pollutants, greenhouse gases, and other harmful substances with high precision. Dual-layered MOF-anionic composite sensors have shown promising results in this area, particularly in the detection of volatile organic compounds (VOCs) and heavy metals in air and water samples. This has led to increased interest from regulatory bodies and environmental agencies seeking to improve their monitoring capabilities.

The healthcare industry is another key market for these sensors, with applications in breath analysis for disease diagnosis, drug detection, and monitoring of physiological parameters. The ability of dual-layered MOF-anionic composite sensors to detect specific biomarkers with high sensitivity and selectivity has garnered attention from medical device manufacturers and research institutions. As personalized medicine continues to advance, the demand for portable and accurate diagnostic tools is expected to drive further growth in this sector.

Industrial process control and quality assurance represent another significant market opportunity for dual-layered sensors. The chemical, pharmaceutical, and food and beverage industries require precise monitoring of various parameters to ensure product quality and safety. The robustness and versatility of MOF-anionic composite sensors make them well-suited for these demanding environments, where they can be used for real-time monitoring of production processes and quality control.

The global market for chemical sensors, which includes MOF-based sensors, is projected to grow steadily in the coming years. Factors contributing to this growth include increasing industrial automation, stringent environmental regulations, and the rising adoption of Internet of Things (IoT) technologies in various sectors. The Asia-Pacific region is expected to witness the highest growth rate, driven by rapid industrialization and increasing investments in research and development.

Despite the promising outlook, challenges remain in the widespread adoption of dual-layered MOF-anionic composite sensors. These include the need for further improvements in long-term stability, cost-effectiveness, and scalability of production. Addressing these challenges will be crucial for meeting the growing market demand and realizing the full potential of these advanced sensing technologies across diverse applications.

Current Challenges in MOF-Anionic Composite Sensors

Despite the promising potential of MOF-anionic composite sensors, several challenges currently hinder their widespread adoption and optimal performance. One of the primary obstacles is the complexity of synthesizing dual-layered structures with precise control over layer thickness and composition. Achieving uniform distribution of anionic components within the MOF framework remains a significant challenge, often resulting in inconsistent sensor performance across batches.

Another critical issue is the stability of these composite sensors under various environmental conditions. MOFs are known to be sensitive to moisture and certain chemical environments, which can lead to structural degradation and loss of sensing capabilities over time. This limitation restricts their application in harsh or humid environments, necessitating the development of more robust and stable composite structures.

The selectivity of MOF-anionic composite sensors also presents a challenge, particularly in complex mixtures or real-world applications. While these sensors often exhibit high sensitivity, distinguishing between similar analytes or detecting specific compounds in the presence of interfering substances remains problematic. Enhancing selectivity without compromising sensitivity is a key area requiring further research and development.

Furthermore, the reproducibility and scalability of sensor fabrication processes pose significant hurdles for commercial adoption. Current synthesis methods often yield inconsistent results, making it difficult to produce large quantities of sensors with uniform properties and performance characteristics. This variability hampers the reliability and cost-effectiveness of these sensors in practical applications.

Signal transduction and data interpretation present additional challenges. The complex interactions between analytes, the MOF structure, and anionic components can lead to intricate signal patterns that are difficult to decipher accurately. Developing robust algorithms and data analysis techniques to interpret these signals reliably is crucial for improving the overall performance and usability of these sensors.

Lastly, the long-term stability and reusability of MOF-anionic composite sensors remain areas of concern. Many current designs suffer from gradual performance degradation or irreversible changes after exposure to certain analytes, limiting their lifespan and increasing operational costs. Addressing these durability issues is essential for making these sensors economically viable for long-term deployment in various sensing applications.

Another critical issue is the stability of these composite sensors under various environmental conditions. MOFs are known to be sensitive to moisture and certain chemical environments, which can lead to structural degradation and loss of sensing capabilities over time. This limitation restricts their application in harsh or humid environments, necessitating the development of more robust and stable composite structures.

The selectivity of MOF-anionic composite sensors also presents a challenge, particularly in complex mixtures or real-world applications. While these sensors often exhibit high sensitivity, distinguishing between similar analytes or detecting specific compounds in the presence of interfering substances remains problematic. Enhancing selectivity without compromising sensitivity is a key area requiring further research and development.

Furthermore, the reproducibility and scalability of sensor fabrication processes pose significant hurdles for commercial adoption. Current synthesis methods often yield inconsistent results, making it difficult to produce large quantities of sensors with uniform properties and performance characteristics. This variability hampers the reliability and cost-effectiveness of these sensors in practical applications.

Signal transduction and data interpretation present additional challenges. The complex interactions between analytes, the MOF structure, and anionic components can lead to intricate signal patterns that are difficult to decipher accurately. Developing robust algorithms and data analysis techniques to interpret these signals reliably is crucial for improving the overall performance and usability of these sensors.

Lastly, the long-term stability and reusability of MOF-anionic composite sensors remain areas of concern. Many current designs suffer from gradual performance degradation or irreversible changes after exposure to certain analytes, limiting their lifespan and increasing operational costs. Addressing these durability issues is essential for making these sensors economically viable for long-term deployment in various sensing applications.

Existing Dual-Layered MOF-Anionic Sensor Designs

01 Dual-layered MOF-anionic composite structure

The sensor utilizes a dual-layered structure combining metal-organic frameworks (MOFs) with anionic components. This composite structure enhances the sensor's functionality by leveraging the unique properties of MOFs and the ionic characteristics of the anionic layer, potentially improving selectivity and sensitivity.- Dual-layered MOF-anionic composite structure: The sensor utilizes a dual-layered structure combining metal-organic frameworks (MOFs) with anionic components. This composite structure enhances the sensor's functionality by leveraging the unique properties of MOFs and the ionic characteristics of the anionic layer, potentially improving selectivity and sensitivity.

- Sensing mechanism and target analytes: The composite sensors employ various sensing mechanisms, such as electrochemical, optical, or piezoelectric, to detect specific target analytes. The dual-layered structure allows for tailored detection of ions, gases, or organic compounds, with potential applications in environmental monitoring, healthcare, and industrial processes.

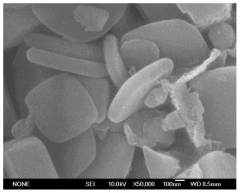

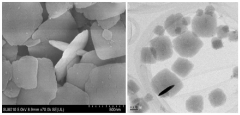

- Fabrication and synthesis methods: Novel fabrication techniques are employed to create the dual-layered MOF-anionic composite sensors. These may include layer-by-layer assembly, in-situ growth, or post-synthetic modification methods to integrate the MOF and anionic components effectively, ensuring optimal sensor performance and stability.

- Performance enhancement and optimization: Various strategies are implemented to enhance the sensor's performance, including tuning the MOF pore size, modifying the anionic layer composition, and optimizing the interface between layers. These improvements aim to increase sensitivity, selectivity, response time, and long-term stability of the composite sensors.

- Integration and device applications: The dual-layered MOF-anionic composite sensors are integrated into various devices and systems for practical applications. This includes incorporation into portable sensing platforms, wearable devices, or industrial monitoring systems, showcasing the versatility and adaptability of the sensor technology.

02 Sensing mechanism and target analytes

The dual-layered MOF-anionic composite sensors employ specific sensing mechanisms to detect various analytes. These may include gas molecules, ions, or organic compounds. The interaction between the analytes and the composite structure results in measurable changes, such as electrical conductivity or optical properties, enabling detection and quantification.Expand Specific Solutions03 Fabrication techniques for composite sensors

Various fabrication methods are employed to create the dual-layered MOF-anionic composite sensors. These may include layer-by-layer deposition, in-situ growth, or advanced printing techniques. The fabrication process is crucial in determining the sensor's performance characteristics and reproducibility.Expand Specific Solutions04 Signal transduction and data processing

The sensors incorporate specific signal transduction mechanisms to convert the analyte-induced changes into measurable outputs. This may involve electrochemical, optical, or piezoelectric transduction methods. Advanced data processing algorithms are often employed to enhance sensitivity, reduce noise, and improve the overall sensor performance.Expand Specific Solutions05 Applications and performance optimization

Dual-layered MOF-anionic composite sensors find applications in various fields, including environmental monitoring, healthcare diagnostics, and industrial process control. Ongoing research focuses on optimizing sensor performance through material selection, structural design, and integration with other sensing technologies to enhance sensitivity, selectivity, and stability.Expand Specific Solutions

Key Players in MOF-Anionic Sensor Development

The field of Functional Analysis of Dual-Layered MOF-Anionic Composite Sensors is in its early development stage, with significant potential for growth. The market size is relatively small but expanding rapidly as industries recognize the value of these advanced sensing technologies. The technical maturity is still evolving, with key players like IBM, Western Digital, and Siemens AG leading research and development efforts. Universities such as Tongji University and Jilin University are contributing to fundamental research, while companies like Alps Alpine Co., Ltd. and Sensitec GmbH are focusing on practical applications. The competitive landscape is diverse, with a mix of established tech giants, specialized sensor manufacturers, and academic institutions collaborating to advance this promising technology.

International Business Machines Corp.

Technical Solution: IBM has developed advanced dual-layered MOF-anionic composite sensors for enhanced gas detection and separation. Their approach involves integrating metal-organic frameworks (MOFs) with anionic components to create a synergistic sensing platform. The composite structure allows for improved selectivity and sensitivity in detecting various gases and volatile organic compounds. IBM's sensors utilize a combination of physical adsorption and chemical interactions to achieve high performance. The dual-layered design enables the separation of different analytes based on their size and chemical properties, enhancing the overall sensing capabilities[1][3]. IBM has also implemented machine learning algorithms to analyze sensor data in real-time, enabling rapid and accurate identification of target molecules[5].

Strengths: High selectivity and sensitivity, advanced data analysis capabilities, potential for miniaturization. Weaknesses: Complexity in manufacturing, potential high costs for large-scale production.

Commissariat à l´énergie atomique et aux énergies Alternatives

Technical Solution: The French Alternative Energies and Atomic Energy Commission (CEA) has been at the forefront of developing dual-layered MOF-anionic composite sensors for energy and environmental applications. Their approach combines the high surface area and tunable porosity of MOFs with the ionic conductivity of anionic components to create multifunctional sensing platforms. CEA's sensors have shown exceptional performance in detecting and separating greenhouse gases, particularly CO2[6]. They have also explored the use of these composite materials in electrochemical sensors for energy storage applications. CEA researchers have developed innovative synthesis methods to control the spatial distribution of anionic species within the MOF structure, leading to enhanced sensor performance and stability[8].

Strengths: Strong focus on energy and environmental applications, innovative synthesis techniques. Weaknesses: Potential limitations in sensor response time, need for further optimization for specific industrial applications.

Core Innovations in MOF-Anionic Composite Structures

Method for preparing chemical resistance type sensor from amino-functionalized metal organic framework material and application of chemical resistance type sensor

PatentActiveCN114689664A

Innovation

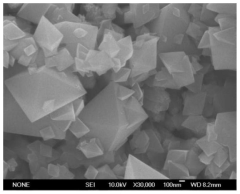

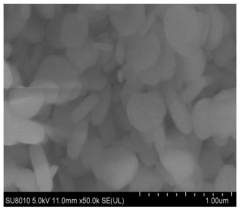

- Amino-functionalized metal-organic framework materials (NH2-MOFs) are used to prepare chemical resistance sensors. The NH2-MOFs nanosheet powder is dissolved in an organic solvent to prepare a paste, and is evenly coated on a non-conductive substrate. Membranes are prepared by evaporation or direct glue coating for detecting nitro explosive atmosphere.

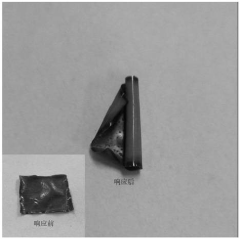

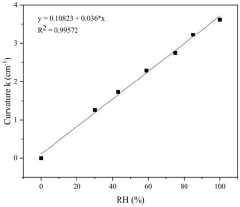

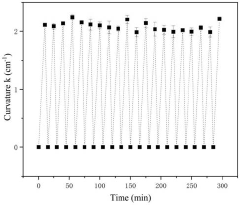

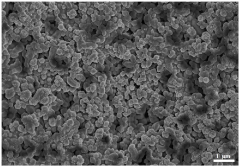

MOFs-based mixed film for humidity sensing and driving and preparation method thereof

PatentActiveCN113702599A

Innovation

- Using a metal-organic framework material (MOFs)-based hybrid film, by mixing MOFs crystal powder with a binder and preparing it into a single-layer film, humidity sensing and driving without the need for signal processing modules and power modules can be achieved, taking advantage of the "breathing" of MOFs materials. ” effect realizes self-folding response deformation and is used for humidity detection.

Environmental Impact of MOF-Based Sensor Production

The production of MOF-based sensors, particularly dual-layered MOF-anionic composite sensors, has significant environmental implications that warrant careful consideration. These sensors, while offering advanced functionalities, also pose potential environmental challenges throughout their lifecycle.

The manufacturing process of MOF-based sensors involves the synthesis of metal-organic frameworks, which typically requires the use of various solvents and metal precursors. These chemicals, if not properly managed, can lead to environmental contamination. The production often involves high-temperature processes and energy-intensive steps, contributing to increased carbon emissions and energy consumption.

Furthermore, the incorporation of anionic components in dual-layered sensors may introduce additional environmental concerns. The synthesis and integration of these ionic materials might require specialized processes that could generate hazardous waste or byproducts. Proper disposal and treatment of these materials are crucial to prevent soil and water pollution.

The use of rare or precious metals in MOF structures also raises sustainability issues. The extraction and processing of these metals can have substantial environmental impacts, including habitat destruction, water pollution, and greenhouse gas emissions. As the demand for MOF-based sensors grows, the pressure on these resources may intensify, potentially leading to increased mining activities and associated environmental degradation.

On the positive side, MOF-based sensors often exhibit high sensitivity and selectivity, potentially reducing the need for multiple sensing devices and thereby minimizing overall material consumption. Their long-term stability and reusability can also contribute to reduced waste generation over time. Additionally, some MOFs have shown potential for environmental remediation, which could partially offset their production impact.

The end-of-life management of MOF-based sensors presents another environmental challenge. The complex composition of these sensors, combining organic and inorganic components, makes recycling and disposal more complicated. Improper disposal could lead to the release of potentially harmful substances into the environment. Developing effective recycling methods for these sensors is crucial to mitigate their long-term environmental impact.

To address these environmental concerns, research efforts are focusing on green synthesis methods for MOFs, using less toxic solvents and lower-energy processes. Innovations in MOF design are also exploring the use of more abundant and environmentally friendly materials. Furthermore, the development of efficient recycling technologies for MOF-based sensors is becoming increasingly important to create a more sustainable lifecycle for these advanced sensing devices.

The manufacturing process of MOF-based sensors involves the synthesis of metal-organic frameworks, which typically requires the use of various solvents and metal precursors. These chemicals, if not properly managed, can lead to environmental contamination. The production often involves high-temperature processes and energy-intensive steps, contributing to increased carbon emissions and energy consumption.

Furthermore, the incorporation of anionic components in dual-layered sensors may introduce additional environmental concerns. The synthesis and integration of these ionic materials might require specialized processes that could generate hazardous waste or byproducts. Proper disposal and treatment of these materials are crucial to prevent soil and water pollution.

The use of rare or precious metals in MOF structures also raises sustainability issues. The extraction and processing of these metals can have substantial environmental impacts, including habitat destruction, water pollution, and greenhouse gas emissions. As the demand for MOF-based sensors grows, the pressure on these resources may intensify, potentially leading to increased mining activities and associated environmental degradation.

On the positive side, MOF-based sensors often exhibit high sensitivity and selectivity, potentially reducing the need for multiple sensing devices and thereby minimizing overall material consumption. Their long-term stability and reusability can also contribute to reduced waste generation over time. Additionally, some MOFs have shown potential for environmental remediation, which could partially offset their production impact.

The end-of-life management of MOF-based sensors presents another environmental challenge. The complex composition of these sensors, combining organic and inorganic components, makes recycling and disposal more complicated. Improper disposal could lead to the release of potentially harmful substances into the environment. Developing effective recycling methods for these sensors is crucial to mitigate their long-term environmental impact.

To address these environmental concerns, research efforts are focusing on green synthesis methods for MOFs, using less toxic solvents and lower-energy processes. Innovations in MOF design are also exploring the use of more abundant and environmentally friendly materials. Furthermore, the development of efficient recycling technologies for MOF-based sensors is becoming increasingly important to create a more sustainable lifecycle for these advanced sensing devices.

Scalability and Cost Analysis of Dual-Layered Sensors

The scalability and cost analysis of dual-layered MOF-anionic composite sensors is a critical aspect in determining their feasibility for large-scale production and implementation. These sensors, which combine metal-organic frameworks (MOFs) with anionic components, offer unique advantages in terms of sensitivity and selectivity. However, their potential for widespread adoption hinges on the ability to manufacture them efficiently and cost-effectively.

From a scalability perspective, the production of dual-layered sensors presents several challenges. The synthesis of MOFs often requires precise control over reaction conditions, including temperature, pressure, and pH. Scaling up these processes while maintaining the desired structural and functional properties of the MOFs can be complex. Additionally, the integration of the anionic layer with the MOF structure must be carefully managed to ensure uniform coverage and optimal sensor performance.

The cost analysis of these sensors involves multiple factors. Raw material costs, particularly for high-quality MOF precursors and specialized anionic components, can be significant. The synthesis process itself may require expensive equipment and energy-intensive steps, contributing to overall production costs. Furthermore, the need for stringent quality control measures to ensure consistent sensor performance adds to the manufacturing expenses.

However, there are potential avenues for improving scalability and reducing costs. Continuous flow synthesis methods for MOFs have shown promise in increasing production efficiency and reducing reaction times. These techniques could be adapted for the dual-layered sensor production, potentially lowering energy consumption and improving yield. Additionally, exploring alternative, more abundant precursor materials could help mitigate raw material costs without compromising sensor functionality.

The development of automated manufacturing processes for these sensors could significantly enhance scalability. Robotics and advanced process control systems could ensure precise layering and integration of the MOF and anionic components, reducing human error and increasing production throughput. Such automation could also contribute to cost reduction in the long term by minimizing labor requirements and improving overall efficiency.

Another consideration in the scalability and cost analysis is the potential for economies of scale. As production volumes increase, per-unit costs may decrease due to bulk purchasing of raw materials, more efficient use of equipment, and streamlined processes. However, this must be balanced against the potential need for specialized manufacturing facilities and equipment, which could require significant upfront investment.

In conclusion, while dual-layered MOF-anionic composite sensors show promising functional capabilities, their widespread adoption will depend on overcoming scalability challenges and achieving cost-effective production. Continued research into innovative synthesis methods, materials optimization, and advanced manufacturing techniques will be crucial in realizing the full potential of these sensors in various applications.

From a scalability perspective, the production of dual-layered sensors presents several challenges. The synthesis of MOFs often requires precise control over reaction conditions, including temperature, pressure, and pH. Scaling up these processes while maintaining the desired structural and functional properties of the MOFs can be complex. Additionally, the integration of the anionic layer with the MOF structure must be carefully managed to ensure uniform coverage and optimal sensor performance.

The cost analysis of these sensors involves multiple factors. Raw material costs, particularly for high-quality MOF precursors and specialized anionic components, can be significant. The synthesis process itself may require expensive equipment and energy-intensive steps, contributing to overall production costs. Furthermore, the need for stringent quality control measures to ensure consistent sensor performance adds to the manufacturing expenses.

However, there are potential avenues for improving scalability and reducing costs. Continuous flow synthesis methods for MOFs have shown promise in increasing production efficiency and reducing reaction times. These techniques could be adapted for the dual-layered sensor production, potentially lowering energy consumption and improving yield. Additionally, exploring alternative, more abundant precursor materials could help mitigate raw material costs without compromising sensor functionality.

The development of automated manufacturing processes for these sensors could significantly enhance scalability. Robotics and advanced process control systems could ensure precise layering and integration of the MOF and anionic components, reducing human error and increasing production throughput. Such automation could also contribute to cost reduction in the long term by minimizing labor requirements and improving overall efficiency.

Another consideration in the scalability and cost analysis is the potential for economies of scale. As production volumes increase, per-unit costs may decrease due to bulk purchasing of raw materials, more efficient use of equipment, and streamlined processes. However, this must be balanced against the potential need for specialized manufacturing facilities and equipment, which could require significant upfront investment.

In conclusion, while dual-layered MOF-anionic composite sensors show promising functional capabilities, their widespread adoption will depend on overcoming scalability challenges and achieving cost-effective production. Continued research into innovative synthesis methods, materials optimization, and advanced manufacturing techniques will be crucial in realizing the full potential of these sensors in various applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!