Aluminum Anode Surface Treatments to Improve Cyclability — Lab Protocols

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Aluminum Anode Research Background and Objectives

Aluminum anodes have garnered significant attention in the field of energy storage due to their high theoretical capacity, abundance, and low cost. The evolution of aluminum-based battery technologies has been driven by the increasing demand for high-performance, sustainable energy storage solutions. This research aims to explore and develop innovative surface treatments for aluminum anodes to enhance their cyclability, addressing one of the key challenges in aluminum-based battery systems.

The primary objective of this study is to investigate various surface treatment methods for aluminum anodes and their impact on the electrochemical performance, particularly focusing on improving the cycling stability. By modifying the surface properties of aluminum anodes, we aim to mitigate issues such as parasitic side reactions, dendrite formation, and capacity fading, which have historically limited the practical application of aluminum-based batteries.

The development of aluminum anodes with enhanced cyclability aligns with the broader goals of advancing next-generation energy storage technologies. As the world transitions towards renewable energy sources and electrification of transportation, there is a growing need for batteries that offer higher energy density, longer lifespan, and improved safety compared to current lithium-ion technologies. Aluminum-based batteries have the potential to meet these requirements, making them a promising candidate for future energy storage applications.

This research builds upon previous studies that have demonstrated the potential of aluminum as an anode material in various battery chemistries, including aluminum-ion, aluminum-air, and aluminum-sulfur batteries. While these systems have shown promising initial performance, their widespread adoption has been hindered by rapid capacity decay during cycling. By focusing on surface treatments, we aim to address this critical limitation and unlock the full potential of aluminum anodes.

The scope of this study encompasses a comprehensive exploration of surface modification techniques, including but not limited to chemical etching, electrochemical pre-treatment, protective coatings, and nanostructured surface engineering. Through systematic investigation and optimization of these methods, we seek to establish a fundamental understanding of the relationship between surface properties and electrochemical performance of aluminum anodes.

Furthermore, this research aims to develop standardized lab protocols for surface treatment procedures, enabling reproducible and scalable manufacturing processes. By establishing robust methodologies, we intend to facilitate the translation of laboratory findings into practical applications, paving the way for the commercialization of high-performance aluminum-based energy storage devices.

The primary objective of this study is to investigate various surface treatment methods for aluminum anodes and their impact on the electrochemical performance, particularly focusing on improving the cycling stability. By modifying the surface properties of aluminum anodes, we aim to mitigate issues such as parasitic side reactions, dendrite formation, and capacity fading, which have historically limited the practical application of aluminum-based batteries.

The development of aluminum anodes with enhanced cyclability aligns with the broader goals of advancing next-generation energy storage technologies. As the world transitions towards renewable energy sources and electrification of transportation, there is a growing need for batteries that offer higher energy density, longer lifespan, and improved safety compared to current lithium-ion technologies. Aluminum-based batteries have the potential to meet these requirements, making them a promising candidate for future energy storage applications.

This research builds upon previous studies that have demonstrated the potential of aluminum as an anode material in various battery chemistries, including aluminum-ion, aluminum-air, and aluminum-sulfur batteries. While these systems have shown promising initial performance, their widespread adoption has been hindered by rapid capacity decay during cycling. By focusing on surface treatments, we aim to address this critical limitation and unlock the full potential of aluminum anodes.

The scope of this study encompasses a comprehensive exploration of surface modification techniques, including but not limited to chemical etching, electrochemical pre-treatment, protective coatings, and nanostructured surface engineering. Through systematic investigation and optimization of these methods, we seek to establish a fundamental understanding of the relationship between surface properties and electrochemical performance of aluminum anodes.

Furthermore, this research aims to develop standardized lab protocols for surface treatment procedures, enabling reproducible and scalable manufacturing processes. By establishing robust methodologies, we intend to facilitate the translation of laboratory findings into practical applications, paving the way for the commercialization of high-performance aluminum-based energy storage devices.

Market Analysis for Advanced Battery Technologies

The advanced battery technology market is experiencing significant growth, driven by the increasing demand for electric vehicles, renewable energy storage, and portable electronic devices. The global market for advanced batteries is projected to reach substantial figures in the coming years, with lithium-ion batteries dominating the landscape. However, there is a growing interest in alternative battery chemistries, including aluminum-based batteries, due to their potential for higher energy density, improved safety, and lower costs.

Aluminum-based batteries, particularly those utilizing aluminum anodes, are gaining attention as a promising alternative to lithium-ion batteries. The market for aluminum battery technologies is still in its nascent stage but shows potential for rapid growth. This is primarily due to the abundance of aluminum, its lower cost compared to lithium, and its theoretical capacity to store more energy per gram than lithium.

The demand for improved battery cyclability is a critical factor driving research and development in this field. As the market for electric vehicles and renewable energy storage expands, there is an increasing need for batteries that can withstand thousands of charge-discharge cycles without significant degradation. This requirement is pushing researchers and manufacturers to explore innovative surface treatments for aluminum anodes to enhance their longevity and performance.

The automotive industry is expected to be a major driver for the adoption of advanced battery technologies, including those based on aluminum anodes. As electric vehicle production scales up, manufacturers are seeking battery solutions that offer longer range, faster charging times, and improved safety profiles. Aluminum-based batteries with enhanced cyclability could potentially meet these requirements, making them an attractive option for future electric vehicle designs.

Energy storage for grid applications represents another significant market opportunity for advanced battery technologies. The intermittent nature of renewable energy sources like solar and wind necessitates efficient and durable energy storage solutions. Aluminum-based batteries with improved cyclability could play a crucial role in this sector, providing a cost-effective and reliable means of storing and distributing renewable energy.

Consumer electronics is another key market segment that could benefit from advancements in aluminum anode surface treatments. As portable devices become more powerful and energy-intensive, there is a growing demand for batteries that can deliver higher capacity and longer lifespan. Improved aluminum-based batteries could potentially offer these benefits, leading to longer-lasting smartphones, laptops, and other personal electronic devices.

The market analysis indicates that while lithium-ion batteries currently dominate, there is a clear opportunity for alternative technologies like aluminum-based batteries to gain market share. The success of these technologies will largely depend on the ability to overcome current limitations, particularly in terms of cyclability. Research on aluminum anode surface treatments to improve cyclability is therefore not just a technical pursuit but a response to clear market demands across multiple sectors.

Aluminum-based batteries, particularly those utilizing aluminum anodes, are gaining attention as a promising alternative to lithium-ion batteries. The market for aluminum battery technologies is still in its nascent stage but shows potential for rapid growth. This is primarily due to the abundance of aluminum, its lower cost compared to lithium, and its theoretical capacity to store more energy per gram than lithium.

The demand for improved battery cyclability is a critical factor driving research and development in this field. As the market for electric vehicles and renewable energy storage expands, there is an increasing need for batteries that can withstand thousands of charge-discharge cycles without significant degradation. This requirement is pushing researchers and manufacturers to explore innovative surface treatments for aluminum anodes to enhance their longevity and performance.

The automotive industry is expected to be a major driver for the adoption of advanced battery technologies, including those based on aluminum anodes. As electric vehicle production scales up, manufacturers are seeking battery solutions that offer longer range, faster charging times, and improved safety profiles. Aluminum-based batteries with enhanced cyclability could potentially meet these requirements, making them an attractive option for future electric vehicle designs.

Energy storage for grid applications represents another significant market opportunity for advanced battery technologies. The intermittent nature of renewable energy sources like solar and wind necessitates efficient and durable energy storage solutions. Aluminum-based batteries with improved cyclability could play a crucial role in this sector, providing a cost-effective and reliable means of storing and distributing renewable energy.

Consumer electronics is another key market segment that could benefit from advancements in aluminum anode surface treatments. As portable devices become more powerful and energy-intensive, there is a growing demand for batteries that can deliver higher capacity and longer lifespan. Improved aluminum-based batteries could potentially offer these benefits, leading to longer-lasting smartphones, laptops, and other personal electronic devices.

The market analysis indicates that while lithium-ion batteries currently dominate, there is a clear opportunity for alternative technologies like aluminum-based batteries to gain market share. The success of these technologies will largely depend on the ability to overcome current limitations, particularly in terms of cyclability. Research on aluminum anode surface treatments to improve cyclability is therefore not just a technical pursuit but a response to clear market demands across multiple sectors.

Current Challenges in Aluminum Anode Development

The development of aluminum anodes for rechargeable batteries faces several significant challenges that hinder their widespread adoption and commercialization. One of the primary issues is the high reactivity of aluminum with electrolytes, leading to rapid degradation of the anode surface. This reactivity results in the formation of a passivation layer, which, while initially protective, can grow excessively thick and impede ion transport, ultimately reducing battery performance.

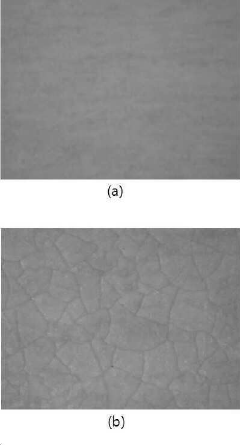

Another major challenge is the volume expansion and contraction of aluminum anodes during charge-discharge cycles. This mechanical stress can cause cracking and pulverization of the anode material, leading to loss of electrical contact and capacity fading over time. The issue is particularly pronounced in high-capacity aluminum anodes, where the volume changes are more significant.

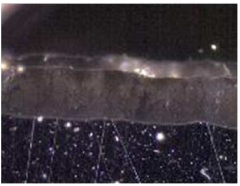

Dendrite formation is also a critical concern in aluminum anode development. During charging, aluminum ions can deposit unevenly on the anode surface, forming needle-like structures that can penetrate the separator and cause short circuits. This not only poses safety risks but also reduces the overall cycle life of the battery.

The choice of electrolyte presents another challenge. Many conventional electrolytes are incompatible with aluminum anodes due to their corrosive nature or inability to form a stable solid electrolyte interphase (SEI) layer. Developing electrolytes that are both stable and conducive to efficient aluminum ion transport remains an ongoing research focus.

Furthermore, the low Coulombic efficiency of aluminum anodes in many electrolyte systems is a significant hurdle. This inefficiency is often due to side reactions and the continuous breakdown and reformation of the SEI layer, leading to capacity loss and reduced cycle life.

The integration of aluminum anodes into full cell configurations presents additional challenges. Matching the aluminum anode with suitable cathode materials and optimizing the overall cell chemistry to achieve high energy density and long cycle life is a complex task that requires extensive research and development efforts.

Lastly, scaling up laboratory-scale aluminum anode technologies to commercial production levels presents its own set of challenges. Issues such as maintaining uniform surface treatments, ensuring consistent performance across large-scale anodes, and developing cost-effective manufacturing processes need to be addressed for successful commercialization.

Another major challenge is the volume expansion and contraction of aluminum anodes during charge-discharge cycles. This mechanical stress can cause cracking and pulverization of the anode material, leading to loss of electrical contact and capacity fading over time. The issue is particularly pronounced in high-capacity aluminum anodes, where the volume changes are more significant.

Dendrite formation is also a critical concern in aluminum anode development. During charging, aluminum ions can deposit unevenly on the anode surface, forming needle-like structures that can penetrate the separator and cause short circuits. This not only poses safety risks but also reduces the overall cycle life of the battery.

The choice of electrolyte presents another challenge. Many conventional electrolytes are incompatible with aluminum anodes due to their corrosive nature or inability to form a stable solid electrolyte interphase (SEI) layer. Developing electrolytes that are both stable and conducive to efficient aluminum ion transport remains an ongoing research focus.

Furthermore, the low Coulombic efficiency of aluminum anodes in many electrolyte systems is a significant hurdle. This inefficiency is often due to side reactions and the continuous breakdown and reformation of the SEI layer, leading to capacity loss and reduced cycle life.

The integration of aluminum anodes into full cell configurations presents additional challenges. Matching the aluminum anode with suitable cathode materials and optimizing the overall cell chemistry to achieve high energy density and long cycle life is a complex task that requires extensive research and development efforts.

Lastly, scaling up laboratory-scale aluminum anode technologies to commercial production levels presents its own set of challenges. Issues such as maintaining uniform surface treatments, ensuring consistent performance across large-scale anodes, and developing cost-effective manufacturing processes need to be addressed for successful commercialization.

Existing Surface Treatment Protocols for Aluminum Anodes

01 Electrolyte composition for improved cyclability

Optimizing the electrolyte composition can significantly enhance the cyclability of aluminum anodes. This may involve using specific salts, solvents, or additives that form a stable solid electrolyte interphase (SEI) layer, reduce side reactions, or improve ion transport. These modifications can lead to better capacity retention and longer cycle life of aluminum-based batteries.- Electrolyte composition for improved cyclability: Specific electrolyte compositions can significantly enhance the cyclability of aluminum anodes. These compositions may include additives or solvents that form a stable passivation layer on the aluminum surface, reducing side reactions and improving overall performance. The electrolyte formulation plays a crucial role in maintaining the anode's structural integrity during repeated charge-discharge cycles.

- Surface modification of aluminum anodes: Various surface modification techniques can be applied to aluminum anodes to improve their cyclability. These may include coatings, chemical treatments, or nanostructuring of the anode surface. Such modifications can enhance the stability of the solid-electrolyte interphase (SEI) layer, reduce parasitic reactions, and improve the overall electrochemical performance of the anode.

- Alloying and composite materials for enhanced stability: Incorporating alloying elements or creating composite materials with aluminum can significantly improve the anode's cyclability. These approaches can help mitigate volume expansion issues, enhance conductivity, and provide better structural stability during cycling. The choice of alloying elements or composite materials is critical in achieving the desired performance improvements.

- Optimized charging protocols and current density control: Developing and implementing optimized charging protocols and controlling current density can greatly impact the cyclability of aluminum anodes. These strategies can help minimize dendrite formation, reduce side reactions, and maintain the anode's structural integrity over multiple cycles. Proper management of charging parameters is essential for extending the anode's lifespan.

- Novel cell designs for improved aluminum anode performance: Innovative cell designs can address specific challenges associated with aluminum anodes, leading to improved cyclability. These designs may include specialized separators, current collectors, or cell architectures that accommodate the unique characteristics of aluminum anodes. Such approaches can help manage issues like volume expansion, electrolyte degradation, and uneven current distribution.

02 Surface modification of aluminum anodes

Modifying the surface of aluminum anodes can improve their cyclability. This may include coating the anode with protective layers, creating nanostructured surfaces, or introducing dopants. These modifications can help prevent unwanted reactions, reduce volume changes during cycling, and enhance the overall stability and performance of the anode.Expand Specific Solutions03 Binder and conductive additive optimization

The choice and optimization of binders and conductive additives play a crucial role in improving the cyclability of aluminum anodes. Appropriate binders can enhance the mechanical stability of the electrode, while conductive additives can improve electron transport. Together, they can help maintain the integrity of the anode structure during repeated charge-discharge cycles.Expand Specific Solutions04 Novel aluminum alloy compositions

Developing new aluminum alloy compositions can enhance the cyclability of aluminum anodes. By incorporating specific elements or compounds into the aluminum matrix, it's possible to improve the mechanical properties, reduce corrosion, and enhance the electrochemical performance of the anode. These alloys can exhibit better stability and longer cycle life compared to pure aluminum.Expand Specific Solutions05 Advanced manufacturing techniques

Employing advanced manufacturing techniques can significantly improve the cyclability of aluminum anodes. These may include novel deposition methods, 3D printing, or other fabrication processes that allow for precise control over the anode structure and composition. Such techniques can lead to anodes with optimized porosity, reduced internal stress, and enhanced overall performance.Expand Specific Solutions

Key Players in Aluminum Battery Research

The research on aluminum anode surface treatments for improved cyclability is in a developing stage, with significant potential for growth in the energy storage sector. The market size is expanding as demand for high-performance batteries increases across various industries. Technologically, the field is progressing rapidly, with companies like Samsung Electronics, Samsung SDI, and Ningde Amperex Technology leading the way in innovation. These firms are investing heavily in R&D to enhance aluminum anode performance, focusing on surface modification techniques to overcome challenges such as electrolyte decomposition and capacity fading. The competitive landscape is intensifying, with both established electronics giants and specialized battery manufacturers vying for market share and technological breakthroughs.

Samsung SDI Co., Ltd.

Technical Solution: Samsung SDI has developed an advanced surface treatment protocol for aluminum anodes in lithium-ion batteries to improve cyclability. Their approach involves a multi-stage process that combines physical and chemical treatments. Initially, the aluminum surface undergoes controlled oxidation to create a thin, uniform oxide layer. This is followed by a proprietary chemical etching process that selectively removes parts of the oxide layer, creating a nanostructured surface with high surface area[5]. Samsung SDI has also implemented a novel doping technique, introducing specific elements into the surface layer to enhance its electrical conductivity and stability[6]. The final stage involves the application of a protective coating using atomic layer deposition (ALD) technology, which forms an ultra-thin, conformal layer that further stabilizes the electrode-electrolyte interface.

Strengths: Highly engineered surface structure, improved conductivity, and enhanced stability. Weaknesses: Complex multi-stage process may increase production costs.

BASF Corp.

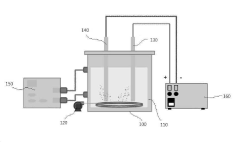

Technical Solution: BASF Corp. has developed an innovative surface treatment protocol for aluminum anodes to enhance the cyclability of lithium-ion batteries. Their approach focuses on creating a hierarchical surface structure through a combination of chemical and electrochemical processes. The treatment begins with a controlled chemical etching using a proprietary solution that selectively dissolves certain areas of the aluminum surface, creating micro-scale features. This is followed by an electrochemical anodization process that generates a nanoporous oxide layer on top of the micro-structured surface[7]. BASF has also incorporated a unique surface functionalization step, where organic molecules are grafted onto the treated surface to further improve the electrode-electrolyte interface stability[8]. This multi-scale surface modification approach significantly enhances the active surface area while providing improved mechanical stability and reduced side reactions.

Strengths: Hierarchical surface structure for optimized performance, improved interface stability. Weaknesses: Potentially time-consuming multi-step process.

Innovative Surface Modification Techniques

Surface treatment method of aluminium material

PatentActiveKR1020170111322A

Innovation

- A surface treatment method using an electrolyte solution of distilled water, citric acid, oxalic acid, and boric acid, with a controlled voltage application process to form a thicker, non-porous oxide film, eliminating the need for a sealing process.

Surface treatment of aluminium

PatentInactiveKR1020200039502A

Innovation

- A surface treatment method using oxalic acid anodizing to enhance the thickness and properties of the oxide film, eliminating the need for post-treatment processes and improving corrosion and thermal shock resistance.

Environmental Impact of Aluminum Battery Production

The environmental impact of aluminum battery production is a crucial consideration in the development and adoption of this emerging technology. As aluminum-based batteries gain traction as a potential alternative to lithium-ion batteries, it is essential to assess their ecological footprint throughout the entire lifecycle, from raw material extraction to manufacturing, use, and disposal.

Aluminum is an abundant element in the Earth's crust, making it a more sustainable option compared to lithium. The extraction and processing of aluminum for battery production generally have a lower environmental impact than lithium mining. However, the energy-intensive nature of aluminum production, particularly the electrolysis process used to refine bauxite ore into pure aluminum, remains a significant concern. This process contributes to greenhouse gas emissions and energy consumption, although advancements in renewable energy integration in aluminum production are helping to mitigate these effects.

The manufacturing of aluminum anodes for batteries involves various surface treatments to improve cyclability and overall performance. These treatments may include chemical etching, electrochemical polishing, or the application of protective coatings. While these processes can enhance battery efficiency and lifespan, they may also introduce additional environmental considerations, such as the use of potentially hazardous chemicals and the generation of waste products that require proper disposal or recycling.

Water usage is another important factor in aluminum battery production. The manufacturing processes, including surface treatments and cooling systems, can consume significant amounts of water. Implementing water recycling and conservation measures in production facilities is crucial to minimize the environmental impact and preserve this valuable resource.

One of the key advantages of aluminum batteries from an environmental perspective is their potential for improved recyclability compared to lithium-ion batteries. Aluminum is highly recyclable, and the infrastructure for aluminum recycling is well-established in many parts of the world. This could lead to a more circular economy approach in battery production, reducing the need for primary raw materials and minimizing waste.

The use phase of aluminum batteries also presents environmental benefits. If the improved cyclability achieved through surface treatments translates to longer battery lifespans, it could reduce the frequency of battery replacements and the associated environmental impacts of production and disposal. Additionally, the higher theoretical energy density of aluminum batteries could lead to more efficient energy storage systems, potentially reducing overall energy consumption in various applications.

End-of-life management for aluminum batteries is an area that requires careful consideration. While the recyclability of aluminum is advantageous, the presence of other materials and components in the battery, including electrolytes and surface treatment residues, may complicate the recycling process. Developing efficient and environmentally friendly recycling technologies specifically tailored to aluminum batteries will be crucial for minimizing their long-term environmental impact.

Aluminum is an abundant element in the Earth's crust, making it a more sustainable option compared to lithium. The extraction and processing of aluminum for battery production generally have a lower environmental impact than lithium mining. However, the energy-intensive nature of aluminum production, particularly the electrolysis process used to refine bauxite ore into pure aluminum, remains a significant concern. This process contributes to greenhouse gas emissions and energy consumption, although advancements in renewable energy integration in aluminum production are helping to mitigate these effects.

The manufacturing of aluminum anodes for batteries involves various surface treatments to improve cyclability and overall performance. These treatments may include chemical etching, electrochemical polishing, or the application of protective coatings. While these processes can enhance battery efficiency and lifespan, they may also introduce additional environmental considerations, such as the use of potentially hazardous chemicals and the generation of waste products that require proper disposal or recycling.

Water usage is another important factor in aluminum battery production. The manufacturing processes, including surface treatments and cooling systems, can consume significant amounts of water. Implementing water recycling and conservation measures in production facilities is crucial to minimize the environmental impact and preserve this valuable resource.

One of the key advantages of aluminum batteries from an environmental perspective is their potential for improved recyclability compared to lithium-ion batteries. Aluminum is highly recyclable, and the infrastructure for aluminum recycling is well-established in many parts of the world. This could lead to a more circular economy approach in battery production, reducing the need for primary raw materials and minimizing waste.

The use phase of aluminum batteries also presents environmental benefits. If the improved cyclability achieved through surface treatments translates to longer battery lifespans, it could reduce the frequency of battery replacements and the associated environmental impacts of production and disposal. Additionally, the higher theoretical energy density of aluminum batteries could lead to more efficient energy storage systems, potentially reducing overall energy consumption in various applications.

End-of-life management for aluminum batteries is an area that requires careful consideration. While the recyclability of aluminum is advantageous, the presence of other materials and components in the battery, including electrolytes and surface treatment residues, may complicate the recycling process. Developing efficient and environmentally friendly recycling technologies specifically tailored to aluminum batteries will be crucial for minimizing their long-term environmental impact.

Safety Considerations in Aluminum Anode Research

Safety considerations are paramount in aluminum anode research due to the reactive nature of aluminum and the potential hazards associated with battery materials. Researchers must prioritize personal protective equipment (PPE) when handling aluminum anodes, including safety goggles, chemical-resistant gloves, and lab coats. Proper ventilation is crucial, as aluminum can react with water to produce hydrogen gas, which is highly flammable. All experiments should be conducted in a fume hood to minimize exposure to potentially harmful fumes or gases.

Fire safety is a critical concern in aluminum anode research. Aluminum powder is highly combustible and can ignite spontaneously in air, especially when finely divided. Researchers must store and handle aluminum materials in inert atmospheres or sealed containers to prevent oxidation and potential fire hazards. Fire extinguishers suitable for metal fires (Class D) should be readily available in the laboratory.

Chemical safety is another vital aspect of aluminum anode research. Many surface treatments involve corrosive or toxic chemicals, such as strong acids or bases. Proper storage, handling, and disposal of these chemicals are essential to prevent accidents and environmental contamination. Material Safety Data Sheets (MSDS) for all chemicals used in the research should be easily accessible, and researchers must be familiar with the specific hazards and emergency procedures for each substance.

Electrical safety is crucial when working with battery materials. Researchers should use insulated tools and equipment to prevent short circuits and electrical shocks. Proper grounding and isolation of electrical components are necessary to minimize the risk of electrocution or equipment damage. When testing aluminum anodes in battery configurations, appropriate safety measures must be in place to prevent thermal runaway or explosion.

Waste management is an often-overlooked aspect of safety in aluminum anode research. Proper disposal of spent anodes, electrolytes, and other battery materials is essential to prevent environmental contamination and comply with regulations. Researchers should establish clear protocols for segregating and disposing of different types of waste, including hazardous materials.

Training and education are fundamental to maintaining a safe research environment. All personnel involved in aluminum anode research should receive comprehensive safety training, including proper handling of materials, emergency procedures, and the use of safety equipment. Regular safety audits and refresher courses can help ensure that all team members remain vigilant and up-to-date on best practices in laboratory safety.

Fire safety is a critical concern in aluminum anode research. Aluminum powder is highly combustible and can ignite spontaneously in air, especially when finely divided. Researchers must store and handle aluminum materials in inert atmospheres or sealed containers to prevent oxidation and potential fire hazards. Fire extinguishers suitable for metal fires (Class D) should be readily available in the laboratory.

Chemical safety is another vital aspect of aluminum anode research. Many surface treatments involve corrosive or toxic chemicals, such as strong acids or bases. Proper storage, handling, and disposal of these chemicals are essential to prevent accidents and environmental contamination. Material Safety Data Sheets (MSDS) for all chemicals used in the research should be easily accessible, and researchers must be familiar with the specific hazards and emergency procedures for each substance.

Electrical safety is crucial when working with battery materials. Researchers should use insulated tools and equipment to prevent short circuits and electrical shocks. Proper grounding and isolation of electrical components are necessary to minimize the risk of electrocution or equipment damage. When testing aluminum anodes in battery configurations, appropriate safety measures must be in place to prevent thermal runaway or explosion.

Waste management is an often-overlooked aspect of safety in aluminum anode research. Proper disposal of spent anodes, electrolytes, and other battery materials is essential to prevent environmental contamination and comply with regulations. Researchers should establish clear protocols for segregating and disposing of different types of waste, including hazardous materials.

Training and education are fundamental to maintaining a safe research environment. All personnel involved in aluminum anode research should receive comprehensive safety training, including proper handling of materials, emergency procedures, and the use of safety equipment. Regular safety audits and refresher courses can help ensure that all team members remain vigilant and up-to-date on best practices in laboratory safety.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!