Solid vs Liquid Electrolytes for AIBs: Ionic Conductivity, Stability and Safety Tradeoffs

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

AIB Electrolyte Evolution

The evolution of electrolytes for Aluminum-Ion Batteries (AIBs) has been a critical factor in advancing their performance and potential applications. Initially, AIBs utilized liquid electrolytes due to their high ionic conductivity and ease of implementation. These early liquid electrolytes were typically composed of AlCl3 dissolved in organic solvents or ionic liquids, providing a medium for aluminum ion transport between electrodes.

As research progressed, the focus shifted towards improving the stability and safety of AIB electrolytes. Liquid electrolytes, while offering excellent ionic conductivity, often suffered from issues such as volatility, flammability, and potential leakage. This led to the exploration of more stable liquid electrolyte formulations, including the use of deep eutectic solvents and room-temperature ionic liquids, which offered improved safety profiles and wider electrochemical windows.

The quest for enhanced stability and safety eventually paved the way for the development of solid electrolytes for AIBs. Solid electrolytes promised several advantages, including improved mechanical stability, reduced risk of leakage, and potentially higher energy density due to the possibility of using metallic aluminum anodes. Early solid electrolytes for AIBs were primarily ceramic-based materials, such as β-alumina and NASICON-type structures.

However, the transition to solid electrolytes brought new challenges, particularly in terms of ionic conductivity. Solid electrolytes typically exhibited lower ionic conductivity compared to their liquid counterparts, which limited the power density of AIBs. This trade-off between stability and conductivity became a central focus of research efforts.

Recent developments in AIB electrolyte evolution have seen the emergence of hybrid and composite electrolytes, attempting to combine the benefits of both liquid and solid systems. These include gel electrolytes, polymer electrolytes infused with ionic liquids, and ceramic-polymer composites. Such hybrid approaches aim to strike a balance between the high ionic conductivity of liquids and the enhanced stability and safety of solids.

The ongoing evolution of AIB electrolytes continues to address the fundamental trade-offs between ionic conductivity, stability, and safety. Current research directions include the development of novel solid electrolyte materials with improved ionic conductivity, the engineering of interfaces between electrodes and solid electrolytes to enhance ion transport, and the exploration of advanced composite electrolyte systems that can offer the best of both worlds.

As research progressed, the focus shifted towards improving the stability and safety of AIB electrolytes. Liquid electrolytes, while offering excellent ionic conductivity, often suffered from issues such as volatility, flammability, and potential leakage. This led to the exploration of more stable liquid electrolyte formulations, including the use of deep eutectic solvents and room-temperature ionic liquids, which offered improved safety profiles and wider electrochemical windows.

The quest for enhanced stability and safety eventually paved the way for the development of solid electrolytes for AIBs. Solid electrolytes promised several advantages, including improved mechanical stability, reduced risk of leakage, and potentially higher energy density due to the possibility of using metallic aluminum anodes. Early solid electrolytes for AIBs were primarily ceramic-based materials, such as β-alumina and NASICON-type structures.

However, the transition to solid electrolytes brought new challenges, particularly in terms of ionic conductivity. Solid electrolytes typically exhibited lower ionic conductivity compared to their liquid counterparts, which limited the power density of AIBs. This trade-off between stability and conductivity became a central focus of research efforts.

Recent developments in AIB electrolyte evolution have seen the emergence of hybrid and composite electrolytes, attempting to combine the benefits of both liquid and solid systems. These include gel electrolytes, polymer electrolytes infused with ionic liquids, and ceramic-polymer composites. Such hybrid approaches aim to strike a balance between the high ionic conductivity of liquids and the enhanced stability and safety of solids.

The ongoing evolution of AIB electrolytes continues to address the fundamental trade-offs between ionic conductivity, stability, and safety. Current research directions include the development of novel solid electrolyte materials with improved ionic conductivity, the engineering of interfaces between electrodes and solid electrolytes to enhance ion transport, and the exploration of advanced composite electrolyte systems that can offer the best of both worlds.

Market Demand for AIBs

The market demand for Aluminum-Ion Batteries (AIBs) is experiencing a significant upward trajectory, driven by the increasing need for sustainable and high-performance energy storage solutions. As the global push for electrification intensifies, particularly in the automotive and renewable energy sectors, AIBs are emerging as a promising alternative to traditional lithium-ion batteries.

The automotive industry represents a key driver of AIB market demand. With the rapid growth of electric vehicles (EVs), manufacturers are seeking battery technologies that offer improved safety, faster charging times, and longer lifespans. AIBs, with their potential for higher energy density and enhanced safety features, are attracting considerable attention from EV producers looking to differentiate their products in a competitive market.

In the renewable energy sector, the demand for efficient and cost-effective energy storage systems is fueling interest in AIBs. As wind and solar power generation continues to expand, the need for reliable storage solutions to manage intermittent energy production becomes increasingly critical. AIBs' potential for longer cycle life and improved stability makes them an attractive option for grid-scale energy storage applications.

Consumer electronics represent another significant market for AIBs. The ever-growing demand for smartphones, laptops, and wearable devices with longer battery life and faster charging capabilities aligns well with the potential benefits of AIB technology. Manufacturers in this sector are closely monitoring AIB developments as they seek to meet consumer expectations for improved device performance and convenience.

The industrial sector is also showing interest in AIBs, particularly for applications requiring high-power output and rapid charging. From power tools to material handling equipment, the potential for AIBs to provide longer operational times and reduced downtime for charging is driving demand in this segment.

However, the market demand for AIBs is not without challenges. The technology is still in its early stages of development, and concerns about production scalability and cost-effectiveness need to be addressed. Additionally, the established infrastructure and supply chains for lithium-ion batteries present a significant barrier to widespread AIB adoption.

Despite these challenges, the potential benefits of AIBs in terms of safety, performance, and sustainability are driving continued investment and research in this technology. As advancements are made in addressing the trade-offs between ionic conductivity, stability, and safety in both solid and liquid electrolytes, the market demand for AIBs is expected to grow substantially in the coming years.

The automotive industry represents a key driver of AIB market demand. With the rapid growth of electric vehicles (EVs), manufacturers are seeking battery technologies that offer improved safety, faster charging times, and longer lifespans. AIBs, with their potential for higher energy density and enhanced safety features, are attracting considerable attention from EV producers looking to differentiate their products in a competitive market.

In the renewable energy sector, the demand for efficient and cost-effective energy storage systems is fueling interest in AIBs. As wind and solar power generation continues to expand, the need for reliable storage solutions to manage intermittent energy production becomes increasingly critical. AIBs' potential for longer cycle life and improved stability makes them an attractive option for grid-scale energy storage applications.

Consumer electronics represent another significant market for AIBs. The ever-growing demand for smartphones, laptops, and wearable devices with longer battery life and faster charging capabilities aligns well with the potential benefits of AIB technology. Manufacturers in this sector are closely monitoring AIB developments as they seek to meet consumer expectations for improved device performance and convenience.

The industrial sector is also showing interest in AIBs, particularly for applications requiring high-power output and rapid charging. From power tools to material handling equipment, the potential for AIBs to provide longer operational times and reduced downtime for charging is driving demand in this segment.

However, the market demand for AIBs is not without challenges. The technology is still in its early stages of development, and concerns about production scalability and cost-effectiveness need to be addressed. Additionally, the established infrastructure and supply chains for lithium-ion batteries present a significant barrier to widespread AIB adoption.

Despite these challenges, the potential benefits of AIBs in terms of safety, performance, and sustainability are driving continued investment and research in this technology. As advancements are made in addressing the trade-offs between ionic conductivity, stability, and safety in both solid and liquid electrolytes, the market demand for AIBs is expected to grow substantially in the coming years.

Solid vs Liquid Challenges

The development of Aluminum-Ion Batteries (AIBs) faces significant challenges in both solid and liquid electrolyte systems. Liquid electrolytes, while offering high ionic conductivity, struggle with stability issues and safety concerns. They are prone to leakage, flammability, and corrosion, which can lead to reduced battery life and potential hazards. Additionally, the volatile nature of liquid electrolytes limits the operating temperature range of AIBs, restricting their application in extreme environments.

Solid electrolytes, on the other hand, address many of the safety and stability concerns associated with liquid electrolytes. They offer improved thermal stability, reduced risk of leakage, and enhanced mechanical strength. However, solid electrolytes face their own set of challenges, primarily related to ionic conductivity. The ionic conductivity of solid electrolytes is typically lower than that of their liquid counterparts, which can result in reduced battery performance and slower charging rates.

The interface between the solid electrolyte and the electrodes presents another significant challenge. Poor contact at this interface can lead to increased resistance and reduced ion transfer, ultimately affecting the battery's overall performance. Researchers are exploring various strategies to improve this interface, including the development of composite electrolytes and novel electrode designs.

Manufacturability is another crucial aspect to consider when comparing solid and liquid electrolytes. Liquid electrolytes are generally easier to integrate into existing battery production processes, while solid electrolytes often require more complex manufacturing techniques. This can impact the scalability and cost-effectiveness of AIBs with solid electrolytes.

The long-term stability of both electrolyte systems remains a concern. Liquid electrolytes may suffer from gradual degradation and side reactions over time, while solid electrolytes can experience issues related to mechanical stress and potential crack formation during repeated charge-discharge cycles.

Balancing the trade-offs between ionic conductivity, stability, and safety is a key challenge in the development of AIBs. While solid electrolytes offer promising solutions to many of the issues associated with liquid electrolytes, they introduce new challenges that must be addressed. Ongoing research efforts are focused on developing novel materials and architectures that can combine the best properties of both solid and liquid systems, potentially leading to hybrid electrolyte solutions that optimize performance, safety, and longevity in AIBs.

Solid electrolytes, on the other hand, address many of the safety and stability concerns associated with liquid electrolytes. They offer improved thermal stability, reduced risk of leakage, and enhanced mechanical strength. However, solid electrolytes face their own set of challenges, primarily related to ionic conductivity. The ionic conductivity of solid electrolytes is typically lower than that of their liquid counterparts, which can result in reduced battery performance and slower charging rates.

The interface between the solid electrolyte and the electrodes presents another significant challenge. Poor contact at this interface can lead to increased resistance and reduced ion transfer, ultimately affecting the battery's overall performance. Researchers are exploring various strategies to improve this interface, including the development of composite electrolytes and novel electrode designs.

Manufacturability is another crucial aspect to consider when comparing solid and liquid electrolytes. Liquid electrolytes are generally easier to integrate into existing battery production processes, while solid electrolytes often require more complex manufacturing techniques. This can impact the scalability and cost-effectiveness of AIBs with solid electrolytes.

The long-term stability of both electrolyte systems remains a concern. Liquid electrolytes may suffer from gradual degradation and side reactions over time, while solid electrolytes can experience issues related to mechanical stress and potential crack formation during repeated charge-discharge cycles.

Balancing the trade-offs between ionic conductivity, stability, and safety is a key challenge in the development of AIBs. While solid electrolytes offer promising solutions to many of the issues associated with liquid electrolytes, they introduce new challenges that must be addressed. Ongoing research efforts are focused on developing novel materials and architectures that can combine the best properties of both solid and liquid systems, potentially leading to hybrid electrolyte solutions that optimize performance, safety, and longevity in AIBs.

Current Electrolyte Solutions

01 Ionic liquid electrolytes for AIBs

Ionic liquids are used as electrolytes in aluminum-ion batteries due to their high ionic conductivity, wide electrochemical window, and thermal stability. These properties contribute to improved battery performance and safety. Ionic liquids can be tailored to optimize their conductivity and stability for AIB applications.- Ionic liquid electrolytes for AIBs: Ionic liquids are being explored as electrolytes for aluminum-ion batteries due to their high ionic conductivity, wide electrochemical window, and thermal stability. These properties contribute to improved battery performance and safety. Ionic liquids can be tailored to optimize their conductivity and stability for AIB applications.

- Polymer-based electrolytes for AIBs: Polymer-based electrolytes are being developed for aluminum-ion batteries to enhance safety and stability. These electrolytes can provide a solid or gel-like matrix that improves mechanical properties and reduces the risk of leakage. Some polymer electrolytes also offer improved ionic conductivity and electrochemical stability.

- Composite electrolytes for enhanced performance: Composite electrolytes, combining different materials such as ceramics, polymers, and ionic liquids, are being investigated to achieve a balance between ionic conductivity, stability, and safety in AIBs. These hybrid electrolytes aim to synergize the advantages of different components while mitigating their individual limitations.

- Additives for electrolyte optimization: Various additives are being incorporated into AIB electrolytes to enhance their performance and safety characteristics. These additives can improve ionic conductivity, stabilize the electrode-electrolyte interface, suppress dendrite formation, and enhance the overall electrochemical stability of the battery system.

- Novel electrolyte formulations for high-performance AIBs: Researchers are exploring new electrolyte formulations specifically designed for aluminum-ion batteries. These formulations focus on optimizing the composition and concentration of aluminum salts, solvents, and supporting electrolytes to achieve high ionic conductivity, wide electrochemical windows, and improved stability at the electrode-electrolyte interface.

02 Polymer-based electrolytes for AIBs

Polymer-based electrolytes are explored for AIBs to enhance safety and stability. These electrolytes can be in the form of gel polymer electrolytes or solid polymer electrolytes. They offer advantages such as improved mechanical strength, reduced leakage risk, and better interfacial stability with electrodes.Expand Specific Solutions03 Additives for electrolyte enhancement

Various additives are incorporated into AIB electrolytes to improve their performance and safety. These additives can enhance ionic conductivity, stabilize the electrode-electrolyte interface, suppress aluminum corrosion, and improve the overall electrochemical stability of the battery system.Expand Specific Solutions04 Novel electrolyte compositions for AIBs

Research focuses on developing new electrolyte compositions specifically designed for AIBs. These compositions aim to address the unique challenges of aluminum-ion chemistry, such as aluminum deposition/stripping efficiency and cathode material compatibility. Novel electrolytes may include mixtures of organic solvents, ionic liquids, and inorganic salts.Expand Specific Solutions05 Safety features in AIB electrolyte design

Safety considerations are paramount in AIB electrolyte design. Approaches include developing non-flammable or flame-retardant electrolytes, incorporating shutdown mechanisms to prevent thermal runaway, and optimizing electrolyte composition to minimize gas generation and electrode corrosion under abuse conditions.Expand Specific Solutions

Key AIB Electrolyte Players

The competition landscape for solid vs liquid electrolytes in aluminum-ion batteries (AIBs) is evolving rapidly, reflecting the early stage of development in this field. The market size is still relatively small but growing, driven by increasing demand for safer and more efficient energy storage solutions. Technologically, liquid electrolytes are more mature, while solid electrolytes are emerging as a promising alternative. Companies like Samsung SDI, Corning, and Nissan are investing in research and development of both electrolyte types, with a focus on improving ionic conductivity, stability, and safety. Academic institutions such as Northwestern University and the University of Chinese Academy of Sciences are also contributing significantly to advancing the fundamental understanding and practical applications of these technologies.

Northwestern University

Technical Solution: Northwestern University has developed a hybrid solid-liquid electrolyte system for aluminum-ion batteries (AIBs). This approach combines the high ionic conductivity of liquid electrolytes with the improved safety and stability of solid electrolytes. The university's research team has created a gel polymer electrolyte using a cross-linked polyethylene oxide (PEO) matrix infused with an aluminum chloride-based ionic liquid[1]. This hybrid electrolyte demonstrates enhanced aluminum ion transport while maintaining mechanical stability. The team has also explored the use of ceramic fillers to further improve the electrolyte's performance and reduce dendrite formation[2].

Strengths: High ionic conductivity, improved safety, and reduced dendrite formation. Weaknesses: Potential challenges in large-scale production and long-term stability under various operating conditions.

Samsung SDI Co., Ltd.

Technical Solution: Samsung SDI has been actively researching solid electrolytes for AIBs, focusing on inorganic solid electrolytes. Their approach involves developing sulfide-based solid electrolytes with high ionic conductivity and stability. The company has made significant progress in optimizing the composition and synthesis methods of these electrolytes to achieve room-temperature ionic conductivities comparable to liquid electrolytes[3]. Samsung SDI has also explored the use of nanocomposite solid electrolytes, combining inorganic particles with polymer matrices to enhance mechanical properties and interfacial stability[4]. Additionally, they have invested in advanced manufacturing techniques to address the challenges of large-scale production of solid electrolytes for AIBs.

Strengths: High ionic conductivity, improved safety, and potential for large-scale production. Weaknesses: Challenges in achieving good electrode-electrolyte contact and managing interfacial resistance.

Ionic Conductivity Innovations

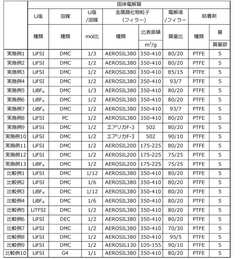

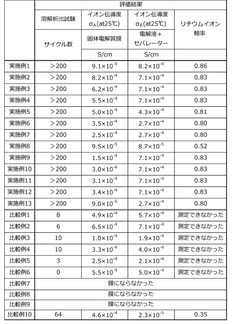

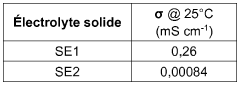

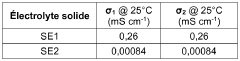

Solid electrolyte and battery

PatentWO2022210774A1

Innovation

- A solid electrolyte comprising a lithium salt, a carbonate-based solvent, and metal oxide particles, with specific molar and mass ratios, and optionally a binder like polytetrafluoroethylene, to enhance lithium ion transport number, ionic conductivity, and stability against lithium metal, while preventing electrolyte leakage and maintaining ionic conductivity.

Solid electrolyte

PatentWO2023052736A1

Innovation

- A solid electrolyte composition comprising zeolite crystals immobilized by a polymer binder, with a specific ratio of zeolite to polymer and an ionic conductor, providing mechanical strength, flexibility, and high ionic conductivity, while being anhydrous and non-flammable, thus preventing leakage and maintaining conductivity and stability across a wide temperature range.

Safety Regulations for AIBs

Safety regulations for Aluminum-Ion Batteries (AIBs) are crucial for ensuring the safe development, production, and use of these emerging energy storage devices. As AIBs continue to evolve, regulatory bodies must adapt existing frameworks and create new guidelines to address the unique characteristics and potential risks associated with this technology.

One of the primary safety concerns for AIBs is the reactivity of aluminum with water, which can lead to the production of hydrogen gas. This risk necessitates stringent regulations on the design and construction of AIB cells to prevent moisture ingress. Manufacturers must demonstrate compliance with hermetic sealing standards and undergo rigorous testing to ensure the integrity of the battery enclosure under various environmental conditions.

Thermal management is another critical aspect of AIB safety regulations. While AIBs generally have lower thermal runaway risks compared to lithium-ion batteries, regulators still require comprehensive thermal testing and the implementation of adequate heat dissipation mechanisms. This includes establishing temperature thresholds for safe operation and mandating the integration of thermal cut-off devices to prevent overheating.

Electrolyte safety is a key focus area for AIB regulations, particularly given the ongoing debate between solid and liquid electrolytes. For liquid electrolytes, regulations typically address flammability, toxicity, and corrosiveness. Manufacturers must provide detailed safety data sheets and implement appropriate containment measures. Solid electrolytes, while generally considered safer, are subject to regulations concerning their mechanical stability and potential for dendrite formation.

Transportation safety is a significant concern for AIBs, especially during air travel. Regulatory bodies such as the International Air Transport Association (IATA) are developing specific guidelines for the safe shipment of AIBs, considering their unique chemical composition and potential failure modes. These regulations may include restrictions on the state of charge during transport and special packaging requirements.

End-of-life management and recycling regulations for AIBs are also being developed. These guidelines aim to address the environmental impact of AIB disposal and promote the recovery of valuable materials. Manufacturers are increasingly required to implement take-back programs and demonstrate compliance with recycling efficiency standards.

As AIB technology advances, safety regulations will continue to evolve. Ongoing research into failure modes, long-term stability, and potential environmental impacts will inform future regulatory updates. Collaboration between industry stakeholders, research institutions, and regulatory bodies is essential to ensure that safety standards keep pace with technological developments in the field of aluminum-ion batteries.

One of the primary safety concerns for AIBs is the reactivity of aluminum with water, which can lead to the production of hydrogen gas. This risk necessitates stringent regulations on the design and construction of AIB cells to prevent moisture ingress. Manufacturers must demonstrate compliance with hermetic sealing standards and undergo rigorous testing to ensure the integrity of the battery enclosure under various environmental conditions.

Thermal management is another critical aspect of AIB safety regulations. While AIBs generally have lower thermal runaway risks compared to lithium-ion batteries, regulators still require comprehensive thermal testing and the implementation of adequate heat dissipation mechanisms. This includes establishing temperature thresholds for safe operation and mandating the integration of thermal cut-off devices to prevent overheating.

Electrolyte safety is a key focus area for AIB regulations, particularly given the ongoing debate between solid and liquid electrolytes. For liquid electrolytes, regulations typically address flammability, toxicity, and corrosiveness. Manufacturers must provide detailed safety data sheets and implement appropriate containment measures. Solid electrolytes, while generally considered safer, are subject to regulations concerning their mechanical stability and potential for dendrite formation.

Transportation safety is a significant concern for AIBs, especially during air travel. Regulatory bodies such as the International Air Transport Association (IATA) are developing specific guidelines for the safe shipment of AIBs, considering their unique chemical composition and potential failure modes. These regulations may include restrictions on the state of charge during transport and special packaging requirements.

End-of-life management and recycling regulations for AIBs are also being developed. These guidelines aim to address the environmental impact of AIB disposal and promote the recovery of valuable materials. Manufacturers are increasingly required to implement take-back programs and demonstrate compliance with recycling efficiency standards.

As AIB technology advances, safety regulations will continue to evolve. Ongoing research into failure modes, long-term stability, and potential environmental impacts will inform future regulatory updates. Collaboration between industry stakeholders, research institutions, and regulatory bodies is essential to ensure that safety standards keep pace with technological developments in the field of aluminum-ion batteries.

Environmental Impact of AIBs

The environmental impact of Aluminum-Ion Batteries (AIBs) is a crucial consideration in their development and adoption. AIBs offer several potential environmental advantages over traditional lithium-ion batteries, primarily due to the abundance and recyclability of aluminum. The Earth's crust contains approximately 8% aluminum, making it the third most abundant element and significantly more available than lithium.

The production of AIBs generally has a lower environmental footprint compared to lithium-ion batteries. Aluminum extraction and processing are well-established industries with relatively efficient and clean processes. This contrasts with lithium mining, which can have significant environmental impacts, including water depletion and ecosystem disruption in sensitive areas like salt flats.

In terms of recyclability, AIBs show promising potential. Aluminum is one of the most recycled materials globally, with well-established recycling infrastructure. This suggests that end-of-life management for AIBs could be more environmentally friendly than for lithium-ion batteries, which face challenges in recycling due to complex material compositions.

The choice between solid and liquid electrolytes in AIBs also has environmental implications. Solid electrolytes may offer advantages in terms of safety and longevity, potentially reducing the frequency of battery replacement and associated waste. However, the production of some solid electrolytes may involve energy-intensive processes or rare materials, which could offset some environmental benefits.

Liquid electrolytes, while potentially less stable, often use more common and easily recyclable materials. The environmental impact of electrolyte production and disposal should be carefully considered in the overall lifecycle assessment of AIBs.

The energy density and efficiency of AIBs also play a role in their environmental impact. Higher energy density batteries can lead to reduced material use and potentially lower transportation emissions in applications like electric vehicles. The efficiency of charge-discharge cycles affects the overall energy consumption over the battery's lifetime.

Safety considerations, particularly the reduced fire risk of AIBs compared to lithium-ion batteries, have indirect environmental benefits. Safer batteries reduce the risk of environmental contamination from battery fires or explosions, which can release toxic materials into ecosystems.

In conclusion, while AIBs show promise for reduced environmental impact compared to current battery technologies, comprehensive lifecycle assessments are necessary to fully understand their environmental implications. Factors such as raw material sourcing, production processes, use-phase efficiency, and end-of-life management all contribute to the overall environmental footprint of these emerging battery technologies.

The production of AIBs generally has a lower environmental footprint compared to lithium-ion batteries. Aluminum extraction and processing are well-established industries with relatively efficient and clean processes. This contrasts with lithium mining, which can have significant environmental impacts, including water depletion and ecosystem disruption in sensitive areas like salt flats.

In terms of recyclability, AIBs show promising potential. Aluminum is one of the most recycled materials globally, with well-established recycling infrastructure. This suggests that end-of-life management for AIBs could be more environmentally friendly than for lithium-ion batteries, which face challenges in recycling due to complex material compositions.

The choice between solid and liquid electrolytes in AIBs also has environmental implications. Solid electrolytes may offer advantages in terms of safety and longevity, potentially reducing the frequency of battery replacement and associated waste. However, the production of some solid electrolytes may involve energy-intensive processes or rare materials, which could offset some environmental benefits.

Liquid electrolytes, while potentially less stable, often use more common and easily recyclable materials. The environmental impact of electrolyte production and disposal should be carefully considered in the overall lifecycle assessment of AIBs.

The energy density and efficiency of AIBs also play a role in their environmental impact. Higher energy density batteries can lead to reduced material use and potentially lower transportation emissions in applications like electric vehicles. The efficiency of charge-discharge cycles affects the overall energy consumption over the battery's lifetime.

Safety considerations, particularly the reduced fire risk of AIBs compared to lithium-ion batteries, have indirect environmental benefits. Safer batteries reduce the risk of environmental contamination from battery fires or explosions, which can release toxic materials into ecosystems.

In conclusion, while AIBs show promise for reduced environmental impact compared to current battery technologies, comprehensive lifecycle assessments are necessary to fully understand their environmental implications. Factors such as raw material sourcing, production processes, use-phase efficiency, and end-of-life management all contribute to the overall environmental footprint of these emerging battery technologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!