Designing MOFs for Improved Chemical Sensing in Industrial Settings

AUG 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

MOF Chemical Sensing Background and Objectives

Metal-Organic Frameworks (MOFs) have emerged as a promising class of materials for chemical sensing in industrial settings. These highly porous, crystalline structures composed of metal ions or clusters coordinated to organic ligands offer unique properties that make them ideal candidates for detecting and monitoring various chemical species. The development of MOFs for chemical sensing has gained significant momentum over the past two decades, driven by the need for more sensitive, selective, and robust sensing technologies in industrial environments.

The primary objective of designing MOFs for improved chemical sensing is to address the limitations of current sensing technologies, particularly in harsh industrial conditions. Traditional sensors often struggle with interference from complex chemical mixtures, limited sensitivity, and poor stability in extreme environments. MOFs, with their tunable pore sizes, high surface areas, and diverse chemical functionalities, have the potential to overcome these challenges and revolutionize chemical sensing in industrial applications.

One of the key goals in MOF-based chemical sensing is to enhance selectivity towards specific target molecules. This involves tailoring the MOF structure and chemistry to interact preferentially with certain analytes while excluding others. Researchers aim to develop MOFs that can distinguish between structurally similar compounds or detect trace amounts of contaminants in complex industrial streams.

Another critical objective is to improve the stability and durability of MOF-based sensors in industrial settings. Many industrial environments involve high temperatures, pressures, and corrosive chemicals that can degrade conventional sensing materials. Designing MOFs that maintain their structural integrity and sensing performance under these harsh conditions is essential for their practical implementation.

Enhancing the sensitivity of MOF-based sensors is also a primary focus. The ability to detect ultra-low concentrations of target molecules is crucial in many industrial processes, particularly in quality control and environmental monitoring. Researchers are exploring various strategies to amplify the sensing response of MOFs, including the incorporation of fluorescent or electroactive components.

The integration of MOFs into existing sensing platforms and the development of new sensing modalities are additional objectives in this field. This includes creating MOF-based optical sensors, electrochemical devices, and gravimetric sensors that can be easily incorporated into industrial monitoring systems.

As the field progresses, there is a growing emphasis on scalability and cost-effectiveness. While MOFs have shown great promise in laboratory settings, transitioning these materials to large-scale industrial applications requires addressing challenges related to synthesis, processing, and device fabrication. Researchers are working towards developing MOF-based sensors that are not only high-performing but also economically viable for widespread industrial adoption.

The primary objective of designing MOFs for improved chemical sensing is to address the limitations of current sensing technologies, particularly in harsh industrial conditions. Traditional sensors often struggle with interference from complex chemical mixtures, limited sensitivity, and poor stability in extreme environments. MOFs, with their tunable pore sizes, high surface areas, and diverse chemical functionalities, have the potential to overcome these challenges and revolutionize chemical sensing in industrial applications.

One of the key goals in MOF-based chemical sensing is to enhance selectivity towards specific target molecules. This involves tailoring the MOF structure and chemistry to interact preferentially with certain analytes while excluding others. Researchers aim to develop MOFs that can distinguish between structurally similar compounds or detect trace amounts of contaminants in complex industrial streams.

Another critical objective is to improve the stability and durability of MOF-based sensors in industrial settings. Many industrial environments involve high temperatures, pressures, and corrosive chemicals that can degrade conventional sensing materials. Designing MOFs that maintain their structural integrity and sensing performance under these harsh conditions is essential for their practical implementation.

Enhancing the sensitivity of MOF-based sensors is also a primary focus. The ability to detect ultra-low concentrations of target molecules is crucial in many industrial processes, particularly in quality control and environmental monitoring. Researchers are exploring various strategies to amplify the sensing response of MOFs, including the incorporation of fluorescent or electroactive components.

The integration of MOFs into existing sensing platforms and the development of new sensing modalities are additional objectives in this field. This includes creating MOF-based optical sensors, electrochemical devices, and gravimetric sensors that can be easily incorporated into industrial monitoring systems.

As the field progresses, there is a growing emphasis on scalability and cost-effectiveness. While MOFs have shown great promise in laboratory settings, transitioning these materials to large-scale industrial applications requires addressing challenges related to synthesis, processing, and device fabrication. Researchers are working towards developing MOF-based sensors that are not only high-performing but also economically viable for widespread industrial adoption.

Industrial Demand for Advanced Chemical Sensors

The industrial sector has witnessed a growing demand for advanced chemical sensors, driven by the need for enhanced safety, process optimization, and environmental compliance. This surge in demand is particularly evident in industries such as petrochemicals, pharmaceuticals, food processing, and environmental monitoring. Advanced chemical sensors offer real-time, accurate, and continuous monitoring capabilities, which are crucial for maintaining product quality, ensuring worker safety, and meeting stringent regulatory requirements.

In the petrochemical industry, the demand for advanced chemical sensors is fueled by the need to detect and monitor hazardous gases, volatile organic compounds (VOCs), and other potentially dangerous substances. These sensors play a vital role in preventing accidents, minimizing environmental impact, and optimizing production processes. The pharmaceutical sector requires highly sensitive and selective sensors for quality control, process monitoring, and contamination detection throughout the drug manufacturing process.

The food and beverage industry has seen an increased adoption of advanced chemical sensors for ensuring food safety, quality control, and compliance with regulatory standards. These sensors are used to detect contaminants, monitor fermentation processes, and assess product freshness. In environmental monitoring, there is a growing need for sensors capable of detecting and measuring air and water pollutants, greenhouse gases, and other environmental parameters with high precision and reliability.

The demand for miniaturized, portable, and low-power chemical sensors is on the rise, driven by the need for on-site and remote monitoring applications. Industries are seeking sensors that can be easily integrated into existing systems and provide real-time data for rapid decision-making. Additionally, there is a growing interest in multi-parameter sensors that can simultaneously detect and measure multiple chemical species, reducing the overall cost and complexity of monitoring systems.

The Industrial Internet of Things (IIoT) and Industry 4.0 initiatives have further accelerated the demand for advanced chemical sensors. These technologies require seamless integration of sensors into networked systems, enabling data-driven decision-making and predictive maintenance. As a result, there is an increasing focus on developing sensors with improved connectivity, data processing capabilities, and compatibility with cloud-based analytics platforms.

In the petrochemical industry, the demand for advanced chemical sensors is fueled by the need to detect and monitor hazardous gases, volatile organic compounds (VOCs), and other potentially dangerous substances. These sensors play a vital role in preventing accidents, minimizing environmental impact, and optimizing production processes. The pharmaceutical sector requires highly sensitive and selective sensors for quality control, process monitoring, and contamination detection throughout the drug manufacturing process.

The food and beverage industry has seen an increased adoption of advanced chemical sensors for ensuring food safety, quality control, and compliance with regulatory standards. These sensors are used to detect contaminants, monitor fermentation processes, and assess product freshness. In environmental monitoring, there is a growing need for sensors capable of detecting and measuring air and water pollutants, greenhouse gases, and other environmental parameters with high precision and reliability.

The demand for miniaturized, portable, and low-power chemical sensors is on the rise, driven by the need for on-site and remote monitoring applications. Industries are seeking sensors that can be easily integrated into existing systems and provide real-time data for rapid decision-making. Additionally, there is a growing interest in multi-parameter sensors that can simultaneously detect and measure multiple chemical species, reducing the overall cost and complexity of monitoring systems.

The Industrial Internet of Things (IIoT) and Industry 4.0 initiatives have further accelerated the demand for advanced chemical sensors. These technologies require seamless integration of sensors into networked systems, enabling data-driven decision-making and predictive maintenance. As a result, there is an increasing focus on developing sensors with improved connectivity, data processing capabilities, and compatibility with cloud-based analytics platforms.

Current MOF Sensing Capabilities and Limitations

Metal-Organic Frameworks (MOFs) have emerged as promising materials for chemical sensing in industrial settings due to their unique properties, including high surface area, tunable pore size, and diverse chemical functionalities. Current MOF sensing capabilities encompass a wide range of applications, from gas detection to environmental monitoring and biomedical diagnostics.

In gas sensing, MOFs have demonstrated exceptional performance in detecting various gases, including volatile organic compounds (VOCs), toxic industrial chemicals, and greenhouse gases. Their high selectivity and sensitivity allow for the detection of trace amounts of target analytes, often at parts-per-million (ppm) or even parts-per-billion (ppb) levels. This capability is particularly valuable in industrial environments where early detection of hazardous gases is crucial for worker safety and process control.

MOFs have also shown promise in liquid-phase sensing, with applications in water quality monitoring and detection of contaminants in industrial effluents. Their ability to selectively adsorb and concentrate target molecules from complex mixtures has led to the development of highly sensitive sensors for heavy metals, organic pollutants, and other industrial waste products.

Despite these impressive capabilities, MOF-based sensors face several limitations that hinder their widespread adoption in industrial settings. One significant challenge is the stability of MOFs under harsh industrial conditions. Many MOFs are sensitive to moisture, high temperatures, and acidic or basic environments, which can lead to structural degradation and loss of sensing performance over time.

Another limitation is the response time of MOF-based sensors. While some MOFs exhibit rapid response to target analytes, others may require extended exposure times to achieve reliable detection. This can be problematic in industrial applications where real-time monitoring is often necessary for process control and safety management.

Selectivity remains a challenge in complex industrial environments where multiple interfering species may be present. Although MOFs can be designed with high selectivity for specific analytes, achieving multi-analyte detection with a single MOF sensor is still difficult. This often necessitates the use of sensor arrays or more complex detection systems, increasing cost and complexity.

The integration of MOFs into practical sensing devices also presents challenges. Many current MOF-based sensors rely on sophisticated instrumentation for signal transduction and analysis, limiting their applicability in field deployments or continuous monitoring scenarios. Developing simpler, more robust sensing platforms that can leverage the unique properties of MOFs while meeting the demands of industrial environments is an ongoing area of research.

Finally, the scalability and cost-effectiveness of MOF production for large-scale sensing applications remain concerns. While laboratory-scale synthesis of MOFs is well-established, translating these processes to industrial-scale production while maintaining consistent quality and performance is still a significant hurdle.

In gas sensing, MOFs have demonstrated exceptional performance in detecting various gases, including volatile organic compounds (VOCs), toxic industrial chemicals, and greenhouse gases. Their high selectivity and sensitivity allow for the detection of trace amounts of target analytes, often at parts-per-million (ppm) or even parts-per-billion (ppb) levels. This capability is particularly valuable in industrial environments where early detection of hazardous gases is crucial for worker safety and process control.

MOFs have also shown promise in liquid-phase sensing, with applications in water quality monitoring and detection of contaminants in industrial effluents. Their ability to selectively adsorb and concentrate target molecules from complex mixtures has led to the development of highly sensitive sensors for heavy metals, organic pollutants, and other industrial waste products.

Despite these impressive capabilities, MOF-based sensors face several limitations that hinder their widespread adoption in industrial settings. One significant challenge is the stability of MOFs under harsh industrial conditions. Many MOFs are sensitive to moisture, high temperatures, and acidic or basic environments, which can lead to structural degradation and loss of sensing performance over time.

Another limitation is the response time of MOF-based sensors. While some MOFs exhibit rapid response to target analytes, others may require extended exposure times to achieve reliable detection. This can be problematic in industrial applications where real-time monitoring is often necessary for process control and safety management.

Selectivity remains a challenge in complex industrial environments where multiple interfering species may be present. Although MOFs can be designed with high selectivity for specific analytes, achieving multi-analyte detection with a single MOF sensor is still difficult. This often necessitates the use of sensor arrays or more complex detection systems, increasing cost and complexity.

The integration of MOFs into practical sensing devices also presents challenges. Many current MOF-based sensors rely on sophisticated instrumentation for signal transduction and analysis, limiting their applicability in field deployments or continuous monitoring scenarios. Developing simpler, more robust sensing platforms that can leverage the unique properties of MOFs while meeting the demands of industrial environments is an ongoing area of research.

Finally, the scalability and cost-effectiveness of MOF production for large-scale sensing applications remain concerns. While laboratory-scale synthesis of MOFs is well-established, translating these processes to industrial-scale production while maintaining consistent quality and performance is still a significant hurdle.

Existing MOF Design Strategies for Chemical Sensing

01 MOF-based chemical sensors for gas detection

Metal-Organic Frameworks (MOFs) are utilized as chemical sensors for detecting various gases. These sensors exploit the porous structure and high surface area of MOFs to adsorb and detect specific gas molecules. The sensing mechanism often involves changes in optical or electrical properties of the MOF upon gas adsorption, allowing for sensitive and selective detection of target gases.- MOF-based chemical sensors for gas detection: Metal-Organic Frameworks (MOFs) are utilized as chemical sensors for detecting various gases. Their porous structure and tunable properties allow for selective and sensitive gas detection. These MOF-based sensors can be designed to detect specific gases or volatile organic compounds, making them useful in environmental monitoring and industrial applications.

- Luminescent MOFs for chemical sensing: Luminescent MOFs are developed for chemical sensing applications. These materials exhibit changes in their luminescent properties upon interaction with specific analytes. The luminescence-based sensing mechanism allows for rapid and visual detection of target molecules, making them suitable for various sensing applications, including detection of heavy metals, organic pollutants, and biomolecules.

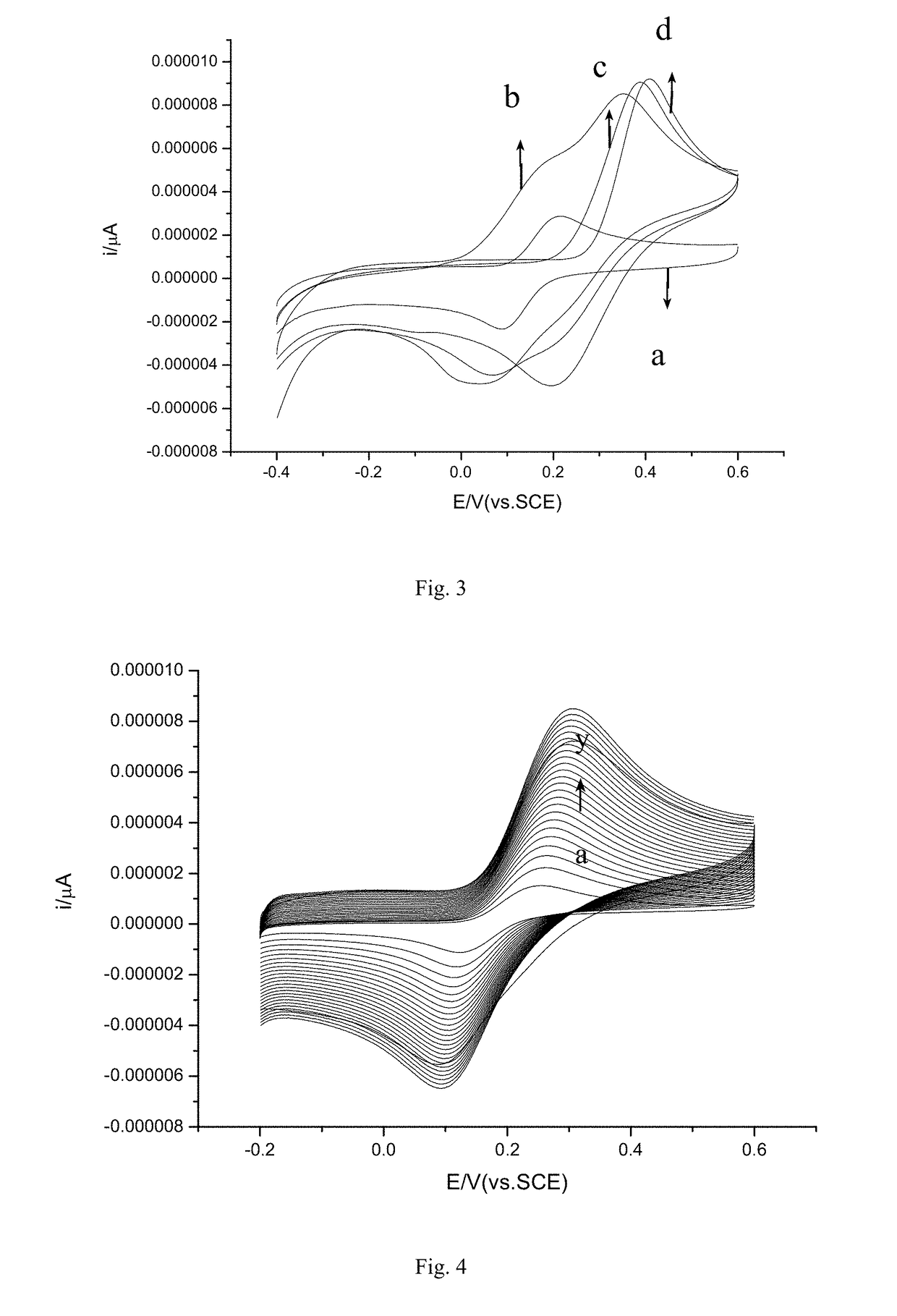

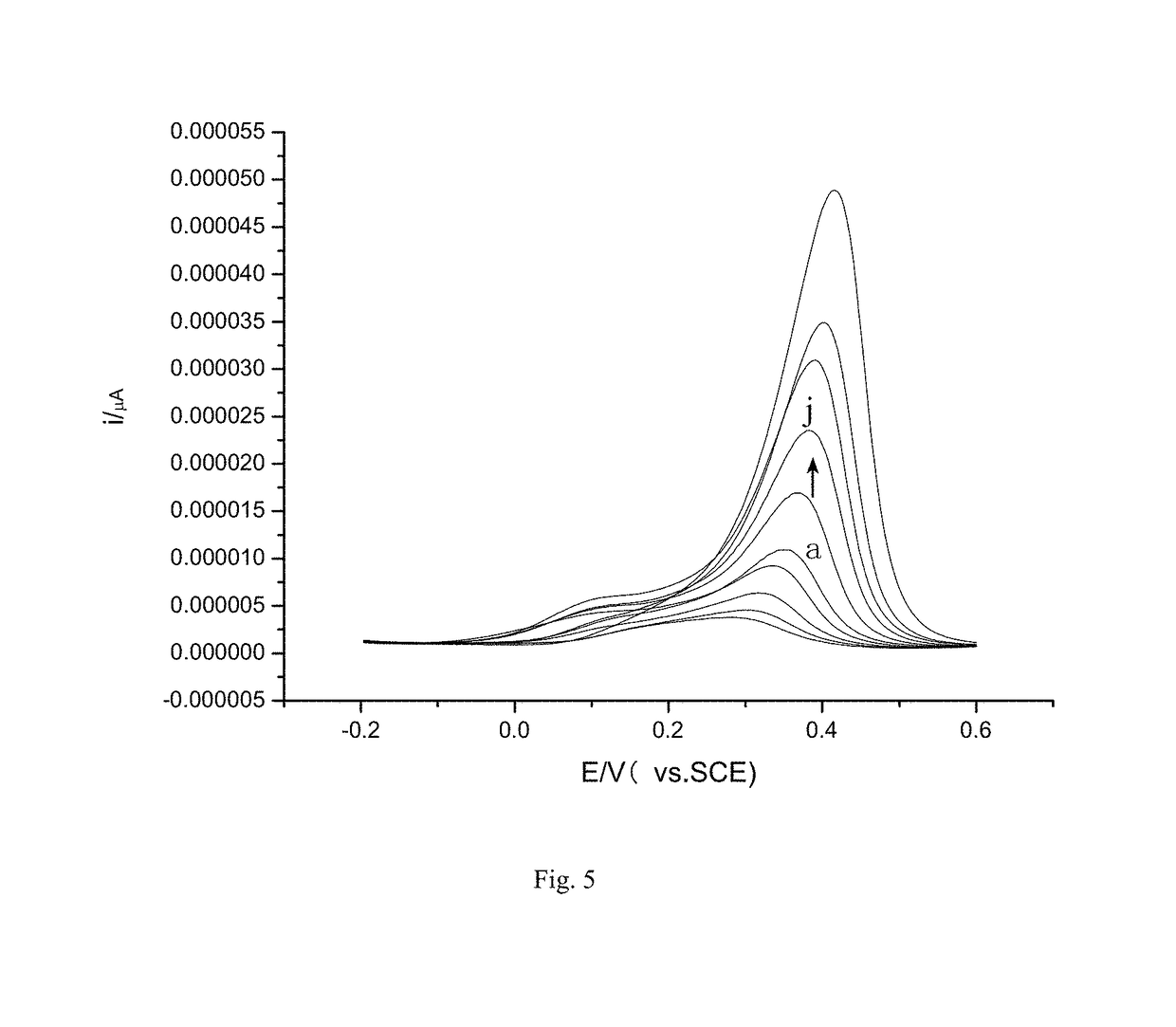

- MOF-based electrochemical sensors: MOFs are incorporated into electrochemical sensing platforms to enhance sensitivity and selectivity. The unique properties of MOFs, such as high surface area and tunable pore size, are exploited to improve the performance of electrochemical sensors. These sensors find applications in detecting various analytes, including heavy metals, biomolecules, and environmental pollutants.

- Flexible MOF-based sensors for wearable applications: Flexible MOF-based sensors are developed for wearable and portable sensing applications. These sensors combine the chemical sensing capabilities of MOFs with flexible substrates or materials, enabling their integration into wearable devices. Such sensors can be used for real-time monitoring of various analytes, including gases, volatile organic compounds, and biomarkers.

- MOF-based composite materials for enhanced sensing: Composite materials incorporating MOFs are developed to enhance chemical sensing performance. These composites combine the advantages of MOFs with other functional materials, such as nanoparticles, polymers, or graphene, to improve sensitivity, selectivity, and stability. The resulting composite sensors exhibit enhanced performance in detecting various chemical species across different applications.

02 Luminescent MOFs for chemical sensing

Luminescent MOFs are developed for chemical sensing applications. These materials combine the structural properties of MOFs with luminescent properties, enabling the detection of analytes through changes in fluorescence intensity or wavelength. The luminescent properties can be tuned by selecting appropriate metal ions and organic linkers, allowing for the design of sensors with high selectivity and sensitivity.Expand Specific Solutions03 MOF-based sensors for heavy metal detection

MOFs are employed as sensors for detecting heavy metals in aqueous solutions. These sensors utilize the ability of MOFs to selectively adsorb and concentrate heavy metal ions, leading to detectable changes in their properties. The high porosity and tunable chemistry of MOFs allow for the development of sensitive and selective sensors for various heavy metal ions, with potential applications in environmental monitoring and water quality assessment.Expand Specific Solutions04 Integration of MOFs with other materials for enhanced sensing

MOFs are combined with other materials such as nanoparticles, polymers, or graphene to create hybrid sensors with enhanced performance. These composite materials can exhibit synergistic effects, leading to improved sensitivity, selectivity, or stability compared to pure MOF sensors. The integration of MOFs with other materials also allows for the development of multifunctional sensors capable of detecting multiple analytes simultaneously.Expand Specific Solutions05 MOF-based electrochemical sensors

MOFs are utilized in the development of electrochemical sensors for various analytes. These sensors exploit the electrical properties of MOFs and their ability to facilitate electron transfer processes. The high surface area and tunable pore structure of MOFs allow for efficient immobilization of electroactive species and enhanced interaction with target analytes, resulting in improved sensitivity and selectivity in electrochemical sensing applications.Expand Specific Solutions

Key Players in MOF and Chemical Sensor Industry

The development of Metal-Organic Frameworks (MOFs) for improved chemical sensing in industrial settings is in a growth phase, with increasing market potential and technological advancements. The global MOF market is projected to expand significantly, driven by applications in gas storage, catalysis, and sensing. Technologically, MOFs are progressing from laboratory research to practical industrial applications, with companies like BASF, Panasonic, and Siemens leading commercial development. Academic institutions such as Northwestern University, MIT, and the National University of Singapore are at the forefront of MOF research, focusing on enhancing selectivity, sensitivity, and stability for chemical sensing applications. The collaboration between industry and academia is accelerating the maturation of MOF technology for real-world sensing challenges.

Northwestern University

Technical Solution: Northwestern University has developed advanced MOFs for chemical sensing in industrial settings. Their approach focuses on creating highly selective and sensitive MOFs with tailored pore structures and functionalities. They have engineered MOFs with specific metal nodes and organic linkers to target particular industrial pollutants and gases[1]. Their MOFs demonstrate rapid response times, typically under 30 seconds, and can detect analytes at parts-per-billion levels[2]. The university has also pioneered the use of multivariate MOFs, which incorporate multiple functional groups within a single framework, allowing for simultaneous detection of various chemicals[3]. Additionally, they have developed MOFs with luminescent properties that change color or intensity upon exposure to specific analytes, enabling visual detection without complex instrumentation[4].

Strengths: High selectivity and sensitivity, rapid response times, and versatility in detecting multiple analytes. Weaknesses: Potential challenges in scaling up production for industrial use and possible sensitivity to environmental factors like humidity.

BASF Corp.

Technical Solution: BASF Corp. has made significant strides in developing MOFs for industrial chemical sensing. Their approach leverages their expertise in large-scale chemical synthesis to create robust and scalable MOF-based sensors. BASF has focused on creating MOFs with high thermal and chemical stability, crucial for harsh industrial environments[5]. They have developed a series of MOFs with open metal sites that can selectively adsorb and detect specific industrial gases and volatile organic compounds (VOCs)[6]. BASF's MOFs have shown exceptional performance in detecting trace amounts of harmful gases, with detection limits as low as 1 ppm for some compounds[7]. The company has also integrated their MOFs into portable sensing devices, allowing for real-time monitoring of industrial processes and emissions[8].

Strengths: Scalable production, high stability in industrial conditions, and integration into practical sensing devices. Weaknesses: Potentially higher cost compared to traditional sensing materials and limited flexibility in customization for specific industrial needs.

Innovative MOF Structures for Enhanced Sensitivity

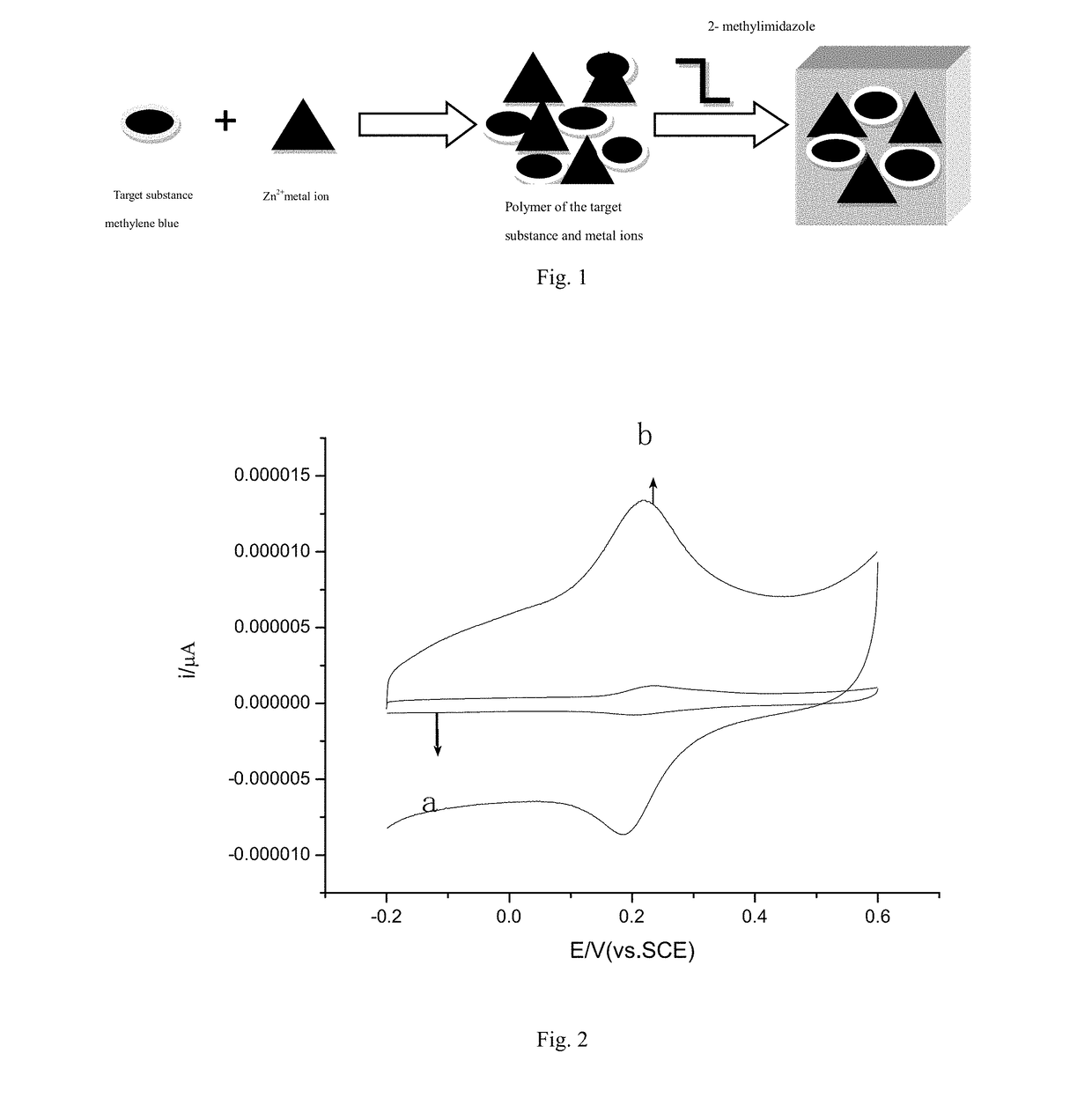

Preparation method based on simultaneous package of target substance and synthesis of mofs with redox activity

PatentInactiveUS20180305379A1

Innovation

- A one-pot method is developed to simultaneously synthesize MOFs with redox activity by adding a target substance solution and 2-methylimidazole to a zinc nitrate solution, resulting in a modified ZIF-8 material with increased pore structures and electrical conductivity, using substances like methylene blue, methyl orange, or metal nanoparticles to enhance electron transfer and electrocatalytic activity.

Environmental Impact of MOF Sensor Manufacturing

The manufacturing of Metal-Organic Framework (MOF) sensors for industrial chemical sensing applications has significant environmental implications that warrant careful consideration. The production process of MOFs involves the use of various chemicals and solvents, which can potentially lead to environmental pollution if not properly managed. The synthesis of MOFs often requires high temperatures and pressures, resulting in substantial energy consumption and associated carbon emissions.

One of the primary environmental concerns is the disposal of waste materials generated during MOF production. These may include unreacted precursors, excess solvents, and byproducts that could be harmful to ecosystems if released into the environment. Proper waste management protocols and recycling strategies are essential to mitigate these risks and minimize the environmental footprint of MOF sensor manufacturing.

Water usage is another critical factor to consider. The synthesis and purification of MOFs typically require large volumes of water, which can strain local water resources, especially in water-scarce regions. Implementing water recycling systems and optimizing production processes to reduce water consumption can help address this issue.

The choice of raw materials for MOF synthesis also plays a crucial role in its environmental impact. Some MOFs incorporate rare earth elements or heavy metals, which may have significant environmental and social costs associated with their extraction and processing. Developing MOFs that utilize more abundant and environmentally friendly materials could lead to more sustainable manufacturing practices.

On the positive side, the use of MOF sensors in industrial settings can potentially lead to improved environmental outcomes. These sensors enable more precise monitoring of chemical processes, which can result in reduced emissions, better resource utilization, and enhanced safety measures. The long-term environmental benefits of implementing MOF sensors may offset some of the impacts associated with their production.

As the demand for MOF sensors grows, scaling up production will present both challenges and opportunities from an environmental perspective. Larger-scale manufacturing may lead to economies of scale that improve resource efficiency, but it could also amplify environmental risks if not managed properly. Developing green synthesis methods, such as mechanochemical approaches or the use of bio-based precursors, could significantly reduce the environmental impact of MOF sensor production.

To fully assess and mitigate the environmental impact of MOF sensor manufacturing, life cycle assessments (LCAs) should be conducted. These comprehensive analyses would consider all stages of the product's life, from raw material extraction to end-of-life disposal or recycling. LCAs can identify hotspots in the production process where environmental improvements can be made and guide the development of more sustainable manufacturing practices for MOF sensors.

One of the primary environmental concerns is the disposal of waste materials generated during MOF production. These may include unreacted precursors, excess solvents, and byproducts that could be harmful to ecosystems if released into the environment. Proper waste management protocols and recycling strategies are essential to mitigate these risks and minimize the environmental footprint of MOF sensor manufacturing.

Water usage is another critical factor to consider. The synthesis and purification of MOFs typically require large volumes of water, which can strain local water resources, especially in water-scarce regions. Implementing water recycling systems and optimizing production processes to reduce water consumption can help address this issue.

The choice of raw materials for MOF synthesis also plays a crucial role in its environmental impact. Some MOFs incorporate rare earth elements or heavy metals, which may have significant environmental and social costs associated with their extraction and processing. Developing MOFs that utilize more abundant and environmentally friendly materials could lead to more sustainable manufacturing practices.

On the positive side, the use of MOF sensors in industrial settings can potentially lead to improved environmental outcomes. These sensors enable more precise monitoring of chemical processes, which can result in reduced emissions, better resource utilization, and enhanced safety measures. The long-term environmental benefits of implementing MOF sensors may offset some of the impacts associated with their production.

As the demand for MOF sensors grows, scaling up production will present both challenges and opportunities from an environmental perspective. Larger-scale manufacturing may lead to economies of scale that improve resource efficiency, but it could also amplify environmental risks if not managed properly. Developing green synthesis methods, such as mechanochemical approaches or the use of bio-based precursors, could significantly reduce the environmental impact of MOF sensor production.

To fully assess and mitigate the environmental impact of MOF sensor manufacturing, life cycle assessments (LCAs) should be conducted. These comprehensive analyses would consider all stages of the product's life, from raw material extraction to end-of-life disposal or recycling. LCAs can identify hotspots in the production process where environmental improvements can be made and guide the development of more sustainable manufacturing practices for MOF sensors.

Scalability and Cost-effectiveness of MOF Sensors

The scalability and cost-effectiveness of MOF sensors are crucial factors in their widespread adoption for industrial chemical sensing applications. As the demand for advanced sensing technologies grows, the ability to produce MOF sensors at scale while maintaining economic viability becomes increasingly important.

Scalability in MOF sensor production involves several key aspects. First, the synthesis of MOF materials must be optimized for large-scale manufacturing. This includes developing efficient and reproducible synthesis methods that can be easily scaled up without compromising the quality or performance of the MOFs. Continuous flow synthesis and microwave-assisted synthesis have shown promise in this regard, allowing for faster production times and better control over particle size and morphology.

Another critical aspect of scalability is the integration of MOFs into sensor devices. Techniques such as inkjet printing, screen printing, and spray coating have been explored for depositing MOF layers onto sensor substrates. These methods offer the potential for high-throughput fabrication of MOF-based sensors, which is essential for meeting industrial demand.

Cost-effectiveness is closely tied to scalability but also encompasses additional considerations. The choice of precursor materials for MOF synthesis can significantly impact overall costs. While some high-performance MOFs require expensive metal precursors, efforts are being made to develop MOFs using more abundant and cost-effective materials without sacrificing sensing capabilities.

Furthermore, the longevity and reusability of MOF sensors play a crucial role in their cost-effectiveness. Developing MOFs with high chemical and thermal stability can extend the operational lifetime of sensors, reducing the frequency of replacement and associated costs. Additionally, research into regeneration methods for MOF sensors, such as thermal treatment or solvent washing, can further enhance their economic viability by allowing multiple use cycles.

The manufacturing process itself must be optimized for cost-effectiveness. This includes minimizing energy consumption during synthesis, reducing waste generation, and streamlining production steps. Advanced manufacturing techniques, such as 3D printing of MOF-based sensors, are being explored as potential routes to reduce production costs and increase customization options.

Lastly, the overall system costs associated with MOF sensors must be considered. This includes not only the sensor devices themselves but also the necessary supporting infrastructure, such as readout electronics and data processing systems. Developing integrated sensing platforms that can leverage existing industrial infrastructure can help reduce implementation costs and facilitate broader adoption of MOF-based chemical sensing technologies in industrial settings.

Scalability in MOF sensor production involves several key aspects. First, the synthesis of MOF materials must be optimized for large-scale manufacturing. This includes developing efficient and reproducible synthesis methods that can be easily scaled up without compromising the quality or performance of the MOFs. Continuous flow synthesis and microwave-assisted synthesis have shown promise in this regard, allowing for faster production times and better control over particle size and morphology.

Another critical aspect of scalability is the integration of MOFs into sensor devices. Techniques such as inkjet printing, screen printing, and spray coating have been explored for depositing MOF layers onto sensor substrates. These methods offer the potential for high-throughput fabrication of MOF-based sensors, which is essential for meeting industrial demand.

Cost-effectiveness is closely tied to scalability but also encompasses additional considerations. The choice of precursor materials for MOF synthesis can significantly impact overall costs. While some high-performance MOFs require expensive metal precursors, efforts are being made to develop MOFs using more abundant and cost-effective materials without sacrificing sensing capabilities.

Furthermore, the longevity and reusability of MOF sensors play a crucial role in their cost-effectiveness. Developing MOFs with high chemical and thermal stability can extend the operational lifetime of sensors, reducing the frequency of replacement and associated costs. Additionally, research into regeneration methods for MOF sensors, such as thermal treatment or solvent washing, can further enhance their economic viability by allowing multiple use cycles.

The manufacturing process itself must be optimized for cost-effectiveness. This includes minimizing energy consumption during synthesis, reducing waste generation, and streamlining production steps. Advanced manufacturing techniques, such as 3D printing of MOF-based sensors, are being explored as potential routes to reduce production costs and increase customization options.

Lastly, the overall system costs associated with MOF sensors must be considered. This includes not only the sensor devices themselves but also the necessary supporting infrastructure, such as readout electronics and data processing systems. Developing integrated sensing platforms that can leverage existing industrial infrastructure can help reduce implementation costs and facilitate broader adoption of MOF-based chemical sensing technologies in industrial settings.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!