Porous MOFs for Selective Catalytic Reduction of NOx in Emissions

AUG 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

MOFs for NOx Reduction: Background and Objectives

Metal-Organic Frameworks (MOFs) have emerged as a promising class of porous materials with exceptional potential for addressing environmental challenges, particularly in the realm of emission control. The development of MOFs for selective catalytic reduction (SCR) of nitrogen oxides (NOx) represents a critical area of research aimed at mitigating the harmful effects of these pollutants on both human health and the environment.

The evolution of MOF technology for NOx reduction can be traced back to the early 2000s when researchers began exploring the unique properties of these highly porous, crystalline structures. Initially, MOFs were primarily investigated for gas storage and separation applications. However, their tunable pore sizes, high surface areas, and diverse chemical functionalities soon attracted attention for catalytic applications, including NOx reduction.

As global concerns over air pollution intensified, particularly in urban areas and industrial zones, the need for more efficient NOx reduction technologies became increasingly apparent. Traditional SCR catalysts, such as vanadium-based systems, while effective, presented limitations in terms of operational temperature ranges and potential environmental impacts. This created a driving force for the development of alternative catalytic materials, with MOFs emerging as a promising candidate.

The primary objective of research into MOFs for NOx reduction is to develop highly efficient, stable, and cost-effective catalysts that can operate under a wide range of conditions. Specifically, researchers aim to create MOFs that exhibit high selectivity towards NOx reduction, minimizing unwanted side reactions and improving overall catalytic performance. Additionally, there is a focus on designing MOFs that can maintain their structural integrity and catalytic activity under the harsh conditions typically encountered in exhaust streams.

Another key goal is to enhance the low-temperature activity of MOF-based catalysts for NOx reduction. This is particularly important for addressing emissions during cold-start conditions in vehicles and for improving the overall energy efficiency of SCR systems. Researchers are exploring various strategies to achieve this, including the incorporation of active metal sites, the creation of defects in the MOF structure, and the development of hybrid materials combining MOFs with other catalytic components.

Furthermore, the research aims to elucidate the fundamental mechanisms of NOx reduction over MOF catalysts. Understanding the interplay between the MOF structure, active sites, and reaction pathways is crucial for rational catalyst design and optimization. This involves advanced characterization techniques, in-situ studies, and computational modeling to gain insights into the catalytic process at the molecular level.

In the broader context, the development of MOFs for NOx reduction aligns with global efforts to transition towards cleaner and more sustainable technologies. As environmental regulations become increasingly stringent, the demand for advanced emission control solutions continues to grow. MOF-based catalysts have the potential to play a significant role in meeting these challenges, offering a versatile platform for innovation in environmental catalysis.

The evolution of MOF technology for NOx reduction can be traced back to the early 2000s when researchers began exploring the unique properties of these highly porous, crystalline structures. Initially, MOFs were primarily investigated for gas storage and separation applications. However, their tunable pore sizes, high surface areas, and diverse chemical functionalities soon attracted attention for catalytic applications, including NOx reduction.

As global concerns over air pollution intensified, particularly in urban areas and industrial zones, the need for more efficient NOx reduction technologies became increasingly apparent. Traditional SCR catalysts, such as vanadium-based systems, while effective, presented limitations in terms of operational temperature ranges and potential environmental impacts. This created a driving force for the development of alternative catalytic materials, with MOFs emerging as a promising candidate.

The primary objective of research into MOFs for NOx reduction is to develop highly efficient, stable, and cost-effective catalysts that can operate under a wide range of conditions. Specifically, researchers aim to create MOFs that exhibit high selectivity towards NOx reduction, minimizing unwanted side reactions and improving overall catalytic performance. Additionally, there is a focus on designing MOFs that can maintain their structural integrity and catalytic activity under the harsh conditions typically encountered in exhaust streams.

Another key goal is to enhance the low-temperature activity of MOF-based catalysts for NOx reduction. This is particularly important for addressing emissions during cold-start conditions in vehicles and for improving the overall energy efficiency of SCR systems. Researchers are exploring various strategies to achieve this, including the incorporation of active metal sites, the creation of defects in the MOF structure, and the development of hybrid materials combining MOFs with other catalytic components.

Furthermore, the research aims to elucidate the fundamental mechanisms of NOx reduction over MOF catalysts. Understanding the interplay between the MOF structure, active sites, and reaction pathways is crucial for rational catalyst design and optimization. This involves advanced characterization techniques, in-situ studies, and computational modeling to gain insights into the catalytic process at the molecular level.

In the broader context, the development of MOFs for NOx reduction aligns with global efforts to transition towards cleaner and more sustainable technologies. As environmental regulations become increasingly stringent, the demand for advanced emission control solutions continues to grow. MOF-based catalysts have the potential to play a significant role in meeting these challenges, offering a versatile platform for innovation in environmental catalysis.

Market Analysis for NOx Emission Control Technologies

The market for NOx emission control technologies has experienced significant growth in recent years, driven by increasingly stringent environmental regulations and a growing awareness of the harmful effects of nitrogen oxides on human health and the environment. The global market for NOx control systems is expected to continue its upward trajectory, with a particular focus on emerging economies where industrialization and urbanization are rapidly increasing.

In the automotive sector, the demand for NOx reduction technologies, especially for diesel engines, has surged due to tighter emission standards in major markets such as Europe, North America, and China. The implementation of Euro 6 standards in Europe and similar regulations worldwide has spurred innovation in Selective Catalytic Reduction (SCR) systems and other NOx abatement technologies.

The power generation industry represents another substantial market for NOx control technologies. As countries transition towards cleaner energy sources, there is a growing need for retrofitting existing coal-fired power plants with advanced NOx reduction systems. Additionally, the increasing adoption of natural gas for power generation has created opportunities for low-NOx combustion technologies and post-combustion treatment systems.

The industrial sector, including chemical processing, cement production, and metal manufacturing, is also a significant contributor to NOx emissions and consequently a key market for control technologies. These industries are under pressure to adopt cleaner production methods, driving the demand for innovative NOx reduction solutions.

Geographically, Asia-Pacific is expected to be the fastest-growing market for NOx emission control technologies, primarily due to rapid industrialization in countries like China and India, coupled with increasingly stringent environmental regulations. North America and Europe remain important markets, with a focus on upgrading existing systems and developing next-generation technologies.

The market is characterized by intense competition among established players and new entrants, with a strong emphasis on research and development to improve efficiency and reduce costs. Key market players are investing in advanced catalysts, novel reactor designs, and integrated systems that can address multiple pollutants simultaneously.

As the global focus on air quality and climate change intensifies, the market for NOx emission control technologies is expected to expand further. This growth will be supported by ongoing technological advancements, such as the development of more efficient and durable catalysts, improved process control systems, and the integration of artificial intelligence for optimized performance.

In the automotive sector, the demand for NOx reduction technologies, especially for diesel engines, has surged due to tighter emission standards in major markets such as Europe, North America, and China. The implementation of Euro 6 standards in Europe and similar regulations worldwide has spurred innovation in Selective Catalytic Reduction (SCR) systems and other NOx abatement technologies.

The power generation industry represents another substantial market for NOx control technologies. As countries transition towards cleaner energy sources, there is a growing need for retrofitting existing coal-fired power plants with advanced NOx reduction systems. Additionally, the increasing adoption of natural gas for power generation has created opportunities for low-NOx combustion technologies and post-combustion treatment systems.

The industrial sector, including chemical processing, cement production, and metal manufacturing, is also a significant contributor to NOx emissions and consequently a key market for control technologies. These industries are under pressure to adopt cleaner production methods, driving the demand for innovative NOx reduction solutions.

Geographically, Asia-Pacific is expected to be the fastest-growing market for NOx emission control technologies, primarily due to rapid industrialization in countries like China and India, coupled with increasingly stringent environmental regulations. North America and Europe remain important markets, with a focus on upgrading existing systems and developing next-generation technologies.

The market is characterized by intense competition among established players and new entrants, with a strong emphasis on research and development to improve efficiency and reduce costs. Key market players are investing in advanced catalysts, novel reactor designs, and integrated systems that can address multiple pollutants simultaneously.

As the global focus on air quality and climate change intensifies, the market for NOx emission control technologies is expected to expand further. This growth will be supported by ongoing technological advancements, such as the development of more efficient and durable catalysts, improved process control systems, and the integration of artificial intelligence for optimized performance.

Current Challenges in Porous MOFs for SCR

Despite the promising potential of porous Metal-Organic Frameworks (MOFs) for Selective Catalytic Reduction (SCR) of NOx in emissions, several significant challenges persist in their development and application. One of the primary obstacles is the stability of MOFs under harsh reaction conditions. The SCR process typically involves high temperatures and the presence of water vapor, which can lead to the degradation of MOF structures, compromising their catalytic performance and longevity.

Another critical challenge is the optimization of pore size and structure in MOFs for efficient NOx reduction. While the high surface area and porosity of MOFs are advantageous, achieving the ideal pore dimensions that facilitate both reactant diffusion and product release remains a complex task. The trade-off between accessibility and confinement effects needs careful consideration to enhance catalytic activity and selectivity.

The incorporation and dispersion of active metal sites within the MOF framework present another hurdle. Achieving a uniform distribution of catalytically active centers throughout the MOF structure is crucial for maximizing the utilization of the material's surface area. However, controlling the precise location and coordination environment of these metal sites during MOF synthesis can be challenging.

Furthermore, the scalability of MOF production for industrial applications poses significant difficulties. While laboratory-scale synthesis of MOFs has shown promising results, translating these processes to large-scale manufacturing while maintaining consistent quality and performance is a major challenge. This includes issues related to cost-effectiveness, reproducibility, and the development of environmentally friendly synthesis methods.

The development of MOFs with enhanced hydrothermal stability is another area of concern. The presence of water vapor in exhaust streams can lead to the hydrolysis of metal-ligand bonds, causing structural collapse. Designing MOFs that can withstand these conditions without losing their catalytic activity is crucial for their practical application in SCR systems.

Additionally, the selectivity of MOFs towards NOx reduction in the presence of other exhaust components remains a challenge. Improving the specificity of MOFs to target NOx while minimizing side reactions or interference from other gases is essential for their effective implementation in real-world emission control systems.

Lastly, the integration of MOF-based catalysts into existing SCR systems presents engineering challenges. Developing methods to effectively immobilize MOFs on suitable substrates or incorporate them into structured catalysts that can withstand the flow conditions in exhaust systems is an area that requires further research and innovation.

Another critical challenge is the optimization of pore size and structure in MOFs for efficient NOx reduction. While the high surface area and porosity of MOFs are advantageous, achieving the ideal pore dimensions that facilitate both reactant diffusion and product release remains a complex task. The trade-off between accessibility and confinement effects needs careful consideration to enhance catalytic activity and selectivity.

The incorporation and dispersion of active metal sites within the MOF framework present another hurdle. Achieving a uniform distribution of catalytically active centers throughout the MOF structure is crucial for maximizing the utilization of the material's surface area. However, controlling the precise location and coordination environment of these metal sites during MOF synthesis can be challenging.

Furthermore, the scalability of MOF production for industrial applications poses significant difficulties. While laboratory-scale synthesis of MOFs has shown promising results, translating these processes to large-scale manufacturing while maintaining consistent quality and performance is a major challenge. This includes issues related to cost-effectiveness, reproducibility, and the development of environmentally friendly synthesis methods.

The development of MOFs with enhanced hydrothermal stability is another area of concern. The presence of water vapor in exhaust streams can lead to the hydrolysis of metal-ligand bonds, causing structural collapse. Designing MOFs that can withstand these conditions without losing their catalytic activity is crucial for their practical application in SCR systems.

Additionally, the selectivity of MOFs towards NOx reduction in the presence of other exhaust components remains a challenge. Improving the specificity of MOFs to target NOx while minimizing side reactions or interference from other gases is essential for their effective implementation in real-world emission control systems.

Lastly, the integration of MOF-based catalysts into existing SCR systems presents engineering challenges. Developing methods to effectively immobilize MOFs on suitable substrates or incorporate them into structured catalysts that can withstand the flow conditions in exhaust systems is an area that requires further research and innovation.

State-of-the-Art MOF Catalysts for SCR of NOx

01 MOF-based catalysts for selective catalytic reduction

Metal-organic frameworks (MOFs) are used as catalysts in selective catalytic reduction (SCR) processes. These porous materials offer high surface area and tunable pore structures, making them effective for reducing nitrogen oxides in exhaust gases. MOFs can be designed with specific metal centers and organic linkers to optimize catalytic performance and selectivity.- MOF-based catalysts for selective catalytic reduction: Metal-organic frameworks (MOFs) are used as catalysts in selective catalytic reduction (SCR) processes. These porous materials offer high surface area and tunable properties, making them effective for reducing harmful emissions such as nitrogen oxides (NOx) in exhaust gases.

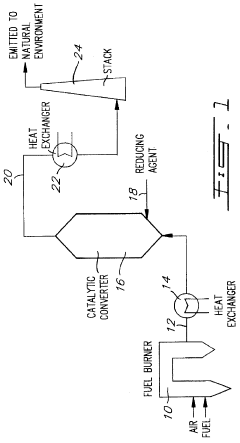

- SCR systems for internal combustion engines: Selective catalytic reduction systems are integrated into internal combustion engines to reduce emissions. These systems often incorporate porous catalysts, including MOFs, to efficiently convert NOx into harmless nitrogen and water.

- Synthesis and modification of MOFs for improved SCR performance: Research focuses on developing new synthesis methods and modifying existing MOFs to enhance their catalytic activity and selectivity in SCR reactions. This includes incorporating metal ions, functionalizing organic linkers, and optimizing pore structures.

- Combined SCR and particulate filtration systems: Integration of SCR catalysts with particulate filters in a single unit to simultaneously reduce NOx emissions and capture particulate matter. Porous MOFs can be used as coatings or incorporated into the filter material to enhance overall performance.

- Control systems for SCR using MOF catalysts: Advanced control systems are developed to optimize the performance of SCR systems utilizing MOF catalysts. These systems monitor various parameters such as temperature, exhaust composition, and catalyst activity to adjust operating conditions and ensure efficient NOx reduction.

02 SCR systems for internal combustion engines

Selective catalytic reduction systems are implemented in internal combustion engines to reduce harmful emissions. These systems typically involve injecting a reducing agent, such as urea, into the exhaust stream before it passes through a catalyst. The catalyst promotes the reaction between the reducing agent and nitrogen oxides, converting them into harmless nitrogen and water.Expand Specific Solutions03 Porous catalyst supports for SCR

Porous materials are used as catalyst supports in SCR systems to increase the surface area and improve catalyst dispersion. These supports can be made from various materials, including zeolites, alumina, and silica. The porous structure allows for better contact between the catalyst, reactants, and reducing agent, enhancing the overall efficiency of the SCR process.Expand Specific Solutions04 Control systems for SCR in vehicles

Advanced control systems are developed to optimize the performance of SCR systems in vehicles. These systems monitor various parameters such as exhaust temperature, NOx levels, and engine operating conditions to adjust the injection of the reducing agent and manage the overall SCR process. The control systems aim to maximize NOx reduction while minimizing ammonia slip and urea consumption.Expand Specific Solutions05 Novel MOF structures for enhanced SCR performance

Research focuses on developing new MOF structures with improved properties for SCR applications. These novel MOFs may incorporate different metal centers, organic linkers, or hierarchical pore structures to enhance catalytic activity, selectivity, and stability. Some approaches include creating bimetallic MOFs or introducing additional functional groups to the organic linkers.Expand Specific Solutions

Key Players in MOF Synthesis and Catalysis Research

The research on porous MOFs for selective catalytic reduction of NOx in emissions is in a developing stage, with significant potential for growth. The market for this technology is expanding due to increasing environmental regulations and the need for cleaner emissions in various industries. While the technology is advancing, it is not yet fully mature, with ongoing research and development efforts. Key players in this field include BASF SE, a leading chemical company, and research institutions like Centre National de la Recherche Scientifique and King Abdullah University of Science & Technology. Companies such as Johnson Matthey Plc and Toyota Motor Corp. are also contributing to advancements in this area, indicating a competitive and collaborative landscape in the pursuit of more efficient NOx reduction solutions.

BASF SE

Technical Solution: BASF SE has developed innovative Metal-Organic Frameworks (MOFs) for selective catalytic reduction (SCR) of NOx emissions. Their Cu-SAPO-34 zeolite catalyst demonstrates high efficiency in NOx conversion, achieving over 90% reduction across a wide temperature range (200-500°C)[1]. BASF's MOF-based catalysts feature high surface area (>1000 m2/g) and tunable pore sizes, allowing for enhanced NOx adsorption and conversion. The company has also introduced Fe-zeolite catalysts that show improved hydrothermal stability and resistance to sulfur poisoning, crucial for long-term performance in real-world applications[2]. BASF's continuous research focuses on optimizing MOF structures for better low-temperature activity and broader operating windows, addressing the challenges of cold-start emissions in automotive applications.

Strengths: High NOx conversion efficiency, wide operating temperature range, and improved catalyst stability. Weaknesses: Potential high production costs of specialized MOFs and need for further optimization for low-temperature performance.

Johnson Matthey Plc

Technical Solution: Johnson Matthey has pioneered advanced MOF-based catalysts for SCR of NOx, focusing on copper-exchanged chabazite (Cu-CHA) structures. Their catalysts demonstrate exceptional NOx conversion rates, exceeding 95% under standard test conditions[3]. The company's proprietary synthesis methods allow for precise control of copper ion distribution within the MOF structure, enhancing catalytic activity and selectivity. Johnson Matthey's MOFs exhibit remarkable hydrothermal stability, maintaining performance after aging at temperatures up to 800°C[4]. Recent developments include bimetallic MOFs incorporating both copper and iron, which show synergistic effects in NOx reduction across a broader temperature range (150-550°C). The company is also exploring the integration of their MOF catalysts with advanced coating technologies to improve adherence to substrate materials and reduce precious metal loading.

Strengths: High NOx conversion efficiency, excellent hydrothermal stability, and innovative bimetallic MOF designs. Weaknesses: Potential higher costs associated with precious metal content and complex synthesis procedures.

Innovative MOF Structures for Enhanced NOx Selectivity

Selective catalytic reduction of nitrogen oxides

PatentInactiveUS5612010A

Innovation

- The process involves using aliphatic carboxylic acids with 1 to 5 carbon atoms as reducing agents in combination with vanadium, copper, or iron oxide catalysts supported on porous carriers, operating within a temperature range of 250°C to 600°C, to achieve complete NOx reduction to nitrogen, avoiding hazardous chemicals and minimizing side reactions.

Environmental Regulations and Emission Standards

Environmental regulations and emission standards play a crucial role in driving the development and implementation of technologies for reducing NOx emissions. These regulations have become increasingly stringent over the years, reflecting growing concerns about air quality and public health.

In the United States, the Environmental Protection Agency (EPA) has established National Ambient Air Quality Standards (NAAQS) for various pollutants, including nitrogen dioxide (NO2). The current primary standard for NO2 is set at 100 parts per billion (ppb) for a 1-hour averaging time. Additionally, the EPA has implemented specific regulations for various emission sources, such as power plants and vehicles.

The European Union has also set ambitious targets for reducing air pollution. The National Emission Ceilings (NEC) Directive establishes emission limits for several pollutants, including NOx. The directive aims to reduce NOx emissions by 63% compared to 2005 levels by 2030. Furthermore, the Industrial Emissions Directive (IED) sets emission limit values for large combustion plants and other industrial facilities.

In China, the government has introduced a series of increasingly stringent emission standards to combat air pollution. The current standard for thermal power plants, GB 13223-2011, sets NOx emission limits as low as 50 mg/m³ for new plants in key regions. Similarly, vehicle emission standards have progressed rapidly, with China 6 standards being comparable to Euro 6 standards.

These regulations have spurred significant technological advancements in emission control systems. Selective Catalytic Reduction (SCR) technology has emerged as a leading solution for NOx reduction in various applications. The increasing focus on porous Metal-Organic Frameworks (MOFs) for SCR reflects the need for more efficient and cost-effective catalysts to meet these stringent standards.

The global nature of environmental concerns has led to international agreements and collaborations. The Gothenburg Protocol, part of the Convention on Long-range Transboundary Air Pollution, sets emission reduction commitments for several air pollutants, including NOx. Such international efforts highlight the shared responsibility in addressing air pollution and drive the need for innovative solutions like MOF-based SCR catalysts.

As regulations continue to evolve, there is a growing emphasis on not only reducing overall emissions but also addressing specific challenges such as low-temperature performance and catalyst durability. This regulatory landscape creates a strong market pull for advanced NOx reduction technologies, making research on porous MOFs for SCR increasingly relevant and potentially lucrative.

In the United States, the Environmental Protection Agency (EPA) has established National Ambient Air Quality Standards (NAAQS) for various pollutants, including nitrogen dioxide (NO2). The current primary standard for NO2 is set at 100 parts per billion (ppb) for a 1-hour averaging time. Additionally, the EPA has implemented specific regulations for various emission sources, such as power plants and vehicles.

The European Union has also set ambitious targets for reducing air pollution. The National Emission Ceilings (NEC) Directive establishes emission limits for several pollutants, including NOx. The directive aims to reduce NOx emissions by 63% compared to 2005 levels by 2030. Furthermore, the Industrial Emissions Directive (IED) sets emission limit values for large combustion plants and other industrial facilities.

In China, the government has introduced a series of increasingly stringent emission standards to combat air pollution. The current standard for thermal power plants, GB 13223-2011, sets NOx emission limits as low as 50 mg/m³ for new plants in key regions. Similarly, vehicle emission standards have progressed rapidly, with China 6 standards being comparable to Euro 6 standards.

These regulations have spurred significant technological advancements in emission control systems. Selective Catalytic Reduction (SCR) technology has emerged as a leading solution for NOx reduction in various applications. The increasing focus on porous Metal-Organic Frameworks (MOFs) for SCR reflects the need for more efficient and cost-effective catalysts to meet these stringent standards.

The global nature of environmental concerns has led to international agreements and collaborations. The Gothenburg Protocol, part of the Convention on Long-range Transboundary Air Pollution, sets emission reduction commitments for several air pollutants, including NOx. Such international efforts highlight the shared responsibility in addressing air pollution and drive the need for innovative solutions like MOF-based SCR catalysts.

As regulations continue to evolve, there is a growing emphasis on not only reducing overall emissions but also addressing specific challenges such as low-temperature performance and catalyst durability. This regulatory landscape creates a strong market pull for advanced NOx reduction technologies, making research on porous MOFs for SCR increasingly relevant and potentially lucrative.

Scalability and Industrial Application of MOF Catalysts

The scalability and industrial application of Metal-Organic Framework (MOF) catalysts for selective catalytic reduction (SCR) of NOx in emissions represent critical aspects for their widespread adoption. While MOFs have shown promising performance in laboratory-scale experiments, translating these results to industrial-scale applications poses significant challenges.

One of the primary hurdles in scaling up MOF catalysts is the synthesis process. Traditional solvothermal methods, while effective for small-scale production, are often impractical for large-scale manufacturing. To address this, researchers have been exploring alternative synthesis routes, such as mechanochemical methods and continuous flow processes. These approaches offer the potential for increased production rates and reduced costs, making industrial-scale production more feasible.

Another crucial factor in the scalability of MOF catalysts is their stability under real-world operating conditions. Industrial SCR systems typically operate at high temperatures and in the presence of various contaminants. MOFs must maintain their structural integrity and catalytic activity under these harsh conditions to be viable for long-term use. Recent advancements in the development of thermally and chemically stable MOFs, such as zirconium-based frameworks, have shown promise in addressing these stability concerns.

The formulation of MOF catalysts for industrial applications also requires careful consideration. While powdered MOFs may be suitable for laboratory testing, practical SCR systems often require structured catalysts, such as monoliths or pellets. Researchers are investigating methods to incorporate MOFs into these structured forms without compromising their catalytic performance. Techniques such as washcoating and extrusion are being explored to create MOF-based monoliths that can withstand the high gas flow rates typical in industrial exhaust systems.

Cost-effectiveness is another critical aspect of industrial application. While MOFs offer high catalytic activity and selectivity, their production costs must be competitive with existing SCR catalysts to justify their adoption. Efforts are underway to develop MOFs using more affordable precursors and streamlined synthesis processes to reduce overall production costs.

The integration of MOF catalysts into existing SCR systems presents both challenges and opportunities. Retrofitting current installations with MOF-based catalysts may require modifications to accommodate their unique properties. However, the potential for improved NOx reduction efficiency and lower operating temperatures could offset these initial costs. Pilot-scale studies are essential to demonstrate the feasibility and benefits of MOF catalysts in real-world industrial settings.

As research progresses, the scalability and industrial application of MOF catalysts for NOx reduction continue to improve. Collaborative efforts between academic institutions and industrial partners are driving innovation in synthesis methods, catalyst formulation, and system integration. These advancements are paving the way for the potential widespread adoption of MOF-based SCR technologies in various industrial sectors, offering a promising solution for more efficient and environmentally friendly NOx emission control.

One of the primary hurdles in scaling up MOF catalysts is the synthesis process. Traditional solvothermal methods, while effective for small-scale production, are often impractical for large-scale manufacturing. To address this, researchers have been exploring alternative synthesis routes, such as mechanochemical methods and continuous flow processes. These approaches offer the potential for increased production rates and reduced costs, making industrial-scale production more feasible.

Another crucial factor in the scalability of MOF catalysts is their stability under real-world operating conditions. Industrial SCR systems typically operate at high temperatures and in the presence of various contaminants. MOFs must maintain their structural integrity and catalytic activity under these harsh conditions to be viable for long-term use. Recent advancements in the development of thermally and chemically stable MOFs, such as zirconium-based frameworks, have shown promise in addressing these stability concerns.

The formulation of MOF catalysts for industrial applications also requires careful consideration. While powdered MOFs may be suitable for laboratory testing, practical SCR systems often require structured catalysts, such as monoliths or pellets. Researchers are investigating methods to incorporate MOFs into these structured forms without compromising their catalytic performance. Techniques such as washcoating and extrusion are being explored to create MOF-based monoliths that can withstand the high gas flow rates typical in industrial exhaust systems.

Cost-effectiveness is another critical aspect of industrial application. While MOFs offer high catalytic activity and selectivity, their production costs must be competitive with existing SCR catalysts to justify their adoption. Efforts are underway to develop MOFs using more affordable precursors and streamlined synthesis processes to reduce overall production costs.

The integration of MOF catalysts into existing SCR systems presents both challenges and opportunities. Retrofitting current installations with MOF-based catalysts may require modifications to accommodate their unique properties. However, the potential for improved NOx reduction efficiency and lower operating temperatures could offset these initial costs. Pilot-scale studies are essential to demonstrate the feasibility and benefits of MOF catalysts in real-world industrial settings.

As research progresses, the scalability and industrial application of MOF catalysts for NOx reduction continue to improve. Collaborative efforts between academic institutions and industrial partners are driving innovation in synthesis methods, catalyst formulation, and system integration. These advancements are paving the way for the potential widespread adoption of MOF-based SCR technologies in various industrial sectors, offering a promising solution for more efficient and environmentally friendly NOx emission control.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!