Incorporating MOFs into Polymer Membranes for Gas Separation

AUG 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

MOF-Polymer Membrane Evolution and Objectives

The evolution of Metal-Organic Framework (MOF) incorporation into polymer membranes for gas separation represents a significant advancement in membrane technology. This field has progressed from initial conceptualization to practical implementation over the past two decades. The journey began with the discovery of MOFs in the late 1990s, which opened up new possibilities for enhancing membrane performance.

Early research focused on understanding the fundamental properties of MOFs and their potential for gas adsorption and separation. As the field matured, scientists began exploring ways to integrate these porous materials into polymer matrices. The first attempts at incorporating MOFs into polymers were rudimentary, often resulting in poor dispersion and limited enhancement of separation properties.

A major breakthrough came in the mid-2000s when researchers successfully developed methods to create mixed-matrix membranes (MMMs) containing well-dispersed MOF particles. This marked the beginning of a new era in gas separation membrane technology, combining the processability and mechanical strength of polymers with the superior gas selectivity of MOFs.

The evolution continued with the development of more sophisticated synthesis techniques, such as in-situ growth of MOFs within polymer matrices and the creation of MOF-based thin film composite membranes. These advancements led to significant improvements in membrane performance, particularly in terms of gas permeability and selectivity.

Recent years have seen a shift towards tailoring MOF-polymer membranes for specific gas separation applications. This includes the design of MOFs with specific pore sizes and functionalities to target particular gas molecules, as well as the selection of compatible polymer matrices to optimize overall membrane performance.

The primary objective of incorporating MOFs into polymer membranes for gas separation is to overcome the inherent limitations of traditional polymer membranes. These limitations include the trade-off between permeability and selectivity, known as the Robeson upper bound. By integrating MOFs, researchers aim to surpass this upper bound and achieve unprecedented levels of separation efficiency.

Another key objective is to develop membranes with enhanced stability and longevity under harsh operating conditions. This is particularly important for industrial applications where membranes are exposed to high pressures, temperatures, and potentially corrosive gas streams.

Furthermore, researchers are working towards scaling up the production of MOF-polymer membranes to meet industrial demands. This involves developing cost-effective and reproducible manufacturing processes that can maintain the high performance of lab-scale membranes at a larger scale.

Ultimately, the goal is to create a new generation of gas separation membranes that can significantly improve the efficiency and sustainability of various industrial processes, including natural gas purification, carbon capture, and hydrogen production. As research in this field continues to advance, it is expected that MOF-polymer membranes will play a crucial role in addressing global energy and environmental challenges.

Early research focused on understanding the fundamental properties of MOFs and their potential for gas adsorption and separation. As the field matured, scientists began exploring ways to integrate these porous materials into polymer matrices. The first attempts at incorporating MOFs into polymers were rudimentary, often resulting in poor dispersion and limited enhancement of separation properties.

A major breakthrough came in the mid-2000s when researchers successfully developed methods to create mixed-matrix membranes (MMMs) containing well-dispersed MOF particles. This marked the beginning of a new era in gas separation membrane technology, combining the processability and mechanical strength of polymers with the superior gas selectivity of MOFs.

The evolution continued with the development of more sophisticated synthesis techniques, such as in-situ growth of MOFs within polymer matrices and the creation of MOF-based thin film composite membranes. These advancements led to significant improvements in membrane performance, particularly in terms of gas permeability and selectivity.

Recent years have seen a shift towards tailoring MOF-polymer membranes for specific gas separation applications. This includes the design of MOFs with specific pore sizes and functionalities to target particular gas molecules, as well as the selection of compatible polymer matrices to optimize overall membrane performance.

The primary objective of incorporating MOFs into polymer membranes for gas separation is to overcome the inherent limitations of traditional polymer membranes. These limitations include the trade-off between permeability and selectivity, known as the Robeson upper bound. By integrating MOFs, researchers aim to surpass this upper bound and achieve unprecedented levels of separation efficiency.

Another key objective is to develop membranes with enhanced stability and longevity under harsh operating conditions. This is particularly important for industrial applications where membranes are exposed to high pressures, temperatures, and potentially corrosive gas streams.

Furthermore, researchers are working towards scaling up the production of MOF-polymer membranes to meet industrial demands. This involves developing cost-effective and reproducible manufacturing processes that can maintain the high performance of lab-scale membranes at a larger scale.

Ultimately, the goal is to create a new generation of gas separation membranes that can significantly improve the efficiency and sustainability of various industrial processes, including natural gas purification, carbon capture, and hydrogen production. As research in this field continues to advance, it is expected that MOF-polymer membranes will play a crucial role in addressing global energy and environmental challenges.

Gas Separation Market Analysis

The gas separation market has been experiencing significant growth in recent years, driven by increasing demand for clean energy, environmental regulations, and industrial applications. The global gas separation membrane market was valued at approximately $1.1 billion in 2020 and is projected to reach $2.3 billion by 2027, growing at a CAGR of around 7.5% during the forecast period.

The market for gas separation technologies is primarily segmented into membrane separation, cryogenic distillation, and pressure swing adsorption. Among these, membrane-based gas separation has gained substantial traction due to its energy efficiency, lower capital costs, and smaller footprint compared to traditional separation methods. The incorporation of Metal-Organic Frameworks (MOFs) into polymer membranes represents a cutting-edge development in this field, offering enhanced selectivity and permeability for various gas separation applications.

Key industries driving the demand for gas separation technologies include oil and gas, chemical and petrochemical, power generation, and healthcare. The oil and gas sector, in particular, accounts for a significant share of the market, with applications in natural gas processing, carbon dioxide removal, and hydrogen purification. The growing emphasis on reducing greenhouse gas emissions and the transition towards cleaner energy sources have further boosted the demand for efficient gas separation solutions.

Geographically, North America and Europe currently dominate the gas separation market, owing to stringent environmental regulations and well-established industrial infrastructure. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, fueled by rapid industrialization, increasing energy demand, and growing environmental awareness in countries like China and India.

The integration of MOFs into polymer membranes for gas separation addresses several key market needs. These include improved separation efficiency, reduced energy consumption, and the ability to handle complex gas mixtures. As industries seek more sustainable and cost-effective solutions, the development of MOF-based polymer membranes aligns well with market trends towards higher performance and lower environmental impact.

Challenges in the gas separation market include the need for membranes with higher selectivity and permeability, resistance to harsh operating conditions, and long-term stability. The successful incorporation of MOFs into polymer membranes has the potential to overcome these limitations, opening up new opportunities for market growth and technological advancement in the gas separation industry.

The market for gas separation technologies is primarily segmented into membrane separation, cryogenic distillation, and pressure swing adsorption. Among these, membrane-based gas separation has gained substantial traction due to its energy efficiency, lower capital costs, and smaller footprint compared to traditional separation methods. The incorporation of Metal-Organic Frameworks (MOFs) into polymer membranes represents a cutting-edge development in this field, offering enhanced selectivity and permeability for various gas separation applications.

Key industries driving the demand for gas separation technologies include oil and gas, chemical and petrochemical, power generation, and healthcare. The oil and gas sector, in particular, accounts for a significant share of the market, with applications in natural gas processing, carbon dioxide removal, and hydrogen purification. The growing emphasis on reducing greenhouse gas emissions and the transition towards cleaner energy sources have further boosted the demand for efficient gas separation solutions.

Geographically, North America and Europe currently dominate the gas separation market, owing to stringent environmental regulations and well-established industrial infrastructure. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, fueled by rapid industrialization, increasing energy demand, and growing environmental awareness in countries like China and India.

The integration of MOFs into polymer membranes for gas separation addresses several key market needs. These include improved separation efficiency, reduced energy consumption, and the ability to handle complex gas mixtures. As industries seek more sustainable and cost-effective solutions, the development of MOF-based polymer membranes aligns well with market trends towards higher performance and lower environmental impact.

Challenges in the gas separation market include the need for membranes with higher selectivity and permeability, resistance to harsh operating conditions, and long-term stability. The successful incorporation of MOFs into polymer membranes has the potential to overcome these limitations, opening up new opportunities for market growth and technological advancement in the gas separation industry.

MOF-Polymer Membrane Challenges

The incorporation of Metal-Organic Frameworks (MOFs) into polymer membranes for gas separation presents several significant challenges that researchers and engineers must overcome. These challenges span from material synthesis to large-scale manufacturing and long-term performance stability.

One of the primary difficulties lies in achieving uniform dispersion of MOF particles within the polymer matrix. The tendency of MOF particles to agglomerate can lead to the formation of non-selective voids and defects in the membrane structure, compromising its separation performance. Researchers are exploring various techniques, such as in-situ growth of MOFs and surface modification of particles, to enhance compatibility and dispersion.

Another critical challenge is maintaining the structural integrity and porosity of MOFs during the membrane fabrication process. The harsh conditions often involved in polymer processing, such as high temperatures or exposure to solvents, can potentially damage the delicate MOF structures. This necessitates the development of more robust MOFs or gentler processing methods that preserve the unique properties of these materials.

The interface between MOF particles and the polymer matrix presents another hurdle. Poor adhesion can result in the formation of non-selective pathways for gas molecules, reducing the overall selectivity of the membrane. Improving the interfacial compatibility through chemical modifications or the use of coupling agents is an active area of research.

Scaling up the production of MOF-polymer membranes from laboratory to industrial scale poses significant challenges. Ensuring consistent quality, uniformity, and performance across large membrane areas is crucial for commercial viability. This requires the development of scalable synthesis methods for both MOFs and membrane fabrication.

Long-term stability and performance of MOF-polymer membranes under real-world operating conditions remain concerns. Exposure to contaminants, moisture, and varying temperatures can potentially degrade the MOF structures or alter the polymer properties over time. Enhancing the chemical and thermal stability of these composite membranes is essential for their practical application.

The cost-effectiveness of MOF-polymer membranes is another challenge that needs addressing. The complex synthesis of MOFs and the additional processing steps required for their incorporation into membranes can significantly increase production costs. Finding ways to reduce material and manufacturing costs while maintaining performance is crucial for commercial adoption.

Lastly, optimizing the balance between permeability and selectivity remains a persistent challenge in membrane technology. While MOFs can potentially enhance both properties, fine-tuning the membrane composition and structure to achieve the desired separation performance for specific gas mixtures requires extensive research and development efforts.

One of the primary difficulties lies in achieving uniform dispersion of MOF particles within the polymer matrix. The tendency of MOF particles to agglomerate can lead to the formation of non-selective voids and defects in the membrane structure, compromising its separation performance. Researchers are exploring various techniques, such as in-situ growth of MOFs and surface modification of particles, to enhance compatibility and dispersion.

Another critical challenge is maintaining the structural integrity and porosity of MOFs during the membrane fabrication process. The harsh conditions often involved in polymer processing, such as high temperatures or exposure to solvents, can potentially damage the delicate MOF structures. This necessitates the development of more robust MOFs or gentler processing methods that preserve the unique properties of these materials.

The interface between MOF particles and the polymer matrix presents another hurdle. Poor adhesion can result in the formation of non-selective pathways for gas molecules, reducing the overall selectivity of the membrane. Improving the interfacial compatibility through chemical modifications or the use of coupling agents is an active area of research.

Scaling up the production of MOF-polymer membranes from laboratory to industrial scale poses significant challenges. Ensuring consistent quality, uniformity, and performance across large membrane areas is crucial for commercial viability. This requires the development of scalable synthesis methods for both MOFs and membrane fabrication.

Long-term stability and performance of MOF-polymer membranes under real-world operating conditions remain concerns. Exposure to contaminants, moisture, and varying temperatures can potentially degrade the MOF structures or alter the polymer properties over time. Enhancing the chemical and thermal stability of these composite membranes is essential for their practical application.

The cost-effectiveness of MOF-polymer membranes is another challenge that needs addressing. The complex synthesis of MOFs and the additional processing steps required for their incorporation into membranes can significantly increase production costs. Finding ways to reduce material and manufacturing costs while maintaining performance is crucial for commercial adoption.

Lastly, optimizing the balance between permeability and selectivity remains a persistent challenge in membrane technology. While MOFs can potentially enhance both properties, fine-tuning the membrane composition and structure to achieve the desired separation performance for specific gas mixtures requires extensive research and development efforts.

Current MOF-Polymer Membrane Solutions

01 MOF-polymer composite membranes for gas separation

Metal-organic frameworks (MOFs) are incorporated into polymer matrices to create composite membranes with enhanced gas separation properties. These membranes combine the high selectivity and permeability of MOFs with the processability and mechanical stability of polymers, resulting in improved performance for various gas separation applications.- MOF-polymer composite membranes for gas separation: Composite membranes incorporating metal-organic frameworks (MOFs) into polymer matrices are developed for enhanced gas separation performance. These membranes combine the high selectivity and permeability of MOFs with the processability and mechanical stability of polymers, resulting in improved separation efficiency for various gas mixtures.

- Fabrication methods for MOF-polymer membranes: Various techniques are employed to fabricate MOF-polymer composite membranes, including in-situ growth of MOFs within polymer matrices, solution blending, and layer-by-layer assembly. These methods aim to achieve uniform dispersion of MOFs and strong interfacial interactions between MOFs and polymers, enhancing the overall membrane performance.

- Tailoring MOF properties for specific gas separations: MOFs are designed and synthesized with specific pore sizes, functionalities, and chemical properties to target particular gas separations. This includes modifying the metal centers, organic linkers, and post-synthetic treatments to enhance selectivity and permeability for gases such as CO2, CH4, and H2.

- Mixed-matrix membranes with MOFs and other fillers: Mixed-matrix membranes are developed by incorporating MOFs along with other inorganic fillers such as zeolites, silica, or carbon nanotubes. This approach combines the advantages of different materials to achieve synergistic effects in gas separation performance, including improved selectivity, permeability, and mechanical properties.

- Surface modification of MOFs for improved polymer compatibility: Surface modification techniques are applied to MOFs to enhance their compatibility with polymer matrices and improve the interfacial adhesion in composite membranes. This includes grafting of polymer chains, functionalization with organic groups, and coating with inorganic materials to prevent agglomeration and enhance gas separation properties.

02 Mixed matrix membranes with MOFs for selective gas permeation

Mixed matrix membranes are developed by dispersing MOF particles within a polymer matrix. This approach enhances the membrane's selectivity and permeability for specific gases, allowing for more efficient separation of gas mixtures. The synergistic effect between the MOF and polymer components results in superior separation performance compared to traditional polymer membranes.Expand Specific Solutions03 Functionalized MOFs for targeted gas separation

MOFs are chemically modified or functionalized to enhance their affinity for specific gas molecules. These functionalized MOFs are then incorporated into polymer membranes to achieve highly selective gas separation. The tailored pore structure and chemical properties of the functionalized MOFs allow for precise control over gas permeation and separation efficiency.Expand Specific Solutions04 Thin film composite membranes with MOF layers

Thin film composite membranes are fabricated by depositing a thin layer of MOFs on top of a porous polymer support. This approach combines the high selectivity of MOFs with the mechanical strength of the polymer substrate, resulting in membranes with excellent gas separation performance and durability. The thin MOF layer acts as a selective barrier for gas molecules, while the polymer support provides structural integrity.Expand Specific Solutions05 Polymer-MOF hybrid materials for gas separation membranes

Novel hybrid materials are developed by combining polymers and MOFs at the molecular level. These hybrid materials exhibit unique properties that enhance gas separation performance, such as improved compatibility between the polymer and MOF components, reduced agglomeration of MOF particles, and enhanced interfacial interactions. The resulting membranes demonstrate superior gas selectivity and permeability compared to conventional composite membranes.Expand Specific Solutions

Key Players in MOF-Polymer Membrane Industry

The incorporation of MOFs into polymer membranes for gas separation is an emerging field in its early development stage. The market size is growing, driven by increasing demand for efficient gas separation technologies in various industries. The technology's maturity is still evolving, with significant research and development ongoing. Key players like UOP LLC, Membrane Technology & Research, Inc., and Air Products & Chemicals, Inc. are actively contributing to advancements in this area. Academic institutions such as MIT, Dalian University of Technology, and Nanjing Tech University are also playing crucial roles in pushing the boundaries of this technology. The competitive landscape is characterized by a mix of established companies and innovative startups, all vying to develop more efficient and cost-effective solutions for gas separation using MOF-polymer composite membranes.

Membrane Technology & Research, Inc.

Technical Solution: Membrane Technology & Research, Inc. (MTR) has developed proprietary techniques for incorporating MOFs into polymer membranes for gas separation. Their approach focuses on creating high-performance mixed-matrix membranes (MMMs) that combine the benefits of MOFs with advanced polymer materials[12]. MTR has successfully integrated various MOFs, including ZIF-8 and UiO-66, into their proprietary polymer blends, resulting in membranes with enhanced CO2 capture capabilities and improved selectivity for natural gas purification[13]. The company has also explored the use of MOF-based hollow fiber membranes for large-scale industrial applications, demonstrating the potential for significant energy savings in gas separation processes[14]. MTR's technology has shown particular promise in the field of biogas upgrading, where their MOF-incorporated membranes have achieved high methane recovery rates while effectively removing CO2 and other impurities[15].

Strengths: Proprietary polymer blends, scalable manufacturing processes, and proven industrial applications. Weaknesses: Potential limitations in adapting to rapidly evolving MOF technologies and possible high production costs.

Massachusetts Institute of Technology

Technical Solution: MIT has developed a novel approach to incorporating MOFs into polymer membranes for enhanced gas separation. Their technique involves the in-situ growth of MOF crystals within polymer matrices, creating a hybrid membrane with improved selectivity and permeability[1]. The researchers have successfully demonstrated the integration of ZIF-8 MOF into polybenzimidazole (PBI) membranes, resulting in a significant increase in CO2/CH4 selectivity[2]. This method allows for precise control over MOF distribution and pore size, leading to optimized gas separation performance. Additionally, MIT has explored the use of mixed-matrix membranes (MMMs) combining MOFs with high-performance polymers like polyimides, achieving exceptional CO2/N2 separation factors[3].

Strengths: High selectivity and permeability, precise control over MOF distribution, and compatibility with various polymers. Weaknesses: Potential challenges in scaling up production and maintaining long-term stability of the hybrid membranes.

Innovative MOF-Polymer Membrane Technologies

Metal organic framework polymer mixed matrix membranes

PatentInactiveEP2512640A2

Innovation

- The development of metal-organic framework (MOF)-polymer mixed matrix membranes, which incorporate high surface area MOF fillers with crystalline zeolite-like structures into a continuous polymer matrix, enhancing gas separation performance by combining molecular sieving and sorption properties with the solution-diffusion mechanism of the polymer.

Gas separation membrane comprising metal-organic framework and method of manufacturing same

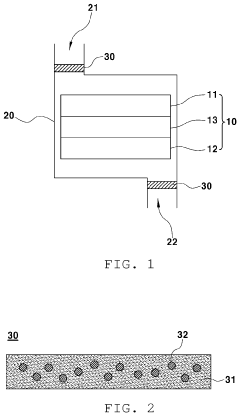

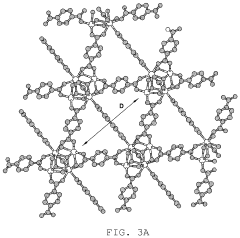

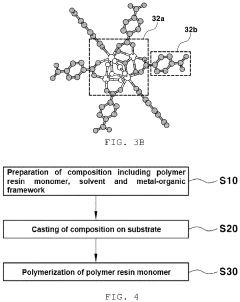

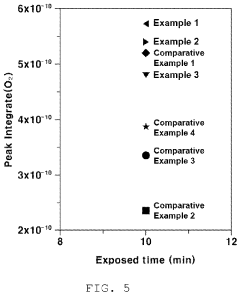

PatentActiveUS11964241B2

Innovation

- A gas separation membrane comprising a polymer resin matrix with a dispersed metal-organic framework (MOF) that includes specific metal ions and organic ligands, such as UiO-66, which enhances oxygen permeability while reducing the permeability of organic compounds and carbon dioxide, is developed. The MOF is uniformly distributed in the polymer resin matrix, and the membrane is manufactured through a process involving polymerization of the polymer resin monomer with a solvent and metal-organic framework.

Environmental Impact of MOF-Polymer Membranes

The incorporation of Metal-Organic Frameworks (MOFs) into polymer membranes for gas separation represents a significant advancement in membrane technology with potential environmental implications. These hybrid membranes offer enhanced gas separation performance, which can lead to more efficient and environmentally friendly industrial processes.

One of the primary environmental benefits of MOF-polymer membranes is their potential to reduce energy consumption in gas separation processes. Traditional gas separation methods, such as cryogenic distillation or pressure swing adsorption, are often energy-intensive. MOF-polymer membranes can operate at ambient temperatures and pressures, significantly lowering the energy requirements and, consequently, reducing greenhouse gas emissions associated with energy production.

The improved selectivity and permeability of MOF-polymer membranes can also contribute to more effective carbon capture and storage (CCS) technologies. By enhancing the separation of CO2 from other gases in industrial emissions, these membranes could play a crucial role in mitigating climate change. The potential for large-scale implementation of CCS using MOF-polymer membranes could lead to substantial reductions in atmospheric CO2 levels.

Furthermore, the use of MOF-polymer membranes in natural gas purification can have positive environmental impacts. These membranes can efficiently remove impurities such as CO2 and H2S from natural gas streams, resulting in cleaner-burning fuel and reduced emissions of sulfur compounds and other pollutants during combustion.

However, the environmental impact of MOF-polymer membranes extends beyond their operational benefits. The production of MOFs and their incorporation into polymer matrices may involve the use of solvents and other chemicals. It is crucial to consider the life cycle environmental impact of these materials, including their synthesis, use, and disposal. Efforts are being made to develop more sustainable MOF synthesis methods and to ensure the recyclability of MOF-polymer membranes at the end of their operational life.

The durability and longevity of MOF-polymer membranes also factor into their environmental impact. Membranes with extended operational lifetimes can reduce the frequency of replacement, thereby minimizing waste generation and resource consumption associated with membrane production and disposal. Ongoing research aims to enhance the stability of these hybrid membranes under various operating conditions to maximize their environmental benefits.

In conclusion, while MOF-polymer membranes show promise for reducing the environmental footprint of gas separation processes, a comprehensive assessment of their life cycle environmental impact is necessary. As research in this field progresses, it is essential to balance the potential benefits of improved gas separation with the environmental considerations of material production and end-of-life management.

One of the primary environmental benefits of MOF-polymer membranes is their potential to reduce energy consumption in gas separation processes. Traditional gas separation methods, such as cryogenic distillation or pressure swing adsorption, are often energy-intensive. MOF-polymer membranes can operate at ambient temperatures and pressures, significantly lowering the energy requirements and, consequently, reducing greenhouse gas emissions associated with energy production.

The improved selectivity and permeability of MOF-polymer membranes can also contribute to more effective carbon capture and storage (CCS) technologies. By enhancing the separation of CO2 from other gases in industrial emissions, these membranes could play a crucial role in mitigating climate change. The potential for large-scale implementation of CCS using MOF-polymer membranes could lead to substantial reductions in atmospheric CO2 levels.

Furthermore, the use of MOF-polymer membranes in natural gas purification can have positive environmental impacts. These membranes can efficiently remove impurities such as CO2 and H2S from natural gas streams, resulting in cleaner-burning fuel and reduced emissions of sulfur compounds and other pollutants during combustion.

However, the environmental impact of MOF-polymer membranes extends beyond their operational benefits. The production of MOFs and their incorporation into polymer matrices may involve the use of solvents and other chemicals. It is crucial to consider the life cycle environmental impact of these materials, including their synthesis, use, and disposal. Efforts are being made to develop more sustainable MOF synthesis methods and to ensure the recyclability of MOF-polymer membranes at the end of their operational life.

The durability and longevity of MOF-polymer membranes also factor into their environmental impact. Membranes with extended operational lifetimes can reduce the frequency of replacement, thereby minimizing waste generation and resource consumption associated with membrane production and disposal. Ongoing research aims to enhance the stability of these hybrid membranes under various operating conditions to maximize their environmental benefits.

In conclusion, while MOF-polymer membranes show promise for reducing the environmental footprint of gas separation processes, a comprehensive assessment of their life cycle environmental impact is necessary. As research in this field progresses, it is essential to balance the potential benefits of improved gas separation with the environmental considerations of material production and end-of-life management.

Scalability and Industrial Application

The scalability and industrial application of incorporating Metal-Organic Frameworks (MOFs) into polymer membranes for gas separation represent critical factors in determining the technology's widespread adoption and commercial viability. While laboratory-scale experiments have demonstrated promising results, transitioning this technology to industrial-scale production presents several challenges and opportunities.

One of the primary challenges in scaling up MOF-polymer membrane production is maintaining consistent quality and performance across large-scale manufacturing processes. The precise control of MOF particle size, distribution, and integration within the polymer matrix becomes increasingly complex as production volumes increase. To address this, researchers and engineers are developing advanced manufacturing techniques, such as continuous flow synthesis and in-situ MOF growth within polymer matrices, to ensure uniform dispersion and optimal membrane properties.

The cost-effectiveness of large-scale production is another crucial consideration for industrial application. Currently, the synthesis of MOFs can be expensive, particularly for more complex structures. However, as research progresses, more cost-effective synthesis methods are emerging, including the use of cheaper precursors and optimized reaction conditions. Additionally, the development of recyclable and regenerable MOF-polymer membranes could significantly enhance the economic viability of this technology in industrial settings.

Durability and long-term stability of MOF-polymer membranes under real-world operating conditions are essential for their industrial application. Researchers are focusing on enhancing the mechanical strength and chemical resistance of these membranes to withstand high pressures, temperature fluctuations, and potentially corrosive gas streams. The incorporation of crosslinking agents and the development of composite structures are among the strategies being explored to improve membrane longevity and performance consistency over extended periods.

The integration of MOF-polymer membranes into existing industrial gas separation processes presents both challenges and opportunities. While these membranes offer superior separation performance for certain gas mixtures, they may require modifications to current plant designs and operating procedures. However, the potential for energy savings and increased separation efficiency makes them attractive for industries seeking to optimize their processes and reduce carbon footprints.

As the technology matures, standardization and quality control protocols for MOF-polymer membranes will become increasingly important for widespread industrial adoption. Collaborative efforts between academic institutions, industry partners, and regulatory bodies are underway to establish guidelines for membrane characterization, performance testing, and quality assurance. These standards will facilitate the commercialization process and build confidence among potential end-users in various industrial sectors.

One of the primary challenges in scaling up MOF-polymer membrane production is maintaining consistent quality and performance across large-scale manufacturing processes. The precise control of MOF particle size, distribution, and integration within the polymer matrix becomes increasingly complex as production volumes increase. To address this, researchers and engineers are developing advanced manufacturing techniques, such as continuous flow synthesis and in-situ MOF growth within polymer matrices, to ensure uniform dispersion and optimal membrane properties.

The cost-effectiveness of large-scale production is another crucial consideration for industrial application. Currently, the synthesis of MOFs can be expensive, particularly for more complex structures. However, as research progresses, more cost-effective synthesis methods are emerging, including the use of cheaper precursors and optimized reaction conditions. Additionally, the development of recyclable and regenerable MOF-polymer membranes could significantly enhance the economic viability of this technology in industrial settings.

Durability and long-term stability of MOF-polymer membranes under real-world operating conditions are essential for their industrial application. Researchers are focusing on enhancing the mechanical strength and chemical resistance of these membranes to withstand high pressures, temperature fluctuations, and potentially corrosive gas streams. The incorporation of crosslinking agents and the development of composite structures are among the strategies being explored to improve membrane longevity and performance consistency over extended periods.

The integration of MOF-polymer membranes into existing industrial gas separation processes presents both challenges and opportunities. While these membranes offer superior separation performance for certain gas mixtures, they may require modifications to current plant designs and operating procedures. However, the potential for energy savings and increased separation efficiency makes them attractive for industries seeking to optimize their processes and reduce carbon footprints.

As the technology matures, standardization and quality control protocols for MOF-polymer membranes will become increasingly important for widespread industrial adoption. Collaborative efforts between academic institutions, industry partners, and regulatory bodies are underway to establish guidelines for membrane characterization, performance testing, and quality assurance. These standards will facilitate the commercialization process and build confidence among potential end-users in various industrial sectors.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!