Advances in Battery Acid Spill Containment Materials

AUG 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Battery Acid Spill Tech Evolution and Objectives

Battery acid spill containment technology has evolved significantly over the past few decades, driven by increasing environmental concerns and stringent safety regulations. The primary objective of this technology is to effectively contain and neutralize battery acid spills, minimizing potential harm to human health and the environment.

The evolution of battery acid spill containment materials can be traced back to the early 1970s when awareness of environmental hazards began to grow. Initially, simple absorbent materials such as sand or sawdust were used to contain spills. However, these methods were often ineffective and posed disposal challenges.

In the 1980s and 1990s, specialized acid-resistant absorbents were developed, including polypropylene-based materials and synthetic sorbents. These materials offered improved absorption capacity and chemical resistance compared to traditional methods. Concurrently, neutralizing agents were introduced to counteract the corrosive effects of battery acid.

The turn of the millennium saw a shift towards more sustainable and environmentally friendly containment solutions. Bio-based absorbents derived from natural materials like cellulose and plant fibers gained popularity due to their biodegradability and renewable nature. These materials offered comparable performance to synthetic alternatives while reducing environmental impact.

Recent advancements have focused on developing smart materials that can rapidly detect and respond to acid spills. These include color-changing indicators that provide visual cues for the presence of acid and self-activating neutralizers that automatically initiate upon contact with spilled acid.

The current technological objectives in battery acid spill containment are multifaceted. Researchers aim to develop materials with enhanced absorption capacity, faster neutralization rates, and improved chemical resistance. There is also a growing emphasis on creating multi-functional materials that can simultaneously absorb, neutralize, and indicate the presence of acid spills.

Another key objective is to improve the sustainability of containment materials. This includes developing biodegradable options that do not compromise on performance and exploring ways to recycle or repurpose used containment materials. Additionally, there is a focus on creating cost-effective solutions to make advanced containment technologies more accessible to a wider range of industries and applications.

As battery technology continues to evolve, particularly with the rise of electric vehicles and renewable energy storage systems, the field of acid spill containment must adapt accordingly. Future objectives may include developing containment materials specifically designed for new types of battery chemistries and addressing the unique challenges posed by large-scale energy storage facilities.

The evolution of battery acid spill containment materials can be traced back to the early 1970s when awareness of environmental hazards began to grow. Initially, simple absorbent materials such as sand or sawdust were used to contain spills. However, these methods were often ineffective and posed disposal challenges.

In the 1980s and 1990s, specialized acid-resistant absorbents were developed, including polypropylene-based materials and synthetic sorbents. These materials offered improved absorption capacity and chemical resistance compared to traditional methods. Concurrently, neutralizing agents were introduced to counteract the corrosive effects of battery acid.

The turn of the millennium saw a shift towards more sustainable and environmentally friendly containment solutions. Bio-based absorbents derived from natural materials like cellulose and plant fibers gained popularity due to their biodegradability and renewable nature. These materials offered comparable performance to synthetic alternatives while reducing environmental impact.

Recent advancements have focused on developing smart materials that can rapidly detect and respond to acid spills. These include color-changing indicators that provide visual cues for the presence of acid and self-activating neutralizers that automatically initiate upon contact with spilled acid.

The current technological objectives in battery acid spill containment are multifaceted. Researchers aim to develop materials with enhanced absorption capacity, faster neutralization rates, and improved chemical resistance. There is also a growing emphasis on creating multi-functional materials that can simultaneously absorb, neutralize, and indicate the presence of acid spills.

Another key objective is to improve the sustainability of containment materials. This includes developing biodegradable options that do not compromise on performance and exploring ways to recycle or repurpose used containment materials. Additionally, there is a focus on creating cost-effective solutions to make advanced containment technologies more accessible to a wider range of industries and applications.

As battery technology continues to evolve, particularly with the rise of electric vehicles and renewable energy storage systems, the field of acid spill containment must adapt accordingly. Future objectives may include developing containment materials specifically designed for new types of battery chemistries and addressing the unique challenges posed by large-scale energy storage facilities.

Market Demand for Spill Containment Solutions

The market demand for battery acid spill containment solutions has been steadily increasing due to the growing awareness of environmental and safety concerns in various industries. As the use of batteries in automotive, industrial, and renewable energy sectors continues to expand, the need for effective spill containment materials has become more critical than ever.

In the automotive industry, the rise of electric vehicles (EVs) has significantly boosted the demand for advanced battery acid spill containment solutions. With the global EV market projected to grow at a compound annual growth rate (CAGR) of over 20% in the coming years, manufacturers are increasingly focused on ensuring the safety of battery systems throughout their lifecycle, including during production, transportation, and disposal.

The industrial sector, particularly in manufacturing and warehousing, has also seen a surge in demand for spill containment materials. As companies strive to comply with stringent environmental regulations and workplace safety standards, the adoption of advanced containment solutions has become a priority. This trend is further driven by the potential financial and reputational risks associated with acid spills and environmental contamination.

Renewable energy applications, such as large-scale battery storage systems for solar and wind power, represent another significant market for spill containment solutions. As these installations become more prevalent, the need for reliable and efficient containment materials to protect against potential acid leaks has grown substantially.

The healthcare sector has emerged as an unexpected driver of demand for battery acid spill containment materials. With the increased use of portable medical devices and backup power systems in hospitals and clinics, there is a growing need for safe and effective containment solutions to mitigate risks associated with battery failures or accidents.

Geographically, developed regions such as North America and Europe currently lead the market for spill containment solutions due to stringent regulations and high awareness levels. However, rapidly industrializing countries in Asia-Pacific and Latin America are expected to witness the fastest growth in demand as they upgrade their safety standards and environmental practices.

The market is also seeing a shift towards more sustainable and eco-friendly containment materials. Customers are increasingly seeking solutions that not only effectively contain spills but also minimize environmental impact and facilitate easier disposal or recycling of contaminated materials.

In conclusion, the market demand for battery acid spill containment solutions is robust and diverse, driven by multiple industries and global trends. As technology advances and regulations tighten, this demand is expected to continue its upward trajectory, presenting significant opportunities for innovation and market growth in the coming years.

In the automotive industry, the rise of electric vehicles (EVs) has significantly boosted the demand for advanced battery acid spill containment solutions. With the global EV market projected to grow at a compound annual growth rate (CAGR) of over 20% in the coming years, manufacturers are increasingly focused on ensuring the safety of battery systems throughout their lifecycle, including during production, transportation, and disposal.

The industrial sector, particularly in manufacturing and warehousing, has also seen a surge in demand for spill containment materials. As companies strive to comply with stringent environmental regulations and workplace safety standards, the adoption of advanced containment solutions has become a priority. This trend is further driven by the potential financial and reputational risks associated with acid spills and environmental contamination.

Renewable energy applications, such as large-scale battery storage systems for solar and wind power, represent another significant market for spill containment solutions. As these installations become more prevalent, the need for reliable and efficient containment materials to protect against potential acid leaks has grown substantially.

The healthcare sector has emerged as an unexpected driver of demand for battery acid spill containment materials. With the increased use of portable medical devices and backup power systems in hospitals and clinics, there is a growing need for safe and effective containment solutions to mitigate risks associated with battery failures or accidents.

Geographically, developed regions such as North America and Europe currently lead the market for spill containment solutions due to stringent regulations and high awareness levels. However, rapidly industrializing countries in Asia-Pacific and Latin America are expected to witness the fastest growth in demand as they upgrade their safety standards and environmental practices.

The market is also seeing a shift towards more sustainable and eco-friendly containment materials. Customers are increasingly seeking solutions that not only effectively contain spills but also minimize environmental impact and facilitate easier disposal or recycling of contaminated materials.

In conclusion, the market demand for battery acid spill containment solutions is robust and diverse, driven by multiple industries and global trends. As technology advances and regulations tighten, this demand is expected to continue its upward trajectory, presenting significant opportunities for innovation and market growth in the coming years.

Current Challenges in Acid Spill Containment

Despite significant advancements in battery technology, acid spill containment remains a critical challenge in the industry. The primary issue stems from the corrosive nature of battery acids, which can cause severe damage to equipment, infrastructure, and pose serious health risks to personnel. Current containment methods often struggle to provide rapid and effective neutralization while ensuring long-term stability.

One of the main challenges is the development of materials that can quickly absorb and neutralize large volumes of acid without becoming saturated or losing effectiveness over time. Traditional absorbents like sand or clay have limited capacity and do not address the chemical hazards of the spill. More advanced solutions, such as specialized polymer-based absorbents, show promise but still face issues with scalability and cost-effectiveness for large-scale industrial applications.

Another significant hurdle is the creation of containment systems that can withstand the extreme pH levels and corrosive properties of battery acids for extended periods. Many current materials degrade rapidly when exposed to strong acids, leading to potential breaches in containment and secondary spills. This necessitates frequent replacement and monitoring, increasing operational costs and risks.

The environmental impact of containment materials themselves presents an additional challenge. Many effective acid-neutralizing compounds are not environmentally friendly, creating a trade-off between immediate spill control and long-term ecological considerations. Developing green alternatives that are both highly effective and environmentally sustainable remains an ongoing struggle for researchers and manufacturers.

In industrial settings, the need for rapid deployment of containment solutions during emergencies is crucial. However, many current systems are cumbersome to implement quickly, requiring specialized training or equipment. This delay in response time can exacerbate the damage caused by acid spills, highlighting the need for more user-friendly and instantly deployable containment technologies.

Furthermore, the diverse range of battery chemistries in use today complicates the development of universal containment solutions. What works effectively for lead-acid battery spills may not be suitable for lithium-ion or other advanced battery technologies. This variability necessitates either the development of highly adaptable containment materials or a range of specialized solutions, each tailored to specific battery chemistries.

Lastly, the integration of smart technologies into containment systems presents both opportunities and challenges. While sensors and automated response systems could potentially improve reaction times and effectiveness, they also introduce new complexities in terms of reliability, maintenance, and cost. Striking the right balance between technological advancement and practical, foolproof solutions remains a significant challenge in the field of battery acid spill containment.

One of the main challenges is the development of materials that can quickly absorb and neutralize large volumes of acid without becoming saturated or losing effectiveness over time. Traditional absorbents like sand or clay have limited capacity and do not address the chemical hazards of the spill. More advanced solutions, such as specialized polymer-based absorbents, show promise but still face issues with scalability and cost-effectiveness for large-scale industrial applications.

Another significant hurdle is the creation of containment systems that can withstand the extreme pH levels and corrosive properties of battery acids for extended periods. Many current materials degrade rapidly when exposed to strong acids, leading to potential breaches in containment and secondary spills. This necessitates frequent replacement and monitoring, increasing operational costs and risks.

The environmental impact of containment materials themselves presents an additional challenge. Many effective acid-neutralizing compounds are not environmentally friendly, creating a trade-off between immediate spill control and long-term ecological considerations. Developing green alternatives that are both highly effective and environmentally sustainable remains an ongoing struggle for researchers and manufacturers.

In industrial settings, the need for rapid deployment of containment solutions during emergencies is crucial. However, many current systems are cumbersome to implement quickly, requiring specialized training or equipment. This delay in response time can exacerbate the damage caused by acid spills, highlighting the need for more user-friendly and instantly deployable containment technologies.

Furthermore, the diverse range of battery chemistries in use today complicates the development of universal containment solutions. What works effectively for lead-acid battery spills may not be suitable for lithium-ion or other advanced battery technologies. This variability necessitates either the development of highly adaptable containment materials or a range of specialized solutions, each tailored to specific battery chemistries.

Lastly, the integration of smart technologies into containment systems presents both opportunities and challenges. While sensors and automated response systems could potentially improve reaction times and effectiveness, they also introduce new complexities in terms of reliability, maintenance, and cost. Striking the right balance between technological advancement and practical, foolproof solutions remains a significant challenge in the field of battery acid spill containment.

Existing Acid Spill Containment Solutions

01 Containment systems for battery acid spills

Various containment systems are designed specifically for battery acid spills. These systems include specialized trays, liners, and barriers that can effectively contain and neutralize acid leaks from batteries. The containment systems are often made of acid-resistant materials and may incorporate absorbent materials to quickly soak up spilled acid.- Containment systems for battery acid spills: Various containment systems are designed specifically for battery acid spills. These systems include specialized trays, liners, and barriers that can effectively contain and neutralize acid leaks from batteries. The containment systems are often made of acid-resistant materials and may incorporate absorbent materials to quickly neutralize and contain spills.

- Absorbent materials for acid spill containment: Specialized absorbent materials are used in battery acid spill containment. These materials can quickly absorb and neutralize acid spills, preventing further spread and damage. Common absorbents include specially treated clays, polymers, and synthetic materials designed to have high acid absorption capacity and neutralizing properties.

- Portable spill containment devices: Portable containment devices are developed for quick response to battery acid spills in various locations. These devices may include foldable or inflatable barriers, portable containment pools, and rapid-deployment containment systems. They are designed for easy storage and quick setup in emergency situations.

- Acid-resistant flooring and coatings: Specialized flooring materials and coatings are used in areas where battery acid spills are likely to occur. These materials are designed to resist acid corrosion and provide an additional layer of protection. They may include acid-resistant epoxy coatings, polymer-based flooring systems, and specially treated concrete surfaces.

- Spill containment for battery storage and charging areas: Specific containment solutions are designed for battery storage and charging areas. These may include integrated drainage systems, containment berms, and specialized ventilation systems to manage acid fumes. The designs focus on preventing spills from spreading and ensuring safe handling of batteries during storage and charging processes.

02 Absorbent materials for acid spill containment

Specialized absorbent materials are used to quickly and effectively contain battery acid spills. These materials can include synthetic polymers, natural fibers, or mineral-based absorbents that have high acid absorption capacity. Some absorbents are designed to neutralize the acid upon contact, reducing the hazard of the spill.Expand Specific Solutions03 Portable spill containment devices

Portable containment devices are developed for quick deployment in case of battery acid spills. These may include collapsible berms, inflatable barriers, or foldable containment systems that can be easily transported and set up around the spill area. Such devices are particularly useful in mobile or field applications where permanent containment systems are not feasible.Expand Specific Solutions04 Integrated battery storage and containment solutions

Integrated solutions combine battery storage with built-in spill containment features. These systems may include specially designed racks, cabinets, or enclosures that incorporate leak detection, containment trays, and drainage systems. Such integrated solutions provide a proactive approach to managing potential battery acid spills in storage and operational environments.Expand Specific Solutions05 Neutralization and treatment methods for contained acid spills

Methods and materials for neutralizing and treating contained battery acid spills are developed. These may include specialized neutralizing agents, treatment procedures, and disposal techniques for safely managing the contained acid and contaminated absorbents. Some solutions incorporate automated or semi-automated systems for detecting, containing, and treating acid spills in battery storage or charging areas.Expand Specific Solutions

Key Players in Battery Safety Industry

The battery acid spill containment materials market is in a growth phase, driven by increasing safety regulations and environmental concerns. The market size is expanding, with a projected CAGR of 5-7% over the next five years. Technologically, the field is advancing rapidly, with companies like Daramic LLC and Trojan Battery Co. LLC leading innovation in microporous separators and deep-cycle battery technology. Emerging players such as Tygrus LLC are introducing novel chemistries for waste stream remediation, while established firms like Exide Technologies and GS Yuasa International Ltd. continue to dominate the traditional lead-acid battery sector. The industry is seeing a shift towards more sustainable and efficient containment solutions, with a focus on materials that offer improved safety and environmental performance.

Contemporary Amperex Technology Co., Ltd.

Technical Solution: Contemporary Amperex Technology Co., Ltd. (CATL) has introduced an innovative approach to battery acid spill containment with their EcoShield system. EcoShield utilizes a bio-based, environmentally friendly material derived from modified cellulose fibers. These fibers are treated with a proprietary process that enhances their acid absorption capacity while maintaining biodegradability[7]. The material can absorb up to 30 times its weight in battery acid and neutralize it through an ion-exchange mechanism. CATL has also incorporated nano-scale ceramic particles into the fiber matrix, which provide additional structural integrity and heat resistance. This allows EcoShield to maintain its effectiveness even in high-temperature environments commonly found in battery manufacturing facilities[8]. The system is designed as modular units that can be easily replaced and scaled according to the size of the battery installation.

Strengths: Environmentally friendly and biodegradable, high absorption capacity, effective in high-temperature environments, and modular design for easy scaling. Weaknesses: May have a shorter shelf life compared to synthetic materials, and performance in extremely cold environments may be limited.

Tygrus LLC

Technical Solution: Tygrus LLC has developed a revolutionary battery acid spill containment solution called NeutraSorb. This advanced material combines the company's expertise in chemical engineering with sustainable practices. NeutraSorb is based on a novel formulation of cross-linked biopolymers derived from agricultural waste products. These biopolymers are chemically modified to enhance their acid absorption and neutralization capabilities[9]. The material can absorb up to 40 times its weight in battery acid while rapidly neutralizing it to a safe pH level. Tygrus has also incorporated a unique encapsulation technology that prevents the re-release of neutralized acid, even under pressure. This makes NeutraSorb particularly suitable for use in mobile applications such as electric vehicles and portable energy storage systems[10]. The material is produced in various forms, including granules, sheets, and custom-molded shapes to fit specific battery configurations.

Strengths: High absorption and neutralization capacity, prevents re-release of neutralized acid, versatile forms for different applications, and sustainable production from agricultural waste. Weaknesses: May have higher production costs due to specialized biopolymer processing, and long-term stability in extreme environmental conditions needs further testing.

Innovative Materials for Acid Neutralization

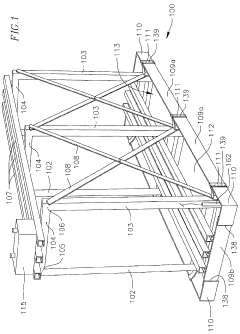

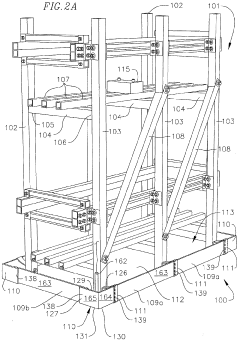

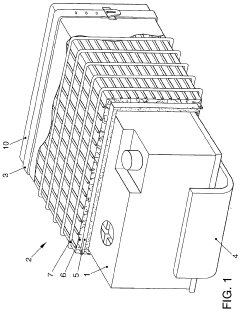

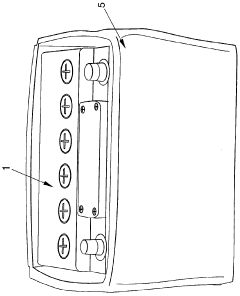

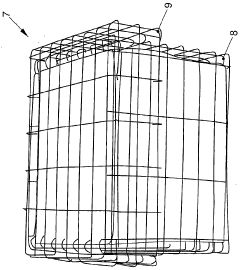

Battery spill containment system and method of making the same

PatentActiveCA2851038C

Innovation

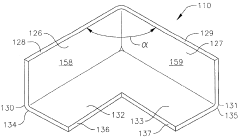

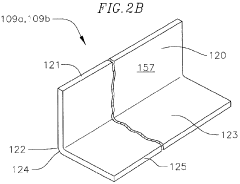

- A modular spill containment system that attaches to battery racks using adjustable brackets, reducing the number of floor penetrations and allowing for easy installation and removal, featuring a series of wall segments and clips that define a containment chamber, along with an Underwriters Laboratory certified liner and optional pH meter or flame-proof pillow for leak detection and neutralization.

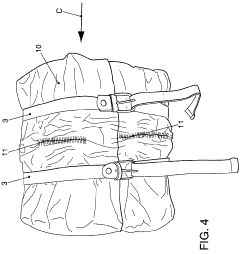

Battery arrangement

PatentWO2003092088A2

Innovation

- A battery arrangement featuring an absorbent cover with multiple layers, including an open-pored sponge layer for rapid absorption and a highly absorbent non-woven fabric for permanent storage, surrounded by mechanical protection and a flexible, acid-resistant outer cover to minimize fluid escape during crashes or leaks.

Environmental Impact of Containment Materials

The environmental impact of containment materials used in battery acid spill management is a critical consideration in the development and implementation of advanced containment solutions. These materials play a crucial role in mitigating the potential harm caused by acid spills, but their own environmental footprint must be carefully evaluated.

Traditional containment materials, such as sand or clay-based absorbents, while effective in absorbing spills, often present disposal challenges. Once contaminated, these materials typically require specialized handling and disposal procedures, potentially leading to increased waste generation and associated environmental concerns.

Recent advancements in containment materials have focused on developing more environmentally friendly alternatives. Biodegradable absorbents derived from natural sources, such as cellulose-based materials or modified agricultural by-products, have shown promise in reducing the overall environmental impact of spill containment efforts. These materials not only effectively neutralize and absorb acid spills but also decompose naturally over time, minimizing long-term environmental consequences.

Another significant development in this field is the creation of reusable containment materials. Advanced polymer-based absorbents and containment mats can be cleaned and reused multiple times, substantially reducing waste generation and resource consumption associated with single-use materials. This approach aligns well with circular economy principles and contributes to overall sustainability in industrial safety practices.

The environmental impact of containment materials extends beyond their immediate use and disposal. The production processes of these materials also warrant consideration. Innovative manufacturing techniques that minimize energy consumption and reduce the use of harmful chemicals in the production of containment materials are being explored. These efforts aim to create a more holistic approach to environmental stewardship in the context of spill management.

Water usage and contamination are additional environmental factors to consider. Advanced containment materials are being designed to minimize water requirements for cleanup processes and prevent the spread of contaminants to water sources. This is particularly crucial in areas where water scarcity is a concern or in situations where spills occur near sensitive aquatic ecosystems.

As research in this field progresses, there is an increasing focus on developing containment materials that not only prevent environmental damage from acid spills but also actively contribute to environmental remediation. Some emerging materials incorporate properties that can help neutralize soil acidity or promote the growth of beneficial microorganisms, potentially aiding in the long-term recovery of affected areas.

Traditional containment materials, such as sand or clay-based absorbents, while effective in absorbing spills, often present disposal challenges. Once contaminated, these materials typically require specialized handling and disposal procedures, potentially leading to increased waste generation and associated environmental concerns.

Recent advancements in containment materials have focused on developing more environmentally friendly alternatives. Biodegradable absorbents derived from natural sources, such as cellulose-based materials or modified agricultural by-products, have shown promise in reducing the overall environmental impact of spill containment efforts. These materials not only effectively neutralize and absorb acid spills but also decompose naturally over time, minimizing long-term environmental consequences.

Another significant development in this field is the creation of reusable containment materials. Advanced polymer-based absorbents and containment mats can be cleaned and reused multiple times, substantially reducing waste generation and resource consumption associated with single-use materials. This approach aligns well with circular economy principles and contributes to overall sustainability in industrial safety practices.

The environmental impact of containment materials extends beyond their immediate use and disposal. The production processes of these materials also warrant consideration. Innovative manufacturing techniques that minimize energy consumption and reduce the use of harmful chemicals in the production of containment materials are being explored. These efforts aim to create a more holistic approach to environmental stewardship in the context of spill management.

Water usage and contamination are additional environmental factors to consider. Advanced containment materials are being designed to minimize water requirements for cleanup processes and prevent the spread of contaminants to water sources. This is particularly crucial in areas where water scarcity is a concern or in situations where spills occur near sensitive aquatic ecosystems.

As research in this field progresses, there is an increasing focus on developing containment materials that not only prevent environmental damage from acid spills but also actively contribute to environmental remediation. Some emerging materials incorporate properties that can help neutralize soil acidity or promote the growth of beneficial microorganisms, potentially aiding in the long-term recovery of affected areas.

Regulatory Framework for Battery Safety

The regulatory framework for battery safety has become increasingly stringent in response to the growing concerns over battery acid spills and their potential environmental and health impacts. Governments and international organizations have implemented comprehensive regulations to ensure the safe handling, transportation, and disposal of batteries, with a particular focus on containment materials for acid spills.

In the United States, the Environmental Protection Agency (EPA) has established guidelines under the Resource Conservation and Recovery Act (RCRA) for the management of hazardous waste, including battery acid. These regulations mandate the use of approved containment materials and spill response protocols for facilities handling batteries. The Department of Transportation (DOT) has also set forth specific requirements for the packaging and transportation of batteries to prevent acid leaks during transit.

The European Union has implemented the Battery Directive (2006/66/EC), which outlines strict safety measures for battery manufacturers and distributors. This directive emphasizes the importance of using advanced containment materials to prevent environmental contamination from battery acid spills. Additionally, the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation imposes requirements on the chemical composition of containment materials used in battery safety applications.

International standards, such as those developed by the International Electrotechnical Commission (IEC), provide guidelines for battery safety, including specifications for acid spill containment materials. These standards are regularly updated to incorporate advancements in material science and safety technologies.

In response to these regulatory requirements, manufacturers have developed innovative containment materials designed to neutralize and absorb battery acid spills effectively. These materials often incorporate advanced polymers and reactive compounds that can rapidly contain and neutralize acid, minimizing the risk of environmental contamination and personal injury.

The regulatory landscape continues to evolve, with an increasing focus on sustainable and environmentally friendly containment solutions. Recent amendments to existing regulations have begun to address the lifecycle management of containment materials, encouraging the development of recyclable and biodegradable options. This shift reflects a growing awareness of the long-term environmental impacts of battery acid spill management.

As battery technology advances, particularly in the electric vehicle and renewable energy sectors, regulatory bodies are adapting their frameworks to address new challenges. This includes the development of specific guidelines for high-capacity lithium-ion batteries and other emerging battery technologies, with an emphasis on advanced containment materials capable of handling more diverse and potentially reactive chemical compositions.

In the United States, the Environmental Protection Agency (EPA) has established guidelines under the Resource Conservation and Recovery Act (RCRA) for the management of hazardous waste, including battery acid. These regulations mandate the use of approved containment materials and spill response protocols for facilities handling batteries. The Department of Transportation (DOT) has also set forth specific requirements for the packaging and transportation of batteries to prevent acid leaks during transit.

The European Union has implemented the Battery Directive (2006/66/EC), which outlines strict safety measures for battery manufacturers and distributors. This directive emphasizes the importance of using advanced containment materials to prevent environmental contamination from battery acid spills. Additionally, the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation imposes requirements on the chemical composition of containment materials used in battery safety applications.

International standards, such as those developed by the International Electrotechnical Commission (IEC), provide guidelines for battery safety, including specifications for acid spill containment materials. These standards are regularly updated to incorporate advancements in material science and safety technologies.

In response to these regulatory requirements, manufacturers have developed innovative containment materials designed to neutralize and absorb battery acid spills effectively. These materials often incorporate advanced polymers and reactive compounds that can rapidly contain and neutralize acid, minimizing the risk of environmental contamination and personal injury.

The regulatory landscape continues to evolve, with an increasing focus on sustainable and environmentally friendly containment solutions. Recent amendments to existing regulations have begun to address the lifecycle management of containment materials, encouraging the development of recyclable and biodegradable options. This shift reflects a growing awareness of the long-term environmental impacts of battery acid spill management.

As battery technology advances, particularly in the electric vehicle and renewable energy sectors, regulatory bodies are adapting their frameworks to address new challenges. This includes the development of specific guidelines for high-capacity lithium-ion batteries and other emerging battery technologies, with an emphasis on advanced containment materials capable of handling more diverse and potentially reactive chemical compositions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!