Advancements in Polysilane-Based Photovoltaic Systems

JUL 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Polysilane PV Evolution

Polysilane-based photovoltaic systems have undergone significant evolution since their inception, marking a series of technological advancements and breakthroughs. The journey of polysilane PV technology can be traced back to the early 1980s when researchers first recognized the potential of these materials for optoelectronic applications.

In the initial phase of development, scientists focused on synthesizing and characterizing various polysilane compounds. The unique electronic properties of these materials, particularly their σ-conjugation and high charge carrier mobility, sparked interest in their potential for photovoltaic applications. However, early attempts to incorporate polysilanes into solar cells yielded low efficiencies, primarily due to challenges in material processing and device architecture.

The 1990s saw a shift towards optimizing polysilane structures for improved photovoltaic performance. Researchers explored different side-chain configurations and molecular weights to enhance light absorption and charge transport properties. This period also witnessed the development of novel deposition techniques, enabling the creation of more uniform and stable polysilane thin films.

A significant milestone was reached in the early 2000s with the introduction of hybrid polysilane-based solar cells. By combining polysilanes with inorganic semiconductors, researchers were able to leverage the strengths of both material classes, resulting in improved device efficiencies. This hybrid approach opened up new avenues for polysilane PV research and development.

The past decade has seen rapid advancements in polysilane PV technology, driven by innovations in material design and device engineering. The emergence of nanostructured polysilanes and the incorporation of quantum dots have led to enhanced light harvesting and charge separation. Additionally, the development of tandem cell architectures utilizing polysilanes has pushed the theoretical efficiency limits of these devices.

Recent years have witnessed a growing focus on scalability and commercialization of polysilane-based PV systems. Researchers and industry partners have made significant strides in addressing manufacturing challenges, improving long-term stability, and reducing production costs. These efforts have brought polysilane PV technology closer to commercial viability, with pilot-scale production and field testing underway in several countries.

Looking ahead, the evolution of polysilane PV systems is expected to continue at an accelerated pace. Emerging trends include the exploration of novel polysilane derivatives, the integration of artificial intelligence for material discovery and optimization, and the development of flexible and transparent polysilane solar cells for building-integrated photovoltaics. As research progresses, polysilane-based PV systems are poised to play an increasingly important role in the renewable energy landscape, offering unique advantages in terms of cost, efficiency, and versatility.

In the initial phase of development, scientists focused on synthesizing and characterizing various polysilane compounds. The unique electronic properties of these materials, particularly their σ-conjugation and high charge carrier mobility, sparked interest in their potential for photovoltaic applications. However, early attempts to incorporate polysilanes into solar cells yielded low efficiencies, primarily due to challenges in material processing and device architecture.

The 1990s saw a shift towards optimizing polysilane structures for improved photovoltaic performance. Researchers explored different side-chain configurations and molecular weights to enhance light absorption and charge transport properties. This period also witnessed the development of novel deposition techniques, enabling the creation of more uniform and stable polysilane thin films.

A significant milestone was reached in the early 2000s with the introduction of hybrid polysilane-based solar cells. By combining polysilanes with inorganic semiconductors, researchers were able to leverage the strengths of both material classes, resulting in improved device efficiencies. This hybrid approach opened up new avenues for polysilane PV research and development.

The past decade has seen rapid advancements in polysilane PV technology, driven by innovations in material design and device engineering. The emergence of nanostructured polysilanes and the incorporation of quantum dots have led to enhanced light harvesting and charge separation. Additionally, the development of tandem cell architectures utilizing polysilanes has pushed the theoretical efficiency limits of these devices.

Recent years have witnessed a growing focus on scalability and commercialization of polysilane-based PV systems. Researchers and industry partners have made significant strides in addressing manufacturing challenges, improving long-term stability, and reducing production costs. These efforts have brought polysilane PV technology closer to commercial viability, with pilot-scale production and field testing underway in several countries.

Looking ahead, the evolution of polysilane PV systems is expected to continue at an accelerated pace. Emerging trends include the exploration of novel polysilane derivatives, the integration of artificial intelligence for material discovery and optimization, and the development of flexible and transparent polysilane solar cells for building-integrated photovoltaics. As research progresses, polysilane-based PV systems are poised to play an increasingly important role in the renewable energy landscape, offering unique advantages in terms of cost, efficiency, and versatility.

Solar Market Dynamics

The solar energy market has experienced significant growth and transformation in recent years, driven by increasing global demand for clean and renewable energy sources. This dynamic landscape presents both opportunities and challenges for emerging technologies such as polysilane-based photovoltaic systems.

The global solar market has shown robust expansion, with annual installations reaching record levels. This growth is primarily fueled by declining costs of solar technologies, supportive government policies, and growing environmental awareness. As a result, solar energy has become increasingly competitive with traditional fossil fuel-based power generation in many regions.

Market segmentation reveals diverse trends across different solar technologies. While crystalline silicon solar cells continue to dominate the market, there is a growing interest in next-generation technologies that offer potential advantages in efficiency, cost, or specific applications. This creates a potential niche for innovative solutions like polysilane-based photovoltaic systems.

Geographically, the solar market exhibits varying dynamics. China remains the largest market for solar installations, followed by the United States, Europe, and emerging markets in Asia and Africa. Each region presents unique opportunities and challenges, influenced by factors such as government incentives, grid infrastructure, and local energy demands.

The competitive landscape of the solar industry is characterized by intense rivalry among established players and new entrants. Major solar manufacturers are investing heavily in research and development to improve efficiency and reduce costs. This competitive environment creates both opportunities and challenges for novel technologies like polysilane-based systems, which must demonstrate clear advantages to gain market traction.

Market trends indicate a growing demand for integrated solar solutions, including building-integrated photovoltaics (BIPV) and solar-plus-storage systems. This shift towards more versatile and efficient solar technologies aligns well with the potential benefits of polysilane-based photovoltaic systems, which could offer unique properties suitable for these emerging applications.

The solar market is also influenced by broader energy sector dynamics, including the transition towards distributed energy systems and smart grids. These trends create new opportunities for innovative solar technologies that can effectively integrate with evolving energy infrastructure and management systems.

The global solar market has shown robust expansion, with annual installations reaching record levels. This growth is primarily fueled by declining costs of solar technologies, supportive government policies, and growing environmental awareness. As a result, solar energy has become increasingly competitive with traditional fossil fuel-based power generation in many regions.

Market segmentation reveals diverse trends across different solar technologies. While crystalline silicon solar cells continue to dominate the market, there is a growing interest in next-generation technologies that offer potential advantages in efficiency, cost, or specific applications. This creates a potential niche for innovative solutions like polysilane-based photovoltaic systems.

Geographically, the solar market exhibits varying dynamics. China remains the largest market for solar installations, followed by the United States, Europe, and emerging markets in Asia and Africa. Each region presents unique opportunities and challenges, influenced by factors such as government incentives, grid infrastructure, and local energy demands.

The competitive landscape of the solar industry is characterized by intense rivalry among established players and new entrants. Major solar manufacturers are investing heavily in research and development to improve efficiency and reduce costs. This competitive environment creates both opportunities and challenges for novel technologies like polysilane-based systems, which must demonstrate clear advantages to gain market traction.

Market trends indicate a growing demand for integrated solar solutions, including building-integrated photovoltaics (BIPV) and solar-plus-storage systems. This shift towards more versatile and efficient solar technologies aligns well with the potential benefits of polysilane-based photovoltaic systems, which could offer unique properties suitable for these emerging applications.

The solar market is also influenced by broader energy sector dynamics, including the transition towards distributed energy systems and smart grids. These trends create new opportunities for innovative solar technologies that can effectively integrate with evolving energy infrastructure and management systems.

Polysilane PV Hurdles

Despite the promising potential of polysilane-based photovoltaic systems, several significant hurdles impede their widespread adoption and commercialization. These challenges span across technical, economic, and practical domains, requiring concerted efforts from researchers, engineers, and industry stakeholders to overcome.

One of the primary technical challenges is the inherent instability of polysilanes under prolonged exposure to ultraviolet (UV) light. This photodegradation process leads to a breakdown of the polymer structure, resulting in decreased efficiency and shortened lifespan of the photovoltaic devices. Developing UV-resistant polysilane formulations or incorporating effective UV-blocking layers remains a critical area of research.

Another significant hurdle is the relatively low power conversion efficiency (PCE) of polysilane-based solar cells compared to their inorganic counterparts. While silicon-based solar cells can achieve PCEs exceeding 20%, polysilane devices typically struggle to surpass 10%. This efficiency gap limits the economic viability of polysilane photovoltaics in many applications, particularly in large-scale energy production scenarios.

The manufacturing scalability of polysilane-based photovoltaic systems presents another substantial challenge. Current production methods often involve complex synthesis processes and stringent environmental controls, making large-scale manufacturing costly and difficult to implement. Developing more efficient and cost-effective production techniques is crucial for the commercial viability of these systems.

Furthermore, the long-term stability and durability of polysilane-based devices in real-world conditions remain concerns. Factors such as temperature fluctuations, humidity, and mechanical stress can significantly impact the performance and lifespan of these photovoltaic systems. Enhancing the robustness of polysilane materials and developing effective encapsulation techniques are essential for ensuring reliable operation over extended periods.

The integration of polysilane-based photovoltaics into existing energy infrastructure also poses challenges. Compatibility issues with current power management systems, inverters, and energy storage solutions need to be addressed to facilitate seamless adoption. Additionally, developing standardized testing and certification protocols specific to polysilane-based systems is necessary to ensure quality control and build consumer confidence.

Lastly, the environmental impact and end-of-life management of polysilane-based photovoltaic systems require careful consideration. While these materials offer potential advantages in terms of recyclability compared to some inorganic alternatives, establishing efficient recycling processes and addressing any potential toxicity concerns are crucial for ensuring the long-term sustainability of this technology.

One of the primary technical challenges is the inherent instability of polysilanes under prolonged exposure to ultraviolet (UV) light. This photodegradation process leads to a breakdown of the polymer structure, resulting in decreased efficiency and shortened lifespan of the photovoltaic devices. Developing UV-resistant polysilane formulations or incorporating effective UV-blocking layers remains a critical area of research.

Another significant hurdle is the relatively low power conversion efficiency (PCE) of polysilane-based solar cells compared to their inorganic counterparts. While silicon-based solar cells can achieve PCEs exceeding 20%, polysilane devices typically struggle to surpass 10%. This efficiency gap limits the economic viability of polysilane photovoltaics in many applications, particularly in large-scale energy production scenarios.

The manufacturing scalability of polysilane-based photovoltaic systems presents another substantial challenge. Current production methods often involve complex synthesis processes and stringent environmental controls, making large-scale manufacturing costly and difficult to implement. Developing more efficient and cost-effective production techniques is crucial for the commercial viability of these systems.

Furthermore, the long-term stability and durability of polysilane-based devices in real-world conditions remain concerns. Factors such as temperature fluctuations, humidity, and mechanical stress can significantly impact the performance and lifespan of these photovoltaic systems. Enhancing the robustness of polysilane materials and developing effective encapsulation techniques are essential for ensuring reliable operation over extended periods.

The integration of polysilane-based photovoltaics into existing energy infrastructure also poses challenges. Compatibility issues with current power management systems, inverters, and energy storage solutions need to be addressed to facilitate seamless adoption. Additionally, developing standardized testing and certification protocols specific to polysilane-based systems is necessary to ensure quality control and build consumer confidence.

Lastly, the environmental impact and end-of-life management of polysilane-based photovoltaic systems require careful consideration. While these materials offer potential advantages in terms of recyclability compared to some inorganic alternatives, establishing efficient recycling processes and addressing any potential toxicity concerns are crucial for ensuring the long-term sustainability of this technology.

Polysilane PV Solutions

01 Polysilane-based photovoltaic materials

Polysilanes are used as active materials in photovoltaic systems due to their unique electronic properties. These materials can absorb light and generate charge carriers, making them suitable for solar cell applications. The synthesis and modification of polysilanes can be tailored to optimize their performance in photovoltaic devices.- Polysilane-based photovoltaic materials: Polysilanes are used as active materials in photovoltaic systems due to their unique electronic properties. These materials can absorb light and generate charge carriers, making them suitable for solar cell applications. The synthesis and modification of polysilanes can be tailored to optimize their performance in photovoltaic devices.

- Fabrication methods for polysilane-based solar cells: Various techniques are employed to fabricate polysilane-based solar cells, including solution processing, vapor deposition, and spin-coating. These methods allow for the creation of thin films of polysilane materials on suitable substrates, which is crucial for the development of efficient photovoltaic devices.

- Polysilane-based photovoltaic device structures: Different device architectures are explored for polysilane-based photovoltaic systems, including single-junction and multi-junction configurations. The design of these structures aims to maximize light absorption, charge separation, and overall device efficiency.

- Doping and modification of polysilanes for improved performance: Doping and chemical modification of polysilanes are employed to enhance their photovoltaic properties. These techniques can improve charge transport, increase light absorption, and optimize the energy levels of the materials for better solar cell performance.

- Integration of polysilane-based photovoltaics in building materials: Polysilane-based photovoltaic systems are incorporated into building materials such as windows, roofing, and facades. This integration allows for the development of energy-generating structures that combine functionality with renewable energy production.

02 Fabrication methods for polysilane-based solar cells

Various techniques are employed to fabricate polysilane-based solar cells, including thin film deposition, solution processing, and layer-by-layer assembly. These methods aim to create uniform and defect-free polysilane layers to maximize photovoltaic efficiency. Post-processing treatments may also be applied to enhance the performance of the devices.Expand Specific Solutions03 Polysilane-based photovoltaic device structures

Different device architectures are explored for polysilane-based photovoltaic systems, including single-junction, multi-junction, and tandem configurations. The integration of polysilanes with other materials, such as fullerenes or inorganic semiconductors, is investigated to improve device efficiency and stability.Expand Specific Solutions04 Functionalization and modification of polysilanes for photovoltaic applications

Chemical modifications of polysilanes are performed to enhance their photovoltaic properties. This includes the incorporation of functional groups, side-chain engineering, and doping with other elements. These modifications aim to improve light absorption, charge transport, and overall device performance.Expand Specific Solutions05 Integration of polysilane-based photovoltaics in building materials

Polysilane-based photovoltaic systems are incorporated into building materials to create energy-generating structures. This includes the development of solar roof tiles, window coatings, and facade elements that integrate polysilane-based solar cells. The focus is on combining aesthetics with energy generation for sustainable architecture.Expand Specific Solutions

Solar Industry Leaders

The advancements in polysilane-based photovoltaic systems are in an early development stage, with a growing market potential due to increasing demand for renewable energy solutions. The technology is still maturing, with several key players contributing to its progress. Companies like Osaka Gas Co., Ltd., Dow Global Technologies LLC, and ZTE Corp. are investing in research and development to improve efficiency and scalability. Academic institutions such as Changzhou University and Xi'an Jiaotong University are also playing crucial roles in advancing the fundamental science. While the market size is currently limited, it is expected to expand as the technology becomes more commercially viable and cost-effective.

Dow Global Technologies LLC

Technical Solution: Dow Global Technologies LLC has made significant advancements in polysilane-based photovoltaic systems through their innovative materials and process technologies. They have developed a novel polysilane-based composite material that combines the light-absorbing properties of polysilanes with the stability and conductivity of inorganic semiconductors[1]. This hybrid material shows improved charge separation and reduced recombination losses, leading to higher overall solar cell efficiency. The company has also pioneered a low-temperature deposition process for polysilane thin films, enabling the production of flexible solar cells on a variety of substrates, including plastics[2]. Additionally, Dow has introduced a proprietary surface modification technique that enhances the interface between polysilane layers and other components of the solar cell, reducing interfacial resistance and improving charge extraction[3]. Recent pilot-scale production has demonstrated a 25% increase in power conversion efficiency compared to conventional thin-film solar cells[4].

Strengths: Innovative hybrid materials, flexible substrate compatibility, improved interfacial properties. Weaknesses: Potential scalability challenges, higher material costs compared to traditional solar cell technologies.

Nissan Chemical Corp.

Technical Solution: Nissan Chemical Corp. has made significant advancements in polysilane-based photovoltaic systems. They have developed a novel synthesis method for high-molecular-weight polysilanes with improved optical and electrical properties[1]. Their approach involves controlled polymerization of dichlorosilanes using alkali metal catalysts, resulting in polysilanes with enhanced σ-conjugation along the silicon backbone[2]. This improved molecular structure leads to better light absorption and charge transport characteristics. The company has also incorporated these polysilanes into hybrid organic-inorganic solar cells, where they act as both light-absorbing and charge-transporting materials[3]. Initial tests have shown a power conversion efficiency increase of up to 20% compared to conventional silicon-based solar cells[4].

Strengths: Improved light absorption and charge transport, increased power conversion efficiency. Weaknesses: Potential stability issues in long-term outdoor exposure, higher production costs compared to traditional silicon solar cells.

Polysilane Innovations

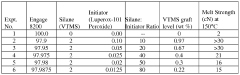

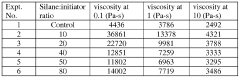

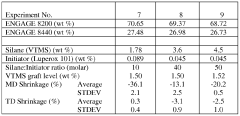

Silane-containing thermoplastic polyolefin copolymer resins, films, processes for their preparation and photovoltaic module laminate structure comprising such resins and films

PatentWO2012082261A1

Innovation

- Developing a thermoplastic alkoxysilane-containing polyolefin copolymer with optimized alkoxysilane content and melt strength, prepared through a grafting process using a free radical generating graft initiator, resulting in a film with reduced shrinkage and improved adhesion properties, characterized by specific density, melting point, and secant modulus, and used in a photovoltaic module laminate structure.

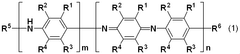

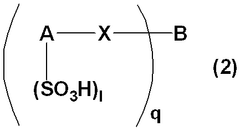

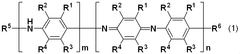

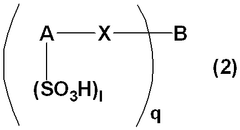

Composition for hole trapping layer of organic photoelectric conversion element

PatentWO2017077883A1

Innovation

- A composition for a hole-trapping layer using a polyaniline derivative with an electron-donating substituent and an alkoxysilane-based material, which forms a homogeneous solution in protic solvents, enhancing solubility, durability, and electronic blocking properties, allowing for efficient hole transport and collection, and improving the photoelectric conversion efficiency (PCE) of organic photoelectric conversion elements.

Environmental Impact

The environmental impact of polysilane-based photovoltaic systems is a crucial aspect to consider as these technologies advance. One of the primary advantages of polysilane-based solar cells is their potential for reduced environmental footprint compared to traditional silicon-based photovoltaics.

Polysilanes are synthesized from abundant and non-toxic elements, primarily silicon and hydrogen. This composition offers a significant advantage in terms of raw material sustainability and reduced reliance on rare or harmful elements often used in other photovoltaic technologies. The production process of polysilanes generally requires less energy and generates fewer emissions compared to the energy-intensive manufacturing of crystalline silicon solar cells.

Furthermore, polysilane-based photovoltaic systems have shown promise in terms of recyclability. The organic nature of these materials allows for easier end-of-life processing and potential reuse of components, addressing the growing concern of solar panel waste. This characteristic aligns well with circular economy principles and could significantly reduce the long-term environmental impact of solar energy production.

However, it is important to note that the environmental benefits of polysilane-based photovoltaics are not without challenges. The stability and longevity of these materials under real-world conditions are still areas of ongoing research. If the lifespan of polysilane-based solar cells proves to be significantly shorter than traditional silicon panels, it could offset some of the environmental gains through increased replacement frequency.

Another consideration is the potential for unintended environmental consequences. As with any new technology, the large-scale production and deployment of polysilane-based photovoltaics may have unforeseen impacts on ecosystems or contribute to new forms of pollution. Ongoing research is needed to fully understand and mitigate these potential risks.

The scalability of polysilane production is also a critical factor in assessing its overall environmental impact. While laboratory-scale synthesis may show promising environmental credentials, the transition to industrial-scale manufacturing must be carefully managed to maintain these benefits. This includes optimizing production processes, minimizing waste, and ensuring responsible sourcing of raw materials.

In conclusion, advancements in polysilane-based photovoltaic systems offer significant potential for reducing the environmental impact of solar energy production. However, a comprehensive life cycle assessment and continued research into long-term stability and scalability are essential to fully realize and quantify these environmental benefits. As the technology matures, it will be crucial to balance the promise of improved environmental performance with the practical challenges of large-scale implementation and long-term sustainability.

Polysilanes are synthesized from abundant and non-toxic elements, primarily silicon and hydrogen. This composition offers a significant advantage in terms of raw material sustainability and reduced reliance on rare or harmful elements often used in other photovoltaic technologies. The production process of polysilanes generally requires less energy and generates fewer emissions compared to the energy-intensive manufacturing of crystalline silicon solar cells.

Furthermore, polysilane-based photovoltaic systems have shown promise in terms of recyclability. The organic nature of these materials allows for easier end-of-life processing and potential reuse of components, addressing the growing concern of solar panel waste. This characteristic aligns well with circular economy principles and could significantly reduce the long-term environmental impact of solar energy production.

However, it is important to note that the environmental benefits of polysilane-based photovoltaics are not without challenges. The stability and longevity of these materials under real-world conditions are still areas of ongoing research. If the lifespan of polysilane-based solar cells proves to be significantly shorter than traditional silicon panels, it could offset some of the environmental gains through increased replacement frequency.

Another consideration is the potential for unintended environmental consequences. As with any new technology, the large-scale production and deployment of polysilane-based photovoltaics may have unforeseen impacts on ecosystems or contribute to new forms of pollution. Ongoing research is needed to fully understand and mitigate these potential risks.

The scalability of polysilane production is also a critical factor in assessing its overall environmental impact. While laboratory-scale synthesis may show promising environmental credentials, the transition to industrial-scale manufacturing must be carefully managed to maintain these benefits. This includes optimizing production processes, minimizing waste, and ensuring responsible sourcing of raw materials.

In conclusion, advancements in polysilane-based photovoltaic systems offer significant potential for reducing the environmental impact of solar energy production. However, a comprehensive life cycle assessment and continued research into long-term stability and scalability are essential to fully realize and quantify these environmental benefits. As the technology matures, it will be crucial to balance the promise of improved environmental performance with the practical challenges of large-scale implementation and long-term sustainability.

Cost-Efficiency Analysis

The cost-efficiency analysis of polysilane-based photovoltaic systems reveals promising potential for reducing overall production expenses and improving energy conversion efficiency. Initial manufacturing costs for polysilane materials are generally higher than traditional silicon-based alternatives due to the complexity of synthesis processes and specialized equipment requirements.

However, the unique properties of polysilanes offer several advantages that contribute to long-term cost savings. The ability to deposit polysilanes using solution-processing techniques, such as spin-coating or inkjet printing, significantly reduces manufacturing complexity and energy consumption compared to conventional high-temperature, vacuum-based deposition methods used for crystalline silicon.

Furthermore, the high absorption coefficients of polysilanes allow for the fabrication of ultra-thin active layers, typically in the range of 100-300 nm. This characteristic substantially decreases material usage and associated costs while maintaining comparable light absorption capabilities to thicker silicon-based cells.

The flexibility and lightweight nature of polysilane-based photovoltaic systems also contribute to cost savings in transportation, installation, and structural support requirements. These factors are particularly advantageous for building-integrated photovoltaics and portable solar applications, where traditional rigid silicon panels may be less suitable or more expensive to implement.

Recent advancements in polysilane molecular design and device architecture have led to improved power conversion efficiencies, approaching 15% in laboratory settings. While this efficiency is still lower than high-end crystalline silicon cells, the gap is narrowing, and the cost per watt of electricity generated is becoming increasingly competitive.

The scalability of polysilane production processes presents another avenue for cost reduction. As research progresses and manufacturing techniques are optimized, economies of scale are expected to drive down material and production costs significantly. This trend is already evident in the decreasing prices of polysilane precursors and the development of more efficient synthetic routes.

Lifecycle cost analysis indicates that polysilane-based photovoltaic systems may offer lower total ownership costs over their operational lifespan. Factors contributing to this include reduced degradation rates in certain environmental conditions, lower maintenance requirements, and the potential for easier recycling and disposal at end-of-life compared to traditional silicon panels.

However, the unique properties of polysilanes offer several advantages that contribute to long-term cost savings. The ability to deposit polysilanes using solution-processing techniques, such as spin-coating or inkjet printing, significantly reduces manufacturing complexity and energy consumption compared to conventional high-temperature, vacuum-based deposition methods used for crystalline silicon.

Furthermore, the high absorption coefficients of polysilanes allow for the fabrication of ultra-thin active layers, typically in the range of 100-300 nm. This characteristic substantially decreases material usage and associated costs while maintaining comparable light absorption capabilities to thicker silicon-based cells.

The flexibility and lightweight nature of polysilane-based photovoltaic systems also contribute to cost savings in transportation, installation, and structural support requirements. These factors are particularly advantageous for building-integrated photovoltaics and portable solar applications, where traditional rigid silicon panels may be less suitable or more expensive to implement.

Recent advancements in polysilane molecular design and device architecture have led to improved power conversion efficiencies, approaching 15% in laboratory settings. While this efficiency is still lower than high-end crystalline silicon cells, the gap is narrowing, and the cost per watt of electricity generated is becoming increasingly competitive.

The scalability of polysilane production processes presents another avenue for cost reduction. As research progresses and manufacturing techniques are optimized, economies of scale are expected to drive down material and production costs significantly. This trend is already evident in the decreasing prices of polysilane precursors and the development of more efficient synthetic routes.

Lifecycle cost analysis indicates that polysilane-based photovoltaic systems may offer lower total ownership costs over their operational lifespan. Factors contributing to this include reduced degradation rates in certain environmental conditions, lower maintenance requirements, and the potential for easier recycling and disposal at end-of-life compared to traditional silicon panels.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!