How to Scale AIB Material Synthesis: Powder Quality and Electrode Coating Guidelines

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

AIB Material Synthesis Background and Objectives

Aluminum-ion batteries (AIBs) have emerged as a promising alternative to lithium-ion batteries, offering potential advantages in terms of safety, cost, and environmental impact. The development of AIB technology has gained significant momentum in recent years, driven by the growing demand for sustainable energy storage solutions. The primary objective of scaling AIB material synthesis is to address the challenges associated with large-scale production while maintaining high-quality standards for powder materials and electrode coatings.

The evolution of AIB technology can be traced back to the early 2000s when researchers began exploring aluminum as a potential electrode material. Since then, significant progress has been made in understanding the electrochemistry of aluminum-ion systems and developing suitable electrode materials and electrolytes. The current focus is on overcoming the limitations of existing materials and processes to enable commercial-scale production of AIBs.

One of the key technical goals in scaling AIB material synthesis is to develop efficient and reproducible methods for producing high-quality cathode and anode materials. This involves optimizing particle size, morphology, and composition to enhance the electrochemical performance of the batteries. Additionally, researchers aim to improve the stability and conductivity of electrolytes to facilitate faster ion transport and longer cycle life.

Another critical objective is to establish guidelines for electrode coating that ensure uniform distribution of active materials and optimal adhesion to current collectors. This is essential for maximizing the energy density and power output of AIBs while maintaining mechanical integrity during cycling. Researchers are exploring various coating techniques and binder formulations to achieve these goals.

The scaling of AIB material synthesis also aims to address environmental and economic considerations. This includes developing sustainable sourcing strategies for raw materials, minimizing waste generation during production, and reducing energy consumption in manufacturing processes. By focusing on these aspects, researchers hope to position AIBs as a viable and eco-friendly alternative to existing battery technologies.

As the field progresses, there is a growing emphasis on interdisciplinary collaboration to tackle the multifaceted challenges of scaling AIB technology. This involves combining expertise from materials science, electrochemistry, chemical engineering, and manufacturing to develop integrated solutions for large-scale production. The ultimate goal is to establish a robust and scalable manufacturing ecosystem for AIBs that can meet the increasing demand for advanced energy storage systems in various applications, from portable electronics to grid-scale storage.

The evolution of AIB technology can be traced back to the early 2000s when researchers began exploring aluminum as a potential electrode material. Since then, significant progress has been made in understanding the electrochemistry of aluminum-ion systems and developing suitable electrode materials and electrolytes. The current focus is on overcoming the limitations of existing materials and processes to enable commercial-scale production of AIBs.

One of the key technical goals in scaling AIB material synthesis is to develop efficient and reproducible methods for producing high-quality cathode and anode materials. This involves optimizing particle size, morphology, and composition to enhance the electrochemical performance of the batteries. Additionally, researchers aim to improve the stability and conductivity of electrolytes to facilitate faster ion transport and longer cycle life.

Another critical objective is to establish guidelines for electrode coating that ensure uniform distribution of active materials and optimal adhesion to current collectors. This is essential for maximizing the energy density and power output of AIBs while maintaining mechanical integrity during cycling. Researchers are exploring various coating techniques and binder formulations to achieve these goals.

The scaling of AIB material synthesis also aims to address environmental and economic considerations. This includes developing sustainable sourcing strategies for raw materials, minimizing waste generation during production, and reducing energy consumption in manufacturing processes. By focusing on these aspects, researchers hope to position AIBs as a viable and eco-friendly alternative to existing battery technologies.

As the field progresses, there is a growing emphasis on interdisciplinary collaboration to tackle the multifaceted challenges of scaling AIB technology. This involves combining expertise from materials science, electrochemistry, chemical engineering, and manufacturing to develop integrated solutions for large-scale production. The ultimate goal is to establish a robust and scalable manufacturing ecosystem for AIBs that can meet the increasing demand for advanced energy storage systems in various applications, from portable electronics to grid-scale storage.

Market Analysis for AIB Materials

The market for aluminum-ion battery (AIB) materials is experiencing significant growth as the demand for sustainable and high-performance energy storage solutions continues to rise. The global push towards electrification and renewable energy integration has created a fertile ground for AIB technology to flourish. Currently, the AIB materials market is in its nascent stage but shows promising potential for rapid expansion in the coming years.

Key drivers of market growth include the increasing adoption of electric vehicles, the need for grid-scale energy storage systems, and the growing consumer electronics sector. AIB materials offer several advantages over traditional lithium-ion batteries, such as faster charging rates, improved safety, and potentially lower costs, which are attracting attention from various industries.

The market for AIB materials can be segmented into cathode materials, anode materials, and electrolytes. Among these, cathode materials are expected to hold the largest market share due to their critical role in determining battery performance and cost. Graphite and other carbon-based materials are emerging as popular choices for anodes in AIBs, while research into novel electrolyte compositions is ongoing to enhance overall battery efficiency.

Geographically, Asia-Pacific is anticipated to dominate the AIB materials market, with China leading in both production and consumption. This is primarily due to the region's strong presence in the battery manufacturing industry and government initiatives supporting the development of advanced energy storage technologies. North America and Europe are also expected to witness substantial growth in the AIB materials market, driven by increasing investments in renewable energy and electric vehicle infrastructure.

The competitive landscape of the AIB materials market is characterized by a mix of established battery material manufacturers and innovative startups. Major players are investing heavily in research and development to improve material synthesis techniques and scale up production capabilities. Collaborations between material suppliers, battery manufacturers, and end-users are becoming increasingly common to accelerate the commercialization of AIB technology.

Despite the promising outlook, challenges remain in scaling up AIB material synthesis while maintaining powder quality and optimizing electrode coating processes. Overcoming these hurdles is crucial for the widespread adoption of AIB technology and the realization of its full market potential. As research progresses and manufacturing processes improve, the AIB materials market is expected to witness substantial growth, potentially disrupting the current energy storage landscape.

Key drivers of market growth include the increasing adoption of electric vehicles, the need for grid-scale energy storage systems, and the growing consumer electronics sector. AIB materials offer several advantages over traditional lithium-ion batteries, such as faster charging rates, improved safety, and potentially lower costs, which are attracting attention from various industries.

The market for AIB materials can be segmented into cathode materials, anode materials, and electrolytes. Among these, cathode materials are expected to hold the largest market share due to their critical role in determining battery performance and cost. Graphite and other carbon-based materials are emerging as popular choices for anodes in AIBs, while research into novel electrolyte compositions is ongoing to enhance overall battery efficiency.

Geographically, Asia-Pacific is anticipated to dominate the AIB materials market, with China leading in both production and consumption. This is primarily due to the region's strong presence in the battery manufacturing industry and government initiatives supporting the development of advanced energy storage technologies. North America and Europe are also expected to witness substantial growth in the AIB materials market, driven by increasing investments in renewable energy and electric vehicle infrastructure.

The competitive landscape of the AIB materials market is characterized by a mix of established battery material manufacturers and innovative startups. Major players are investing heavily in research and development to improve material synthesis techniques and scale up production capabilities. Collaborations between material suppliers, battery manufacturers, and end-users are becoming increasingly common to accelerate the commercialization of AIB technology.

Despite the promising outlook, challenges remain in scaling up AIB material synthesis while maintaining powder quality and optimizing electrode coating processes. Overcoming these hurdles is crucial for the widespread adoption of AIB technology and the realization of its full market potential. As research progresses and manufacturing processes improve, the AIB materials market is expected to witness substantial growth, potentially disrupting the current energy storage landscape.

Current Challenges in AIB Powder Synthesis

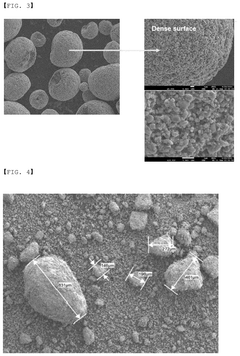

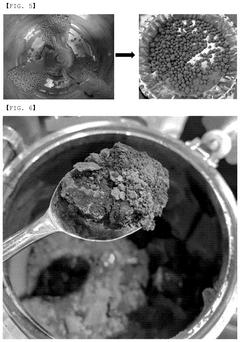

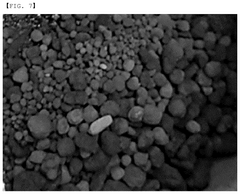

The synthesis of high-quality AIB (Aluminum-Ion Battery) powder materials presents several significant challenges that hinder the large-scale production and commercialization of AIB technology. One of the primary issues is achieving consistent particle size distribution and morphology. The performance of AIB electrodes heavily depends on the uniformity of the active material particles, which directly impacts the battery's capacity, rate capability, and cycle life.

Another major challenge lies in controlling the chemical composition and purity of the synthesized powders. Impurities and defects in the crystal structure can significantly affect the electrochemical properties of the materials, leading to reduced battery performance and reliability. The presence of unwanted phases or contaminants can also lead to side reactions during battery operation, potentially compromising safety and longevity.

Scalability of the synthesis process itself poses a considerable hurdle. Many laboratory-scale methods for producing AIB materials are not easily transferable to industrial-scale production. Issues such as heat and mass transfer limitations, reaction kinetics, and process control become more pronounced as the production volume increases. This scaling challenge often results in compromised material quality or increased production costs.

The environmental impact and sustainability of AIB powder synthesis methods are also growing concerns. Many current synthesis routes involve the use of hazardous chemicals, high-energy processes, or rare elements. Developing greener, more sustainable synthesis methods that maintain or improve material quality while reducing environmental footprint is a critical challenge facing researchers and manufacturers.

Stability and shelf life of the synthesized powders present another significant challenge. AIB materials, particularly those based on organic compounds or sensitive to moisture and oxygen, may degrade over time or during storage. This instability can lead to inconsistent battery performance and reduced product reliability, necessitating the development of more robust materials or advanced packaging and storage solutions.

Lastly, the cost-effectiveness of AIB powder synthesis remains a major hurdle for widespread adoption. Current production methods often involve expensive precursors, complex processes, or energy-intensive steps. Balancing the trade-offs between material quality, production costs, and scalability is crucial for the commercial viability of AIB technology. Overcoming these challenges requires innovative approaches to material design, process optimization, and manufacturing techniques.

Another major challenge lies in controlling the chemical composition and purity of the synthesized powders. Impurities and defects in the crystal structure can significantly affect the electrochemical properties of the materials, leading to reduced battery performance and reliability. The presence of unwanted phases or contaminants can also lead to side reactions during battery operation, potentially compromising safety and longevity.

Scalability of the synthesis process itself poses a considerable hurdle. Many laboratory-scale methods for producing AIB materials are not easily transferable to industrial-scale production. Issues such as heat and mass transfer limitations, reaction kinetics, and process control become more pronounced as the production volume increases. This scaling challenge often results in compromised material quality or increased production costs.

The environmental impact and sustainability of AIB powder synthesis methods are also growing concerns. Many current synthesis routes involve the use of hazardous chemicals, high-energy processes, or rare elements. Developing greener, more sustainable synthesis methods that maintain or improve material quality while reducing environmental footprint is a critical challenge facing researchers and manufacturers.

Stability and shelf life of the synthesized powders present another significant challenge. AIB materials, particularly those based on organic compounds or sensitive to moisture and oxygen, may degrade over time or during storage. This instability can lead to inconsistent battery performance and reduced product reliability, necessitating the development of more robust materials or advanced packaging and storage solutions.

Lastly, the cost-effectiveness of AIB powder synthesis remains a major hurdle for widespread adoption. Current production methods often involve expensive precursors, complex processes, or energy-intensive steps. Balancing the trade-offs between material quality, production costs, and scalability is crucial for the commercial viability of AIB technology. Overcoming these challenges requires innovative approaches to material design, process optimization, and manufacturing techniques.

Existing AIB Powder Synthesis Methods

01 AIB material synthesis for improved powder quality

Advanced synthesis methods for AIB (Aluminum-Ion Battery) materials are developed to enhance powder quality. These techniques focus on controlling particle size, morphology, and composition to optimize the performance of electrode materials. Improved powder quality leads to better electrochemical properties and increased battery efficiency.- AIB material synthesis methods: Various methods for synthesizing AIB (Aluminum-Ion Battery) materials are explored, focusing on improving powder quality for electrode applications. These methods may include sol-gel processes, hydrothermal synthesis, or solid-state reactions to produce high-quality AIB materials with controlled particle size and morphology.

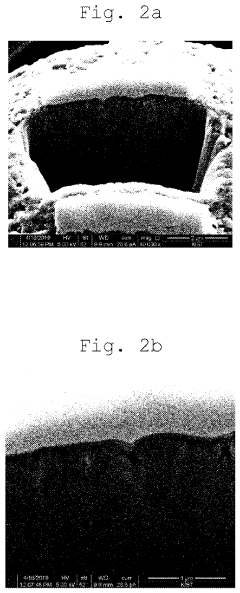

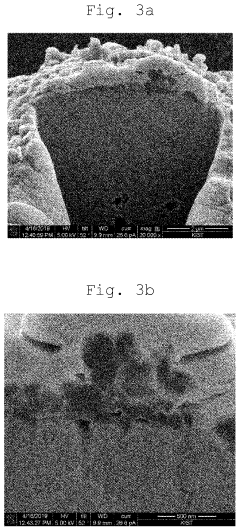

- Powder quality control techniques: Techniques for controlling and enhancing the quality of AIB material powders are discussed. These may include particle size distribution analysis, surface area measurements, and purity assessments. Advanced characterization methods such as X-ray diffraction and electron microscopy are employed to ensure optimal powder properties for electrode coating.

- Electrode coating processes: Various electrode coating processes for AIB materials are examined, including slurry preparation, coating techniques, and drying methods. The focus is on achieving uniform and adherent coatings with optimal thickness and porosity to enhance battery performance. Advanced coating technologies such as spray coating or doctor blade methods may be utilized.

- Binder and additive optimization: The role of binders and additives in improving electrode coating quality is explored. This includes the selection of appropriate binder materials, conductive additives, and dispersants to enhance the adhesion, conductivity, and stability of the electrode coating. The optimization of binder-to-active material ratios and additive concentrations is crucial for achieving high-performance AIB electrodes.

- Post-coating treatments: Various post-coating treatments are investigated to further enhance the quality and performance of AIB electrodes. These may include calendering processes to control electrode density, thermal treatments to improve adhesion and conductivity, or surface modifications to enhance electrolyte wetting and ion transport properties.

02 Electrode coating techniques for AIB materials

Various coating methods are employed to apply AIB materials onto electrode substrates. These techniques aim to create uniform and stable coatings, enhancing the electrode's performance and durability. Specialized binders and additives are used to improve adhesion and conductivity of the coated layer.Expand Specific Solutions03 Quality control measures for AIB powder production

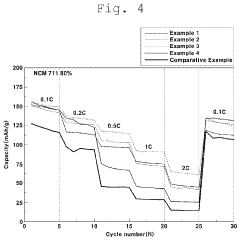

Stringent quality control processes are implemented throughout the AIB powder production. These include in-line monitoring systems, advanced characterization techniques, and standardized testing protocols to ensure consistent powder properties. Quality control measures help maintain the reliability and performance of the final battery products.Expand Specific Solutions04 Optimization of electrode composition for AIB performance

Research focuses on optimizing the composition of AIB electrodes to enhance overall battery performance. This includes adjusting the ratios of active materials, conductive additives, and binders. The optimized composition aims to improve capacity, cycling stability, and rate capability of the batteries.Expand Specific Solutions05 Novel AIB materials for enhanced electrochemical properties

Development of new AIB materials with improved electrochemical properties is ongoing. These materials are designed to offer higher energy density, faster charging rates, and longer cycle life. Research includes exploring new chemical compositions and nanostructured materials to push the boundaries of AIB technology.Expand Specific Solutions

Key Players in AIB Material Industry

The AIB material synthesis market is in a growth phase, with increasing demand driven by advancements in battery technology. The market size is expanding rapidly, fueled by the electric vehicle revolution and energy storage applications. Technologically, AIB material synthesis is progressing, but challenges remain in scaling production while maintaining powder quality and optimizing electrode coating processes. Key players like Evonik Operations, Resonac Holdings, and Sika Technology are investing heavily in R&D to overcome these hurdles. Universities such as Xi'an University of Technology and Jiangsu University are contributing valuable research. While the technology shows promise, further innovations are needed to achieve large-scale commercial viability and meet industry standards for powder quality and electrode performance.

Evonik Operations GmbH

Technical Solution: Evonik has developed a proprietary AIB (Aluminum-Ion Battery) material synthesis process that focuses on optimizing powder quality and electrode coating. Their approach involves a controlled precipitation method to produce high-purity AIB cathode materials with uniform particle size distribution[1]. The company utilizes advanced milling techniques to achieve optimal particle morphology, enhancing the material's electrochemical performance[2]. Evonik's electrode coating process incorporates a specially formulated binder system that improves adhesion and conductivity while maintaining flexibility[3]. They have also implemented a quality control system using in-line particle size analysis and X-ray diffraction to ensure consistent powder characteristics throughout the production process[4].

Strengths: High-quality powder production, advanced coating techniques, and robust quality control. Weaknesses: Potentially higher production costs due to specialized processes and equipment.

Resonac Holdings Corp.

Technical Solution: Resonac Holdings has developed a scalable AIB material synthesis method focusing on high-performance cathode materials. Their process utilizes a hydrothermal synthesis approach to create nanostructured AIB cathode materials with enhanced ionic conductivity[1]. The company has implemented a continuous flow reactor system for large-scale production, ensuring consistent quality and reducing batch-to-batch variations[2]. Resonac's electrode coating technology incorporates a gradient porosity design, optimizing electrolyte penetration and ion transport within the electrode structure[3]. They have also developed a proprietary surface modification technique to improve the interface between the active material and the electrolyte, enhancing overall battery performance[4].

Strengths: Scalable production process, innovative electrode design, and improved material-electrolyte interface. Weaknesses: Potential challenges in maintaining nanostructure integrity during large-scale production.

Innovations in AIB Powder Quality Control

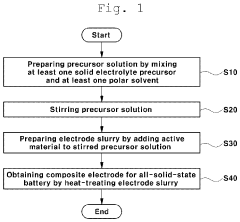

Method of manufacturing composite electrode for all-solid-state battery, and composite electrode for all-solid-state battery manufactured thereby

PatentActiveUS20240097119A1

Innovation

- A method involving mixing a solid electrolyte precursor with a polar solvent to create a precursor solution, stirring, and adding an active material to form an electrode slurry, followed by heat treatment, which synthesizes a solid electrolyte and forms a coating layer on the active material, allowing for flexible electrolyte composition and improved processing efficiency.

Method for preparing granules for all-solid-state battery electrode, and electrode for all-solid-state battery

PatentPendingUS20250183250A1

Innovation

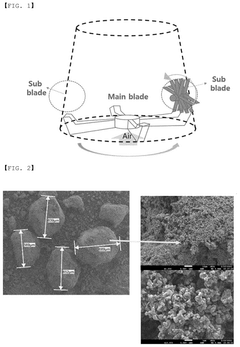

- A method involving coating an electrically conductive material on an active material and then spraying a binder to produce granules, with specific blade rotation speeds and configurations to control binder distribution and granule porosity.

Environmental Impact of AIB Production

The environmental impact of Aluminum-Ion Battery (AIB) production is a critical consideration as the technology scales up for commercial applications. The synthesis of AIB materials, particularly the production of high-quality powders and electrode coatings, can have significant environmental implications that need to be carefully assessed and mitigated.

One of the primary environmental concerns in AIB production is the energy-intensive nature of material synthesis processes. The creation of high-quality powders for AIB electrodes often requires high-temperature treatments and energy-consuming milling processes. These energy demands contribute to increased carbon emissions if not sourced from renewable energy. Additionally, the use of solvents and binders in electrode coating processes can lead to the release of volatile organic compounds (VOCs) into the atmosphere, potentially impacting air quality and contributing to smog formation in urban areas.

Water usage and contamination are also significant environmental factors to consider. The synthesis of AIB materials may require substantial amounts of water for cooling, cleaning, and processing. Proper water management and recycling systems are essential to minimize consumption and prevent the release of contaminated wastewater into local ecosystems. Furthermore, the disposal of process byproducts and waste materials from AIB production can pose risks to soil and groundwater if not handled appropriately.

The extraction and processing of raw materials for AIB components, such as aluminum and graphite, have their own environmental footprints. Mining operations can lead to habitat destruction, soil erosion, and water pollution if not managed sustainably. The transportation of these materials to production facilities also contributes to greenhouse gas emissions and air pollution.

As AIB technology scales up, there is an increasing need for environmentally friendly synthesis methods and materials. Research into green chemistry approaches, such as aqueous processing and the use of bio-derived binders, shows promise in reducing the environmental impact of AIB production. Additionally, the development of closed-loop manufacturing systems and the implementation of advanced recycling technologies can help minimize waste and conserve resources.

The long-term environmental benefits of AIBs should also be considered. If AIBs can achieve higher energy densities and longer cycle lives compared to current battery technologies, they could potentially reduce the overall environmental impact of energy storage systems over their lifetime. This could lead to decreased resource consumption and lower emissions associated with battery replacement and disposal.

To fully assess and mitigate the environmental impact of AIB production, comprehensive life cycle assessments (LCAs) are crucial. These studies can identify hotspots in the production process where environmental improvements can be made, guiding the development of more sustainable manufacturing practices. As the AIB industry grows, it will be essential to establish and adhere to stringent environmental standards and regulations to ensure responsible production and minimize ecological harm.

One of the primary environmental concerns in AIB production is the energy-intensive nature of material synthesis processes. The creation of high-quality powders for AIB electrodes often requires high-temperature treatments and energy-consuming milling processes. These energy demands contribute to increased carbon emissions if not sourced from renewable energy. Additionally, the use of solvents and binders in electrode coating processes can lead to the release of volatile organic compounds (VOCs) into the atmosphere, potentially impacting air quality and contributing to smog formation in urban areas.

Water usage and contamination are also significant environmental factors to consider. The synthesis of AIB materials may require substantial amounts of water for cooling, cleaning, and processing. Proper water management and recycling systems are essential to minimize consumption and prevent the release of contaminated wastewater into local ecosystems. Furthermore, the disposal of process byproducts and waste materials from AIB production can pose risks to soil and groundwater if not handled appropriately.

The extraction and processing of raw materials for AIB components, such as aluminum and graphite, have their own environmental footprints. Mining operations can lead to habitat destruction, soil erosion, and water pollution if not managed sustainably. The transportation of these materials to production facilities also contributes to greenhouse gas emissions and air pollution.

As AIB technology scales up, there is an increasing need for environmentally friendly synthesis methods and materials. Research into green chemistry approaches, such as aqueous processing and the use of bio-derived binders, shows promise in reducing the environmental impact of AIB production. Additionally, the development of closed-loop manufacturing systems and the implementation of advanced recycling technologies can help minimize waste and conserve resources.

The long-term environmental benefits of AIBs should also be considered. If AIBs can achieve higher energy densities and longer cycle lives compared to current battery technologies, they could potentially reduce the overall environmental impact of energy storage systems over their lifetime. This could lead to decreased resource consumption and lower emissions associated with battery replacement and disposal.

To fully assess and mitigate the environmental impact of AIB production, comprehensive life cycle assessments (LCAs) are crucial. These studies can identify hotspots in the production process where environmental improvements can be made, guiding the development of more sustainable manufacturing practices. As the AIB industry grows, it will be essential to establish and adhere to stringent environmental standards and regulations to ensure responsible production and minimize ecological harm.

Safety Protocols for AIB Material Handling

Safety protocols for handling AIB (Aluminum-Ion Battery) materials are crucial for ensuring the well-being of personnel and maintaining the integrity of the production process. These protocols should address the unique characteristics and potential hazards associated with AIB materials, particularly during the synthesis and electrode coating stages.

Personal protective equipment (PPE) is essential when working with AIB materials. This includes wearing chemical-resistant gloves, safety goggles, and lab coats or protective suits. Respiratory protection may also be necessary, especially when handling fine powders or volatile substances. The specific type of PPE required should be determined based on a thorough risk assessment of the materials and processes involved.

Proper ventilation is critical in areas where AIB materials are synthesized or processed. Fume hoods or local exhaust ventilation systems should be used to minimize exposure to potentially harmful vapors or airborne particles. Regular maintenance and testing of these systems are necessary to ensure their effectiveness.

Storage and handling of AIB materials require special attention. Materials should be stored in sealed containers in a cool, dry area away from incompatible substances. Proper labeling of all containers is essential, including information on the contents, hazards, and necessary precautions. Access to storage areas should be restricted to authorized personnel only.

Spill response procedures must be established and communicated to all relevant personnel. This includes having appropriate spill kits readily available and training employees on their proper use. Containment and cleanup methods should be tailored to the specific materials involved in AIB synthesis and electrode coating.

Regular safety training and education programs should be implemented for all personnel working with AIB materials. These programs should cover proper handling techniques, emergency procedures, and the importance of adhering to safety protocols. Refresher courses should be conducted periodically to reinforce safety practices and introduce any updates to procedures.

Waste management is another critical aspect of AIB material handling safety. Proper disposal methods for different types of waste generated during synthesis and coating processes must be established and followed. This may include segregation of waste streams, use of specialized containers, and compliance with local and national regulations regarding hazardous waste disposal.

Emergency response plans should be developed and regularly reviewed. These plans should address potential scenarios such as fires, chemical spills, or personnel exposure. Clear evacuation routes, emergency shower and eyewash stations, and first aid equipment must be readily accessible in all areas where AIB materials are handled.

Implementing a robust system for monitoring and documenting safety practices is essential. This includes regular safety audits, incident reporting mechanisms, and continuous improvement processes. By maintaining detailed records and analyzing safety data, organizations can identify trends, address potential issues proactively, and refine their safety protocols over time.

Personal protective equipment (PPE) is essential when working with AIB materials. This includes wearing chemical-resistant gloves, safety goggles, and lab coats or protective suits. Respiratory protection may also be necessary, especially when handling fine powders or volatile substances. The specific type of PPE required should be determined based on a thorough risk assessment of the materials and processes involved.

Proper ventilation is critical in areas where AIB materials are synthesized or processed. Fume hoods or local exhaust ventilation systems should be used to minimize exposure to potentially harmful vapors or airborne particles. Regular maintenance and testing of these systems are necessary to ensure their effectiveness.

Storage and handling of AIB materials require special attention. Materials should be stored in sealed containers in a cool, dry area away from incompatible substances. Proper labeling of all containers is essential, including information on the contents, hazards, and necessary precautions. Access to storage areas should be restricted to authorized personnel only.

Spill response procedures must be established and communicated to all relevant personnel. This includes having appropriate spill kits readily available and training employees on their proper use. Containment and cleanup methods should be tailored to the specific materials involved in AIB synthesis and electrode coating.

Regular safety training and education programs should be implemented for all personnel working with AIB materials. These programs should cover proper handling techniques, emergency procedures, and the importance of adhering to safety protocols. Refresher courses should be conducted periodically to reinforce safety practices and introduce any updates to procedures.

Waste management is another critical aspect of AIB material handling safety. Proper disposal methods for different types of waste generated during synthesis and coating processes must be established and followed. This may include segregation of waste streams, use of specialized containers, and compliance with local and national regulations regarding hazardous waste disposal.

Emergency response plans should be developed and regularly reviewed. These plans should address potential scenarios such as fires, chemical spills, or personnel exposure. Clear evacuation routes, emergency shower and eyewash stations, and first aid equipment must be readily accessible in all areas where AIB materials are handled.

Implementing a robust system for monitoring and documenting safety practices is essential. This includes regular safety audits, incident reporting mechanisms, and continuous improvement processes. By maintaining detailed records and analyzing safety data, organizations can identify trends, address potential issues proactively, and refine their safety protocols over time.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!