AIB Cell Assembly Best Practices: Anode Preparation, Electrolyte Filling and Sealing

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

AIB Cell Assembly Overview and Objectives

Aluminum-ion batteries (AIBs) have emerged as a promising alternative to lithium-ion batteries, offering potential advantages in terms of safety, cost, and environmental impact. The assembly of AIB cells is a critical process that significantly influences their performance and reliability. This overview focuses on the best practices for AIB cell assembly, specifically addressing anode preparation, electrolyte filling, and sealing techniques.

The primary objective of optimizing AIB cell assembly is to enhance the overall battery performance, including energy density, power output, cycle life, and safety. By implementing best practices in anode preparation, electrolyte filling, and sealing, manufacturers can achieve consistent and high-quality AIB cells that meet the demanding requirements of various applications.

Anode preparation is a crucial step in AIB cell assembly. The anode typically consists of aluminum foil or other aluminum-based materials. The preparation process involves surface treatment, such as etching or electrochemical activation, to increase the active surface area and improve the electrochemical performance. Proper anode preparation ensures efficient ion transfer and minimizes side reactions that could lead to capacity loss or safety issues.

Electrolyte filling is another critical aspect of AIB cell assembly. The electrolyte in AIBs usually consists of an aluminum salt dissolved in an organic solvent or ionic liquid. The filling process must be conducted in a controlled environment to prevent contamination and ensure uniform distribution of the electrolyte throughout the cell. Precise control of the electrolyte volume and composition is essential for optimal battery performance and longevity.

Sealing the AIB cell is the final step in the assembly process and plays a vital role in maintaining the integrity of the battery. Proper sealing prevents electrolyte leakage, moisture ingress, and contamination from external sources. Various sealing techniques, such as heat sealing, laser welding, or mechanical crimping, can be employed depending on the cell design and intended application.

The development of best practices for AIB cell assembly aims to address several challenges inherent to this emerging technology. These include minimizing parasitic reactions between the aluminum anode and electrolyte, preventing dendrite formation, and ensuring long-term stability of the cell components. By focusing on these key areas, researchers and manufacturers can improve the overall performance and reliability of AIBs, making them more competitive with established battery technologies.

As the field of AIBs continues to evolve, ongoing research and development efforts are focused on refining assembly techniques, exploring new materials, and optimizing cell designs. The ultimate goal is to create AIBs that can meet or exceed the performance of current lithium-ion batteries while offering advantages in terms of cost, safety, and sustainability.

The primary objective of optimizing AIB cell assembly is to enhance the overall battery performance, including energy density, power output, cycle life, and safety. By implementing best practices in anode preparation, electrolyte filling, and sealing, manufacturers can achieve consistent and high-quality AIB cells that meet the demanding requirements of various applications.

Anode preparation is a crucial step in AIB cell assembly. The anode typically consists of aluminum foil or other aluminum-based materials. The preparation process involves surface treatment, such as etching or electrochemical activation, to increase the active surface area and improve the electrochemical performance. Proper anode preparation ensures efficient ion transfer and minimizes side reactions that could lead to capacity loss or safety issues.

Electrolyte filling is another critical aspect of AIB cell assembly. The electrolyte in AIBs usually consists of an aluminum salt dissolved in an organic solvent or ionic liquid. The filling process must be conducted in a controlled environment to prevent contamination and ensure uniform distribution of the electrolyte throughout the cell. Precise control of the electrolyte volume and composition is essential for optimal battery performance and longevity.

Sealing the AIB cell is the final step in the assembly process and plays a vital role in maintaining the integrity of the battery. Proper sealing prevents electrolyte leakage, moisture ingress, and contamination from external sources. Various sealing techniques, such as heat sealing, laser welding, or mechanical crimping, can be employed depending on the cell design and intended application.

The development of best practices for AIB cell assembly aims to address several challenges inherent to this emerging technology. These include minimizing parasitic reactions between the aluminum anode and electrolyte, preventing dendrite formation, and ensuring long-term stability of the cell components. By focusing on these key areas, researchers and manufacturers can improve the overall performance and reliability of AIBs, making them more competitive with established battery technologies.

As the field of AIBs continues to evolve, ongoing research and development efforts are focused on refining assembly techniques, exploring new materials, and optimizing cell designs. The ultimate goal is to create AIBs that can meet or exceed the performance of current lithium-ion batteries while offering advantages in terms of cost, safety, and sustainability.

Market Analysis for AIB Technology

The market for Aluminum-Ion Battery (AIB) technology is experiencing significant growth and attracting increasing attention from various sectors. As a promising alternative to lithium-ion batteries, AIBs offer several advantages, including higher safety, faster charging rates, and potentially lower costs. These factors are driving the expansion of the AIB market across multiple industries.

The automotive sector represents a substantial portion of the AIB market potential. With the rapid growth of electric vehicles (EVs), there is a pressing need for safer, more efficient, and cost-effective battery technologies. AIBs' ability to charge quickly and their improved safety profile make them an attractive option for EV manufacturers looking to address consumer concerns about charging times and battery-related safety issues.

In the consumer electronics industry, AIBs are gaining traction due to their fast-charging capabilities and longer cycle life. Smartphones, laptops, and other portable devices could benefit from AIB technology, potentially extending battery life and reducing charging times. This market segment is expected to be an early adopter of AIB technology, driving initial commercialization efforts.

The renewable energy storage sector also presents significant opportunities for AIB technology. As the world transitions towards cleaner energy sources, there is a growing demand for efficient and reliable energy storage solutions. AIBs' potential for grid-scale energy storage applications could play a crucial role in stabilizing power grids and integrating intermittent renewable energy sources like solar and wind.

Geographically, Asia-Pacific is expected to lead the AIB market growth, with China at the forefront of research and development efforts. North America and Europe are also showing strong interest in AIB technology, particularly in the automotive and renewable energy sectors.

Despite the promising outlook, the AIB market faces challenges. The technology is still in its early stages, and significant research and development are required to optimize performance and scale up production. Additionally, the established lithium-ion battery infrastructure presents a barrier to entry for new battery technologies.

The market for AIB technology is characterized by intense competition and collaboration among startups, established battery manufacturers, and research institutions. Strategic partnerships between these entities are likely to play a crucial role in advancing AIB technology and bringing it to market.

In conclusion, the AIB market shows strong growth potential across multiple sectors, driven by the technology's advantages over existing battery solutions. However, the success of AIBs will depend on continued technological advancements, cost reductions, and the ability to overcome existing market barriers.

The automotive sector represents a substantial portion of the AIB market potential. With the rapid growth of electric vehicles (EVs), there is a pressing need for safer, more efficient, and cost-effective battery technologies. AIBs' ability to charge quickly and their improved safety profile make them an attractive option for EV manufacturers looking to address consumer concerns about charging times and battery-related safety issues.

In the consumer electronics industry, AIBs are gaining traction due to their fast-charging capabilities and longer cycle life. Smartphones, laptops, and other portable devices could benefit from AIB technology, potentially extending battery life and reducing charging times. This market segment is expected to be an early adopter of AIB technology, driving initial commercialization efforts.

The renewable energy storage sector also presents significant opportunities for AIB technology. As the world transitions towards cleaner energy sources, there is a growing demand for efficient and reliable energy storage solutions. AIBs' potential for grid-scale energy storage applications could play a crucial role in stabilizing power grids and integrating intermittent renewable energy sources like solar and wind.

Geographically, Asia-Pacific is expected to lead the AIB market growth, with China at the forefront of research and development efforts. North America and Europe are also showing strong interest in AIB technology, particularly in the automotive and renewable energy sectors.

Despite the promising outlook, the AIB market faces challenges. The technology is still in its early stages, and significant research and development are required to optimize performance and scale up production. Additionally, the established lithium-ion battery infrastructure presents a barrier to entry for new battery technologies.

The market for AIB technology is characterized by intense competition and collaboration among startups, established battery manufacturers, and research institutions. Strategic partnerships between these entities are likely to play a crucial role in advancing AIB technology and bringing it to market.

In conclusion, the AIB market shows strong growth potential across multiple sectors, driven by the technology's advantages over existing battery solutions. However, the success of AIBs will depend on continued technological advancements, cost reductions, and the ability to overcome existing market barriers.

Current Challenges in AIB Cell Assembly

The assembly of Aluminum-Ion Battery (AIB) cells presents several significant challenges that hinder their widespread adoption and commercialization. One of the primary issues is the preparation of the anode, which typically consists of aluminum foil. The surface of the aluminum anode is prone to oxidation, forming a passivation layer that can impede ion transfer and reduce battery performance. Developing effective methods to clean and prepare the aluminum surface while maintaining its reactivity remains a critical challenge.

Electrolyte filling is another area of concern in AIB cell assembly. The electrolyte used in AIBs is often highly corrosive and moisture-sensitive, making handling and filling processes complex and potentially hazardous. Ensuring uniform distribution of the electrolyte throughout the cell without introducing contaminants or air bubbles is crucial for optimal battery performance. The development of precise and efficient electrolyte filling techniques that can be scaled for mass production is an ongoing challenge.

Sealing the AIB cell effectively is paramount to prevent electrolyte leakage and moisture ingress, both of which can severely degrade battery performance and safety. The highly corrosive nature of the electrolyte poses challenges in selecting appropriate sealing materials that can withstand long-term exposure. Additionally, achieving a hermetic seal while allowing for potential gas evolution during battery operation adds another layer of complexity to the sealing process.

The reactive nature of aluminum with many common materials used in battery construction necessitates careful selection of cell components. Finding materials that are compatible with both the aluminum anode and the corrosive electrolyte, while also meeting performance and cost requirements, remains a significant challenge in AIB development.

Temperature control during the assembly process is critical, as many of the materials used in AIBs are sensitive to thermal fluctuations. Maintaining a stable and controlled environment throughout the assembly, particularly during electrolyte filling and sealing, is essential to ensure consistent cell quality and performance.

Scaling up AIB cell assembly for mass production presents its own set of challenges. Current laboratory-scale assembly techniques often involve manual processes that are difficult to automate. Developing high-throughput assembly methods that maintain precision and quality control is crucial for the commercial viability of AIBs.

Lastly, the lack of standardized assembly protocols and quality control measures specific to AIBs hinders consistent production and performance evaluation. Establishing industry-wide best practices and standards for AIB cell assembly, including anode preparation, electrolyte filling, and sealing, is essential for advancing the technology and ensuring reliability across different manufacturers and applications.

Electrolyte filling is another area of concern in AIB cell assembly. The electrolyte used in AIBs is often highly corrosive and moisture-sensitive, making handling and filling processes complex and potentially hazardous. Ensuring uniform distribution of the electrolyte throughout the cell without introducing contaminants or air bubbles is crucial for optimal battery performance. The development of precise and efficient electrolyte filling techniques that can be scaled for mass production is an ongoing challenge.

Sealing the AIB cell effectively is paramount to prevent electrolyte leakage and moisture ingress, both of which can severely degrade battery performance and safety. The highly corrosive nature of the electrolyte poses challenges in selecting appropriate sealing materials that can withstand long-term exposure. Additionally, achieving a hermetic seal while allowing for potential gas evolution during battery operation adds another layer of complexity to the sealing process.

The reactive nature of aluminum with many common materials used in battery construction necessitates careful selection of cell components. Finding materials that are compatible with both the aluminum anode and the corrosive electrolyte, while also meeting performance and cost requirements, remains a significant challenge in AIB development.

Temperature control during the assembly process is critical, as many of the materials used in AIBs are sensitive to thermal fluctuations. Maintaining a stable and controlled environment throughout the assembly, particularly during electrolyte filling and sealing, is essential to ensure consistent cell quality and performance.

Scaling up AIB cell assembly for mass production presents its own set of challenges. Current laboratory-scale assembly techniques often involve manual processes that are difficult to automate. Developing high-throughput assembly methods that maintain precision and quality control is crucial for the commercial viability of AIBs.

Lastly, the lack of standardized assembly protocols and quality control measures specific to AIBs hinders consistent production and performance evaluation. Establishing industry-wide best practices and standards for AIB cell assembly, including anode preparation, electrolyte filling, and sealing, is essential for advancing the technology and ensuring reliability across different manufacturers and applications.

Best Practices in Anode Preparation

01 AIB Cell Structure and Composition

AIB (Artificial Intelligence Battery) cells are advanced energy storage units that incorporate AI-driven control systems. These cells typically consist of specialized electrodes, electrolytes, and integrated sensors for real-time monitoring and optimization of battery performance.- AIB Cell Structure and Composition: AIB (Artificial Intelligence Battery) cells are designed with advanced structures and compositions to enhance energy storage and performance. These cells may incorporate novel electrode materials, electrolytes, and separators to improve capacity, cycling stability, and safety.

- AIB Cell Manufacturing Processes: Innovative manufacturing processes are developed for AIB cells, focusing on precision assembly, quality control, and scalability. These methods may include advanced coating techniques, electrode fabrication, and cell assembly processes to ensure consistent performance and reliability.

- AIB Cell Management Systems: Intelligent management systems are integrated into AIB cells to optimize performance, monitor health, and enhance safety. These systems may include advanced sensors, data analytics, and machine learning algorithms to predict and prevent potential issues, as well as to maximize energy efficiency.

- AIB Cell Applications in Electric Vehicles: AIB cells are specifically designed for use in electric vehicles, offering improved energy density, faster charging capabilities, and enhanced safety features. These cells may be optimized for high-power applications and integrated with vehicle systems for better overall performance.

- AIB Cell Recycling and Sustainability: Sustainable practices are incorporated into the design and lifecycle of AIB cells, focusing on recyclability and environmental impact. This includes the development of eco-friendly materials, efficient recycling processes, and strategies to extend the lifespan of the cells.

02 AI-driven Battery Management Systems

AIB cells utilize sophisticated AI algorithms for battery management, including predictive maintenance, charge-discharge optimization, and thermal management. These systems continuously analyze cell performance data to enhance efficiency and extend battery life.Expand Specific Solutions03 Self-healing and Adaptive Capabilities

Advanced AIB cells incorporate self-healing mechanisms and adaptive capabilities. These features allow the cells to automatically adjust their internal chemistry or structure in response to degradation or changing environmental conditions, thereby maintaining optimal performance over time.Expand Specific Solutions04 Integration with Smart Grid Systems

AIB cells are designed to seamlessly integrate with smart grid systems, enabling bidirectional energy flow and intelligent load balancing. This integration allows for more efficient energy distribution and storage at both individual and grid-wide levels.Expand Specific Solutions05 Enhanced Safety Features

AIB cells incorporate advanced safety features, including AI-driven early warning systems for potential failures, intelligent thermal management, and automatic shutdown mechanisms in case of critical issues. These features significantly reduce the risk of thermal runaway and other battery-related safety concerns.Expand Specific Solutions

Key Players in AIB Manufacturing

The AIB cell assembly market is in a growth phase, driven by increasing demand for advanced battery technologies in electric vehicles and energy storage systems. The market size is expanding rapidly, with major players like LG Energy Solution, Samsung SDI, and Toyota Motor Corp investing heavily in research and development. The technology is maturing, but still evolving, with companies like Sila Nanotechnologies and 24M Technologies pushing innovations in anode preparation and electrolyte filling. Established automotive giants such as GM and Ford are also entering the space, indicating the technology's growing importance. Overall, the competitive landscape is dynamic, with both traditional battery manufacturers and new entrants vying for market share and technological leadership.

LG Chem Ltd.

Technical Solution: LG Chem has developed advanced AIB (Aluminum-Ion Battery) cell assembly techniques focusing on anode preparation, electrolyte filling, and sealing. Their process involves using high-purity aluminum foil as the anode, which is treated with a proprietary surface modification technique to enhance its electrochemical performance[1]. For electrolyte filling, they employ a vacuum-assisted method to ensure complete and uniform distribution within the cell[2]. The sealing process utilizes a laser welding technique that creates a hermetic seal, crucial for preventing electrolyte leakage and maintaining long-term cell stability[3]. LG Chem's approach also incorporates real-time quality control measures during assembly, using AI-powered imaging systems to detect defects and ensure consistent cell quality[4].

Strengths: High-quality anode preparation, efficient electrolyte filling, and superior sealing technology. Weaknesses: Potentially higher production costs due to advanced techniques and equipment requirements.

Sila Nanotechnologies, Inc.

Technical Solution: Sila Nanotechnologies has pioneered a novel approach to AIB cell assembly, focusing on nanocomposite materials for enhanced performance. Their anode preparation involves a proprietary silicon-based nanocomposite that significantly increases the energy density of the battery[1]. For electrolyte filling, they use a precision-controlled injection system that optimizes the electrolyte-to-active material ratio, crucial for AIB performance[2]. The sealing process employs a multi-layer approach, combining polymer and metallic materials to create a robust barrier against moisture and contaminants[3]. Sila's assembly process also incorporates in-situ formation techniques, allowing for better integration of the anode material with the electrolyte, leading to improved cycle life and capacity retention[4].

Strengths: Innovative nanocomposite materials, precise electrolyte management, and advanced sealing techniques. Weaknesses: Potentially higher material costs and complexity in scaling up production.

Innovations in Electrolyte Filling

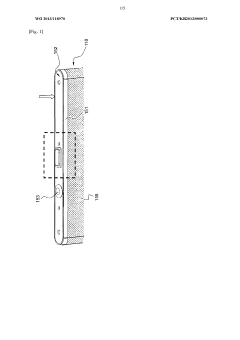

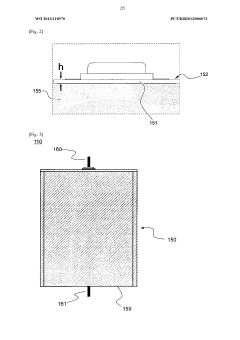

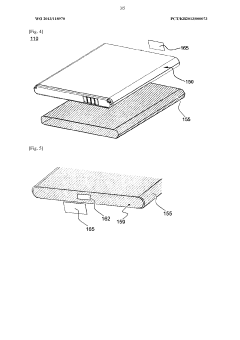

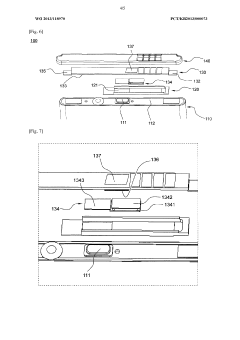

Manufacturing method for battery cells having novel structure

PatentWO2013118970A1

Innovation

- Anodizing the entire surface of the battery case with an uncoated margin section facilitates easy laser welding of the cap plate and reduces the number of parts required, while incorporating a protective circuit module with a minimized height to enhance safety and assembly efficiency.

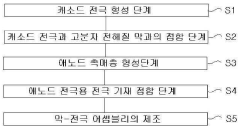

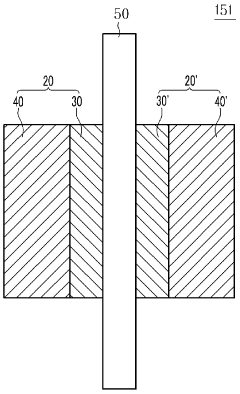

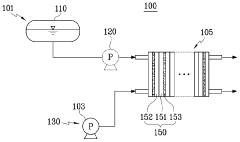

Method of preparing membrane-electrode assembly

PatentInactiveKR1020080045422A

Innovation

- The method involves forming the cathode catalyst layer on an electrode substrate and then bonding it to the polymer electrolyte membrane, while applying the anode catalyst layer directly to the polymer electrolyte membrane, thereby minimizing deformation and enhancing adhesion.

Safety Protocols in AIB Production

Safety protocols in AIB (Aluminum-Ion Battery) production are critical to ensure the well-being of workers and the integrity of the manufacturing process. These protocols encompass a wide range of measures designed to mitigate risks associated with handling potentially hazardous materials and operating specialized equipment.

One of the primary safety concerns in AIB production is the handling of reactive materials. Aluminum, which serves as the anode, can be highly reactive in certain conditions. Strict guidelines must be in place for the storage, preparation, and handling of aluminum components. This includes using appropriate personal protective equipment (PPE) such as gloves, goggles, and flame-resistant clothing when working with aluminum powders or foils.

The electrolyte used in AIBs, typically composed of ionic liquids or molten salts, presents another safety challenge. These materials can be corrosive and may react violently with water or air. Proper containment systems, including sealed storage containers and specialized filling equipment, are essential to prevent spills or exposure. Workers must be trained in the safe handling of these electrolytes and in emergency response procedures in case of accidental release.

During the cell assembly process, particular attention must be paid to the sealing stage. Improper sealing can lead to electrolyte leakage or contamination, which may result in battery failure or safety hazards. Rigorous quality control measures, including visual inspections and leak tests, should be implemented to ensure the integrity of each cell.

Electrical safety is another crucial aspect of AIB production. The assembly and testing of battery cells involve working with electrical systems that can pose shock or fire hazards. Proper insulation, grounding, and the use of appropriate testing equipment are essential. Workers should be trained in electrical safety procedures and equipped with the necessary protective gear.

Fire safety is a paramount concern in battery production facilities. AIBs, while generally considered safer than some other battery technologies, still present fire risks. Adequate fire suppression systems, emergency evacuation procedures, and regular fire drills should be standard practice. Additionally, specialized fire extinguishing agents suitable for metal fires should be readily available.

Environmental controls are also a key component of safety protocols in AIB production. Proper ventilation systems are necessary to manage fumes and particulates that may be generated during various stages of production. Air quality monitoring and regular maintenance of filtration systems help ensure a safe working environment.

Regular safety training and refresher courses for all personnel involved in AIB production are essential. This includes not only production line workers but also supervisors, maintenance staff, and quality control personnel. A culture of safety awareness should be fostered throughout the organization, encouraging reporting of potential hazards and near-miss incidents.

One of the primary safety concerns in AIB production is the handling of reactive materials. Aluminum, which serves as the anode, can be highly reactive in certain conditions. Strict guidelines must be in place for the storage, preparation, and handling of aluminum components. This includes using appropriate personal protective equipment (PPE) such as gloves, goggles, and flame-resistant clothing when working with aluminum powders or foils.

The electrolyte used in AIBs, typically composed of ionic liquids or molten salts, presents another safety challenge. These materials can be corrosive and may react violently with water or air. Proper containment systems, including sealed storage containers and specialized filling equipment, are essential to prevent spills or exposure. Workers must be trained in the safe handling of these electrolytes and in emergency response procedures in case of accidental release.

During the cell assembly process, particular attention must be paid to the sealing stage. Improper sealing can lead to electrolyte leakage or contamination, which may result in battery failure or safety hazards. Rigorous quality control measures, including visual inspections and leak tests, should be implemented to ensure the integrity of each cell.

Electrical safety is another crucial aspect of AIB production. The assembly and testing of battery cells involve working with electrical systems that can pose shock or fire hazards. Proper insulation, grounding, and the use of appropriate testing equipment are essential. Workers should be trained in electrical safety procedures and equipped with the necessary protective gear.

Fire safety is a paramount concern in battery production facilities. AIBs, while generally considered safer than some other battery technologies, still present fire risks. Adequate fire suppression systems, emergency evacuation procedures, and regular fire drills should be standard practice. Additionally, specialized fire extinguishing agents suitable for metal fires should be readily available.

Environmental controls are also a key component of safety protocols in AIB production. Proper ventilation systems are necessary to manage fumes and particulates that may be generated during various stages of production. Air quality monitoring and regular maintenance of filtration systems help ensure a safe working environment.

Regular safety training and refresher courses for all personnel involved in AIB production are essential. This includes not only production line workers but also supervisors, maintenance staff, and quality control personnel. A culture of safety awareness should be fostered throughout the organization, encouraging reporting of potential hazards and near-miss incidents.

Environmental Impact of AIB Manufacturing

The environmental impact of Aluminum-Ion Battery (AIB) manufacturing is a critical consideration in the development and adoption of this emerging energy storage technology. The production process of AIBs involves several stages that can potentially affect the environment, including raw material extraction, component manufacturing, cell assembly, and waste management.

One of the primary environmental concerns in AIB manufacturing is the extraction and processing of aluminum, which serves as the anode material. While aluminum is abundant and widely recyclable, its production is energy-intensive and can lead to significant greenhouse gas emissions. However, compared to lithium extraction for conventional lithium-ion batteries, aluminum mining generally has a lower environmental footprint and less impact on water resources.

The preparation of the cathode material, typically graphite or other carbon-based materials, also contributes to the environmental impact of AIB production. The synthesis and processing of these materials may involve the use of chemicals and energy-intensive processes, potentially resulting in air and water pollution if not properly managed.

Electrolyte production and handling present another environmental challenge in AIB manufacturing. The ionic liquids used as electrolytes in AIBs are often synthesized using organic solvents and reagents, which can have negative environmental implications if released untreated. Proper containment, recycling, and disposal protocols are essential to mitigate these risks.

The cell assembly process, including anode preparation, electrolyte filling, and sealing, requires precision and controlled environments. While these steps may not directly contribute significantly to environmental pollution, the energy consumption of clean rooms and specialized equipment should be considered in the overall environmental assessment of AIB production.

End-of-life management and recycling of AIBs are crucial aspects of their environmental impact. The recyclability of aluminum offers a potential advantage over other battery technologies. However, the development of efficient recycling processes for the entire AIB system, including the separation and recovery of electrolytes and cathode materials, is necessary to minimize waste and resource depletion.

When comparing the environmental footprint of AIB manufacturing to that of lithium-ion batteries, several factors must be considered. While AIBs may have advantages in terms of raw material availability and recyclability, the overall impact depends on factors such as production scale, manufacturing efficiency, and the specific chemistries used. As AIB technology is still evolving, ongoing research and development efforts are focused on optimizing production processes and materials to further reduce environmental impacts.

One of the primary environmental concerns in AIB manufacturing is the extraction and processing of aluminum, which serves as the anode material. While aluminum is abundant and widely recyclable, its production is energy-intensive and can lead to significant greenhouse gas emissions. However, compared to lithium extraction for conventional lithium-ion batteries, aluminum mining generally has a lower environmental footprint and less impact on water resources.

The preparation of the cathode material, typically graphite or other carbon-based materials, also contributes to the environmental impact of AIB production. The synthesis and processing of these materials may involve the use of chemicals and energy-intensive processes, potentially resulting in air and water pollution if not properly managed.

Electrolyte production and handling present another environmental challenge in AIB manufacturing. The ionic liquids used as electrolytes in AIBs are often synthesized using organic solvents and reagents, which can have negative environmental implications if released untreated. Proper containment, recycling, and disposal protocols are essential to mitigate these risks.

The cell assembly process, including anode preparation, electrolyte filling, and sealing, requires precision and controlled environments. While these steps may not directly contribute significantly to environmental pollution, the energy consumption of clean rooms and specialized equipment should be considered in the overall environmental assessment of AIB production.

End-of-life management and recycling of AIBs are crucial aspects of their environmental impact. The recyclability of aluminum offers a potential advantage over other battery technologies. However, the development of efficient recycling processes for the entire AIB system, including the separation and recovery of electrolytes and cathode materials, is necessary to minimize waste and resource depletion.

When comparing the environmental footprint of AIB manufacturing to that of lithium-ion batteries, several factors must be considered. While AIBs may have advantages in terms of raw material availability and recyclability, the overall impact depends on factors such as production scale, manufacturing efficiency, and the specific chemistries used. As AIB technology is still evolving, ongoing research and development efforts are focused on optimizing production processes and materials to further reduce environmental impacts.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!