Thermodynamic Analysis of Gas Adsorption in Flexible MOFs

AUG 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

MOF Gas Adsorption Background and Objectives

Metal-Organic Frameworks (MOFs) have emerged as a revolutionary class of porous materials with exceptional gas adsorption properties. These crystalline structures, composed of metal ions or clusters coordinated to organic ligands, offer unprecedented surface areas and tunable pore sizes, making them ideal candidates for various gas storage and separation applications. The field of MOF gas adsorption has witnessed significant advancements over the past two decades, driven by the growing demand for efficient and sustainable energy storage solutions.

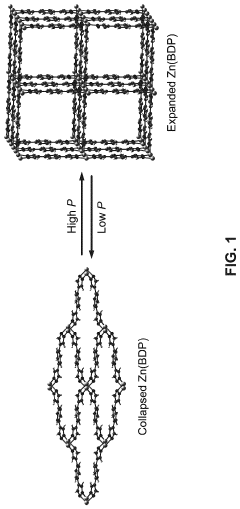

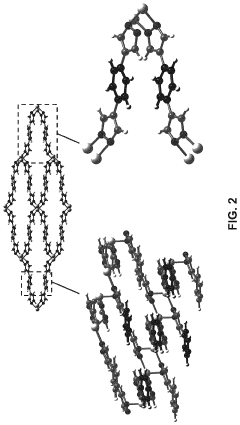

The primary objective of thermodynamic analysis in flexible MOFs is to understand and predict the complex interplay between gas molecules and the dynamic framework structure. Unlike rigid MOFs, flexible MOFs exhibit structural transformations upon gas adsorption, leading to unique adsorption behaviors such as gate-opening and breathing phenomena. These structural changes can significantly impact the adsorption capacity, selectivity, and overall performance of the material.

Recent research has focused on developing advanced experimental techniques and computational models to elucidate the thermodynamic principles governing gas adsorption in flexible MOFs. High-resolution in situ characterization methods, including X-ray diffraction and neutron scattering, have provided valuable insights into the structural evolution of MOFs during adsorption processes. Complementary to experimental approaches, molecular simulations and density functional theory calculations have become indispensable tools for predicting adsorption isotherms and understanding the energetics of gas-framework interactions.

The evolution of MOF gas adsorption technology has been marked by several key milestones. Early studies primarily focused on rigid MOFs, establishing fundamental principles of gas uptake and selectivity. The discovery of framework flexibility introduced a new dimension to MOF design, enabling the creation of materials with enhanced adsorption properties and stimuli-responsive behavior. Recent advancements in the field have led to the development of MOFs with record-breaking surface areas, exceeding 7000 m²/g, and exceptional gas storage capacities.

Looking ahead, the field of MOF gas adsorption faces several challenges and opportunities. Improving the stability and scalability of flexible MOFs remains a critical goal for practical applications. Additionally, there is a growing interest in developing multifunctional MOFs that combine gas adsorption capabilities with other desirable properties, such as catalytic activity or sensing capabilities. The integration of artificial intelligence and machine learning approaches is expected to accelerate the discovery of novel MOF structures with optimized gas adsorption properties.

The primary objective of thermodynamic analysis in flexible MOFs is to understand and predict the complex interplay between gas molecules and the dynamic framework structure. Unlike rigid MOFs, flexible MOFs exhibit structural transformations upon gas adsorption, leading to unique adsorption behaviors such as gate-opening and breathing phenomena. These structural changes can significantly impact the adsorption capacity, selectivity, and overall performance of the material.

Recent research has focused on developing advanced experimental techniques and computational models to elucidate the thermodynamic principles governing gas adsorption in flexible MOFs. High-resolution in situ characterization methods, including X-ray diffraction and neutron scattering, have provided valuable insights into the structural evolution of MOFs during adsorption processes. Complementary to experimental approaches, molecular simulations and density functional theory calculations have become indispensable tools for predicting adsorption isotherms and understanding the energetics of gas-framework interactions.

The evolution of MOF gas adsorption technology has been marked by several key milestones. Early studies primarily focused on rigid MOFs, establishing fundamental principles of gas uptake and selectivity. The discovery of framework flexibility introduced a new dimension to MOF design, enabling the creation of materials with enhanced adsorption properties and stimuli-responsive behavior. Recent advancements in the field have led to the development of MOFs with record-breaking surface areas, exceeding 7000 m²/g, and exceptional gas storage capacities.

Looking ahead, the field of MOF gas adsorption faces several challenges and opportunities. Improving the stability and scalability of flexible MOFs remains a critical goal for practical applications. Additionally, there is a growing interest in developing multifunctional MOFs that combine gas adsorption capabilities with other desirable properties, such as catalytic activity or sensing capabilities. The integration of artificial intelligence and machine learning approaches is expected to accelerate the discovery of novel MOF structures with optimized gas adsorption properties.

Market Demand for Flexible MOF Adsorbents

The market demand for flexible Metal-Organic Framework (MOF) adsorbents has been steadily growing, driven by their unique properties and versatile applications in gas storage, separation, and purification processes. These materials have garnered significant attention in various industries, particularly in energy, environmental, and industrial sectors.

In the energy sector, flexible MOFs show promising potential for natural gas storage and transportation. The global natural gas market is expanding, with a projected compound annual growth rate (CAGR) of 1.7% from 2020 to 2025. Flexible MOFs offer enhanced gas adsorption capacity and improved energy density compared to traditional storage methods, making them attractive for vehicular natural gas storage and small-scale liquefied natural gas (LNG) applications.

Environmental applications, especially in carbon capture and storage (CCS), represent another significant market for flexible MOF adsorbents. With increasing global focus on reducing greenhouse gas emissions, the CCS market is expected to grow substantially. Flexible MOFs demonstrate superior CO2 capture performance and selectivity, positioning them as potential game-changers in this field.

The industrial gas separation market also presents opportunities for flexible MOF adsorbents. Applications include the separation of air components, purification of hydrogen for fuel cells, and removal of impurities from natural gas streams. The global industrial gas market is projected to reach $114 billion by 2026, with a CAGR of 6.0% from 2021 to 2026.

Pharmaceutical and biomedical industries are exploring flexible MOFs for drug delivery and biosensing applications. The controlled release properties and biocompatibility of certain MOFs make them attractive for these high-value markets.

Despite the growing interest, challenges remain in scaling up production and reducing costs of flexible MOF adsorbents. Current market penetration is limited, primarily due to high production costs and competition from established technologies. However, ongoing research and development efforts are focused on addressing these challenges, potentially leading to increased market adoption in the coming years.

The demand for flexible MOF adsorbents is expected to rise as industries seek more efficient and sustainable solutions for gas storage, separation, and purification. As production techniques improve and costs decrease, these materials are likely to capture a larger market share, particularly in niche applications where their unique properties offer significant advantages over conventional adsorbents.

In the energy sector, flexible MOFs show promising potential for natural gas storage and transportation. The global natural gas market is expanding, with a projected compound annual growth rate (CAGR) of 1.7% from 2020 to 2025. Flexible MOFs offer enhanced gas adsorption capacity and improved energy density compared to traditional storage methods, making them attractive for vehicular natural gas storage and small-scale liquefied natural gas (LNG) applications.

Environmental applications, especially in carbon capture and storage (CCS), represent another significant market for flexible MOF adsorbents. With increasing global focus on reducing greenhouse gas emissions, the CCS market is expected to grow substantially. Flexible MOFs demonstrate superior CO2 capture performance and selectivity, positioning them as potential game-changers in this field.

The industrial gas separation market also presents opportunities for flexible MOF adsorbents. Applications include the separation of air components, purification of hydrogen for fuel cells, and removal of impurities from natural gas streams. The global industrial gas market is projected to reach $114 billion by 2026, with a CAGR of 6.0% from 2021 to 2026.

Pharmaceutical and biomedical industries are exploring flexible MOFs for drug delivery and biosensing applications. The controlled release properties and biocompatibility of certain MOFs make them attractive for these high-value markets.

Despite the growing interest, challenges remain in scaling up production and reducing costs of flexible MOF adsorbents. Current market penetration is limited, primarily due to high production costs and competition from established technologies. However, ongoing research and development efforts are focused on addressing these challenges, potentially leading to increased market adoption in the coming years.

The demand for flexible MOF adsorbents is expected to rise as industries seek more efficient and sustainable solutions for gas storage, separation, and purification. As production techniques improve and costs decrease, these materials are likely to capture a larger market share, particularly in niche applications where their unique properties offer significant advantages over conventional adsorbents.

Flexible MOFs: Current State and Challenges

Flexible Metal-Organic Frameworks (MOFs) represent a cutting-edge class of porous materials that exhibit dynamic structural changes in response to external stimuli. These materials have garnered significant attention in recent years due to their unique ability to adapt their pore sizes and shapes, offering unprecedented control over gas adsorption processes. However, the current state of flexible MOFs faces several challenges that hinder their widespread application and commercialization.

One of the primary challenges in the field of flexible MOFs is the precise control and prediction of their structural transitions. While the flexibility of these materials offers advantages in terms of selectivity and capacity, it also introduces complexity in understanding and modeling their behavior. Researchers are still working to develop accurate computational models that can reliably predict the structural changes of flexible MOFs under various conditions, including temperature, pressure, and gas composition.

Another significant challenge lies in the synthesis and scalability of flexible MOFs. Many of the most promising flexible MOF structures have been synthesized only on a laboratory scale, and translating these synthesis methods to industrial-scale production remains a formidable task. Issues such as reproducibility, yield, and cost-effectiveness need to be addressed before flexible MOFs can be widely adopted in commercial applications.

The stability of flexible MOFs under real-world operating conditions is also a critical concern. Many flexible MOFs exhibit degradation or loss of flexibility after repeated adsorption-desorption cycles or exposure to moisture and other contaminants. Enhancing the long-term stability and durability of these materials without compromising their flexibility is a key area of ongoing research.

Furthermore, the integration of flexible MOFs into practical devices and systems poses additional challenges. The dynamic nature of these materials can complicate their incorporation into traditional adsorption and separation systems, requiring novel engineering approaches to fully exploit their unique properties.

Despite these challenges, the current state of flexible MOFs is one of rapid progress and innovation. Researchers are actively developing new synthetic strategies, characterization techniques, and theoretical frameworks to address the limitations of these materials. Advanced in situ characterization methods, such as synchrotron-based X-ray diffraction and spectroscopy, are providing unprecedented insights into the structural dynamics of flexible MOFs during gas adsorption.

In conclusion, while flexible MOFs offer exciting possibilities for gas adsorption and separation applications, significant challenges remain in their development and implementation. Overcoming these hurdles will require continued interdisciplinary collaboration between chemists, materials scientists, and engineers to unlock the full potential of these remarkable materials.

One of the primary challenges in the field of flexible MOFs is the precise control and prediction of their structural transitions. While the flexibility of these materials offers advantages in terms of selectivity and capacity, it also introduces complexity in understanding and modeling their behavior. Researchers are still working to develop accurate computational models that can reliably predict the structural changes of flexible MOFs under various conditions, including temperature, pressure, and gas composition.

Another significant challenge lies in the synthesis and scalability of flexible MOFs. Many of the most promising flexible MOF structures have been synthesized only on a laboratory scale, and translating these synthesis methods to industrial-scale production remains a formidable task. Issues such as reproducibility, yield, and cost-effectiveness need to be addressed before flexible MOFs can be widely adopted in commercial applications.

The stability of flexible MOFs under real-world operating conditions is also a critical concern. Many flexible MOFs exhibit degradation or loss of flexibility after repeated adsorption-desorption cycles or exposure to moisture and other contaminants. Enhancing the long-term stability and durability of these materials without compromising their flexibility is a key area of ongoing research.

Furthermore, the integration of flexible MOFs into practical devices and systems poses additional challenges. The dynamic nature of these materials can complicate their incorporation into traditional adsorption and separation systems, requiring novel engineering approaches to fully exploit their unique properties.

Despite these challenges, the current state of flexible MOFs is one of rapid progress and innovation. Researchers are actively developing new synthetic strategies, characterization techniques, and theoretical frameworks to address the limitations of these materials. Advanced in situ characterization methods, such as synchrotron-based X-ray diffraction and spectroscopy, are providing unprecedented insights into the structural dynamics of flexible MOFs during gas adsorption.

In conclusion, while flexible MOFs offer exciting possibilities for gas adsorption and separation applications, significant challenges remain in their development and implementation. Overcoming these hurdles will require continued interdisciplinary collaboration between chemists, materials scientists, and engineers to unlock the full potential of these remarkable materials.

Current Thermodynamic Analysis Methods

01 Flexible MOF structures for enhanced gas adsorption

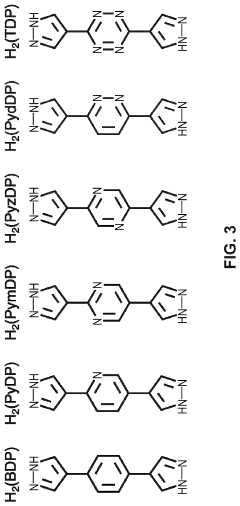

Flexible metal-organic frameworks (MOFs) are designed with dynamic structures that can adapt to different gas molecules, enhancing their adsorption capacity. These materials can undergo reversible structural changes in response to external stimuli or guest molecules, allowing for more efficient gas capture and storage.- Flexible MOF structures for enhanced gas adsorption: Flexible metal-organic frameworks (MOFs) are designed with dynamic structures that can adapt to different gas molecules, enhancing their adsorption capacity. These materials can undergo reversible structural changes in response to external stimuli or guest molecules, allowing for more efficient gas capture and storage.

- Functionalization of MOFs for selective gas adsorption: MOFs are functionalized with specific chemical groups or ligands to improve their selectivity towards target gases. This approach allows for the tailoring of MOF pore sizes and chemical affinities, enabling more efficient separation and purification of gas mixtures.

- Composite MOF materials for enhanced gas adsorption: Composite materials combining MOFs with other adsorbents or support structures are developed to improve gas adsorption performance. These composites can exhibit synergistic effects, leading to increased adsorption capacity, selectivity, and stability compared to individual components.

- Hierarchical pore structures in MOFs for multi-scale gas adsorption: MOFs with hierarchical pore structures are designed to facilitate gas diffusion and adsorption at multiple length scales. These materials combine micropores for high surface area and selectivity with meso- and macropores for improved mass transfer, resulting in enhanced overall gas adsorption performance.

- Stimuli-responsive MOFs for controlled gas release: Stimuli-responsive MOFs are developed to enable controlled release of adsorbed gases in response to external triggers such as temperature, pressure, or light. This feature allows for more efficient gas storage and release cycles, making these materials suitable for various applications including gas sensing and drug delivery.

02 Functionalization of MOFs for selective gas adsorption

MOFs are functionalized with specific chemical groups or ligands to improve their selectivity towards target gases. This approach allows for the development of tailored adsorbents for specific applications, such as carbon dioxide capture or hydrogen storage.Expand Specific Solutions03 Hierarchical pore structures in MOFs for improved gas uptake

MOFs with hierarchical pore structures, combining micropores and mesopores, are developed to enhance gas diffusion and overall adsorption capacity. This design strategy allows for faster kinetics and higher equilibrium uptake of gases.Expand Specific Solutions04 Composite materials incorporating MOFs for gas adsorption

Composite materials that combine MOFs with other adsorbents or support materials are developed to overcome limitations of pure MOFs. These composites can exhibit improved mechanical stability, heat transfer properties, and overall gas adsorption performance.Expand Specific Solutions05 Stimuli-responsive MOFs for controlled gas release

MOFs that respond to external stimuli such as temperature, pressure, or light are designed for controlled gas release applications. These materials can adsorb gases under certain conditions and release them when triggered, allowing for precise control over gas storage and delivery.Expand Specific Solutions

Key Players in MOF Research and Development

The thermodynamic analysis of gas adsorption in flexible MOFs represents a dynamic field with significant potential for industrial applications. The market is in a growth phase, driven by increasing demand for advanced gas storage and separation technologies. While the market size is expanding, it remains relatively niche. Technologically, the field is progressing rapidly, with key players like China Petroleum & Chemical Corp., BASF, and Air Liquide leading industrial research. Academic institutions such as South China University of Technology, École Normale Supérieure, and National University of Singapore are contributing fundamental insights. The technology is maturing, transitioning from theoretical studies to practical applications, with companies like NuMat Technologies bridging the gap between academic research and commercial implementation.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed advanced MOF materials for gas adsorption and separation. Their research focuses on flexible MOFs with high selectivity for CO2 capture. They have synthesized a series of flexible MOFs with breathing effects, achieving CO2 uptake capacities of up to 4.2 mmol/g at 1 bar and 298 K[1]. Sinopec's approach involves tailoring the pore size and chemical functionality of MOFs to enhance CO2 adsorption performance. They have also conducted in-depth thermodynamic analyses to understand the adsorption mechanisms, including the impact of framework flexibility on adsorption isotherms and heat of adsorption[2].

Strengths: Large-scale industrial application potential, extensive R&D resources. Weaknesses: Potential challenges in scaling up laboratory results to industrial processes.

Centre National de la Recherche Scientifique

Technical Solution: The Centre National de la Recherche Scientifique (CNRS) has made significant contributions to the thermodynamic analysis of gas adsorption in flexible MOFs. Their research team has developed advanced in situ characterization techniques, including high-pressure X-ray diffraction and microcalorimetry, to study the structural transitions and energetics of flexible MOFs during gas adsorption[3]. CNRS researchers have proposed a thermodynamic framework to describe the complex interplay between guest adsorption and host flexibility, accounting for both the adsorption energy and the elastic energy of the framework[4]. They have successfully applied this approach to explain the stepped isotherms and hysteresis observed in many flexible MOFs, providing insights into the mechanisms of gate-opening and breathing phenomena.

Strengths: Cutting-edge characterization techniques, strong theoretical foundation. Weaknesses: May face challenges in translating fundamental research into practical applications.

Innovative Approaches in MOF Characterization

Phase change adsorbents for chemical storage and separation applications

PatentPendingUS20240024848A1

Innovation

- Development of a series of tunable metal-organic frameworks based on the zinc variant of the M(BDP) family with heterocyclic interactions, incorporating nitrogen groups into aromatic rings to increase flexibility and step pressure tunability, enhancing air stability and cyclability, and demonstrating stepped-shaped adsorption isotherms for efficient methane storage and separation.

Metal-organic framework

PatentPendingEP4495099A1

Innovation

- A metal organic framework (MOF) is developed with a structure Sx constituted by O2-, OH2, OH-, OCH3, and OC2H5, and a metal ion configuration where two or more metal ions are bonded to one oxygen atom, resulting in a water absorption rate of 25% or more.

Environmental Impact of MOF-based Technologies

The environmental impact of MOF-based technologies is a critical consideration as these materials gain prominence in various applications. Metal-Organic Frameworks (MOFs) offer significant potential for addressing environmental challenges, particularly in gas adsorption and separation processes. However, their widespread adoption also raises questions about their overall environmental footprint.

One of the primary environmental benefits of MOF-based technologies is their potential to reduce energy consumption in industrial processes. The high surface area and tunable pore structures of MOFs make them excellent candidates for efficient gas separation and purification, which can lead to reduced energy requirements in industries such as natural gas processing and carbon capture. This energy efficiency translates to lower greenhouse gas emissions and a reduced carbon footprint for these processes.

MOFs also show promise in environmental remediation applications. Their ability to selectively adsorb pollutants from air and water makes them valuable tools for addressing environmental contamination. For instance, MOFs have been demonstrated to effectively remove heavy metals, organic pollutants, and even radioactive materials from water sources, contributing to improved water quality and ecosystem health.

However, the production of MOFs themselves raises environmental concerns. The synthesis of MOFs often involves the use of organic solvents and metal precursors, which can have negative environmental impacts if not properly managed. The energy-intensive nature of some MOF synthesis methods also contributes to their environmental footprint. As research progresses, there is a growing focus on developing more sustainable synthesis routes, including solvent-free methods and the use of bio-based precursors.

The long-term stability and recyclability of MOFs are crucial factors in assessing their overall environmental impact. While many MOFs exhibit excellent stability and can be regenerated multiple times, some may degrade over time or lose their performance under certain conditions. This degradation could lead to the need for frequent replacement, potentially offsetting the environmental benefits of their use.

Another consideration is the end-of-life management of MOF-based materials. As these materials become more widely used, developing effective recycling or disposal methods becomes increasingly important. Research into the recovery of metal components from spent MOFs and the potential for MOF upcycling is ongoing, aiming to minimize waste and promote a circular economy approach.

The scalability of MOF production also has environmental implications. As demand for MOFs increases, the environmental impact of large-scale manufacturing processes must be carefully evaluated. This includes assessing the availability and sustainability of raw materials, as well as optimizing production processes to minimize resource consumption and waste generation.

One of the primary environmental benefits of MOF-based technologies is their potential to reduce energy consumption in industrial processes. The high surface area and tunable pore structures of MOFs make them excellent candidates for efficient gas separation and purification, which can lead to reduced energy requirements in industries such as natural gas processing and carbon capture. This energy efficiency translates to lower greenhouse gas emissions and a reduced carbon footprint for these processes.

MOFs also show promise in environmental remediation applications. Their ability to selectively adsorb pollutants from air and water makes them valuable tools for addressing environmental contamination. For instance, MOFs have been demonstrated to effectively remove heavy metals, organic pollutants, and even radioactive materials from water sources, contributing to improved water quality and ecosystem health.

However, the production of MOFs themselves raises environmental concerns. The synthesis of MOFs often involves the use of organic solvents and metal precursors, which can have negative environmental impacts if not properly managed. The energy-intensive nature of some MOF synthesis methods also contributes to their environmental footprint. As research progresses, there is a growing focus on developing more sustainable synthesis routes, including solvent-free methods and the use of bio-based precursors.

The long-term stability and recyclability of MOFs are crucial factors in assessing their overall environmental impact. While many MOFs exhibit excellent stability and can be regenerated multiple times, some may degrade over time or lose their performance under certain conditions. This degradation could lead to the need for frequent replacement, potentially offsetting the environmental benefits of their use.

Another consideration is the end-of-life management of MOF-based materials. As these materials become more widely used, developing effective recycling or disposal methods becomes increasingly important. Research into the recovery of metal components from spent MOFs and the potential for MOF upcycling is ongoing, aiming to minimize waste and promote a circular economy approach.

The scalability of MOF production also has environmental implications. As demand for MOFs increases, the environmental impact of large-scale manufacturing processes must be carefully evaluated. This includes assessing the availability and sustainability of raw materials, as well as optimizing production processes to minimize resource consumption and waste generation.

Scalability and Industrial Applications

The scalability and industrial applications of thermodynamic analysis of gas adsorption in flexible Metal-Organic Frameworks (MOFs) present significant opportunities and challenges for large-scale implementation. Flexible MOFs have shown remarkable potential for gas storage, separation, and purification processes due to their unique structural properties and adaptability to different adsorbates.

In terms of scalability, the synthesis of flexible MOFs has made considerable progress in recent years. Laboratory-scale production methods have been successfully adapted for larger-scale manufacturing, with some MOFs now being produced at kilogram scales. However, challenges remain in maintaining consistent quality and structural integrity during scale-up processes. The development of continuous flow synthesis techniques and the optimization of reaction conditions have contributed to improved scalability, but further advancements are needed to meet industrial demands.

Industrial applications of flexible MOFs for gas adsorption are diverse and promising. In the energy sector, these materials show potential for natural gas storage and transportation, offering higher storage capacities compared to traditional compressed gas systems. The automotive industry is exploring flexible MOFs for on-board hydrogen storage in fuel cell vehicles, leveraging their high surface area and tunable pore structures.

Environmental applications include carbon capture and storage, where flexible MOFs can selectively adsorb CO2 from flue gases with high efficiency. The water treatment industry is investigating these materials for the removal of contaminants and the purification of drinking water. Additionally, the pharmaceutical and chemical industries are exploring flexible MOFs for gas separation processes and as catalysts for various reactions.

Despite these promising applications, several challenges must be addressed for widespread industrial adoption. The cost of large-scale MOF production remains a significant barrier, particularly for more complex flexible structures. Enhancing the mechanical and chemical stability of flexible MOFs under industrial operating conditions is crucial for long-term performance and durability.

Furthermore, the integration of flexible MOFs into existing industrial processes and equipment requires careful engineering and design considerations. Optimizing the regeneration and cycling processes for these materials is essential for maintaining their performance over multiple adsorption-desorption cycles. The development of standardized testing protocols and performance metrics for flexible MOFs will facilitate their comparison with conventional adsorbents and accelerate their adoption in industrial settings.

As research in this field progresses, collaborative efforts between academia and industry are driving innovation in scalable synthesis methods and novel applications. The continued refinement of thermodynamic models and simulation techniques for gas adsorption in flexible MOFs will play a crucial role in optimizing their performance and guiding the design of next-generation materials tailored for specific industrial applications.

In terms of scalability, the synthesis of flexible MOFs has made considerable progress in recent years. Laboratory-scale production methods have been successfully adapted for larger-scale manufacturing, with some MOFs now being produced at kilogram scales. However, challenges remain in maintaining consistent quality and structural integrity during scale-up processes. The development of continuous flow synthesis techniques and the optimization of reaction conditions have contributed to improved scalability, but further advancements are needed to meet industrial demands.

Industrial applications of flexible MOFs for gas adsorption are diverse and promising. In the energy sector, these materials show potential for natural gas storage and transportation, offering higher storage capacities compared to traditional compressed gas systems. The automotive industry is exploring flexible MOFs for on-board hydrogen storage in fuel cell vehicles, leveraging their high surface area and tunable pore structures.

Environmental applications include carbon capture and storage, where flexible MOFs can selectively adsorb CO2 from flue gases with high efficiency. The water treatment industry is investigating these materials for the removal of contaminants and the purification of drinking water. Additionally, the pharmaceutical and chemical industries are exploring flexible MOFs for gas separation processes and as catalysts for various reactions.

Despite these promising applications, several challenges must be addressed for widespread industrial adoption. The cost of large-scale MOF production remains a significant barrier, particularly for more complex flexible structures. Enhancing the mechanical and chemical stability of flexible MOFs under industrial operating conditions is crucial for long-term performance and durability.

Furthermore, the integration of flexible MOFs into existing industrial processes and equipment requires careful engineering and design considerations. Optimizing the regeneration and cycling processes for these materials is essential for maintaining their performance over multiple adsorption-desorption cycles. The development of standardized testing protocols and performance metrics for flexible MOFs will facilitate their comparison with conventional adsorbents and accelerate their adoption in industrial settings.

As research in this field progresses, collaborative efforts between academia and industry are driving innovation in scalable synthesis methods and novel applications. The continued refinement of thermodynamic models and simulation techniques for gas adsorption in flexible MOFs will play a crucial role in optimizing their performance and guiding the design of next-generation materials tailored for specific industrial applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!