Smart MOF Coatings for Anti-Bacterial Surface Treatments

AUG 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

MOF Coatings Background

Metal-Organic Frameworks (MOFs) have emerged as a promising class of materials for various applications, including anti-bacterial surface treatments. These crystalline porous materials are composed of metal ions or clusters coordinated to organic ligands, forming three-dimensional structures with exceptional surface areas and tunable properties.

The development of MOF coatings for anti-bacterial applications has gained significant attention in recent years due to the increasing concern over antibiotic-resistant bacteria and healthcare-associated infections. Traditional anti-bacterial coatings often rely on the release of biocides or metal ions, which can lead to environmental concerns and the potential development of bacterial resistance.

MOF coatings offer several advantages over conventional anti-bacterial treatments. Their highly porous structure allows for the controlled release of anti-bacterial agents, potentially extending the efficacy of the treatment. Additionally, the diverse chemistry of MOFs enables the incorporation of various functional groups or metal ions with inherent anti-bacterial properties, providing multiple mechanisms for bacterial inhibition.

The concept of "smart" MOF coatings introduces an additional layer of functionality, allowing the material to respond to external stimuli or environmental changes. This responsiveness can be achieved through the incorporation of stimuli-sensitive components or by designing MOFs that undergo structural changes in response to specific triggers.

Research in this field has focused on developing MOF coatings that can be easily applied to various surfaces, including medical devices, textiles, and building materials. The challenge lies in creating stable coatings that maintain their anti-bacterial properties over extended periods while remaining biocompatible and environmentally friendly.

Recent advancements in MOF synthesis and coating techniques have paved the way for more efficient and scalable production methods. These include room-temperature synthesis, spray coating, and layer-by-layer deposition, which have expanded the potential applications of MOF coatings in real-world settings.

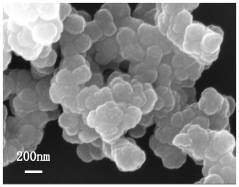

The integration of nanotechnology with MOF coatings has also opened up new possibilities for enhancing their anti-bacterial properties. Nanostructured MOFs or the incorporation of nanoparticles within MOF matrices can lead to improved surface interactions with bacteria and more effective bacterial inhibition.

As research in this field progresses, there is a growing focus on understanding the mechanisms of bacterial inhibition by MOF coatings and optimizing their performance under various environmental conditions. This includes investigating the long-term stability of these coatings, their effectiveness against different bacterial strains, and potential synergistic effects with other anti-bacterial agents.

The development of MOF coatings for anti-bacterial applications has gained significant attention in recent years due to the increasing concern over antibiotic-resistant bacteria and healthcare-associated infections. Traditional anti-bacterial coatings often rely on the release of biocides or metal ions, which can lead to environmental concerns and the potential development of bacterial resistance.

MOF coatings offer several advantages over conventional anti-bacterial treatments. Their highly porous structure allows for the controlled release of anti-bacterial agents, potentially extending the efficacy of the treatment. Additionally, the diverse chemistry of MOFs enables the incorporation of various functional groups or metal ions with inherent anti-bacterial properties, providing multiple mechanisms for bacterial inhibition.

The concept of "smart" MOF coatings introduces an additional layer of functionality, allowing the material to respond to external stimuli or environmental changes. This responsiveness can be achieved through the incorporation of stimuli-sensitive components or by designing MOFs that undergo structural changes in response to specific triggers.

Research in this field has focused on developing MOF coatings that can be easily applied to various surfaces, including medical devices, textiles, and building materials. The challenge lies in creating stable coatings that maintain their anti-bacterial properties over extended periods while remaining biocompatible and environmentally friendly.

Recent advancements in MOF synthesis and coating techniques have paved the way for more efficient and scalable production methods. These include room-temperature synthesis, spray coating, and layer-by-layer deposition, which have expanded the potential applications of MOF coatings in real-world settings.

The integration of nanotechnology with MOF coatings has also opened up new possibilities for enhancing their anti-bacterial properties. Nanostructured MOFs or the incorporation of nanoparticles within MOF matrices can lead to improved surface interactions with bacteria and more effective bacterial inhibition.

As research in this field progresses, there is a growing focus on understanding the mechanisms of bacterial inhibition by MOF coatings and optimizing their performance under various environmental conditions. This includes investigating the long-term stability of these coatings, their effectiveness against different bacterial strains, and potential synergistic effects with other anti-bacterial agents.

Market Analysis

The market for smart MOF (Metal-Organic Framework) coatings in anti-bacterial surface treatments is experiencing significant growth, driven by increasing awareness of hygiene and the need for advanced antimicrobial solutions across various industries. The global anti-bacterial coatings market is projected to expand rapidly, with smart MOF coatings emerging as a promising segment within this sector.

Healthcare facilities, including hospitals and clinics, represent a primary market for smart MOF coatings. The ongoing battle against hospital-acquired infections (HAIs) has created a strong demand for innovative surface treatments that can effectively combat bacterial growth. Smart MOF coatings offer a unique advantage in this context, as they can be designed to release antimicrobial agents in response to specific environmental triggers, providing long-lasting protection.

The food and beverage industry is another key market for smart MOF coatings. With stringent hygiene regulations and consumer expectations for food safety, there is a growing need for anti-bacterial surfaces in food processing and packaging facilities. Smart MOF coatings can help prevent bacterial contamination on food contact surfaces, potentially extending shelf life and reducing foodborne illnesses.

Consumer goods manufacturers are also showing interest in smart MOF coatings for household appliances, kitchenware, and personal care products. The ability to incorporate anti-bacterial properties into everyday items appeals to health-conscious consumers, particularly in the wake of global health crises that have heightened awareness of hygiene practices.

The transportation sector, including public transit systems and aviation, presents another significant market opportunity. High-touch surfaces in these environments can be breeding grounds for bacteria, and smart MOF coatings offer a solution for maintaining cleaner, safer surfaces for passengers and staff.

In the construction industry, there is growing demand for anti-bacterial building materials, especially in public spaces and commercial buildings. Smart MOF coatings can be applied to various surfaces, including walls, floors, and fixtures, providing an additional layer of protection against bacterial growth.

The market for smart MOF coatings is also being driven by advancements in nanotechnology and materials science. As research continues to improve the efficacy and durability of these coatings, their potential applications are expanding, opening up new market segments and opportunities for innovation.

However, the market faces challenges related to cost, scalability, and regulatory approval processes. As with any new technology in the healthcare and food industries, extensive testing and certification are required before widespread adoption can occur. Additionally, educating potential customers about the benefits and proper use of smart MOF coatings will be crucial for market penetration.

Healthcare facilities, including hospitals and clinics, represent a primary market for smart MOF coatings. The ongoing battle against hospital-acquired infections (HAIs) has created a strong demand for innovative surface treatments that can effectively combat bacterial growth. Smart MOF coatings offer a unique advantage in this context, as they can be designed to release antimicrobial agents in response to specific environmental triggers, providing long-lasting protection.

The food and beverage industry is another key market for smart MOF coatings. With stringent hygiene regulations and consumer expectations for food safety, there is a growing need for anti-bacterial surfaces in food processing and packaging facilities. Smart MOF coatings can help prevent bacterial contamination on food contact surfaces, potentially extending shelf life and reducing foodborne illnesses.

Consumer goods manufacturers are also showing interest in smart MOF coatings for household appliances, kitchenware, and personal care products. The ability to incorporate anti-bacterial properties into everyday items appeals to health-conscious consumers, particularly in the wake of global health crises that have heightened awareness of hygiene practices.

The transportation sector, including public transit systems and aviation, presents another significant market opportunity. High-touch surfaces in these environments can be breeding grounds for bacteria, and smart MOF coatings offer a solution for maintaining cleaner, safer surfaces for passengers and staff.

In the construction industry, there is growing demand for anti-bacterial building materials, especially in public spaces and commercial buildings. Smart MOF coatings can be applied to various surfaces, including walls, floors, and fixtures, providing an additional layer of protection against bacterial growth.

The market for smart MOF coatings is also being driven by advancements in nanotechnology and materials science. As research continues to improve the efficacy and durability of these coatings, their potential applications are expanding, opening up new market segments and opportunities for innovation.

However, the market faces challenges related to cost, scalability, and regulatory approval processes. As with any new technology in the healthcare and food industries, extensive testing and certification are required before widespread adoption can occur. Additionally, educating potential customers about the benefits and proper use of smart MOF coatings will be crucial for market penetration.

Technical Challenges

The development of smart MOF coatings for anti-bacterial surface treatments faces several significant technical challenges. One of the primary obstacles is achieving uniform and stable coating deposition on various substrate materials. The intricate porous structure of MOFs makes it difficult to create consistent and well-adhered coatings, especially on complex surface geometries.

Another major challenge lies in maintaining the structural integrity and functionality of MOFs during the coating process. Many MOFs are sensitive to environmental conditions such as temperature, humidity, and pH, which can lead to degradation or loss of their unique properties when applied as coatings. Researchers must develop robust synthesis and application methods that preserve the MOF structure and its anti-bacterial capabilities.

The long-term stability of MOF coatings in real-world applications presents a significant hurdle. Exposure to various environmental factors, mechanical stress, and cleaning agents can compromise the coating's effectiveness over time. Enhancing the durability of these coatings without sacrificing their anti-bacterial properties is a critical area of ongoing research.

Controlling the release kinetics of anti-bacterial agents from MOF coatings is another complex challenge. Achieving a sustained and controlled release of active compounds is crucial for maintaining long-term efficacy. Researchers must fine-tune the MOF structure and composition to optimize the release profile while ensuring sufficient anti-bacterial activity.

Scalability and cost-effectiveness of MOF coating production pose significant obstacles to widespread adoption. Current synthesis methods for many MOFs are often complex, time-consuming, and expensive, making large-scale production challenging. Developing more efficient and economical synthesis routes is essential for the commercial viability of smart MOF coatings.

Biocompatibility and potential toxicity concerns also present challenges, particularly for applications in healthcare settings or food packaging. Ensuring that MOF coatings do not leach harmful substances or trigger adverse reactions in living organisms is crucial for their safe implementation.

Lastly, the integration of smart functionalities, such as stimuli-responsiveness or self-healing properties, into MOF coatings adds another layer of complexity. Developing MOFs that can respond to environmental cues or repair damage autonomously while maintaining their anti-bacterial efficacy requires sophisticated design and engineering approaches.

Another major challenge lies in maintaining the structural integrity and functionality of MOFs during the coating process. Many MOFs are sensitive to environmental conditions such as temperature, humidity, and pH, which can lead to degradation or loss of their unique properties when applied as coatings. Researchers must develop robust synthesis and application methods that preserve the MOF structure and its anti-bacterial capabilities.

The long-term stability of MOF coatings in real-world applications presents a significant hurdle. Exposure to various environmental factors, mechanical stress, and cleaning agents can compromise the coating's effectiveness over time. Enhancing the durability of these coatings without sacrificing their anti-bacterial properties is a critical area of ongoing research.

Controlling the release kinetics of anti-bacterial agents from MOF coatings is another complex challenge. Achieving a sustained and controlled release of active compounds is crucial for maintaining long-term efficacy. Researchers must fine-tune the MOF structure and composition to optimize the release profile while ensuring sufficient anti-bacterial activity.

Scalability and cost-effectiveness of MOF coating production pose significant obstacles to widespread adoption. Current synthesis methods for many MOFs are often complex, time-consuming, and expensive, making large-scale production challenging. Developing more efficient and economical synthesis routes is essential for the commercial viability of smart MOF coatings.

Biocompatibility and potential toxicity concerns also present challenges, particularly for applications in healthcare settings or food packaging. Ensuring that MOF coatings do not leach harmful substances or trigger adverse reactions in living organisms is crucial for their safe implementation.

Lastly, the integration of smart functionalities, such as stimuli-responsiveness or self-healing properties, into MOF coatings adds another layer of complexity. Developing MOFs that can respond to environmental cues or repair damage autonomously while maintaining their anti-bacterial efficacy requires sophisticated design and engineering approaches.

Current MOF Solutions

01 MOF-based coatings with antibacterial properties

Metal-Organic Frameworks (MOFs) can be used to create smart coatings with antibacterial properties. These coatings can be applied to various surfaces to prevent bacterial growth and colonization. The porous structure of MOFs allows for the incorporation of antibacterial agents, which can be released in a controlled manner to provide long-lasting protection against microbial contamination.- MOF-based coatings with antibacterial properties: Metal-Organic Frameworks (MOFs) can be used to create smart coatings with antibacterial properties. These coatings incorporate MOFs that can release antibacterial agents or possess inherent antibacterial activity, providing long-lasting protection against microbial growth on various surfaces.

- Incorporation of silver nanoparticles in MOF coatings: Silver nanoparticles can be incorporated into MOF-based coatings to enhance their antibacterial properties. The silver ions released from these nanoparticles exhibit strong antimicrobial activity, making the coatings effective against a wide range of bacteria and other microorganisms.

- Stimuli-responsive MOF coatings for controlled antibacterial release: Smart MOF coatings can be designed to respond to external stimuli such as pH, temperature, or light. This allows for controlled release of antibacterial agents, ensuring optimal efficacy and prolonged activity of the coating.

- Multifunctional MOF coatings with antibacterial and self-cleaning properties: MOF-based coatings can be engineered to possess both antibacterial and self-cleaning properties. These multifunctional coatings not only inhibit bacterial growth but also facilitate the removal of contaminants, making them ideal for various applications in healthcare and industrial settings.

- Biodegradable MOF coatings for sustainable antibacterial solutions: Biodegradable MOFs can be used to create environmentally friendly antibacterial coatings. These coatings provide effective antimicrobial protection while naturally degrading over time, reducing environmental impact and potential long-term health concerns associated with persistent antimicrobial agents.

02 Incorporation of silver nanoparticles in MOF coatings

Silver nanoparticles can be incorporated into MOF-based coatings to enhance their antibacterial properties. The combination of the porous MOF structure and the inherent antimicrobial activity of silver nanoparticles creates a synergistic effect, resulting in highly effective antibacterial coatings. These coatings can be applied to various surfaces, including medical devices and textiles, to prevent bacterial growth and reduce the risk of infections.Expand Specific Solutions03 Stimuli-responsive MOF coatings for controlled antibacterial release

Smart MOF coatings can be designed to respond to specific stimuli, such as pH changes or temperature fluctuations, to release antibacterial agents in a controlled manner. This approach allows for targeted and efficient antibacterial action while minimizing the risk of developing bacterial resistance. The stimuli-responsive nature of these coatings makes them particularly useful in applications where on-demand antibacterial protection is required.Expand Specific Solutions04 Composite MOF coatings with enhanced durability and antibacterial efficacy

Composite MOF coatings can be developed by combining MOFs with other materials, such as polymers or inorganic nanoparticles, to enhance their durability and antibacterial efficacy. These composite coatings can provide improved adhesion to surfaces, increased mechanical strength, and prolonged antibacterial activity. The synergistic effects of the different components in the composite coating result in superior performance compared to traditional antibacterial coatings.Expand Specific Solutions05 Green synthesis of antibacterial MOF coatings

Environmentally friendly approaches can be used to synthesize antibacterial MOF coatings, utilizing bio-based precursors and mild reaction conditions. These green synthesis methods reduce the environmental impact of coating production while maintaining the desired antibacterial properties. The resulting coatings are biocompatible and suitable for use in various applications, including food packaging and biomedical devices.Expand Specific Solutions

Key Industry Players

The research on smart MOF coatings for anti-bacterial surface treatments is in an emerging stage, with growing market potential due to increasing demand for advanced antimicrobial solutions. The global market for antimicrobial coatings is expected to reach $6.3 billion by 2026, driven by healthcare and industrial applications. While the technology is still developing, several key players are advancing research in this field. Companies like IBM and LG Chem are leveraging their materials expertise, while academic institutions such as Zhejiang University and the University of Melbourne are conducting cutting-edge studies. Collaboration between industry and academia is accelerating progress, though commercial applications are still limited as researchers work to optimize MOF coating performance, durability, and scalability for real-world use.

International Business Machines Corp.

Technical Solution: IBM has developed smart MOF coatings with antibacterial properties for surface treatments. Their approach involves incorporating metal-organic frameworks (MOFs) with specific metal ions known for their antimicrobial activity, such as silver or copper. These MOFs are then integrated into polymer matrices to create durable coatings. The company has implemented a controlled release mechanism, where the antimicrobial agents are gradually released from the MOF structure, providing long-lasting protection[1]. IBM's research also focuses on the scalability of the production process, ensuring that these coatings can be applied to various surfaces in industrial settings[2]. Additionally, they have explored the use of AI and machine learning to optimize the MOF structure for specific bacterial targets, enhancing the overall efficacy of the antibacterial treatment[3].

Strengths: Advanced AI integration for MOF optimization, scalable production processes, and controlled release mechanism for prolonged effectiveness. Weaknesses: Potential high costs associated with AI-driven research and development, and possible regulatory hurdles for widespread commercial application.

The Regents of the University of Michigan

Technical Solution: The University of Michigan has pioneered a novel approach to smart MOF coatings for antibacterial surface treatments. Their research focuses on developing stimuli-responsive MOFs that can be triggered by environmental factors such as pH changes or the presence of specific bacterial metabolites[4]. These smart coatings incorporate biocompatible metals like zinc and calcium into the MOF structure, which are released upon bacterial detection. The university has also explored the integration of enzymes within the MOF framework to enhance the antibacterial activity through targeted degradation of bacterial cell walls[5]. Furthermore, they have developed a method to create hierarchical MOF structures that provide both immediate and sustained antibacterial effects, addressing the need for both rapid and long-term protection[6].

Strengths: Innovative stimuli-responsive MOFs, biocompatible materials, and multi-layered protection approach. Weaknesses: Complexity in manufacturing process may limit large-scale production, and potential issues with long-term stability of enzyme-integrated MOFs.

Core MOF Innovations

Damage-sensing corrosion-early-warning intelligent coating material and application thereof

PatentActiveCN114716879A

Innovation

- A damage-sensing smart coating based on metal-organic framework materials and hydrophobic resin is used to monitor coating damage and metal corrosion in real time through changes in fluorescence color, providing dual-function early warning.

Composite antibacterial filtering fiber membrane for visually detecting sulfur-containing compounds

PatentPendingCN117166136A

Innovation

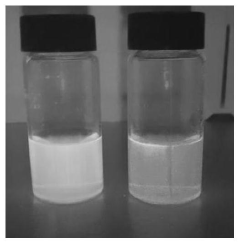

- Hexagonal prismatic Ag@Bi-MOF and polylactic acid composite fiber membranes were prepared through electrospinning technology, and Ag@Bi-MOF was used as a color indicator and antibacterial agent to achieve visual detection and antibacterial filtration of sulfur-containing compounds.

Environmental Impact

The environmental impact of smart MOF coatings for anti-bacterial surface treatments is a crucial aspect to consider in their development and application. These coatings offer significant potential for reducing the use of traditional antibacterial agents, which can have detrimental effects on ecosystems when released into the environment.

One of the primary environmental benefits of smart MOF coatings is their ability to provide long-lasting antibacterial protection without the need for frequent reapplication or the use of harsh chemicals. This can lead to a reduction in the overall chemical burden on the environment, particularly in aquatic ecosystems where many antibacterial agents end up.

The use of MOFs in these coatings also presents opportunities for more sustainable material choices. Many MOFs can be synthesized using environmentally friendly methods and from renewable resources, reducing the reliance on petrochemical-based materials. This aligns with the growing demand for green chemistry solutions in various industries.

However, the environmental impact of MOF coatings is not without potential concerns. The long-term stability and degradation of these materials in different environmental conditions need to be thoroughly investigated. There is a possibility that nanoparticles from degraded coatings could enter ecosystems, with unknown consequences for wildlife and plant life.

The production process of MOF coatings should also be scrutinized for its environmental footprint. While many MOFs can be synthesized using green methods, scaling up production may involve energy-intensive processes or the use of solvents that could have environmental implications if not properly managed.

Another consideration is the end-of-life disposal or recycling of products treated with MOF coatings. The ability to safely recycle or dispose of these materials without releasing harmful substances into the environment is crucial for their long-term sustainability.

Research into the ecotoxicology of MOF coatings is ongoing, with studies focusing on their potential impacts on various organisms and ecosystems. Initial results suggest that many MOFs have low toxicity, but more comprehensive, long-term studies are needed to fully understand their environmental fate and effects.

The development of biodegradable MOF coatings represents a promising direction for minimizing environmental impact. These coatings could be designed to break down into harmless components after their useful life, reducing the risk of persistent environmental contamination.

One of the primary environmental benefits of smart MOF coatings is their ability to provide long-lasting antibacterial protection without the need for frequent reapplication or the use of harsh chemicals. This can lead to a reduction in the overall chemical burden on the environment, particularly in aquatic ecosystems where many antibacterial agents end up.

The use of MOFs in these coatings also presents opportunities for more sustainable material choices. Many MOFs can be synthesized using environmentally friendly methods and from renewable resources, reducing the reliance on petrochemical-based materials. This aligns with the growing demand for green chemistry solutions in various industries.

However, the environmental impact of MOF coatings is not without potential concerns. The long-term stability and degradation of these materials in different environmental conditions need to be thoroughly investigated. There is a possibility that nanoparticles from degraded coatings could enter ecosystems, with unknown consequences for wildlife and plant life.

The production process of MOF coatings should also be scrutinized for its environmental footprint. While many MOFs can be synthesized using green methods, scaling up production may involve energy-intensive processes or the use of solvents that could have environmental implications if not properly managed.

Another consideration is the end-of-life disposal or recycling of products treated with MOF coatings. The ability to safely recycle or dispose of these materials without releasing harmful substances into the environment is crucial for their long-term sustainability.

Research into the ecotoxicology of MOF coatings is ongoing, with studies focusing on their potential impacts on various organisms and ecosystems. Initial results suggest that many MOFs have low toxicity, but more comprehensive, long-term studies are needed to fully understand their environmental fate and effects.

The development of biodegradable MOF coatings represents a promising direction for minimizing environmental impact. These coatings could be designed to break down into harmless components after their useful life, reducing the risk of persistent environmental contamination.

Regulatory Compliance

The regulatory landscape for smart MOF coatings in anti-bacterial surface treatments is complex and evolving. Compliance with relevant regulations is crucial for the development, commercialization, and application of these innovative materials.

In the United States, the Environmental Protection Agency (EPA) plays a significant role in regulating antimicrobial products under the Federal Insecticide, Fungicide, and Rodenticide Act (FIFRA). Smart MOF coatings with anti-bacterial properties may fall under this jurisdiction, requiring registration and approval before market entry. The EPA evaluates the safety and efficacy of such products, considering their potential environmental impact and human health risks.

The Food and Drug Administration (FDA) also has oversight in this area, particularly for applications in medical devices or food contact surfaces. MOF coatings intended for these uses must comply with FDA regulations, including premarket approval processes and good manufacturing practices (GMP).

In the European Union, the Biocidal Products Regulation (BPR) governs the use of substances and materials designed to control harmful organisms. Smart MOF coatings with anti-bacterial properties would likely fall under this regulation, necessitating a thorough assessment of their safety and effectiveness before market authorization.

The Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation in the EU also applies to novel materials like MOFs. Manufacturers and importers must register these substances and provide detailed safety information.

Globally, various countries have their own regulatory frameworks for antimicrobial products and novel materials. Japan's Ministry of Health, Labour and Welfare regulates antimicrobial agents under the Pharmaceutical Affairs Law. In China, the National Medical Products Administration oversees the registration and approval of antimicrobial materials for medical applications.

Compliance with these regulations often requires extensive testing and documentation. This includes toxicology studies, environmental impact assessments, and efficacy trials. For smart MOF coatings, demonstrating the controlled release of antimicrobial agents and the long-term stability of the coating may be particularly important.

As nanotechnology advances, regulatory bodies are increasingly focusing on the potential risks associated with nanomaterials. MOF coatings, which often involve nanostructured materials, may face additional scrutiny in this regard. Researchers and developers must stay informed about emerging regulations and guidelines specific to nanomaterials.

Standardization efforts are also underway to establish consistent methods for characterizing and evaluating antimicrobial surfaces. Organizations like the International Organization for Standardization (ISO) are developing standards that may impact the regulatory compliance of smart MOF coatings.

In the United States, the Environmental Protection Agency (EPA) plays a significant role in regulating antimicrobial products under the Federal Insecticide, Fungicide, and Rodenticide Act (FIFRA). Smart MOF coatings with anti-bacterial properties may fall under this jurisdiction, requiring registration and approval before market entry. The EPA evaluates the safety and efficacy of such products, considering their potential environmental impact and human health risks.

The Food and Drug Administration (FDA) also has oversight in this area, particularly for applications in medical devices or food contact surfaces. MOF coatings intended for these uses must comply with FDA regulations, including premarket approval processes and good manufacturing practices (GMP).

In the European Union, the Biocidal Products Regulation (BPR) governs the use of substances and materials designed to control harmful organisms. Smart MOF coatings with anti-bacterial properties would likely fall under this regulation, necessitating a thorough assessment of their safety and effectiveness before market authorization.

The Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation in the EU also applies to novel materials like MOFs. Manufacturers and importers must register these substances and provide detailed safety information.

Globally, various countries have their own regulatory frameworks for antimicrobial products and novel materials. Japan's Ministry of Health, Labour and Welfare regulates antimicrobial agents under the Pharmaceutical Affairs Law. In China, the National Medical Products Administration oversees the registration and approval of antimicrobial materials for medical applications.

Compliance with these regulations often requires extensive testing and documentation. This includes toxicology studies, environmental impact assessments, and efficacy trials. For smart MOF coatings, demonstrating the controlled release of antimicrobial agents and the long-term stability of the coating may be particularly important.

As nanotechnology advances, regulatory bodies are increasingly focusing on the potential risks associated with nanomaterials. MOF coatings, which often involve nanostructured materials, may face additional scrutiny in this regard. Researchers and developers must stay informed about emerging regulations and guidelines specific to nanomaterials.

Standardization efforts are also underway to establish consistent methods for characterizing and evaluating antimicrobial surfaces. Organizations like the International Organization for Standardization (ISO) are developing standards that may impact the regulatory compliance of smart MOF coatings.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!