How to Mitigate Anodic Corrosion in Aluminum Batteries — Coatings and Electrolyte Design

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Al Battery Corrosion Background and Objectives

Aluminum batteries have emerged as a promising alternative to lithium-ion batteries due to their potential for higher energy density, lower cost, and improved safety. However, one of the major challenges hindering their widespread adoption is the issue of anodic corrosion. This phenomenon occurs when the aluminum anode reacts with the electrolyte, leading to degradation of the battery's performance and lifespan.

The development of aluminum batteries can be traced back to the 1850s when the first aluminum-air battery was invented. Since then, research in this field has progressed through various stages, with significant advancements made in recent decades. The current focus is on addressing the corrosion issue, which has been a persistent problem throughout the technology's evolution.

The primary objective of this research is to explore and develop effective strategies to mitigate anodic corrosion in aluminum batteries. This goal encompasses two main approaches: the design of protective coatings for the aluminum anode and the optimization of electrolyte compositions. By addressing these aspects, we aim to enhance the stability and longevity of aluminum batteries, making them more viable for practical applications.

Coatings play a crucial role in protecting the aluminum anode from corrosion. The development of suitable coating materials and techniques is essential for creating a barrier between the anode and the electrolyte while maintaining the battery's electrochemical performance. Various coating materials, such as polymers, ceramics, and composite materials, are being investigated for their potential to reduce corrosion rates and improve overall battery efficiency.

Electrolyte design is equally important in mitigating anodic corrosion. The composition of the electrolyte significantly influences the corrosion behavior of the aluminum anode. Research efforts are focused on developing novel electrolyte formulations that minimize corrosive reactions while maintaining high ionic conductivity and electrochemical stability. This includes exploring different salt combinations, solvents, and additives to create an optimal electrolyte environment.

The technological evolution in this field is driven by the increasing demand for high-performance energy storage solutions. As renewable energy sources become more prevalent and electric vehicles gain popularity, the need for efficient and durable battery technologies continues to grow. Aluminum batteries, with their potential advantages, are positioned to play a significant role in meeting these energy storage demands, provided the corrosion challenge can be effectively addressed.

By achieving the objectives of this research, we anticipate significant advancements in aluminum battery technology. Successful mitigation of anodic corrosion will pave the way for the development of more reliable and long-lasting aluminum batteries, potentially revolutionizing various sectors, including portable electronics, electric vehicles, and grid-scale energy storage systems.

The development of aluminum batteries can be traced back to the 1850s when the first aluminum-air battery was invented. Since then, research in this field has progressed through various stages, with significant advancements made in recent decades. The current focus is on addressing the corrosion issue, which has been a persistent problem throughout the technology's evolution.

The primary objective of this research is to explore and develop effective strategies to mitigate anodic corrosion in aluminum batteries. This goal encompasses two main approaches: the design of protective coatings for the aluminum anode and the optimization of electrolyte compositions. By addressing these aspects, we aim to enhance the stability and longevity of aluminum batteries, making them more viable for practical applications.

Coatings play a crucial role in protecting the aluminum anode from corrosion. The development of suitable coating materials and techniques is essential for creating a barrier between the anode and the electrolyte while maintaining the battery's electrochemical performance. Various coating materials, such as polymers, ceramics, and composite materials, are being investigated for their potential to reduce corrosion rates and improve overall battery efficiency.

Electrolyte design is equally important in mitigating anodic corrosion. The composition of the electrolyte significantly influences the corrosion behavior of the aluminum anode. Research efforts are focused on developing novel electrolyte formulations that minimize corrosive reactions while maintaining high ionic conductivity and electrochemical stability. This includes exploring different salt combinations, solvents, and additives to create an optimal electrolyte environment.

The technological evolution in this field is driven by the increasing demand for high-performance energy storage solutions. As renewable energy sources become more prevalent and electric vehicles gain popularity, the need for efficient and durable battery technologies continues to grow. Aluminum batteries, with their potential advantages, are positioned to play a significant role in meeting these energy storage demands, provided the corrosion challenge can be effectively addressed.

By achieving the objectives of this research, we anticipate significant advancements in aluminum battery technology. Successful mitigation of anodic corrosion will pave the way for the development of more reliable and long-lasting aluminum batteries, potentially revolutionizing various sectors, including portable electronics, electric vehicles, and grid-scale energy storage systems.

Market Demand for Advanced Al Batteries

The market demand for advanced aluminum batteries has been steadily growing in recent years, driven by the increasing need for sustainable and high-performance energy storage solutions. As the world shifts towards renewable energy sources and electrification of transportation, the limitations of current lithium-ion batteries have become more apparent, creating opportunities for alternative technologies like aluminum batteries.

Aluminum batteries offer several advantages that make them attractive for various applications. Their potential for high energy density, low cost, and improved safety compared to lithium-ion batteries have sparked interest from both industry and research communities. The abundance of aluminum as a raw material also contributes to the appeal of this technology, as it addresses concerns about the long-term sustainability of lithium-based energy storage systems.

The automotive sector represents a significant potential market for advanced aluminum batteries. With the rapid growth of electric vehicles (EVs), there is a strong demand for batteries that can offer longer driving ranges, faster charging times, and enhanced safety. Aluminum batteries, with their theoretical capacity to provide higher energy density and faster charging capabilities, could potentially meet these requirements and accelerate the adoption of EVs.

In the renewable energy sector, the need for large-scale energy storage systems to balance grid fluctuations and store excess energy from intermittent sources like solar and wind has created another market opportunity for aluminum batteries. Their potential for long cycle life and high power output makes them suitable for grid-scale applications, where durability and reliability are crucial.

The consumer electronics industry is also showing interest in aluminum battery technology. As devices become more power-hungry and users demand longer battery life, there is a growing need for batteries that can offer higher energy density in compact form factors. Aluminum batteries' potential for improved performance and safety could make them an attractive option for smartphones, laptops, and other portable devices.

However, the market demand for advanced aluminum batteries is currently tempered by the technology's developmental stage. While the potential benefits are significant, challenges such as anodic corrosion need to be overcome to make aluminum batteries commercially viable. The industry is closely watching advancements in coatings and electrolyte design, as these areas are critical for mitigating corrosion issues and improving overall battery performance.

As research progresses and solutions to technical challenges emerge, the market demand for aluminum batteries is expected to grow. Industries and investors are increasingly recognizing the potential of this technology to disrupt the energy storage market and are allocating resources to support its development. The success of aluminum batteries in addressing current limitations could lead to rapid market adoption across multiple sectors, potentially reshaping the energy storage landscape in the coming years.

Aluminum batteries offer several advantages that make them attractive for various applications. Their potential for high energy density, low cost, and improved safety compared to lithium-ion batteries have sparked interest from both industry and research communities. The abundance of aluminum as a raw material also contributes to the appeal of this technology, as it addresses concerns about the long-term sustainability of lithium-based energy storage systems.

The automotive sector represents a significant potential market for advanced aluminum batteries. With the rapid growth of electric vehicles (EVs), there is a strong demand for batteries that can offer longer driving ranges, faster charging times, and enhanced safety. Aluminum batteries, with their theoretical capacity to provide higher energy density and faster charging capabilities, could potentially meet these requirements and accelerate the adoption of EVs.

In the renewable energy sector, the need for large-scale energy storage systems to balance grid fluctuations and store excess energy from intermittent sources like solar and wind has created another market opportunity for aluminum batteries. Their potential for long cycle life and high power output makes them suitable for grid-scale applications, where durability and reliability are crucial.

The consumer electronics industry is also showing interest in aluminum battery technology. As devices become more power-hungry and users demand longer battery life, there is a growing need for batteries that can offer higher energy density in compact form factors. Aluminum batteries' potential for improved performance and safety could make them an attractive option for smartphones, laptops, and other portable devices.

However, the market demand for advanced aluminum batteries is currently tempered by the technology's developmental stage. While the potential benefits are significant, challenges such as anodic corrosion need to be overcome to make aluminum batteries commercially viable. The industry is closely watching advancements in coatings and electrolyte design, as these areas are critical for mitigating corrosion issues and improving overall battery performance.

As research progresses and solutions to technical challenges emerge, the market demand for aluminum batteries is expected to grow. Industries and investors are increasingly recognizing the potential of this technology to disrupt the energy storage market and are allocating resources to support its development. The success of aluminum batteries in addressing current limitations could lead to rapid market adoption across multiple sectors, potentially reshaping the energy storage landscape in the coming years.

Anodic Corrosion Challenges in Al Batteries

Aluminum batteries have emerged as a promising alternative to lithium-ion batteries due to their potential for higher energy density, lower cost, and improved safety. However, one of the major challenges hindering their widespread adoption is anodic corrosion, which significantly impacts the battery's performance and lifespan.

Anodic corrosion in aluminum batteries occurs when the aluminum anode reacts with the electrolyte, leading to the formation of a passivation layer on the anode surface. This layer, while initially protective, can grow excessively thick over time, impeding the flow of ions and electrons. As a result, the battery's capacity and efficiency gradually decrease, ultimately leading to failure.

The severity of anodic corrosion is influenced by several factors, including the composition of the electrolyte, the purity of the aluminum anode, and the operating conditions of the battery. Conventional aqueous electrolytes, for instance, are particularly aggressive towards aluminum, causing rapid corrosion and hydrogen evolution.

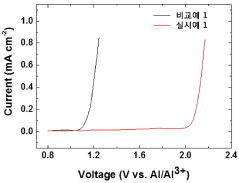

One of the primary challenges in mitigating anodic corrosion is developing electrolytes that are compatible with aluminum while maintaining high ionic conductivity. Researchers have explored various approaches, such as using ionic liquids or deep eutectic solvents as electrolytes. These alternative electrolytes show promise in reducing corrosion rates, but often at the cost of decreased ionic conductivity or increased viscosity.

Another significant challenge lies in designing effective protective coatings for the aluminum anode. While coatings can help reduce direct contact between the aluminum and the electrolyte, they must be carefully engineered to allow for efficient ion transport. Achieving the right balance between protection and functionality remains a complex task.

The dynamic nature of the battery environment further complicates the corrosion mitigation efforts. As the battery cycles through charge and discharge, the anode undergoes repeated expansion and contraction. This mechanical stress can lead to cracking or delamination of protective coatings, exposing fresh aluminum surfaces to corrosion.

Addressing these challenges requires a multidisciplinary approach, combining expertise in materials science, electrochemistry, and surface engineering. Researchers are actively exploring novel electrolyte formulations, advanced coating technologies, and innovative anode designs to overcome the anodic corrosion issue in aluminum batteries.

Anodic corrosion in aluminum batteries occurs when the aluminum anode reacts with the electrolyte, leading to the formation of a passivation layer on the anode surface. This layer, while initially protective, can grow excessively thick over time, impeding the flow of ions and electrons. As a result, the battery's capacity and efficiency gradually decrease, ultimately leading to failure.

The severity of anodic corrosion is influenced by several factors, including the composition of the electrolyte, the purity of the aluminum anode, and the operating conditions of the battery. Conventional aqueous electrolytes, for instance, are particularly aggressive towards aluminum, causing rapid corrosion and hydrogen evolution.

One of the primary challenges in mitigating anodic corrosion is developing electrolytes that are compatible with aluminum while maintaining high ionic conductivity. Researchers have explored various approaches, such as using ionic liquids or deep eutectic solvents as electrolytes. These alternative electrolytes show promise in reducing corrosion rates, but often at the cost of decreased ionic conductivity or increased viscosity.

Another significant challenge lies in designing effective protective coatings for the aluminum anode. While coatings can help reduce direct contact between the aluminum and the electrolyte, they must be carefully engineered to allow for efficient ion transport. Achieving the right balance between protection and functionality remains a complex task.

The dynamic nature of the battery environment further complicates the corrosion mitigation efforts. As the battery cycles through charge and discharge, the anode undergoes repeated expansion and contraction. This mechanical stress can lead to cracking or delamination of protective coatings, exposing fresh aluminum surfaces to corrosion.

Addressing these challenges requires a multidisciplinary approach, combining expertise in materials science, electrochemistry, and surface engineering. Researchers are actively exploring novel electrolyte formulations, advanced coating technologies, and innovative anode designs to overcome the anodic corrosion issue in aluminum batteries.

Current Anodic Corrosion Mitigation Strategies

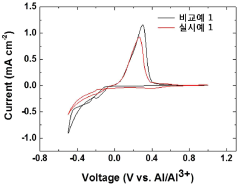

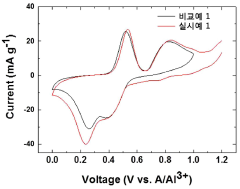

01 Electrolyte composition for reducing anodic corrosion

Specific electrolyte compositions can be used to mitigate anodic corrosion in aluminum batteries. These compositions may include additives or specific salt combinations that form a protective layer on the aluminum anode, reducing corrosion and improving battery performance.- Electrolyte composition for reducing anodic corrosion: Specific electrolyte compositions can be used to mitigate anodic corrosion in aluminum batteries. These compositions may include additives or specific salt combinations that form a protective layer on the aluminum anode, reducing corrosion and improving battery performance.

- Surface treatment of aluminum anodes: Various surface treatment methods can be applied to aluminum anodes to enhance their corrosion resistance. These treatments may involve coating the anode with protective materials or modifying its surface structure to create a more stable interface with the electrolyte.

- Novel anode materials and alloys: Development of new aluminum-based alloys or composite materials for anodes can improve corrosion resistance. These materials may incorporate elements or compounds that enhance the stability of the anode in the battery environment.

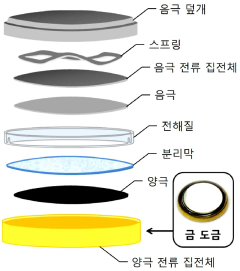

- Battery design and architecture: Innovative battery designs and architectures can help mitigate anodic corrosion. This may include the use of separators, current collectors, or other structural elements that minimize direct contact between the aluminum anode and corrosive components.

- Corrosion inhibitors and additives: Incorporation of specific corrosion inhibitors or additives in the battery system can significantly reduce anodic corrosion. These substances may work by forming protective films on the anode surface or by altering the electrochemical environment to be less corrosive.

02 Surface treatment of aluminum anodes

Various surface treatment methods can be applied to aluminum anodes to enhance their corrosion resistance. These treatments may involve coating the anode with protective materials or modifying its surface structure to create a more stable interface with the electrolyte.Expand Specific Solutions03 Novel anode materials and alloys

Development of new aluminum-based alloys or composite materials for anodes can improve corrosion resistance. These materials may incorporate elements or compounds that enhance the stability of the anode in the battery environment.Expand Specific Solutions04 Battery design and architecture

Innovative battery designs and architectures can help mitigate anodic corrosion. This may include strategies such as using separator materials that reduce direct contact between the anode and corrosive elements, or implementing specific current collector designs.Expand Specific Solutions05 Corrosion inhibitors and additives

Incorporation of specific corrosion inhibitors or additives in the battery system can significantly reduce anodic corrosion. These substances may work by forming protective films on the anode surface or by altering the electrochemical environment to be less corrosive.Expand Specific Solutions

Key Players in Al Battery Technology

The market for mitigating anodic corrosion in aluminum batteries is in its early growth stage, with increasing research and development efforts. The global market size for advanced battery technologies is expanding rapidly, driven by the growing demand for energy storage solutions. While the technology is still evolving, several key players are making significant strides. Companies like Toshiba, GM, Sony, and Samsung are investing in research to improve aluminum battery performance and longevity. Academic institutions such as MIT, Bar-Ilan University, and Northwestern University are contributing to fundamental research in this field. The technology's maturity is progressing, with companies like Phinergy and Molecular Rebar Design focusing on innovative solutions for aluminum-air batteries and nanotechnology applications, respectively.

Massachusetts Institute of Technology

Technical Solution: MIT has developed a novel approach to mitigate anodic corrosion in aluminum batteries through advanced electrolyte design. Their research focuses on using ionic liquid electrolytes with carefully selected anions that form a stable passivation layer on the aluminum anode surface[1]. This protective layer significantly reduces corrosion while maintaining high ionic conductivity. Additionally, MIT researchers have explored the use of additives in the electrolyte, such as fluorinated compounds, which further enhance the stability of the aluminum anode[2]. Their work also includes the development of computational models to predict electrolyte-anode interactions, enabling rapid screening of potential electrolyte compositions for optimal performance[3].

Strengths: Cutting-edge research in electrolyte design, strong focus on fundamental understanding of corrosion mechanisms. Weaknesses: Potential challenges in scaling up laboratory-scale solutions to commercial production.

Dalian Institute of Chemical Physics Chinese Academy of Sci

Technical Solution: The Dalian Institute has made significant advancements in mitigating anodic corrosion in aluminum batteries through innovative coating technologies. Their research has focused on developing ultra-thin, conformal coatings for aluminum anodes using atomic layer deposition (ALD) techniques[7]. These coatings, typically composed of metal oxides or nitrides, provide excellent protection against corrosion while maintaining high ionic conductivity. The institute has also explored the use of graphene-based coatings, which offer superior mechanical flexibility and chemical stability[8]. In addition to coatings, their work extends to electrolyte design, where they have investigated the use of deep eutectic solvents as a novel class of electrolytes that can suppress aluminum corrosion while enhancing overall battery performance[9].

Strengths: Expertise in advanced coating technologies and novel electrolyte systems. Weaknesses: Potential challenges in cost-effective large-scale production of specialized coatings.

Innovative Coatings and Electrolyte Designs

Aluminum secondary battery

PatentInactiveJP2016213101A

Innovation

- Incorporating a non-aqueous electrolyte with controlled water content (≤1000 ppm) containing aluminum complex ions or complexes and ionic liquids, along with specific chelate ligands, to suppress the formation of hydrogen halides and hydrohalic acids, thereby preventing corrosion and maintaining reaction efficiency.

Aluminum battery including cathode current device coated with noble metal

PatentInactiveKR1020160139754A

Innovation

- Coating the cathode current collector with a noble metal having low reactivity with the electrolyte, such as gold, platinum, or alloys thereof, to prevent corrosion and enhance electrochemical efficiency.

Environmental Impact of Al Battery Materials

The environmental impact of aluminum battery materials is a crucial consideration in the development and adoption of this emerging energy storage technology. Aluminum batteries offer several potential advantages over traditional lithium-ion batteries, including higher energy density, lower cost, and improved safety. However, the production, use, and disposal of aluminum battery materials also present environmental challenges that must be carefully addressed.

The extraction and processing of aluminum for battery production can have significant environmental consequences. Bauxite mining, the primary source of aluminum, often involves large-scale land disturbance and habitat destruction. The refining process to produce aluminum from bauxite is energy-intensive, contributing to greenhouse gas emissions if not powered by renewable energy sources. However, aluminum's high recyclability potential can help mitigate some of these impacts in the long term.

The electrolyte used in aluminum batteries also raises environmental concerns. Many current designs utilize ionic liquids or deep eutectic solvents, which may pose toxicity risks if released into the environment. Research into more environmentally benign electrolyte formulations is ongoing, with a focus on biodegradable and less toxic alternatives. The development of safer, more sustainable electrolytes is crucial for minimizing the potential environmental impact of aluminum batteries throughout their lifecycle.

Corrosion mitigation strategies, such as protective coatings and electrolyte additives, may introduce additional environmental considerations. While these approaches aim to extend battery life and improve performance, the materials used in coatings or additives must be evaluated for their environmental impact. Ideally, these materials should be non-toxic, recyclable, and produced through environmentally responsible processes.

End-of-life management and recycling of aluminum batteries present both challenges and opportunities. The high recyclability of aluminum offers the potential for a closed-loop system, reducing the need for primary aluminum production. However, effective recycling processes must be developed to separate and recover the various components of aluminum batteries, including the electrolyte and any protective coatings or additives.

As aluminum battery technology advances, life cycle assessments (LCAs) will be crucial in quantifying and comparing their environmental impact to other energy storage solutions. These assessments should consider factors such as raw material extraction, manufacturing processes, use-phase efficiency, and end-of-life management. By identifying areas of concern and opportunities for improvement, LCAs can guide the development of more environmentally sustainable aluminum battery technologies.

The extraction and processing of aluminum for battery production can have significant environmental consequences. Bauxite mining, the primary source of aluminum, often involves large-scale land disturbance and habitat destruction. The refining process to produce aluminum from bauxite is energy-intensive, contributing to greenhouse gas emissions if not powered by renewable energy sources. However, aluminum's high recyclability potential can help mitigate some of these impacts in the long term.

The electrolyte used in aluminum batteries also raises environmental concerns. Many current designs utilize ionic liquids or deep eutectic solvents, which may pose toxicity risks if released into the environment. Research into more environmentally benign electrolyte formulations is ongoing, with a focus on biodegradable and less toxic alternatives. The development of safer, more sustainable electrolytes is crucial for minimizing the potential environmental impact of aluminum batteries throughout their lifecycle.

Corrosion mitigation strategies, such as protective coatings and electrolyte additives, may introduce additional environmental considerations. While these approaches aim to extend battery life and improve performance, the materials used in coatings or additives must be evaluated for their environmental impact. Ideally, these materials should be non-toxic, recyclable, and produced through environmentally responsible processes.

End-of-life management and recycling of aluminum batteries present both challenges and opportunities. The high recyclability of aluminum offers the potential for a closed-loop system, reducing the need for primary aluminum production. However, effective recycling processes must be developed to separate and recover the various components of aluminum batteries, including the electrolyte and any protective coatings or additives.

As aluminum battery technology advances, life cycle assessments (LCAs) will be crucial in quantifying and comparing their environmental impact to other energy storage solutions. These assessments should consider factors such as raw material extraction, manufacturing processes, use-phase efficiency, and end-of-life management. By identifying areas of concern and opportunities for improvement, LCAs can guide the development of more environmentally sustainable aluminum battery technologies.

Safety Regulations for Al Battery Technologies

Safety regulations for aluminum battery technologies are crucial for ensuring the safe development, production, and use of these emerging energy storage systems. The primary focus of these regulations is to address the potential risks associated with anodic corrosion, which is a significant challenge in aluminum batteries.

One of the key aspects of safety regulations is the requirement for robust protective coatings on aluminum anodes. These coatings must be designed to effectively mitigate corrosion while maintaining the battery's performance. Regulatory bodies often specify minimum standards for coating materials, thickness, and durability to ensure long-term protection against corrosion.

Electrolyte design is another critical area covered by safety regulations. The composition and properties of the electrolyte must be carefully controlled to minimize its corrosive effects on the aluminum anode. Regulations typically mandate the use of specific electrolyte formulations that have been proven to reduce corrosion rates without compromising battery efficiency.

Safety standards also address the need for advanced monitoring systems in aluminum batteries. These systems are required to detect early signs of corrosion and prevent potential safety hazards. Regulations often specify the types of sensors and monitoring equipment that must be integrated into battery designs to ensure real-time detection of corrosion-related issues.

Furthermore, safety regulations for aluminum battery technologies encompass stringent testing protocols. These protocols are designed to evaluate the effectiveness of corrosion mitigation strategies under various operating conditions. Manufacturers are required to conduct extensive testing to demonstrate compliance with safety standards before their products can be approved for commercial use.

Disposal and recycling regulations are also an essential component of the safety framework for aluminum batteries. These regulations aim to minimize environmental impact and ensure the safe handling of used batteries, particularly those affected by corrosion. Manufacturers are often required to implement recycling programs and provide clear guidelines for the proper disposal of aluminum battery components.

In addition to product-specific regulations, safety standards also extend to manufacturing processes. Facilities producing aluminum batteries must adhere to strict guidelines regarding the handling and storage of materials, as well as the implementation of quality control measures to prevent corrosion-related defects during production.

As aluminum battery technology continues to evolve, safety regulations are regularly updated to address new challenges and incorporate the latest research findings. This ongoing process ensures that safety standards remain relevant and effective in mitigating the risks associated with anodic corrosion in aluminum batteries.

One of the key aspects of safety regulations is the requirement for robust protective coatings on aluminum anodes. These coatings must be designed to effectively mitigate corrosion while maintaining the battery's performance. Regulatory bodies often specify minimum standards for coating materials, thickness, and durability to ensure long-term protection against corrosion.

Electrolyte design is another critical area covered by safety regulations. The composition and properties of the electrolyte must be carefully controlled to minimize its corrosive effects on the aluminum anode. Regulations typically mandate the use of specific electrolyte formulations that have been proven to reduce corrosion rates without compromising battery efficiency.

Safety standards also address the need for advanced monitoring systems in aluminum batteries. These systems are required to detect early signs of corrosion and prevent potential safety hazards. Regulations often specify the types of sensors and monitoring equipment that must be integrated into battery designs to ensure real-time detection of corrosion-related issues.

Furthermore, safety regulations for aluminum battery technologies encompass stringent testing protocols. These protocols are designed to evaluate the effectiveness of corrosion mitigation strategies under various operating conditions. Manufacturers are required to conduct extensive testing to demonstrate compliance with safety standards before their products can be approved for commercial use.

Disposal and recycling regulations are also an essential component of the safety framework for aluminum batteries. These regulations aim to minimize environmental impact and ensure the safe handling of used batteries, particularly those affected by corrosion. Manufacturers are often required to implement recycling programs and provide clear guidelines for the proper disposal of aluminum battery components.

In addition to product-specific regulations, safety standards also extend to manufacturing processes. Facilities producing aluminum batteries must adhere to strict guidelines regarding the handling and storage of materials, as well as the implementation of quality control measures to prevent corrosion-related defects during production.

As aluminum battery technology continues to evolve, safety regulations are regularly updated to address new challenges and incorporate the latest research findings. This ongoing process ensures that safety standards remain relevant and effective in mitigating the risks associated with anodic corrosion in aluminum batteries.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!