Investigating MOF Stability under Dynamic Pressure Conditions

AUG 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

MOF Stability Research Background and Objectives

Metal-Organic Frameworks (MOFs) have emerged as a revolutionary class of porous materials with exceptional potential across various applications, including gas storage, catalysis, and drug delivery. The investigation of MOF stability under dynamic pressure conditions represents a critical area of research that has gained significant attention in recent years. This field of study aims to understand and enhance the structural integrity and performance of MOFs when subjected to varying pressure environments, which is crucial for their practical implementation in real-world scenarios.

The evolution of MOF research has been marked by rapid advancements since the late 1990s, with initial focus primarily on synthesis and characterization. As the field matured, emphasis shifted towards exploring the functional properties of MOFs, including their stability under different conditions. The stability of MOFs under dynamic pressure is particularly relevant due to the diverse range of applications where these materials may encounter fluctuating pressure environments, such as in gas separation processes, pressure-swing adsorption systems, and high-pressure catalytic reactions.

The primary objective of investigating MOF stability under dynamic pressure conditions is to develop more robust and reliable materials that can withstand the rigors of industrial applications. This research aims to bridge the gap between laboratory-scale synthesis and large-scale implementation by addressing key challenges related to structural integrity, performance consistency, and long-term durability under varying pressure regimes.

Researchers in this field are focused on several key goals. Firstly, they seek to understand the fundamental mechanisms of structural deformation and collapse in MOFs under dynamic pressure. This involves studying the relationship between MOF composition, framework topology, and pressure-induced changes at the molecular level. Secondly, there is a concerted effort to develop new characterization techniques and in situ measurement methods that can provide real-time insights into MOF behavior under dynamic pressure conditions.

Another crucial objective is the design and synthesis of pressure-resistant MOFs through rational material engineering. This includes exploring novel ligand designs, metal node modifications, and framework architectures that can enhance the mechanical stability of MOFs without compromising their desirable properties such as high surface area and porosity.

Furthermore, researchers aim to establish standardized protocols for evaluating MOF stability under dynamic pressure conditions. This is essential for comparing different MOF systems and predicting their performance in various applications. The development of computational models and simulation techniques to predict MOF behavior under pressure is also a key focus, as it can accelerate the discovery and optimization of stable MOF structures.

Ultimately, the overarching goal of this research is to enable the widespread adoption of MOFs in pressure-sensitive applications by ensuring their reliability and performance under real-world conditions. This has far-reaching implications for advancing technologies in energy storage, environmental remediation, and industrial separations, where MOFs have shown immense promise but face challenges related to stability and durability.

The evolution of MOF research has been marked by rapid advancements since the late 1990s, with initial focus primarily on synthesis and characterization. As the field matured, emphasis shifted towards exploring the functional properties of MOFs, including their stability under different conditions. The stability of MOFs under dynamic pressure is particularly relevant due to the diverse range of applications where these materials may encounter fluctuating pressure environments, such as in gas separation processes, pressure-swing adsorption systems, and high-pressure catalytic reactions.

The primary objective of investigating MOF stability under dynamic pressure conditions is to develop more robust and reliable materials that can withstand the rigors of industrial applications. This research aims to bridge the gap between laboratory-scale synthesis and large-scale implementation by addressing key challenges related to structural integrity, performance consistency, and long-term durability under varying pressure regimes.

Researchers in this field are focused on several key goals. Firstly, they seek to understand the fundamental mechanisms of structural deformation and collapse in MOFs under dynamic pressure. This involves studying the relationship between MOF composition, framework topology, and pressure-induced changes at the molecular level. Secondly, there is a concerted effort to develop new characterization techniques and in situ measurement methods that can provide real-time insights into MOF behavior under dynamic pressure conditions.

Another crucial objective is the design and synthesis of pressure-resistant MOFs through rational material engineering. This includes exploring novel ligand designs, metal node modifications, and framework architectures that can enhance the mechanical stability of MOFs without compromising their desirable properties such as high surface area and porosity.

Furthermore, researchers aim to establish standardized protocols for evaluating MOF stability under dynamic pressure conditions. This is essential for comparing different MOF systems and predicting their performance in various applications. The development of computational models and simulation techniques to predict MOF behavior under pressure is also a key focus, as it can accelerate the discovery and optimization of stable MOF structures.

Ultimately, the overarching goal of this research is to enable the widespread adoption of MOFs in pressure-sensitive applications by ensuring their reliability and performance under real-world conditions. This has far-reaching implications for advancing technologies in energy storage, environmental remediation, and industrial separations, where MOFs have shown immense promise but face challenges related to stability and durability.

Market Demand for Pressure-Resistant MOFs

The market demand for pressure-resistant Metal-Organic Frameworks (MOFs) has been steadily growing across various industries, driven by the unique properties and versatile applications of these materials. MOFs, known for their exceptional porosity and tunable structures, have garnered significant attention in sectors such as gas storage, separation processes, and catalysis. The ability of MOFs to withstand dynamic pressure conditions is particularly crucial in these applications, making pressure-resistant MOFs highly sought after.

In the energy sector, there is a growing need for efficient gas storage solutions, especially for hydrogen and natural gas. Pressure-resistant MOFs offer a promising avenue for high-capacity gas storage under varying pressure conditions, which is essential for the development of clean energy technologies and sustainable transportation systems. The automotive industry, in particular, has shown keen interest in pressure-resistant MOFs for their potential in hydrogen fuel cell vehicles, where stable gas storage under fluctuating pressures is critical.

The chemical and petrochemical industries represent another significant market for pressure-resistant MOFs. These materials are increasingly being explored for use in separation processes, such as carbon capture and storage (CCS) and gas purification. The ability of MOFs to maintain their structural integrity and separation efficiency under dynamic pressure conditions is crucial for industrial-scale applications, where pressure fluctuations are common.

Environmental applications, particularly in air and water purification, have also contributed to the rising demand for pressure-resistant MOFs. These materials show promise in removing contaminants and pollutants under varying pressure conditions, making them valuable in both industrial and municipal water treatment systems, as well as in air filtration technologies.

The pharmaceutical and biomedical sectors are emerging markets for pressure-resistant MOFs. These materials are being investigated for drug delivery systems and as components in medical devices where stability under changing physiological pressures is essential. The potential for controlled release of therapeutic agents under specific pressure conditions opens up new possibilities in targeted drug delivery.

As industries continue to push the boundaries of material performance, the demand for MOFs that can withstand extreme and fluctuating pressure conditions is expected to grow. This trend is further supported by the increasing focus on sustainability and energy efficiency across various sectors, where the unique properties of pressure-resistant MOFs can offer significant advantages.

In the energy sector, there is a growing need for efficient gas storage solutions, especially for hydrogen and natural gas. Pressure-resistant MOFs offer a promising avenue for high-capacity gas storage under varying pressure conditions, which is essential for the development of clean energy technologies and sustainable transportation systems. The automotive industry, in particular, has shown keen interest in pressure-resistant MOFs for their potential in hydrogen fuel cell vehicles, where stable gas storage under fluctuating pressures is critical.

The chemical and petrochemical industries represent another significant market for pressure-resistant MOFs. These materials are increasingly being explored for use in separation processes, such as carbon capture and storage (CCS) and gas purification. The ability of MOFs to maintain their structural integrity and separation efficiency under dynamic pressure conditions is crucial for industrial-scale applications, where pressure fluctuations are common.

Environmental applications, particularly in air and water purification, have also contributed to the rising demand for pressure-resistant MOFs. These materials show promise in removing contaminants and pollutants under varying pressure conditions, making them valuable in both industrial and municipal water treatment systems, as well as in air filtration technologies.

The pharmaceutical and biomedical sectors are emerging markets for pressure-resistant MOFs. These materials are being investigated for drug delivery systems and as components in medical devices where stability under changing physiological pressures is essential. The potential for controlled release of therapeutic agents under specific pressure conditions opens up new possibilities in targeted drug delivery.

As industries continue to push the boundaries of material performance, the demand for MOFs that can withstand extreme and fluctuating pressure conditions is expected to grow. This trend is further supported by the increasing focus on sustainability and energy efficiency across various sectors, where the unique properties of pressure-resistant MOFs can offer significant advantages.

Current Challenges in MOF Stability under Pressure

Metal-Organic Frameworks (MOFs) have garnered significant attention in recent years due to their potential applications in gas storage, separation, and catalysis. However, their stability under dynamic pressure conditions remains a critical challenge that hinders widespread industrial adoption. The current challenges in MOF stability under pressure can be broadly categorized into structural, chemical, and performance-related issues.

Structural stability is a primary concern when subjecting MOFs to dynamic pressure conditions. Many MOFs exhibit framework flexibility, which can lead to structural deformation or collapse under pressure. This phenomenon, known as "breathing" or "gate-opening," can significantly alter the pore size and shape, affecting the material's adsorption properties. Additionally, the weak coordination bonds between metal nodes and organic linkers are susceptible to breakage under high pressure, potentially causing irreversible structural damage.

Chemical stability poses another significant challenge for MOFs under pressure. The increased reactivity of guest molecules at high pressures can lead to undesired chemical reactions within the MOF structure. This may result in the formation of new compounds, degradation of the organic linkers, or displacement of metal nodes. Furthermore, the presence of moisture or other reactive species in the gas stream can accelerate these chemical transformations, compromising the long-term stability of the MOF.

Performance degradation is a consequential challenge arising from the structural and chemical instability of MOFs under pressure. As the framework undergoes deformation or partial collapse, the available surface area and pore volume may decrease, leading to reduced adsorption capacity and selectivity. The alteration of pore geometry can also affect the diffusion kinetics of guest molecules, impacting the overall separation efficiency.

Another critical challenge is the lack of standardized testing protocols for evaluating MOF stability under dynamic pressure conditions. This absence of uniform methodologies makes it difficult to compare results across different studies and hinders the development of predictive models for MOF behavior under pressure. Moreover, the complex interplay between pressure, temperature, and chemical environment further complicates the assessment of MOF stability in real-world applications.

The development of pressure-resistant MOFs is hindered by the limited understanding of structure-property relationships under dynamic pressure conditions. While computational methods have provided valuable insights, there remains a gap between theoretical predictions and experimental observations. This discrepancy underscores the need for advanced in situ characterization techniques that can probe MOF behavior under realistic operating conditions.

Addressing these challenges requires a multidisciplinary approach, combining materials science, chemistry, and engineering. Future research directions should focus on developing novel synthetic strategies to enhance MOF stability, such as incorporating stronger metal-ligand bonds or introducing flexible organic linkers that can accommodate pressure-induced deformations without compromising the overall structure.

Structural stability is a primary concern when subjecting MOFs to dynamic pressure conditions. Many MOFs exhibit framework flexibility, which can lead to structural deformation or collapse under pressure. This phenomenon, known as "breathing" or "gate-opening," can significantly alter the pore size and shape, affecting the material's adsorption properties. Additionally, the weak coordination bonds between metal nodes and organic linkers are susceptible to breakage under high pressure, potentially causing irreversible structural damage.

Chemical stability poses another significant challenge for MOFs under pressure. The increased reactivity of guest molecules at high pressures can lead to undesired chemical reactions within the MOF structure. This may result in the formation of new compounds, degradation of the organic linkers, or displacement of metal nodes. Furthermore, the presence of moisture or other reactive species in the gas stream can accelerate these chemical transformations, compromising the long-term stability of the MOF.

Performance degradation is a consequential challenge arising from the structural and chemical instability of MOFs under pressure. As the framework undergoes deformation or partial collapse, the available surface area and pore volume may decrease, leading to reduced adsorption capacity and selectivity. The alteration of pore geometry can also affect the diffusion kinetics of guest molecules, impacting the overall separation efficiency.

Another critical challenge is the lack of standardized testing protocols for evaluating MOF stability under dynamic pressure conditions. This absence of uniform methodologies makes it difficult to compare results across different studies and hinders the development of predictive models for MOF behavior under pressure. Moreover, the complex interplay between pressure, temperature, and chemical environment further complicates the assessment of MOF stability in real-world applications.

The development of pressure-resistant MOFs is hindered by the limited understanding of structure-property relationships under dynamic pressure conditions. While computational methods have provided valuable insights, there remains a gap between theoretical predictions and experimental observations. This discrepancy underscores the need for advanced in situ characterization techniques that can probe MOF behavior under realistic operating conditions.

Addressing these challenges requires a multidisciplinary approach, combining materials science, chemistry, and engineering. Future research directions should focus on developing novel synthetic strategies to enhance MOF stability, such as incorporating stronger metal-ligand bonds or introducing flexible organic linkers that can accommodate pressure-induced deformations without compromising the overall structure.

Existing Methods for Enhancing MOF Pressure Stability

01 Thermal stability enhancement of MOFs

Improving the thermal stability of Metal-Organic Frameworks (MOFs) is crucial for their application in high-temperature environments. This can be achieved through various methods such as incorporating thermally stable ligands, using metal ions with high coordination numbers, or post-synthetic modifications. Enhanced thermal stability allows MOFs to maintain their structure and functionality under elevated temperatures, broadening their potential applications in catalysis, gas storage, and separation processes.- Enhancing MOF stability through ligand modification: Modifying the organic ligands in MOFs can significantly improve their stability. This can be achieved through strategies such as introducing functional groups, increasing ligand rigidity, or using mixed-ligand systems. These modifications can enhance the framework's resistance to moisture, heat, and chemical degradation.

- Metal ion selection for improved MOF stability: The choice of metal ions plays a crucial role in determining MOF stability. Certain metal ions, particularly those with high oxidation states or strong coordination abilities, can form more stable frameworks. Researchers are exploring various metal combinations to optimize MOF stability under different environmental conditions.

- Post-synthetic modification for enhanced MOF stability: Post-synthetic modification techniques can be applied to existing MOFs to improve their stability. These methods include surface functionalization, pore encapsulation, and cross-linking of framework components. Such modifications can protect the MOF structure from degradation and extend its lifespan in various applications.

- Development of water-stable MOFs: Creating MOFs that are stable in aqueous environments is a significant focus of research. Strategies include designing hydrophobic frameworks, incorporating water-repelling functional groups, and developing MOFs with strong metal-ligand bonds that resist hydrolysis. These water-stable MOFs have potential applications in water purification and catalysis.

- Thermal and chemical stability of MOFs: Improving the thermal and chemical stability of MOFs is crucial for their use in high-temperature or harsh chemical environments. Researchers are developing MOFs with enhanced thermal stability through the use of robust building blocks and optimized synthesis conditions. Additionally, efforts are being made to create MOFs that can withstand exposure to various chemicals and pH conditions.

02 Chemical stability improvement in MOFs

Enhancing the chemical stability of MOFs is essential for their use in diverse chemical environments. Strategies include selecting robust metal-ligand bonds, introducing hydrophobic functional groups, or creating core-shell structures. Improved chemical stability enables MOFs to withstand exposure to various solvents, acids, bases, and other reactive species, making them suitable for applications in harsh chemical conditions such as heterogeneous catalysis and environmental remediation.Expand Specific Solutions03 Mechanical stability enhancement of MOFs

Improving the mechanical stability of MOFs is critical for their practical applications, especially in high-pressure environments. This can be achieved through methods such as increasing framework rigidity, introducing interpenetration, or creating composite materials. Enhanced mechanical stability allows MOFs to maintain their structural integrity under external pressures, making them suitable for applications in gas storage, separation membranes, and pressure-sensitive devices.Expand Specific Solutions04 Water stability improvement in MOFs

Enhancing the water stability of MOFs is crucial for their application in humid environments and aqueous solutions. Strategies include incorporating hydrophobic ligands, creating water-repellent surfaces, or introducing strong metal-ligand coordination bonds. Improved water stability allows MOFs to maintain their structure and functionality in the presence of moisture, enabling their use in applications such as water purification, humidity sensing, and aqueous-phase catalysis.Expand Specific Solutions05 Long-term stability and aging resistance of MOFs

Improving the long-term stability and aging resistance of MOFs is essential for their practical applications and commercial viability. This can be achieved through methods such as encapsulation, surface modification, or the use of stable building blocks. Enhanced long-term stability ensures that MOFs maintain their performance over extended periods, making them suitable for applications in gas storage, drug delivery, and sensing devices where prolonged functionality is required.Expand Specific Solutions

Key Players in MOF Research and Development

The investigation of MOF stability under dynamic pressure conditions is currently in an emerging phase, with growing interest from both academia and industry. The market size is expanding as MOFs show potential in various applications, including gas storage and separation. The technology is still evolving, with research institutions like Centre National de la Recherche Scientifique, Kyoto University, and Shanghai Jiao Tong University leading academic efforts. Companies such as Sumitomo Chemical Co., Ltd. and LG Chem Ltd. are exploring commercial applications, indicating a transition from basic research to applied technology. However, the field remains largely in the research and development stage, with significant opportunities for innovation and technological advancement.

Centre National de la Recherche Scientifique

Technical Solution: CNRS has developed advanced in-situ characterization techniques to investigate MOF stability under dynamic pressure conditions. They utilize high-pressure X-ray diffraction and Raman spectroscopy to monitor structural changes in real-time[1]. Their approach involves custom-designed pressure cells that allow for precise control of pressure up to several GPa while simultaneously collecting spectroscopic data[2]. This enables researchers to observe phase transitions, amorphization processes, and potential recrystallization of MOFs under varying pressure conditions. CNRS has also pioneered the use of molecular dynamics simulations to complement experimental data, providing atomic-level insights into the mechanisms of pressure-induced structural changes in MOFs[3].

Strengths: State-of-the-art in-situ characterization techniques, ability to combine experimental and computational approaches. Weaknesses: High equipment costs, limited to specialized laboratory settings.

Kyoto University

Technical Solution: Kyoto University has developed a novel approach to investigating MOF stability under dynamic pressure conditions using advanced synchrotron-based techniques. Their method combines high-pressure powder X-ray diffraction with pair distribution function analysis to provide detailed insights into both long-range and local structural changes in MOFs[4]. They have also implemented in-situ mechanical testing coupled with spectroscopic measurements to evaluate the mechanical properties and structural integrity of MOFs under various pressure regimes[5]. Additionally, Kyoto University researchers have pioneered the use of high-pressure 129Xe NMR spectroscopy to probe the pore environment and guest-host interactions in MOFs under pressure, offering unique insights into the dynamic behavior of these materials[6].

Strengths: Comprehensive structural analysis capabilities, innovative use of spectroscopic techniques. Weaknesses: Reliance on large-scale facilities for some experiments, potentially limiting accessibility.

Innovative Approaches to Pressure-Resistant MOFs

Metal-organic framework

PatentPendingEP4495099A1

Innovation

- A metal organic framework (MOF) is developed with a structure Sx constituted by O2-, OH2, OH-, OCH3, and OC2H5, and a metal ion configuration where two or more metal ions are bonded to one oxygen atom, resulting in a water absorption rate of 25% or more.

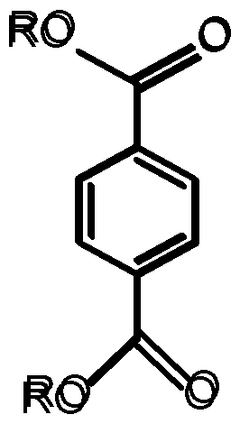

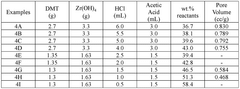

Methods of making metal-organic frameworks with pre-ligands

PatentWO2024155562A1

Innovation

- A method involving the combination of pre-ligands with a metal source in a solvent mixture, where at least 50 wt.% of the reaction mixture consists of reactants, with heating and cooling to produce metal-organic frameworks, avoiding the use of DMF and improving solubility through the conversion of pre-ligands to ligands that react with the metal component.

Environmental Impact of MOF Production and Use

The production and use of Metal-Organic Frameworks (MOFs) have significant environmental implications that warrant careful consideration. The synthesis of MOFs typically involves the use of organic solvents and metal precursors, which can have adverse effects on the environment if not properly managed. Many MOF production processes require high temperatures and pressures, leading to increased energy consumption and associated carbon emissions. Additionally, the use of rare or toxic metals in some MOF structures raises concerns about resource depletion and potential environmental contamination.

However, the environmental impact of MOF production must be balanced against their potential benefits in various applications. MOFs have shown promise in areas such as gas storage, carbon capture, and water purification, which could contribute to mitigating environmental challenges. For instance, MOFs used in carbon capture technologies could help reduce greenhouse gas emissions from industrial processes and power plants.

The stability of MOFs under dynamic pressure conditions is particularly relevant to their environmental impact. MOFs that maintain their structural integrity and functionality under varying pressure conditions are more likely to have prolonged lifespans and reduced need for replacement, thereby minimizing waste generation and resource consumption. Conversely, MOFs that degrade rapidly under pressure fluctuations may require more frequent replacement, leading to increased production and associated environmental costs.

Recycling and disposal of spent MOFs present another environmental consideration. The complex nature of MOF structures can make recycling challenging, potentially leading to accumulation in landfills or the need for specialized disposal methods. Research into sustainable MOF production methods, such as using bio-based precursors or green solvents, is ongoing and could significantly reduce the environmental footprint of MOF manufacturing.

The environmental impact of MOF use extends to their application in various industries. While MOFs can enhance the efficiency of certain processes, potentially reducing overall energy consumption and emissions, their long-term effects on ecosystems and human health require further study. As MOF technology advances, it is crucial to conduct comprehensive life cycle assessments to fully understand and mitigate their environmental impacts throughout production, use, and disposal phases.

However, the environmental impact of MOF production must be balanced against their potential benefits in various applications. MOFs have shown promise in areas such as gas storage, carbon capture, and water purification, which could contribute to mitigating environmental challenges. For instance, MOFs used in carbon capture technologies could help reduce greenhouse gas emissions from industrial processes and power plants.

The stability of MOFs under dynamic pressure conditions is particularly relevant to their environmental impact. MOFs that maintain their structural integrity and functionality under varying pressure conditions are more likely to have prolonged lifespans and reduced need for replacement, thereby minimizing waste generation and resource consumption. Conversely, MOFs that degrade rapidly under pressure fluctuations may require more frequent replacement, leading to increased production and associated environmental costs.

Recycling and disposal of spent MOFs present another environmental consideration. The complex nature of MOF structures can make recycling challenging, potentially leading to accumulation in landfills or the need for specialized disposal methods. Research into sustainable MOF production methods, such as using bio-based precursors or green solvents, is ongoing and could significantly reduce the environmental footprint of MOF manufacturing.

The environmental impact of MOF use extends to their application in various industries. While MOFs can enhance the efficiency of certain processes, potentially reducing overall energy consumption and emissions, their long-term effects on ecosystems and human health require further study. As MOF technology advances, it is crucial to conduct comprehensive life cycle assessments to fully understand and mitigate their environmental impacts throughout production, use, and disposal phases.

Safety Considerations for High-Pressure MOF Applications

Safety considerations are paramount when dealing with Metal-Organic Frameworks (MOFs) under high-pressure conditions. The dynamic nature of pressure changes in MOF applications necessitates a comprehensive approach to risk assessment and mitigation strategies.

Firstly, the structural integrity of MOFs under varying pressure conditions must be thoroughly evaluated. As pressure fluctuates, the potential for framework collapse or deformation increases, which could lead to sudden release of stored gases or chemicals. Regular monitoring of MOF stability through in-situ characterization techniques is essential to detect early signs of structural compromise.

Chemical reactivity is another critical safety aspect. High pressures can alter the chemical behavior of MOFs, potentially catalyzing unexpected reactions or accelerating degradation processes. This is particularly concerning when MOFs are used for gas storage or separation, as pressure-induced changes could lead to the formation of hazardous byproducts or compromise the purity of stored substances.

Thermal management is crucial in high-pressure MOF applications. Pressure changes can result in significant temperature fluctuations due to adsorption and desorption processes. Adequate heat dissipation systems must be in place to prevent localized hotspots that could trigger thermal runaway or compromise the MOF's structural integrity.

Containment and pressure relief mechanisms are vital safety features. High-pressure vessels housing MOFs should be equipped with appropriate safety valves and rupture discs to prevent catastrophic failure in case of over-pressurization. The design of these systems must account for the unique properties of MOFs, including their porosity and potential for gas retention.

Personal protective equipment (PPE) and handling protocols specific to high-pressure MOF applications must be developed and strictly enforced. This includes specialized training for personnel working with these materials, as well as emergency response procedures tailored to potential incidents involving pressurized MOF systems.

Environmental considerations are also important. In the event of a containment breach, the release of MOFs or their contents could pose significant environmental risks. Proper disposal and decontamination procedures must be established to mitigate potential ecological impacts.

Lastly, long-term stability and aging effects of MOFs under cyclic pressure conditions should be carefully studied. Repeated pressure cycling may lead to cumulative damage or performance degradation over time, necessitating regular maintenance schedules and replacement strategies to ensure continued safe operation.

Firstly, the structural integrity of MOFs under varying pressure conditions must be thoroughly evaluated. As pressure fluctuates, the potential for framework collapse or deformation increases, which could lead to sudden release of stored gases or chemicals. Regular monitoring of MOF stability through in-situ characterization techniques is essential to detect early signs of structural compromise.

Chemical reactivity is another critical safety aspect. High pressures can alter the chemical behavior of MOFs, potentially catalyzing unexpected reactions or accelerating degradation processes. This is particularly concerning when MOFs are used for gas storage or separation, as pressure-induced changes could lead to the formation of hazardous byproducts or compromise the purity of stored substances.

Thermal management is crucial in high-pressure MOF applications. Pressure changes can result in significant temperature fluctuations due to adsorption and desorption processes. Adequate heat dissipation systems must be in place to prevent localized hotspots that could trigger thermal runaway or compromise the MOF's structural integrity.

Containment and pressure relief mechanisms are vital safety features. High-pressure vessels housing MOFs should be equipped with appropriate safety valves and rupture discs to prevent catastrophic failure in case of over-pressurization. The design of these systems must account for the unique properties of MOFs, including their porosity and potential for gas retention.

Personal protective equipment (PPE) and handling protocols specific to high-pressure MOF applications must be developed and strictly enforced. This includes specialized training for personnel working with these materials, as well as emergency response procedures tailored to potential incidents involving pressurized MOF systems.

Environmental considerations are also important. In the event of a containment breach, the release of MOFs or their contents could pose significant environmental risks. Proper disposal and decontamination procedures must be established to mitigate potential ecological impacts.

Lastly, long-term stability and aging effects of MOFs under cyclic pressure conditions should be carefully studied. Repeated pressure cycling may lead to cumulative damage or performance degradation over time, necessitating regular maintenance schedules and replacement strategies to ensure continued safe operation.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!