Separator Requirements for AIBs: Chemical Resistance, Porosity and Thickness Tradeoffs

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

AIB Separator Evolution

The evolution of separators for aluminum-ion batteries (AIBs) has been a critical factor in advancing AIB technology. Initially, separators were primarily adapted from lithium-ion battery systems, with limited consideration for the unique chemical environment of AIBs. These early separators often suffered from rapid degradation due to the highly corrosive nature of aluminum chloride electrolytes.

As research in AIBs progressed, the focus shifted towards developing separators specifically tailored for the AIB chemistry. The first significant breakthrough came with the introduction of glass fiber separators, which demonstrated superior chemical resistance compared to traditional polymer-based separators. This advancement allowed for longer battery lifetimes and improved cycling stability.

The next phase of separator evolution centered on optimizing porosity and thickness. Researchers recognized the delicate balance between these parameters and their impact on battery performance. Higher porosity facilitates better ion transport but can compromise mechanical strength, while increased thickness enhances chemical resistance at the cost of increased internal resistance.

To address these challenges, composite separators emerged as a promising solution. These separators combined the chemical resistance of inorganic materials with the flexibility and processability of polymers. For instance, ceramic-coated polymer separators were developed, offering a compromise between the desired properties.

Recent advancements have focused on nanoengineered separators. By incorporating nanostructures such as graphene oxide or metal-organic frameworks, researchers have achieved separators with enhanced chemical stability and controlled porosity. These nanostructured separators have demonstrated the potential to significantly improve AIB performance metrics, including power density and cycle life.

The latest trend in AIB separator evolution involves the development of multifunctional separators. These advanced materials not only serve as a physical barrier between electrodes but also actively contribute to battery performance. For example, separators with catalytic properties have been explored to enhance the kinetics of aluminum deposition and dissolution, addressing one of the key limitations of AIBs.

As the field continues to evolve, there is a growing emphasis on sustainable and environmentally friendly separator materials. Biodegradable polymers and naturally derived materials are being investigated as potential alternatives to traditional synthetic separators, aligning with the broader trend towards green energy storage solutions.

As research in AIBs progressed, the focus shifted towards developing separators specifically tailored for the AIB chemistry. The first significant breakthrough came with the introduction of glass fiber separators, which demonstrated superior chemical resistance compared to traditional polymer-based separators. This advancement allowed for longer battery lifetimes and improved cycling stability.

The next phase of separator evolution centered on optimizing porosity and thickness. Researchers recognized the delicate balance between these parameters and their impact on battery performance. Higher porosity facilitates better ion transport but can compromise mechanical strength, while increased thickness enhances chemical resistance at the cost of increased internal resistance.

To address these challenges, composite separators emerged as a promising solution. These separators combined the chemical resistance of inorganic materials with the flexibility and processability of polymers. For instance, ceramic-coated polymer separators were developed, offering a compromise between the desired properties.

Recent advancements have focused on nanoengineered separators. By incorporating nanostructures such as graphene oxide or metal-organic frameworks, researchers have achieved separators with enhanced chemical stability and controlled porosity. These nanostructured separators have demonstrated the potential to significantly improve AIB performance metrics, including power density and cycle life.

The latest trend in AIB separator evolution involves the development of multifunctional separators. These advanced materials not only serve as a physical barrier between electrodes but also actively contribute to battery performance. For example, separators with catalytic properties have been explored to enhance the kinetics of aluminum deposition and dissolution, addressing one of the key limitations of AIBs.

As the field continues to evolve, there is a growing emphasis on sustainable and environmentally friendly separator materials. Biodegradable polymers and naturally derived materials are being investigated as potential alternatives to traditional synthetic separators, aligning with the broader trend towards green energy storage solutions.

Market Demand Analysis

The market demand for advanced separators in Aqueous Ion Batteries (AIBs) is experiencing significant growth, driven by the increasing need for sustainable energy storage solutions. As the global push for renewable energy and electrification intensifies, AIBs are emerging as a promising alternative to traditional lithium-ion batteries, particularly in grid-scale energy storage applications.

The separator market for AIBs is closely tied to the overall growth of the aqueous battery industry. This sector is projected to expand rapidly in the coming years, with a focus on improving battery performance, safety, and cost-effectiveness. The demand for separators that can withstand the unique chemical environment of AIBs while maintaining optimal porosity and thickness is a critical factor in this market's development.

Chemical resistance is a key requirement for AIB separators, as they must operate in highly corrosive aqueous electrolytes. This has led to increased demand for advanced materials that can maintain their integrity over extended periods, ensuring long-term battery performance and safety. Manufacturers are seeking separators that can resist degradation from both acidic and alkaline electrolytes, depending on the specific AIB chemistry.

Porosity is another crucial factor driving market demand. Separators with optimized porosity allow for efficient ion transport while preventing short circuits. The market is showing a preference for materials that can achieve a balance between high porosity for improved battery performance and sufficient mechanical strength to maintain structural integrity.

Thickness is a third critical parameter influencing market trends. There is a growing demand for thinner separators that can contribute to higher energy density in AIBs. However, this must be balanced against the need for mechanical stability and longevity. The market is seeking innovative solutions that can reduce separator thickness without compromising on safety or performance.

The interplay between these three key requirements – chemical resistance, porosity, and thickness – is shaping the development of new separator materials and designs. Manufacturers are investing in research and development to create products that can meet these often conflicting demands, driving innovation in material science and manufacturing processes.

Geographically, the market for AIB separators is seeing strong growth in regions with significant renewable energy initiatives and grid modernization projects. Countries with ambitious energy storage targets, particularly in Asia, North America, and Europe, are expected to be key drivers of demand for advanced AIB separators.

The separator market for AIBs is closely tied to the overall growth of the aqueous battery industry. This sector is projected to expand rapidly in the coming years, with a focus on improving battery performance, safety, and cost-effectiveness. The demand for separators that can withstand the unique chemical environment of AIBs while maintaining optimal porosity and thickness is a critical factor in this market's development.

Chemical resistance is a key requirement for AIB separators, as they must operate in highly corrosive aqueous electrolytes. This has led to increased demand for advanced materials that can maintain their integrity over extended periods, ensuring long-term battery performance and safety. Manufacturers are seeking separators that can resist degradation from both acidic and alkaline electrolytes, depending on the specific AIB chemistry.

Porosity is another crucial factor driving market demand. Separators with optimized porosity allow for efficient ion transport while preventing short circuits. The market is showing a preference for materials that can achieve a balance between high porosity for improved battery performance and sufficient mechanical strength to maintain structural integrity.

Thickness is a third critical parameter influencing market trends. There is a growing demand for thinner separators that can contribute to higher energy density in AIBs. However, this must be balanced against the need for mechanical stability and longevity. The market is seeking innovative solutions that can reduce separator thickness without compromising on safety or performance.

The interplay between these three key requirements – chemical resistance, porosity, and thickness – is shaping the development of new separator materials and designs. Manufacturers are investing in research and development to create products that can meet these often conflicting demands, driving innovation in material science and manufacturing processes.

Geographically, the market for AIB separators is seeing strong growth in regions with significant renewable energy initiatives and grid modernization projects. Countries with ambitious energy storage targets, particularly in Asia, North America, and Europe, are expected to be key drivers of demand for advanced AIB separators.

Current Challenges

The development of Aluminum-Ion Batteries (AIBs) faces several significant challenges, particularly in the realm of separator requirements. One of the primary obstacles is achieving the optimal balance between chemical resistance, porosity, and thickness of the separator material.

Chemical resistance is crucial for AIB separators due to the highly corrosive nature of the electrolyte used in these batteries. The electrolyte typically contains chloroaluminate ions, which are known to be aggressive towards many conventional separator materials. This corrosiveness can lead to degradation of the separator over time, potentially causing short circuits or reduced battery performance. Developing materials that can withstand this harsh chemical environment while maintaining their structural integrity remains a significant challenge.

Porosity is another critical factor that presents a complex trade-off. On one hand, higher porosity is desirable as it allows for better ion transport between the electrodes, which is essential for efficient battery operation. However, excessive porosity can compromise the mechanical strength of the separator and increase the risk of dendrite formation, which can lead to short circuits. Striking the right balance between porosity and mechanical stability is a delicate task that requires careful material engineering and extensive testing.

The thickness of the separator also presents a challenging trade-off. Thinner separators are generally preferred as they reduce the overall size of the battery and minimize internal resistance, leading to improved power density. However, thinner separators are more prone to mechanical failure and may not provide sufficient protection against dendrite growth. Conversely, thicker separators offer better mechanical stability and dendrite resistance but at the cost of increased internal resistance and reduced energy density.

Furthermore, the interaction between these three parameters - chemical resistance, porosity, and thickness - is complex and interdependent. For instance, increasing the thickness to improve chemical resistance may negatively impact the porosity and ion transport properties. Similarly, modifying the material composition to enhance chemical resistance could affect the mechanical properties and optimal thickness requirements.

Another challenge lies in the scalability and cost-effectiveness of potential separator materials that meet these stringent requirements. Many advanced materials that show promise in laboratory settings may be difficult or expensive to produce at scale, hindering their commercial viability.

In conclusion, addressing these interrelated challenges in separator design for AIBs requires a multidisciplinary approach, combining materials science, electrochemistry, and engineering. Overcoming these hurdles is crucial for the advancement of AIB technology and its potential to compete with or complement existing battery technologies in various applications.

Chemical resistance is crucial for AIB separators due to the highly corrosive nature of the electrolyte used in these batteries. The electrolyte typically contains chloroaluminate ions, which are known to be aggressive towards many conventional separator materials. This corrosiveness can lead to degradation of the separator over time, potentially causing short circuits or reduced battery performance. Developing materials that can withstand this harsh chemical environment while maintaining their structural integrity remains a significant challenge.

Porosity is another critical factor that presents a complex trade-off. On one hand, higher porosity is desirable as it allows for better ion transport between the electrodes, which is essential for efficient battery operation. However, excessive porosity can compromise the mechanical strength of the separator and increase the risk of dendrite formation, which can lead to short circuits. Striking the right balance between porosity and mechanical stability is a delicate task that requires careful material engineering and extensive testing.

The thickness of the separator also presents a challenging trade-off. Thinner separators are generally preferred as they reduce the overall size of the battery and minimize internal resistance, leading to improved power density. However, thinner separators are more prone to mechanical failure and may not provide sufficient protection against dendrite growth. Conversely, thicker separators offer better mechanical stability and dendrite resistance but at the cost of increased internal resistance and reduced energy density.

Furthermore, the interaction between these three parameters - chemical resistance, porosity, and thickness - is complex and interdependent. For instance, increasing the thickness to improve chemical resistance may negatively impact the porosity and ion transport properties. Similarly, modifying the material composition to enhance chemical resistance could affect the mechanical properties and optimal thickness requirements.

Another challenge lies in the scalability and cost-effectiveness of potential separator materials that meet these stringent requirements. Many advanced materials that show promise in laboratory settings may be difficult or expensive to produce at scale, hindering their commercial viability.

In conclusion, addressing these interrelated challenges in separator design for AIBs requires a multidisciplinary approach, combining materials science, electrochemistry, and engineering. Overcoming these hurdles is crucial for the advancement of AIB technology and its potential to compete with or complement existing battery technologies in various applications.

Existing Solutions

01 Chemical resistance of AIB separators

Separators for AIBs are designed with enhanced chemical resistance to withstand the harsh electrolyte environment. This is achieved through the use of specialized polymers and coatings that can resist degradation from the alkaline or acidic electrolytes used in AIBs. The improved chemical stability ensures longer battery life and better performance.- Chemical resistance of AIB separators: Separators for AIBs are designed with enhanced chemical resistance to withstand the harsh electrolyte environment. This is achieved through the use of specialized materials and coatings that can resist degradation from the electrolyte, ensuring longer battery life and improved safety. The chemical resistance of these separators helps prevent short circuits and maintains the integrity of the battery structure over time.

- Porosity control in AIB separators: The porosity of AIB separators is carefully engineered to balance ion transport and mechanical strength. Highly porous separators allow for efficient ion movement between electrodes, improving battery performance. However, the porosity must be optimized to maintain sufficient mechanical strength and prevent dendrite growth. Advanced manufacturing techniques are employed to create separators with controlled pore size and distribution.

- Thickness optimization of AIB separators: The thickness of AIB separators is a critical parameter that affects battery performance and safety. Thinner separators can reduce internal resistance and improve energy density, but they must be thick enough to provide adequate mechanical strength and prevent short circuits. Manufacturers use advanced techniques to produce ultra-thin separators that maintain the necessary protective properties while maximizing battery efficiency.

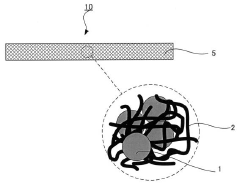

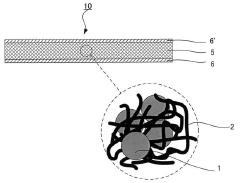

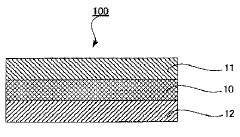

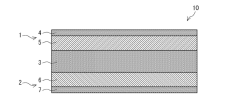

- Multi-layer separator designs for AIBs: Multi-layer separator designs are employed to enhance the overall performance of AIBs. These designs combine layers with different properties to achieve optimal chemical resistance, porosity, and mechanical strength. For example, a separator might include a highly porous layer for ion transport sandwiched between two chemically resistant outer layers. This approach allows for tailored separator properties that meet the specific requirements of AIB systems.

- Surface modification of AIB separators: Surface modification techniques are used to enhance the properties of AIB separators. These modifications can improve wettability, increase chemical resistance, or provide additional functionality such as flame retardancy. Common methods include plasma treatment, chemical grafting, and coating with functional polymers. Surface-modified separators can significantly improve the overall performance and safety of AIBs.

02 Porosity control in AIB separators

The porosity of AIB separators is carefully engineered to balance ion transport and mechanical strength. Techniques such as phase inversion, electrospinning, and template removal are used to create a porous structure that allows for efficient ion movement while maintaining structural integrity. Optimized porosity contributes to improved battery performance and safety.Expand Specific Solutions03 Thickness optimization of AIB separators

The thickness of AIB separators is a critical parameter that affects battery performance and safety. Thinner separators can reduce internal resistance and improve energy density, while thicker separators may offer better mechanical strength and thermal stability. Advanced manufacturing techniques are employed to achieve precise thickness control and uniformity across the separator.Expand Specific Solutions04 Composite and multi-layer separator designs

Innovative separator designs incorporate composite materials and multi-layer structures to enhance overall performance. These designs combine different materials with complementary properties to achieve improved chemical resistance, controlled porosity, and optimized thickness. The layered approach allows for tailoring specific properties to meet the demanding requirements of AIBs.Expand Specific Solutions05 Surface modification techniques for AIB separators

Surface modification of AIB separators is employed to enhance their properties. Techniques such as plasma treatment, grafting, and coating are used to improve wettability, chemical resistance, and ion transport characteristics. These modifications can lead to better electrolyte uptake, reduced internal resistance, and improved overall battery performance.Expand Specific Solutions

Key Industry Players

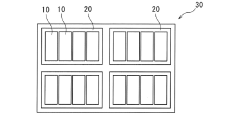

The market for AIB separators is in a growth phase, driven by increasing demand for advanced batteries in electric vehicles and energy storage systems. The global market size is expanding rapidly, with projections indicating significant growth in the coming years. Technologically, the field is advancing but still faces challenges in optimizing the balance between chemical resistance, porosity, and thickness. Key players like LG Energy Solution, CATL, SK Innovation, and Sumitomo Chemical are investing heavily in R&D to improve separator performance. Emerging companies such as Shenzhen Senior Technology and DreamWeaver International are also contributing innovative solutions, indicating a competitive and dynamic landscape as the industry strives to meet evolving battery requirements.

LG Energy Solution Ltd.

Technical Solution: LG Energy Solution has developed advanced separator technology for AIBs focusing on chemical resistance, porosity, and thickness optimization. Their approach involves using a ceramic-coated polyethylene (PE) separator with a thickness of 12-20 μm and porosity of 35-50%[1]. The ceramic coating, typically alumina or silica, enhances chemical stability and thermal resistance. They've implemented a unique multi-layer structure that combines different materials to achieve an optimal balance between mechanical strength and ion permeability[2]. The company has also introduced nano-scale pore control technology to improve electrolyte wetting and ion transport efficiency[3].

Strengths: Enhanced thermal and chemical stability, improved safety, and balanced performance. Weaknesses: Potentially higher production costs and complexity in manufacturing process.

Ningde Amperex Technology Ltd.

Technical Solution: CATL (Ningde Amperex Technology) has developed a novel separator technology for AIBs that addresses chemical resistance, porosity, and thickness trade-offs. Their approach involves a multi-functional composite separator with a base layer of polyethylene (PE) or polypropylene (PP) and a ceramic coating[1]. The separator thickness ranges from 15-25 μm with a porosity of 40-55%[2]. CATL has implemented a unique surface modification technique to enhance chemical resistance against aggressive electrolytes used in AIBs[3]. They've also introduced a gradient porosity design, where the pore size and distribution vary across the separator thickness, optimizing both mechanical strength and ion transport[4].

Strengths: Excellent chemical resistance, optimized ion transport, and improved cycle life. Weaknesses: Potential challenges in scaling up production and higher material costs.

Core Innovations

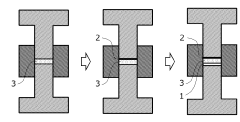

Separator for all-solid battery, manufacturing method thereof, and all-solid battery

PatentActiveJP2020102310A

Innovation

- The use of a first solid electrolyte layer containing a hydrogenated rubber-based resin at 15-30 vol% and optionally a second solid electrolyte layer with 0.1-15 vol% hydrogenated rubber-based resin, combined with specific sulfide-based solid electrolytes like Li2S-P2S5, enhances both tensile strength and ionic conductivity.

All-solid secondary cell separator and all-solid secondary battery

PatentPendingJP2024011645A

Innovation

- Incorporation of a solid electrolyte and a filler with a median aspect ratio of 2.5 or more in the separator, where the shape of each particle is approximated elliptically, effectively blocking dendrite growth from the negative electrode to the positive electrode.

Material Selection Criteria

The selection of materials for separators in Aluminum-Ion Batteries (AIBs) is a critical process that requires careful consideration of multiple factors. The primary criteria for material selection include chemical resistance, porosity, and thickness, each playing a crucial role in the overall performance and safety of the battery.

Chemical resistance is paramount in AIB separators due to the highly corrosive nature of the electrolyte. Materials must withstand prolonged exposure to chloroaluminate-based electrolytes without degradation or loss of structural integrity. Potential candidates include certain polymers like polyethylene (PE) and polypropylene (PP), which have shown promising resistance to chemical attack. However, the search for more advanced materials with enhanced chemical stability continues, with research focusing on fluoropolymers and ceramic-coated separators.

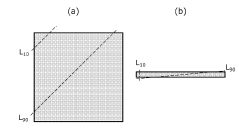

Porosity is another key factor in separator design, directly impacting ionic conductivity and overall battery performance. The ideal separator should have a porosity that allows for efficient ion transport while maintaining mechanical strength. Typically, a porosity range of 30-50% is considered optimal for AIB separators. Achieving this balance often involves techniques such as stretching or phase inversion during material processing. Nanofiber-based separators have gained attention for their ability to provide high porosity while maintaining structural integrity.

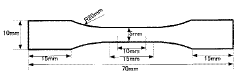

Thickness is a critical parameter that influences both the mechanical strength and the internal resistance of the battery. Thinner separators generally lead to lower internal resistance and higher power density but may compromise mechanical strength and safety. The challenge lies in finding the optimal thickness that balances these competing factors. Current research trends indicate a move towards ultra-thin separators in the range of 10-25 μm, made possible by advanced manufacturing techniques and composite materials.

The interplay between these three criteria - chemical resistance, porosity, and thickness - presents a complex optimization problem. For instance, increasing porosity to enhance ionic conductivity may compromise mechanical strength, necessitating a thicker separator, which in turn could increase internal resistance. Similarly, materials with excellent chemical resistance might not possess the desired porosity or be suitable for ultra-thin configurations.

To address these challenges, researchers are exploring composite materials and multi-layer structures. These approaches aim to combine the benefits of different materials, such as a chemically resistant layer coupled with a highly porous layer. Additionally, surface modifications and coatings are being investigated to enhance specific properties without significantly altering others.

In conclusion, the material selection for AIB separators requires a holistic approach that considers the interdependencies between chemical resistance, porosity, and thickness. As research progresses, novel materials and innovative manufacturing techniques are expected to emerge, potentially offering solutions that better balance these critical requirements.

Chemical resistance is paramount in AIB separators due to the highly corrosive nature of the electrolyte. Materials must withstand prolonged exposure to chloroaluminate-based electrolytes without degradation or loss of structural integrity. Potential candidates include certain polymers like polyethylene (PE) and polypropylene (PP), which have shown promising resistance to chemical attack. However, the search for more advanced materials with enhanced chemical stability continues, with research focusing on fluoropolymers and ceramic-coated separators.

Porosity is another key factor in separator design, directly impacting ionic conductivity and overall battery performance. The ideal separator should have a porosity that allows for efficient ion transport while maintaining mechanical strength. Typically, a porosity range of 30-50% is considered optimal for AIB separators. Achieving this balance often involves techniques such as stretching or phase inversion during material processing. Nanofiber-based separators have gained attention for their ability to provide high porosity while maintaining structural integrity.

Thickness is a critical parameter that influences both the mechanical strength and the internal resistance of the battery. Thinner separators generally lead to lower internal resistance and higher power density but may compromise mechanical strength and safety. The challenge lies in finding the optimal thickness that balances these competing factors. Current research trends indicate a move towards ultra-thin separators in the range of 10-25 μm, made possible by advanced manufacturing techniques and composite materials.

The interplay between these three criteria - chemical resistance, porosity, and thickness - presents a complex optimization problem. For instance, increasing porosity to enhance ionic conductivity may compromise mechanical strength, necessitating a thicker separator, which in turn could increase internal resistance. Similarly, materials with excellent chemical resistance might not possess the desired porosity or be suitable for ultra-thin configurations.

To address these challenges, researchers are exploring composite materials and multi-layer structures. These approaches aim to combine the benefits of different materials, such as a chemically resistant layer coupled with a highly porous layer. Additionally, surface modifications and coatings are being investigated to enhance specific properties without significantly altering others.

In conclusion, the material selection for AIB separators requires a holistic approach that considers the interdependencies between chemical resistance, porosity, and thickness. As research progresses, novel materials and innovative manufacturing techniques are expected to emerge, potentially offering solutions that better balance these critical requirements.

Environmental Impact

The environmental impact of separator materials used in Aluminum-Ion Batteries (AIBs) is a critical consideration in the development and adoption of this emerging energy storage technology. The production, use, and disposal of separators can have significant implications for sustainability and ecological balance.

Separator materials commonly used in AIBs, such as glass fiber or polymer-based membranes, require energy-intensive manufacturing processes. The production of these materials often involves the use of chemical treatments and synthetic polymers, which can contribute to greenhouse gas emissions and resource depletion. Additionally, the extraction of raw materials for separator production may lead to habitat disruption and biodiversity loss in mining areas.

During the operational life of AIBs, the chemical resistance of separators plays a crucial role in preventing environmental contamination. Highly resistant separators minimize the risk of electrolyte leakage, which could otherwise result in soil and water pollution. However, the trade-off between chemical resistance and porosity may impact the overall efficiency of the battery, potentially leading to increased energy consumption and associated environmental burdens.

The end-of-life management of AIB separators presents another environmental challenge. Many separator materials are not easily biodegradable or recyclable, contributing to the growing problem of electronic waste. Improper disposal of these components can lead to the release of harmful substances into ecosystems, affecting wildlife and human health.

Efforts to mitigate the environmental impact of AIB separators are focusing on several key areas. Research into bio-based and biodegradable separator materials is gaining traction, aiming to reduce the reliance on petroleum-derived polymers. These alternative materials could potentially offer a more sustainable lifecycle, from production to disposal.

Advancements in separator design are also addressing environmental concerns. Thinner separators that maintain necessary performance characteristics can reduce material usage and improve the overall energy density of AIBs. This optimization could lead to more efficient batteries, reducing the environmental footprint of energy storage systems.

Recycling technologies for AIB components, including separators, are being developed to create a more circular economy approach. Improved recycling processes could recover valuable materials and minimize waste, although challenges remain in separating and processing the diverse materials used in battery construction.

In conclusion, while AIBs offer promising advancements in energy storage, the environmental impact of their separators requires careful consideration. Balancing the technical requirements of chemical resistance, porosity, and thickness with ecological sustainability remains a key challenge for researchers and manufacturers in this field.

Separator materials commonly used in AIBs, such as glass fiber or polymer-based membranes, require energy-intensive manufacturing processes. The production of these materials often involves the use of chemical treatments and synthetic polymers, which can contribute to greenhouse gas emissions and resource depletion. Additionally, the extraction of raw materials for separator production may lead to habitat disruption and biodiversity loss in mining areas.

During the operational life of AIBs, the chemical resistance of separators plays a crucial role in preventing environmental contamination. Highly resistant separators minimize the risk of electrolyte leakage, which could otherwise result in soil and water pollution. However, the trade-off between chemical resistance and porosity may impact the overall efficiency of the battery, potentially leading to increased energy consumption and associated environmental burdens.

The end-of-life management of AIB separators presents another environmental challenge. Many separator materials are not easily biodegradable or recyclable, contributing to the growing problem of electronic waste. Improper disposal of these components can lead to the release of harmful substances into ecosystems, affecting wildlife and human health.

Efforts to mitigate the environmental impact of AIB separators are focusing on several key areas. Research into bio-based and biodegradable separator materials is gaining traction, aiming to reduce the reliance on petroleum-derived polymers. These alternative materials could potentially offer a more sustainable lifecycle, from production to disposal.

Advancements in separator design are also addressing environmental concerns. Thinner separators that maintain necessary performance characteristics can reduce material usage and improve the overall energy density of AIBs. This optimization could lead to more efficient batteries, reducing the environmental footprint of energy storage systems.

Recycling technologies for AIB components, including separators, are being developed to create a more circular economy approach. Improved recycling processes could recover valuable materials and minimize waste, although challenges remain in separating and processing the diverse materials used in battery construction.

In conclusion, while AIBs offer promising advancements in energy storage, the environmental impact of their separators requires careful consideration. Balancing the technical requirements of chemical resistance, porosity, and thickness with ecological sustainability remains a key challenge for researchers and manufacturers in this field.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!