Advances in Calorimetric Techniques for High-Temperature Superalloys

AUG 5, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Superalloy Calorimetry Evolution and Objectives

Calorimetric techniques have played a crucial role in the development and characterization of high-temperature superalloys since their inception in the 1940s. These advanced materials, designed to withstand extreme temperatures and mechanical stresses, have been instrumental in the aerospace and power generation industries. The evolution of calorimetric methods has been closely intertwined with the progress in superalloy technology, driven by the need for more accurate and comprehensive thermal analysis.

In the early stages, simple calorimetry was used primarily for basic thermal property measurements. As superalloys became more complex, with the introduction of multi-component systems and precise microstructural control, the demand for more sophisticated calorimetric techniques grew. This led to the development of differential scanning calorimetry (DSC) and differential thermal analysis (DTA) in the 1960s, which allowed for more precise measurements of phase transitions and heat capacities.

The 1980s and 1990s saw significant advancements in high-temperature calorimetry, with the introduction of drop calorimetry and laser flash analysis. These techniques enabled researchers to measure thermodynamic properties at temperatures exceeding 1000°C, which is critical for understanding superalloy behavior in operational conditions. Concurrently, the integration of computer-controlled systems and data analysis software greatly enhanced the accuracy and reproducibility of calorimetric measurements.

Recent years have witnessed a surge in the development of in-situ and high-resolution calorimetric techniques. Synchrotron-based X-ray diffraction coupled with calorimetry has emerged as a powerful tool for real-time observation of phase transformations in superalloys. Additionally, the advent of nanocalorimetry has opened new avenues for studying thin films and small-volume samples, which is particularly relevant for the analysis of coatings and surface treatments in superalloys.

The primary objective of current calorimetric research in superalloys is to achieve a comprehensive understanding of their thermal behavior across all relevant temperature ranges and under various environmental conditions. This includes the precise determination of phase transition temperatures, heat capacities, and thermodynamic stability of complex alloy systems. Furthermore, there is a growing emphasis on developing techniques that can provide insights into the kinetics of phase transformations and precipitation processes, which are critical for optimizing heat treatment protocols and predicting long-term material performance.

Looking ahead, the field aims to push the boundaries of calorimetric analysis by developing ultra-high temperature techniques capable of accurate measurements above 2000°C. There is also a focus on combining calorimetry with other analytical methods, such as thermomechanical analysis and mass spectrometry, to create multifunctional characterization platforms. These advancements will be crucial in supporting the development of next-generation superalloys with enhanced temperature capabilities and improved long-term stability for extreme environment applications.

In the early stages, simple calorimetry was used primarily for basic thermal property measurements. As superalloys became more complex, with the introduction of multi-component systems and precise microstructural control, the demand for more sophisticated calorimetric techniques grew. This led to the development of differential scanning calorimetry (DSC) and differential thermal analysis (DTA) in the 1960s, which allowed for more precise measurements of phase transitions and heat capacities.

The 1980s and 1990s saw significant advancements in high-temperature calorimetry, with the introduction of drop calorimetry and laser flash analysis. These techniques enabled researchers to measure thermodynamic properties at temperatures exceeding 1000°C, which is critical for understanding superalloy behavior in operational conditions. Concurrently, the integration of computer-controlled systems and data analysis software greatly enhanced the accuracy and reproducibility of calorimetric measurements.

Recent years have witnessed a surge in the development of in-situ and high-resolution calorimetric techniques. Synchrotron-based X-ray diffraction coupled with calorimetry has emerged as a powerful tool for real-time observation of phase transformations in superalloys. Additionally, the advent of nanocalorimetry has opened new avenues for studying thin films and small-volume samples, which is particularly relevant for the analysis of coatings and surface treatments in superalloys.

The primary objective of current calorimetric research in superalloys is to achieve a comprehensive understanding of their thermal behavior across all relevant temperature ranges and under various environmental conditions. This includes the precise determination of phase transition temperatures, heat capacities, and thermodynamic stability of complex alloy systems. Furthermore, there is a growing emphasis on developing techniques that can provide insights into the kinetics of phase transformations and precipitation processes, which are critical for optimizing heat treatment protocols and predicting long-term material performance.

Looking ahead, the field aims to push the boundaries of calorimetric analysis by developing ultra-high temperature techniques capable of accurate measurements above 2000°C. There is also a focus on combining calorimetry with other analytical methods, such as thermomechanical analysis and mass spectrometry, to create multifunctional characterization platforms. These advancements will be crucial in supporting the development of next-generation superalloys with enhanced temperature capabilities and improved long-term stability for extreme environment applications.

Market Demand for Advanced Superalloy Analysis

The market demand for advanced superalloy analysis, particularly in the realm of high-temperature applications, has been steadily increasing in recent years. This growth is primarily driven by the expanding aerospace, power generation, and automotive industries, where materials capable of withstanding extreme temperatures and harsh environments are crucial. The global superalloy market, which includes the demand for analysis techniques, is projected to experience significant growth over the next decade.

In the aerospace sector, the push for more fuel-efficient and powerful jet engines has intensified the need for advanced superalloys and, consequently, sophisticated analysis methods. Commercial aircraft manufacturers and defense contractors are continuously seeking materials that can operate at higher temperatures to improve engine performance and reduce emissions. This trend has created a substantial market for calorimetric techniques that can accurately characterize the thermal properties of these alloys under extreme conditions.

The power generation industry, particularly in the development of gas turbines for electricity production, represents another major driver for superalloy analysis demand. As the world transitions towards cleaner energy sources, there is an increasing focus on improving the efficiency of gas turbines. This requires materials that can withstand higher operating temperatures, leading to a growing need for advanced calorimetric analysis to assess material performance and durability.

Automotive manufacturers, especially in the high-performance and racing segments, are also contributing to the market demand. The pursuit of lighter, stronger, and more heat-resistant materials for engine components has led to increased adoption of superalloys in this sector. As a result, there is a rising need for precise thermal analysis techniques to evaluate these materials under conditions that simulate real-world automotive applications.

The nuclear power industry, although smaller in market size compared to aerospace and automotive sectors, presents a niche but significant demand for superalloy analysis. The extreme conditions in nuclear reactors necessitate materials with exceptional heat resistance and stability, driving the need for advanced calorimetric techniques to ensure safety and reliability.

Geographically, North America and Europe currently lead the market for superalloy analysis, owing to their strong aerospace and power generation industries. However, the Asia-Pacific region is expected to show the fastest growth in demand, driven by rapid industrialization, increasing aerospace activities, and growing automotive production in countries like China and India.

As industries continue to push the boundaries of material performance, the demand for more sophisticated and accurate calorimetric techniques for high-temperature superalloys is expected to grow. This trend is likely to drive innovation in analysis equipment and methodologies, creating opportunities for both established players and new entrants in the market for advanced superalloy analysis technologies.

In the aerospace sector, the push for more fuel-efficient and powerful jet engines has intensified the need for advanced superalloys and, consequently, sophisticated analysis methods. Commercial aircraft manufacturers and defense contractors are continuously seeking materials that can operate at higher temperatures to improve engine performance and reduce emissions. This trend has created a substantial market for calorimetric techniques that can accurately characterize the thermal properties of these alloys under extreme conditions.

The power generation industry, particularly in the development of gas turbines for electricity production, represents another major driver for superalloy analysis demand. As the world transitions towards cleaner energy sources, there is an increasing focus on improving the efficiency of gas turbines. This requires materials that can withstand higher operating temperatures, leading to a growing need for advanced calorimetric analysis to assess material performance and durability.

Automotive manufacturers, especially in the high-performance and racing segments, are also contributing to the market demand. The pursuit of lighter, stronger, and more heat-resistant materials for engine components has led to increased adoption of superalloys in this sector. As a result, there is a rising need for precise thermal analysis techniques to evaluate these materials under conditions that simulate real-world automotive applications.

The nuclear power industry, although smaller in market size compared to aerospace and automotive sectors, presents a niche but significant demand for superalloy analysis. The extreme conditions in nuclear reactors necessitate materials with exceptional heat resistance and stability, driving the need for advanced calorimetric techniques to ensure safety and reliability.

Geographically, North America and Europe currently lead the market for superalloy analysis, owing to their strong aerospace and power generation industries. However, the Asia-Pacific region is expected to show the fastest growth in demand, driven by rapid industrialization, increasing aerospace activities, and growing automotive production in countries like China and India.

As industries continue to push the boundaries of material performance, the demand for more sophisticated and accurate calorimetric techniques for high-temperature superalloys is expected to grow. This trend is likely to drive innovation in analysis equipment and methodologies, creating opportunities for both established players and new entrants in the market for advanced superalloy analysis technologies.

Calorimetric Challenges in High-Temperature Environments

Calorimetric techniques for high-temperature superalloys face significant challenges due to the extreme conditions under which these materials operate. The primary obstacle lies in maintaining accurate and reliable measurements at temperatures exceeding 1000°C, where traditional calorimetry methods often falter.

One of the key challenges is the thermal stability of the measurement apparatus itself. At such high temperatures, many conventional materials used in calorimeters begin to degrade or react, potentially compromising the accuracy of the results. This necessitates the development of specialized equipment capable of withstanding these harsh conditions without introducing measurement artifacts.

Another critical issue is the increased reactivity of superalloys at elevated temperatures. These materials may undergo phase transformations, oxidation, or other chemical reactions during the measurement process, complicating the interpretation of calorimetric data. Researchers must carefully account for these potential changes to ensure the validity of their results.

The thermal conductivity of high-temperature superalloys presents an additional challenge. These materials are often designed to have low thermal conductivity to withstand extreme environments, which can lead to significant temperature gradients within samples during calorimetric measurements. This non-uniformity can result in inaccurate or misleading data if not properly addressed.

Furthermore, the high specific heat capacity of many superalloys at elevated temperatures requires calorimeters with exceptional sensitivity and precision. Small variations in energy input or output can have substantial effects on the measured properties, demanding advanced instrumentation and data analysis techniques.

The presence of volatile elements in some superalloy compositions adds another layer of complexity. At high temperatures, these elements may vaporize, altering the sample composition and potentially damaging the calorimetric equipment. This necessitates the development of sealed or controlled-atmosphere systems to maintain sample integrity throughout the measurement process.

Lastly, the time-dependent nature of many high-temperature phenomena in superalloys poses a significant challenge for calorimetric studies. Creep, stress relaxation, and microstructural evolution can occur during prolonged exposure to extreme temperatures, requiring researchers to develop methods for rapid, in-situ measurements or to account for these dynamic processes in their experimental design and data interpretation.

One of the key challenges is the thermal stability of the measurement apparatus itself. At such high temperatures, many conventional materials used in calorimeters begin to degrade or react, potentially compromising the accuracy of the results. This necessitates the development of specialized equipment capable of withstanding these harsh conditions without introducing measurement artifacts.

Another critical issue is the increased reactivity of superalloys at elevated temperatures. These materials may undergo phase transformations, oxidation, or other chemical reactions during the measurement process, complicating the interpretation of calorimetric data. Researchers must carefully account for these potential changes to ensure the validity of their results.

The thermal conductivity of high-temperature superalloys presents an additional challenge. These materials are often designed to have low thermal conductivity to withstand extreme environments, which can lead to significant temperature gradients within samples during calorimetric measurements. This non-uniformity can result in inaccurate or misleading data if not properly addressed.

Furthermore, the high specific heat capacity of many superalloys at elevated temperatures requires calorimeters with exceptional sensitivity and precision. Small variations in energy input or output can have substantial effects on the measured properties, demanding advanced instrumentation and data analysis techniques.

The presence of volatile elements in some superalloy compositions adds another layer of complexity. At high temperatures, these elements may vaporize, altering the sample composition and potentially damaging the calorimetric equipment. This necessitates the development of sealed or controlled-atmosphere systems to maintain sample integrity throughout the measurement process.

Lastly, the time-dependent nature of many high-temperature phenomena in superalloys poses a significant challenge for calorimetric studies. Creep, stress relaxation, and microstructural evolution can occur during prolonged exposure to extreme temperatures, requiring researchers to develop methods for rapid, in-situ measurements or to account for these dynamic processes in their experimental design and data interpretation.

Current Calorimetric Techniques for Superalloys

01 Calorimetric measurement devices

Various calorimetric devices are used for temperature measurement, including specialized sensors and probes. These instruments are designed to accurately measure heat flow and temperature changes in different materials and environments, providing precise thermal analysis for scientific and industrial applications.- Differential scanning calorimetry for temperature measurement: Differential scanning calorimetry (DSC) is a calorimetric technique used to measure temperature and heat flow associated with thermal transitions in materials. It can detect phase changes, chemical reactions, and other thermal events by comparing the heat flow between a sample and a reference material as they are subjected to controlled temperature changes.

- Temperature measurement in combustion processes: Calorimetric techniques are applied to measure temperature in combustion processes, such as in engines or industrial furnaces. These methods can provide accurate temperature readings in high-temperature environments where traditional sensors may not be suitable. The techniques often involve analyzing heat transfer or thermal radiation to determine temperature.

- Microfluidic calorimetry for temperature sensing: Microfluidic calorimetry techniques are used for temperature sensing in small-scale systems. These methods involve measuring heat transfer or thermal properties of fluids in microscale channels or chambers. They can provide high sensitivity and spatial resolution for temperature measurements in miniaturized devices or biological systems.

- Calorimetric temperature sensors for industrial applications: Calorimetric temperature sensors are developed for various industrial applications, including process control, quality assurance, and safety monitoring. These sensors often utilize the principle of heat transfer or thermal conductivity to measure temperature. They can be designed for specific environments or materials, offering advantages such as robustness and non-invasive measurement.

- Data processing and calibration for calorimetric temperature measurements: Advanced data processing and calibration techniques are employed to improve the accuracy and reliability of calorimetric temperature measurements. These methods may involve signal processing, mathematical modeling, or machine learning algorithms to interpret calorimetric data and compensate for various factors affecting measurement accuracy.

02 Temperature control systems

Advanced temperature control systems are developed to maintain and regulate precise temperatures in various processes. These systems often incorporate feedback mechanisms, multiple sensors, and sophisticated algorithms to ensure accurate and stable temperature control across a wide range of applications.Expand Specific Solutions03 Thermal analysis techniques

Innovative thermal analysis techniques are employed to study material properties and behavior at different temperatures. These methods involve precise heating and cooling of samples while monitoring various parameters, enabling researchers to gather valuable data on thermal characteristics and phase transitions of materials.Expand Specific Solutions04 High-temperature measurement solutions

Specialized calorimetric techniques and instruments are developed for high-temperature applications. These solutions are designed to withstand extreme conditions and provide accurate measurements in environments such as industrial furnaces, combustion processes, and high-temperature chemical reactions.Expand Specific Solutions05 Miniaturized calorimetric sensors

Advancements in miniaturization technology have led to the development of compact calorimetric sensors for temperature measurement. These small-scale devices offer improved spatial resolution and faster response times, making them suitable for applications in microfluidics, biomedical research, and portable analytical instruments.Expand Specific Solutions

Key Players in Superalloy Calorimetry Research

The field of calorimetric techniques for high-temperature superalloys is in a mature stage, with ongoing advancements driven by the aerospace and energy sectors. The market size is substantial, reflecting the critical role of these materials in turbine engines and power generation. Technologically, companies like Honeywell International, United Technologies, and Rolls-Royce are at the forefront, leveraging their extensive R&D capabilities. Research institutions such as the National Institute for Materials Science and universities like Northwestern Polytechnical University contribute significantly to innovation. The competitive landscape is characterized by a mix of established industrial players and specialized research entities, with collaboration between industry and academia playing a crucial role in driving progress.

Honeywell International Technologies Ltd.

Technical Solution: Honeywell has developed advanced calorimetric techniques for high-temperature superalloys, focusing on Differential Scanning Calorimetry (DSC) and Thermogravimetric Analysis (TGA). Their approach combines high-precision temperature control with real-time mass change measurements, allowing for accurate determination of phase transitions, oxidation kinetics, and thermal stability of superalloys at temperatures exceeding 1200°C [1]. The company has also implemented a novel laser flash method for measuring thermal diffusivity of superalloys at extreme temperatures, enabling more precise thermal conductivity calculations [3]. Honeywell's calorimetric systems incorporate advanced gas flow control to study the behavior of superalloys under various atmospheric conditions, crucial for simulating real-world turbine environments [5].

Strengths: High precision measurements, ability to simulate real-world conditions, and integration with other analytical techniques. Weaknesses: High equipment costs and complexity in data interpretation for multi-component superalloys.

Siemens Energy AG

Technical Solution: Siemens Energy has made significant strides in calorimetric techniques for high-temperature superalloys, particularly for power generation applications. Their approach combines high-temperature Differential Scanning Calorimetry (DSC) with Thermogravimetric Analysis (TGA) to study the thermal stability, phase transformations, and oxidation behavior of superalloys at temperatures up to 1700°C [11]. Siemens has developed a custom calorimetric system that allows for in-situ measurements of creep and fatigue properties while simultaneously monitoring thermal events, providing crucial data for predicting long-term performance of superalloys in turbine applications [13]. The company has also implemented advanced image analysis techniques in conjunction with calorimetry, using high-resolution thermal imaging to map temperature distributions and identify localized phase changes in complex superalloy components [15]. This multi-faceted approach enables a more comprehensive understanding of superalloy behavior under extreme conditions, supporting the development of more efficient and durable power generation systems.

Strengths: Integration of mechanical testing with calorimetry, advanced imaging capabilities for complex components. Weaknesses: High complexity of data interpretation, potential limitations in studying very large-scale components.

Innovative Calorimetric Approaches for Superalloys

Process and product for forming gamma prime precipitation strengthened superalloys

PatentActiveUS20170314114A1

Innovation

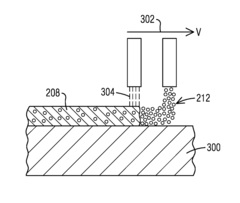

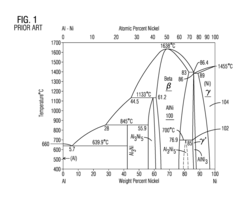

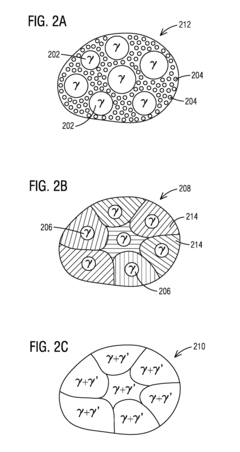

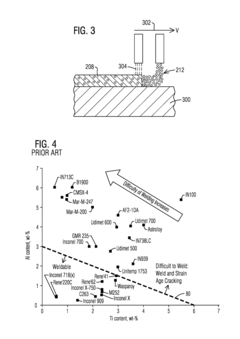

- The process involves forming a beta NiAl phase using laser additive manufacturing and subsequent heat treatment to diffuse gamma prime forming elements, reducing the volume fraction of gamma prime precipitates and avoiding cracking, by using a mixture of powders with differing particle sizes and compositions to create a gamma/gamma prime superalloy with reduced susceptibility to cracking.

Nickel-based superalloy

PatentInactiveEP2224025A1

Innovation

- A nickel-based superalloy with a composition that includes cobalt, tungsten, molybdenum, tantalum, and aluminum, with a high volume percentage of the intermetallic γ' phase, where the solvus temperature is higher than the solidus temperature, providing enhanced high-temperature strength and stability without the need for complex thermal treatments.

Materials Characterization Standards for Superalloys

The development of standardized materials characterization techniques for superalloys is crucial for ensuring consistent quality and performance in high-temperature applications. These standards provide a framework for evaluating the microstructure, mechanical properties, and thermal behavior of superalloys, enabling reliable comparisons between different alloy compositions and processing methods.

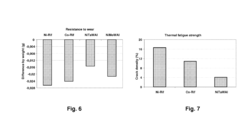

One of the key aspects of materials characterization standards for superalloys is the establishment of uniform testing procedures for mechanical properties. This includes standardized methods for tensile testing, creep testing, and fatigue testing at elevated temperatures. These tests are designed to simulate the extreme conditions that superalloys encounter in service, providing valuable data on their strength, ductility, and long-term durability.

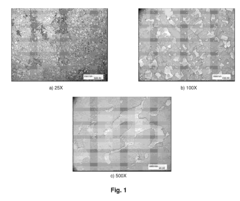

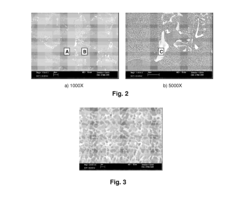

Microstructural characterization standards play a vital role in assessing the quality and consistency of superalloy components. These standards define protocols for sample preparation, etching techniques, and quantitative analysis of grain size, precipitate distribution, and phase composition. Advanced imaging techniques, such as electron microscopy and X-ray diffraction, are integral to these standards, enabling precise measurements of microstructural features that influence alloy performance.

Thermal analysis standards are particularly relevant to the development of calorimetric techniques for high-temperature superalloys. These standards outline procedures for differential scanning calorimetry (DSC) and thermogravimetric analysis (TGA), which are essential for studying phase transformations, oxidation behavior, and thermal stability of superalloys at elevated temperatures. The standardization of these techniques ensures reproducibility and comparability of results across different research institutions and industrial laboratories.

Chemical composition analysis standards are critical for maintaining the precise elemental balance required in superalloys. These standards define methods for spectroscopic analysis, including inductively coupled plasma mass spectrometry (ICP-MS) and X-ray fluorescence (XRF), to accurately determine the concentrations of alloying elements and trace impurities that can significantly impact alloy properties.

The development and refinement of these materials characterization standards for superalloys are ongoing processes, driven by advancements in analytical techniques and the evolving requirements of the aerospace and energy industries. International organizations, such as ASTM International and ISO, play a crucial role in establishing and updating these standards, ensuring that they remain relevant and applicable to the latest superalloy technologies.

One of the key aspects of materials characterization standards for superalloys is the establishment of uniform testing procedures for mechanical properties. This includes standardized methods for tensile testing, creep testing, and fatigue testing at elevated temperatures. These tests are designed to simulate the extreme conditions that superalloys encounter in service, providing valuable data on their strength, ductility, and long-term durability.

Microstructural characterization standards play a vital role in assessing the quality and consistency of superalloy components. These standards define protocols for sample preparation, etching techniques, and quantitative analysis of grain size, precipitate distribution, and phase composition. Advanced imaging techniques, such as electron microscopy and X-ray diffraction, are integral to these standards, enabling precise measurements of microstructural features that influence alloy performance.

Thermal analysis standards are particularly relevant to the development of calorimetric techniques for high-temperature superalloys. These standards outline procedures for differential scanning calorimetry (DSC) and thermogravimetric analysis (TGA), which are essential for studying phase transformations, oxidation behavior, and thermal stability of superalloys at elevated temperatures. The standardization of these techniques ensures reproducibility and comparability of results across different research institutions and industrial laboratories.

Chemical composition analysis standards are critical for maintaining the precise elemental balance required in superalloys. These standards define methods for spectroscopic analysis, including inductively coupled plasma mass spectrometry (ICP-MS) and X-ray fluorescence (XRF), to accurately determine the concentrations of alloying elements and trace impurities that can significantly impact alloy properties.

The development and refinement of these materials characterization standards for superalloys are ongoing processes, driven by advancements in analytical techniques and the evolving requirements of the aerospace and energy industries. International organizations, such as ASTM International and ISO, play a crucial role in establishing and updating these standards, ensuring that they remain relevant and applicable to the latest superalloy technologies.

Environmental Impact of Superalloy Production

The production of high-temperature superalloys, while crucial for advanced technological applications, carries significant environmental implications. The manufacturing process involves energy-intensive operations and the use of rare and potentially hazardous materials, contributing to various environmental concerns.

One of the primary environmental impacts is the high energy consumption associated with superalloy production. The melting and casting processes require extremely high temperatures, often exceeding 1300°C, which demands substantial energy input. This energy-intensive nature contributes to increased greenhouse gas emissions, particularly when fossil fuels are the primary energy source.

The extraction and processing of raw materials for superalloys also pose environmental challenges. Many of the constituent elements, such as nickel, cobalt, and rhenium, are mined through processes that can lead to habitat destruction, soil erosion, and water pollution. The refining of these metals further adds to the environmental footprint through additional energy consumption and potential chemical emissions.

Waste management is another critical environmental concern in superalloy production. The manufacturing process generates various forms of waste, including slag, dust, and chemical byproducts. Some of these waste materials may contain heavy metals or other toxic substances, requiring careful handling and disposal to prevent soil and water contamination.

Water usage and potential contamination are additional environmental factors to consider. The cooling processes in superalloy production often require significant amounts of water, which can strain local water resources. Moreover, the risk of water pollution through chemical leaching or accidental spills during production or waste disposal poses threats to aquatic ecosystems.

Air quality is also affected by superalloy production. The high-temperature processes can release particulate matter, volatile organic compounds, and other air pollutants. These emissions may contribute to local air quality degradation and potentially impact human health in surrounding communities.

The long-term environmental impact of superalloys extends beyond their production phase. While these materials are designed for durability and longevity, their eventual disposal or recycling presents challenges. The complex composition of superalloys can make recycling difficult, potentially leading to increased landfill usage or the need for specialized recycling processes.

To address these environmental concerns, the superalloy industry is increasingly focusing on sustainable practices. This includes efforts to improve energy efficiency, develop cleaner production methods, enhance recycling capabilities, and explore alternative materials with reduced environmental impact. As research in calorimetric techniques for high-temperature superalloys advances, there is potential for these developments to contribute to more environmentally friendly production processes and improved material efficiency.

One of the primary environmental impacts is the high energy consumption associated with superalloy production. The melting and casting processes require extremely high temperatures, often exceeding 1300°C, which demands substantial energy input. This energy-intensive nature contributes to increased greenhouse gas emissions, particularly when fossil fuels are the primary energy source.

The extraction and processing of raw materials for superalloys also pose environmental challenges. Many of the constituent elements, such as nickel, cobalt, and rhenium, are mined through processes that can lead to habitat destruction, soil erosion, and water pollution. The refining of these metals further adds to the environmental footprint through additional energy consumption and potential chemical emissions.

Waste management is another critical environmental concern in superalloy production. The manufacturing process generates various forms of waste, including slag, dust, and chemical byproducts. Some of these waste materials may contain heavy metals or other toxic substances, requiring careful handling and disposal to prevent soil and water contamination.

Water usage and potential contamination are additional environmental factors to consider. The cooling processes in superalloy production often require significant amounts of water, which can strain local water resources. Moreover, the risk of water pollution through chemical leaching or accidental spills during production or waste disposal poses threats to aquatic ecosystems.

Air quality is also affected by superalloy production. The high-temperature processes can release particulate matter, volatile organic compounds, and other air pollutants. These emissions may contribute to local air quality degradation and potentially impact human health in surrounding communities.

The long-term environmental impact of superalloys extends beyond their production phase. While these materials are designed for durability and longevity, their eventual disposal or recycling presents challenges. The complex composition of superalloys can make recycling difficult, potentially leading to increased landfill usage or the need for specialized recycling processes.

To address these environmental concerns, the superalloy industry is increasingly focusing on sustainable practices. This includes efforts to improve energy efficiency, develop cleaner production methods, enhance recycling capabilities, and explore alternative materials with reduced environmental impact. As research in calorimetric techniques for high-temperature superalloys advances, there is potential for these developments to contribute to more environmentally friendly production processes and improved material efficiency.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!