How to Benchmark AIBs Against LFP for Grid & Solar Storage — Metrics and Case Studies

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

AIB vs LFP Background

The energy storage landscape is witnessing a significant shift as new technologies emerge to challenge the dominance of lithium-ion batteries. Among these, Aluminum-ion Batteries (AIBs) have garnered attention as a potential alternative to Lithium Iron Phosphate (LFP) batteries, particularly in grid and solar storage applications. This technological evolution is driven by the increasing demand for more efficient, sustainable, and cost-effective energy storage solutions.

LFP batteries have long been a staple in grid and solar storage due to their stability, long cycle life, and improved safety compared to other lithium-ion chemistries. However, they face limitations in energy density and raw material costs. AIBs, on the other hand, promise several advantages, including higher theoretical energy density, faster charging capabilities, and the use of more abundant and less expensive raw materials.

The development of AIBs can be traced back to the early 2000s, but significant progress has been made in recent years. Researchers have been working on overcoming challenges such as finding suitable electrolytes and cathode materials that can withstand repeated intercalation of aluminum ions. The potential of AIBs lies in their ability to store three electrons per ion, compared to one electron in lithium-ion batteries, theoretically allowing for higher energy density.

In the context of grid and solar storage, both AIBs and LFP batteries aim to address key requirements such as long cycle life, high efficiency, and the ability to handle frequent charge-discharge cycles. LFP batteries have proven their reliability in these applications, with numerous large-scale installations worldwide. AIBs, while still in the research and development phase for grid-scale applications, show promise in potentially offering faster response times and lower production costs.

The comparison between AIBs and LFP batteries encompasses various factors, including energy density, power density, cycle life, safety, raw material availability, and environmental impact. Each technology has its strengths and weaknesses, and the benchmarking process must consider these aspects in the context of specific grid and solar storage requirements. As the energy transition accelerates, the need for diverse and optimized storage solutions becomes increasingly critical, driving the exploration of alternatives like AIBs.

LFP batteries have long been a staple in grid and solar storage due to their stability, long cycle life, and improved safety compared to other lithium-ion chemistries. However, they face limitations in energy density and raw material costs. AIBs, on the other hand, promise several advantages, including higher theoretical energy density, faster charging capabilities, and the use of more abundant and less expensive raw materials.

The development of AIBs can be traced back to the early 2000s, but significant progress has been made in recent years. Researchers have been working on overcoming challenges such as finding suitable electrolytes and cathode materials that can withstand repeated intercalation of aluminum ions. The potential of AIBs lies in their ability to store three electrons per ion, compared to one electron in lithium-ion batteries, theoretically allowing for higher energy density.

In the context of grid and solar storage, both AIBs and LFP batteries aim to address key requirements such as long cycle life, high efficiency, and the ability to handle frequent charge-discharge cycles. LFP batteries have proven their reliability in these applications, with numerous large-scale installations worldwide. AIBs, while still in the research and development phase for grid-scale applications, show promise in potentially offering faster response times and lower production costs.

The comparison between AIBs and LFP batteries encompasses various factors, including energy density, power density, cycle life, safety, raw material availability, and environmental impact. Each technology has its strengths and weaknesses, and the benchmarking process must consider these aspects in the context of specific grid and solar storage requirements. As the energy transition accelerates, the need for diverse and optimized storage solutions becomes increasingly critical, driving the exploration of alternatives like AIBs.

Market Analysis

The market for grid and solar storage solutions is experiencing rapid growth, driven by the increasing adoption of renewable energy sources and the need for reliable energy storage systems. As the demand for clean energy continues to rise, the competition between different battery technologies intensifies, with Lithium Iron Phosphate (LFP) batteries and Aqueous Ion Batteries (AIBs) emerging as key contenders in this space.

LFP batteries have gained significant traction in recent years due to their safety, long cycle life, and cost-effectiveness. They have become a popular choice for grid-scale energy storage projects and solar applications. The market for LFP batteries in grid and solar storage is expected to grow substantially, with major players like CATL, BYD, and Tesla leading the charge.

On the other hand, AIBs represent a promising alternative to traditional lithium-ion batteries, offering potential advantages in terms of safety, environmental impact, and raw material availability. While still in the early stages of commercialization, AIBs are attracting increasing attention from researchers, investors, and industry stakeholders.

The market dynamics between LFP and AIBs are shaped by several factors, including performance characteristics, cost considerations, and environmental impact. LFP batteries currently hold a dominant position in the grid and solar storage market, benefiting from established manufacturing processes and a proven track record. However, AIBs are gaining ground as ongoing research and development efforts aim to improve their performance and scalability.

Key market drivers for both technologies include the growing need for energy storage to support renewable energy integration, grid stabilization, and peak shaving applications. Government policies and incentives promoting clean energy adoption also play a crucial role in shaping market demand for advanced battery technologies.

The competitive landscape is evolving rapidly, with established battery manufacturers expanding their LFP production capacities and new entrants focusing on AIB development. Collaborations between technology companies, battery manufacturers, and utility providers are becoming increasingly common as the industry seeks to accelerate innovation and commercialization efforts.

As the market for grid and solar storage continues to expand, the need for robust benchmarking methodologies becomes paramount. Stakeholders require reliable metrics and case studies to evaluate the performance, cost-effectiveness, and long-term viability of different battery technologies. This benchmarking process will be crucial in guiding investment decisions, informing policy frameworks, and driving technological advancements in the energy storage sector.

LFP batteries have gained significant traction in recent years due to their safety, long cycle life, and cost-effectiveness. They have become a popular choice for grid-scale energy storage projects and solar applications. The market for LFP batteries in grid and solar storage is expected to grow substantially, with major players like CATL, BYD, and Tesla leading the charge.

On the other hand, AIBs represent a promising alternative to traditional lithium-ion batteries, offering potential advantages in terms of safety, environmental impact, and raw material availability. While still in the early stages of commercialization, AIBs are attracting increasing attention from researchers, investors, and industry stakeholders.

The market dynamics between LFP and AIBs are shaped by several factors, including performance characteristics, cost considerations, and environmental impact. LFP batteries currently hold a dominant position in the grid and solar storage market, benefiting from established manufacturing processes and a proven track record. However, AIBs are gaining ground as ongoing research and development efforts aim to improve their performance and scalability.

Key market drivers for both technologies include the growing need for energy storage to support renewable energy integration, grid stabilization, and peak shaving applications. Government policies and incentives promoting clean energy adoption also play a crucial role in shaping market demand for advanced battery technologies.

The competitive landscape is evolving rapidly, with established battery manufacturers expanding their LFP production capacities and new entrants focusing on AIB development. Collaborations between technology companies, battery manufacturers, and utility providers are becoming increasingly common as the industry seeks to accelerate innovation and commercialization efforts.

As the market for grid and solar storage continues to expand, the need for robust benchmarking methodologies becomes paramount. Stakeholders require reliable metrics and case studies to evaluate the performance, cost-effectiveness, and long-term viability of different battery technologies. This benchmarking process will be crucial in guiding investment decisions, informing policy frameworks, and driving technological advancements in the energy storage sector.

Technical Challenges

The benchmarking of Aluminum-Ion Batteries (AIBs) against Lithium Iron Phosphate (LFP) batteries for grid and solar storage applications presents several technical challenges. One of the primary difficulties lies in the nascent stage of AIB technology compared to the well-established LFP batteries. This disparity in maturity levels makes direct comparisons complex, as AIBs are still evolving rapidly while LFP technology has reached a more stable state.

A significant challenge is the development of standardized testing protocols that can accurately assess both AIBs and LFP batteries under comparable conditions. The unique characteristics of AIBs, such as their potentially higher charge/discharge rates and different voltage profiles, require careful consideration when designing benchmarking tests. Ensuring that these tests provide a fair and meaningful comparison without favoring the inherent strengths of either technology is crucial.

The long-term performance and degradation patterns of AIBs are not yet fully understood, particularly in the context of grid and solar storage applications. This lack of extensive field data makes it difficult to predict and compare the lifecycle performance of AIBs against the well-documented behavior of LFP batteries. Accelerated aging tests may not accurately reflect real-world conditions, adding another layer of complexity to the benchmarking process.

Safety considerations pose another technical challenge. While LFP batteries are known for their stability and safety profile, the safety characteristics of AIBs at scale are still being evaluated. Developing appropriate safety metrics and testing procedures that can be applied equally to both technologies is essential for a comprehensive comparison.

The environmental impact and recyclability of AIBs versus LFP batteries present additional benchmarking challenges. Assessing the full lifecycle environmental footprint, including raw material extraction, manufacturing processes, and end-of-life disposal or recycling, requires extensive data and standardized methodologies that may not yet be fully developed for AIBs.

Scalability and manufacturing processes also introduce complexities in benchmarking. LFP battery production is highly optimized and scaled, while AIB manufacturing is still in its early stages. Comparing the potential for cost reduction, production efficiency, and quality control between these technologies at different stages of industrial maturity presents significant technical hurdles.

Lastly, the integration of AIBs into existing grid and solar storage systems, which are primarily designed for lithium-ion chemistries, poses challenges in assessing real-world performance and compatibility. Developing metrics that can accurately capture the ease of integration, system-level efficiency, and overall performance in diverse operational scenarios is crucial for a comprehensive benchmarking effort.

A significant challenge is the development of standardized testing protocols that can accurately assess both AIBs and LFP batteries under comparable conditions. The unique characteristics of AIBs, such as their potentially higher charge/discharge rates and different voltage profiles, require careful consideration when designing benchmarking tests. Ensuring that these tests provide a fair and meaningful comparison without favoring the inherent strengths of either technology is crucial.

The long-term performance and degradation patterns of AIBs are not yet fully understood, particularly in the context of grid and solar storage applications. This lack of extensive field data makes it difficult to predict and compare the lifecycle performance of AIBs against the well-documented behavior of LFP batteries. Accelerated aging tests may not accurately reflect real-world conditions, adding another layer of complexity to the benchmarking process.

Safety considerations pose another technical challenge. While LFP batteries are known for their stability and safety profile, the safety characteristics of AIBs at scale are still being evaluated. Developing appropriate safety metrics and testing procedures that can be applied equally to both technologies is essential for a comprehensive comparison.

The environmental impact and recyclability of AIBs versus LFP batteries present additional benchmarking challenges. Assessing the full lifecycle environmental footprint, including raw material extraction, manufacturing processes, and end-of-life disposal or recycling, requires extensive data and standardized methodologies that may not yet be fully developed for AIBs.

Scalability and manufacturing processes also introduce complexities in benchmarking. LFP battery production is highly optimized and scaled, while AIB manufacturing is still in its early stages. Comparing the potential for cost reduction, production efficiency, and quality control between these technologies at different stages of industrial maturity presents significant technical hurdles.

Lastly, the integration of AIBs into existing grid and solar storage systems, which are primarily designed for lithium-ion chemistries, poses challenges in assessing real-world performance and compatibility. Developing metrics that can accurately capture the ease of integration, system-level efficiency, and overall performance in diverse operational scenarios is crucial for a comprehensive benchmarking effort.

Benchmarking Methods

01 Energy density comparison

AIBs and LFP batteries have different energy densities, with LFP generally offering higher energy density. This affects the overall performance and application range of the batteries. The energy density of AIBs is being improved through research into new electrode materials and electrolyte compositions.- Energy density comparison: AIBs and LFP batteries differ in their energy density capabilities. LFP batteries generally offer higher energy density, making them suitable for applications requiring longer operating times. AIBs, while having lower energy density, show promise in rapid charging applications and situations where weight is a critical factor.

- Cycle life and stability: LFP batteries are known for their excellent cycle life and thermal stability, often lasting thousands of charge-discharge cycles. AIBs, while still developing, show potential for long cycle life due to the stability of aluminum electrodes. Both battery types demonstrate good safety profiles, with LFP having a slight edge in thermal runaway resistance.

- Charging speed and power density: AIBs excel in rapid charging capabilities, potentially offering faster charge times compared to LFP batteries. This characteristic makes AIBs attractive for applications requiring quick power replenishment. LFP batteries, while not as fast-charging as AIBs, still offer respectable charging speeds and high power density, suitable for various electric vehicle and grid storage applications.

- Cost and resource availability: LFP batteries benefit from the abundance of iron and phosphate, leading to potentially lower production costs. AIBs, utilizing aluminum which is abundant and recyclable, may offer cost advantages in the future as the technology matures. Both battery types present opportunities for reducing dependency on rare earth elements, contributing to more sustainable energy storage solutions.

- Environmental impact and recyclability: Both AIBs and LFP batteries show promising environmental profiles. LFP batteries are considered more environmentally friendly compared to other lithium-ion chemistries due to the absence of cobalt. AIBs potentially offer easier recyclability due to the use of aluminum, which is highly recyclable. The development of efficient recycling processes for both battery types is ongoing, aiming to minimize environmental impact and improve sustainability in the energy storage sector.

02 Cycle life and stability

LFP batteries are known for their excellent cycle life and stability. AIBs are showing promise in this area, with some research indicating potential for long cycle life. Improvements in electrode materials and electrolyte formulations are key to enhancing the cycle life of AIBs to compete with LFP batteries.Expand Specific Solutions03 Charging and discharging rates

Both AIBs and LFP batteries have different charging and discharging characteristics. LFP batteries generally offer good fast-charging capabilities. Research on AIBs is focusing on improving their charge-discharge rates through novel electrode designs and electrolyte optimizations to match or exceed LFP performance.Expand Specific Solutions04 Safety and thermal stability

LFP batteries are known for their high thermal stability and safety. AIBs are being developed with a focus on safety, leveraging the non-flammable nature of aluminum-based electrolytes. Comparative studies are being conducted to assess the safety profiles of both battery types under various conditions.Expand Specific Solutions05 Cost and resource availability

The cost and availability of raw materials play a crucial role in battery performance metrics. LFP batteries benefit from abundant iron and phosphate resources. AIBs are being explored as a potentially cost-effective alternative due to the abundance of aluminum. Research is ongoing to optimize production processes and reduce costs for both battery types.Expand Specific Solutions

Key Industry Players

The competition landscape for benchmarking AIBs against LFP for grid and solar storage is evolving rapidly as the market for energy storage solutions expands. The industry is in a growth phase, with increasing demand driven by renewable energy integration and grid modernization efforts. Key players like Enphase Energy, TWAICE Technologies, and Ampere Power Energy are developing advanced battery management systems and predictive analytics software to optimize performance. Established utilities such as Hydro-Québec and State Grid Corporation of China are also investing in this space. The technology is maturing but still advancing, with ongoing research at institutions like the University of Toledo and Fudan University to improve energy density, cycle life, and safety of both AIB and LFP chemistries.

State Grid Corp. of China

Technical Solution: State Grid Corp. of China has developed a comprehensive benchmarking system for comparing Aluminum-Ion Batteries (AIBs) against Lithium Iron Phosphate (LFP) batteries in grid and solar storage applications. Their approach involves a multi-dimensional analysis framework that considers energy density, cycle life, safety performance, and cost-effectiveness[1]. The company has implemented advanced Battery Management Systems (BMS) that continuously monitor and optimize the performance of both AIB and LFP batteries in real-world grid scenarios[2]. State Grid's benchmarking process includes rigorous testing under various environmental conditions and load profiles, simulating actual grid demands. They have also developed proprietary algorithms to predict long-term degradation patterns and overall system efficiency[3].

Strengths: Extensive real-world data from grid applications, advanced BMS capabilities, and comprehensive testing protocols. Weaknesses: Potential bias towards grid-specific applications, may not fully capture solar storage nuances.

Enphase Energy, Inc.

Technical Solution: Enphase Energy has developed a sophisticated benchmarking methodology specifically tailored for comparing AIBs and LFP batteries in solar storage applications. Their approach focuses on integrating battery performance metrics with solar energy generation patterns to provide a holistic view of system efficiency. Enphase utilizes high-resolution data logging and advanced analytics to assess battery performance under various solar conditions, including intermittent cloud cover and seasonal variations[4]. Their benchmarking process incorporates real-time monitoring of charge/discharge cycles, depth of discharge, and temperature effects on both AIB and LFP technologies. Enphase has also developed simulation models that predict long-term system performance and degradation based on historical solar production data and battery usage patterns[5].

Strengths: Specialized expertise in solar+storage systems, extensive real-world data from diverse geographical locations. Weaknesses: May have limited experience with large-scale grid storage applications.

Performance Metrics

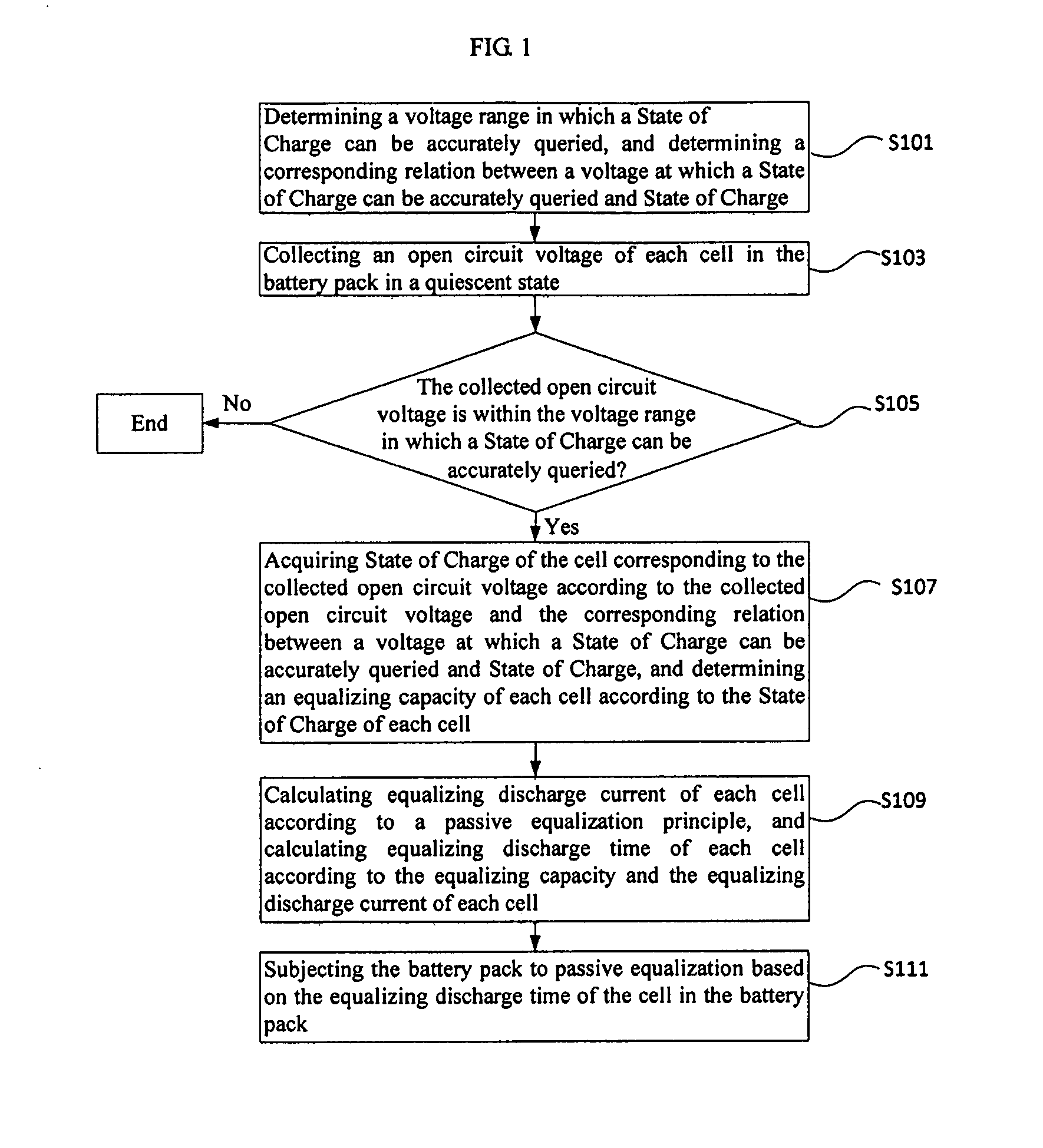

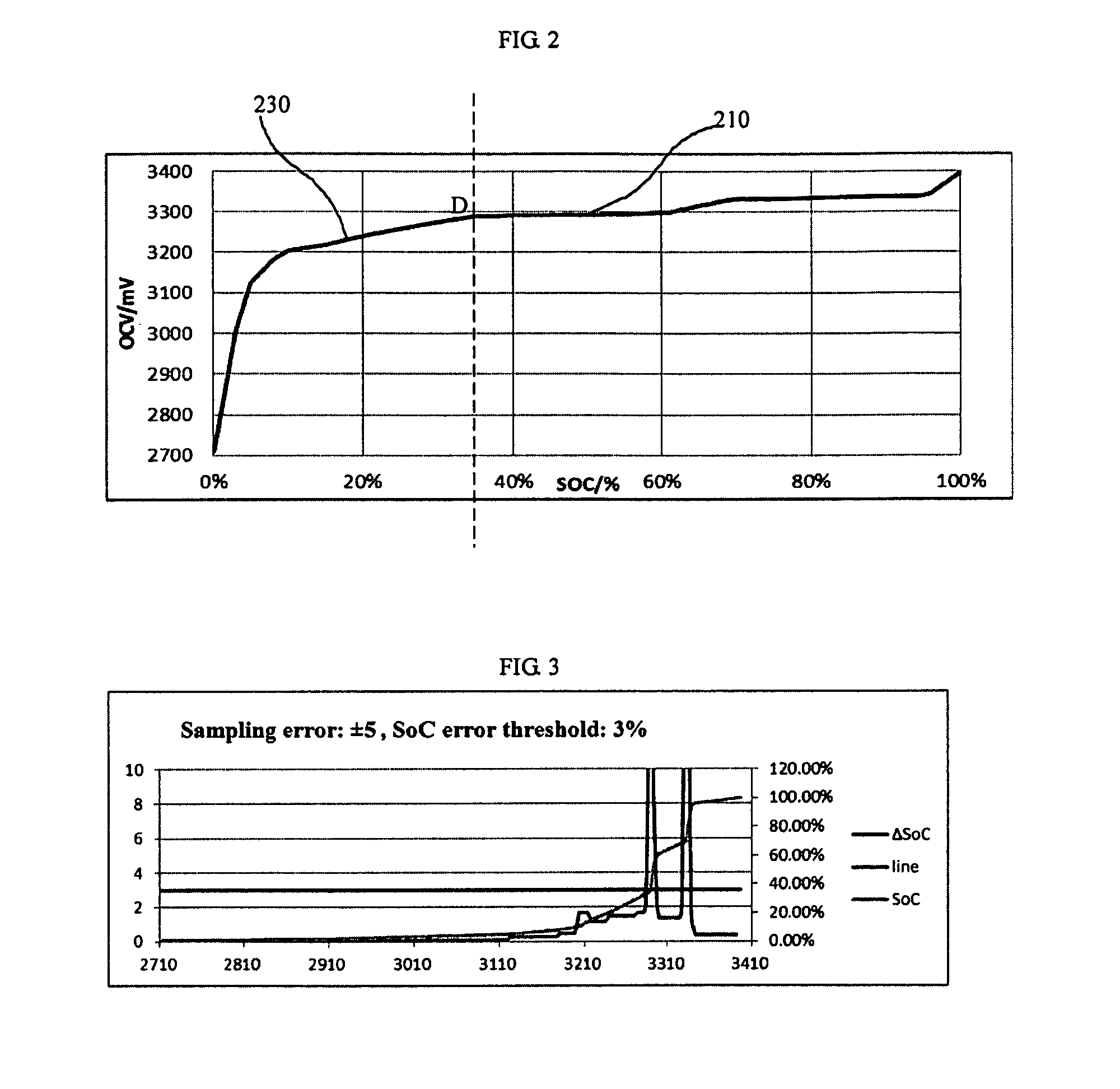

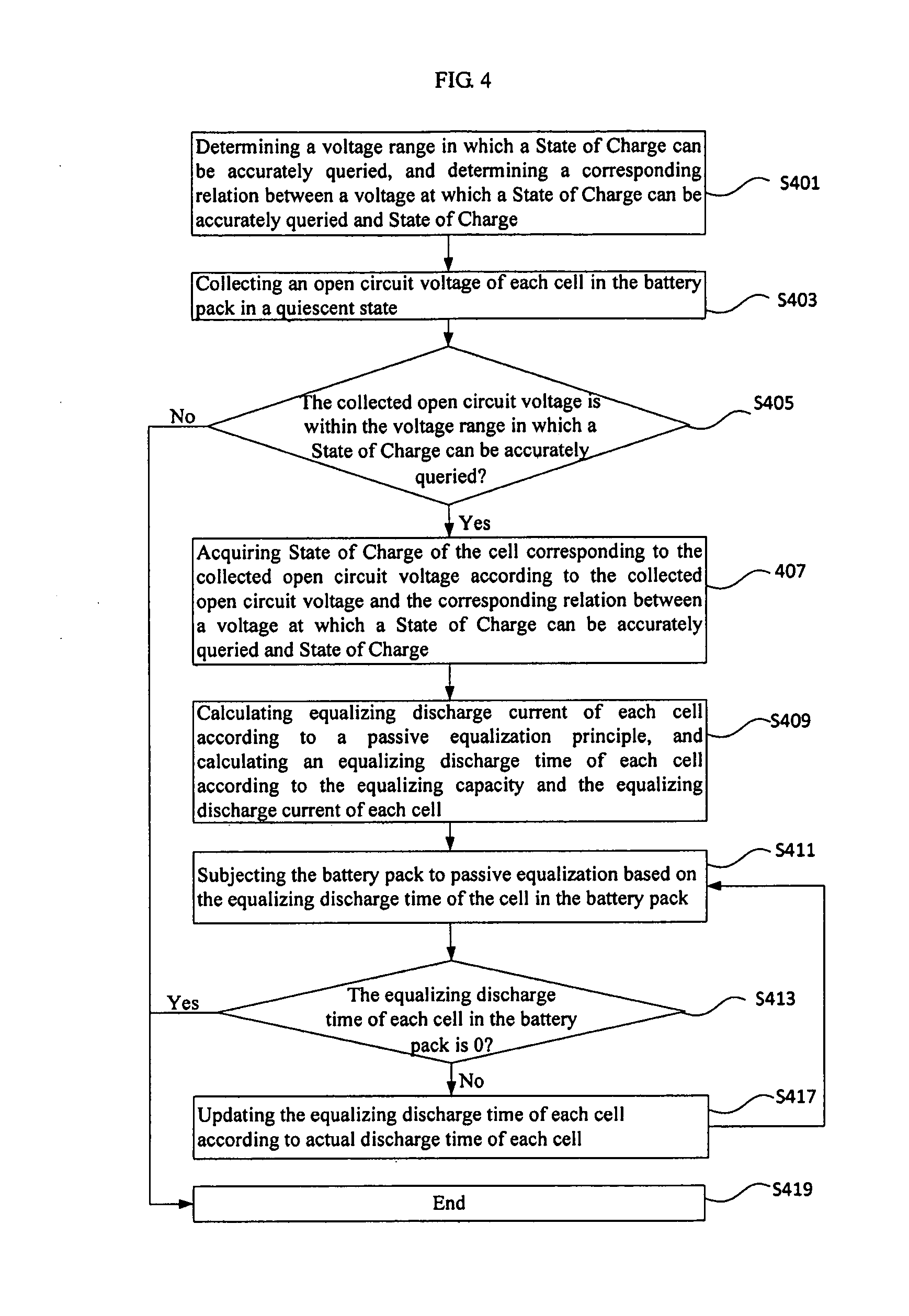

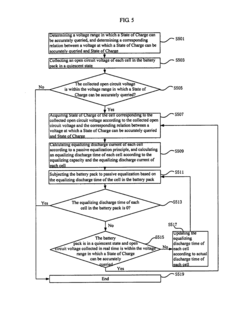

Passive equalization method and system for lithium iron phosphate battery pack

PatentActiveUS20160190829A1

Innovation

- A passive equalization method and system that determines an accurate voltage range for SoC querying, calculates equalizing capacity and discharge time for each cell, and subjects the battery pack to passive equalization based on these calculations, using a system with a storage module, collection module, judgment module, acquisition module, and equalization module, including an energy consumption circuit with a discharge equalizing resistor and field effect transistor.

High power electrode materials

PatentWO2015134948A1

Innovation

- A high-purity ammonium iron phosphate precursor, spheniscidite, is synthesized to produce LFP active materials with specific particle sizes and surface areas, resulting in improved electrochemical properties, including increased power and capacity retention at low temperatures.

Environmental Impact

The environmental impact of energy storage technologies is a critical consideration in the transition to renewable energy systems. When comparing Aluminum-Ion Batteries (AIBs) against Lithium Iron Phosphate (LFP) batteries for grid and solar storage applications, several environmental factors must be evaluated.

AIBs offer potential environmental advantages over LFP batteries in terms of raw material sourcing and end-of-life management. Aluminum is the third most abundant element in the Earth's crust, making it more readily available and potentially less environmentally damaging to extract compared to lithium. The mining and processing of lithium for LFP batteries can have significant environmental impacts, including water depletion and pollution in lithium-rich regions.

In terms of production, AIBs may have a lower carbon footprint compared to LFP batteries. The energy-intensive processes required for lithium extraction and refining contribute to higher greenhouse gas emissions in LFP battery production. However, a comprehensive life cycle assessment (LCA) is necessary to accurately compare the overall environmental impact of manufacturing both battery types.

Recycling and disposal are crucial aspects of environmental impact. AIBs have the potential for easier recycling due to the widespread existing infrastructure for aluminum recycling. In contrast, LFP battery recycling processes are still developing and can be more complex due to the variety of materials used. The recyclability of AIBs could lead to reduced waste and a more circular economy approach in the energy storage sector.

During operation, both AIB and LFP technologies contribute to reducing greenhouse gas emissions by enabling greater integration of renewable energy sources into the grid. However, the efficiency and lifespan of these batteries play a role in their long-term environmental impact. If AIBs can demonstrate comparable or superior cycle life and energy efficiency to LFP batteries, they may offer additional environmental benefits through reduced replacement frequency and improved energy conservation.

Water usage is another important environmental consideration. LFP battery production typically requires significant water resources, particularly in the lithium extraction phase. AIBs may have an advantage in this area, potentially requiring less water in their production process. This could be particularly beneficial in water-stressed regions where energy storage deployment is crucial for renewable energy integration.

Lastly, the potential for environmental contamination in case of accidents or improper disposal should be assessed. While both battery types pose risks, the environmental impact of aluminum leakage may be less severe than that of lithium and other materials used in LFP batteries. However, proper safety measures and disposal protocols are essential for both technologies to minimize environmental risks.

AIBs offer potential environmental advantages over LFP batteries in terms of raw material sourcing and end-of-life management. Aluminum is the third most abundant element in the Earth's crust, making it more readily available and potentially less environmentally damaging to extract compared to lithium. The mining and processing of lithium for LFP batteries can have significant environmental impacts, including water depletion and pollution in lithium-rich regions.

In terms of production, AIBs may have a lower carbon footprint compared to LFP batteries. The energy-intensive processes required for lithium extraction and refining contribute to higher greenhouse gas emissions in LFP battery production. However, a comprehensive life cycle assessment (LCA) is necessary to accurately compare the overall environmental impact of manufacturing both battery types.

Recycling and disposal are crucial aspects of environmental impact. AIBs have the potential for easier recycling due to the widespread existing infrastructure for aluminum recycling. In contrast, LFP battery recycling processes are still developing and can be more complex due to the variety of materials used. The recyclability of AIBs could lead to reduced waste and a more circular economy approach in the energy storage sector.

During operation, both AIB and LFP technologies contribute to reducing greenhouse gas emissions by enabling greater integration of renewable energy sources into the grid. However, the efficiency and lifespan of these batteries play a role in their long-term environmental impact. If AIBs can demonstrate comparable or superior cycle life and energy efficiency to LFP batteries, they may offer additional environmental benefits through reduced replacement frequency and improved energy conservation.

Water usage is another important environmental consideration. LFP battery production typically requires significant water resources, particularly in the lithium extraction phase. AIBs may have an advantage in this area, potentially requiring less water in their production process. This could be particularly beneficial in water-stressed regions where energy storage deployment is crucial for renewable energy integration.

Lastly, the potential for environmental contamination in case of accidents or improper disposal should be assessed. While both battery types pose risks, the environmental impact of aluminum leakage may be less severe than that of lithium and other materials used in LFP batteries. However, proper safety measures and disposal protocols are essential for both technologies to minimize environmental risks.

Regulatory Framework

The regulatory framework surrounding energy storage technologies, particularly for grid and solar applications, plays a crucial role in shaping the adoption and implementation of Aluminum-Ion Batteries (AIBs) and Lithium Iron Phosphate (LFP) batteries. As these technologies compete for market share, understanding the regulatory landscape is essential for benchmarking their performance and potential.

In many jurisdictions, energy storage systems are subject to safety standards and grid interconnection requirements. For AIBs and LFP batteries, compliance with standards such as UL 9540 for energy storage systems and IEEE 1547 for interconnecting distributed resources with electric power systems is mandatory. These standards ensure the safe operation and integration of storage technologies into existing grid infrastructure.

Environmental regulations also significantly impact the deployment of energy storage solutions. The European Union's Battery Directive and similar regulations in other regions set guidelines for the manufacturing, use, and disposal of batteries. AIBs may have an advantage in this area due to their potentially lower environmental impact compared to LFP batteries, which contain lithium and phosphate.

Grid operators and utilities are subject to regulatory frameworks that influence energy storage deployment. For instance, FERC Order 841 in the United States requires grid operators to facilitate the participation of energy storage resources in wholesale electricity markets. Such regulations create opportunities for both AIB and LFP technologies to demonstrate their value in grid applications.

Performance metrics for energy storage systems are often defined by regulatory bodies. These metrics, including round-trip efficiency, cycle life, and response time, form the basis for comparing AIBs and LFP batteries. Regulatory agencies may also set targets for energy storage deployment, influencing the market potential for these technologies.

The regulatory landscape for energy storage is evolving rapidly. Policymakers are increasingly recognizing the role of energy storage in achieving renewable energy integration and grid stability goals. This has led to the development of specific energy storage policies and incentives in many regions, which can impact the competitiveness of AIBs versus LFP batteries.

Lastly, regulations surrounding the sourcing of raw materials and supply chain transparency are becoming more stringent. This aspect of the regulatory framework may influence the adoption of AIBs and LFP batteries differently, depending on the availability and sustainability of their respective raw materials.

In many jurisdictions, energy storage systems are subject to safety standards and grid interconnection requirements. For AIBs and LFP batteries, compliance with standards such as UL 9540 for energy storage systems and IEEE 1547 for interconnecting distributed resources with electric power systems is mandatory. These standards ensure the safe operation and integration of storage technologies into existing grid infrastructure.

Environmental regulations also significantly impact the deployment of energy storage solutions. The European Union's Battery Directive and similar regulations in other regions set guidelines for the manufacturing, use, and disposal of batteries. AIBs may have an advantage in this area due to their potentially lower environmental impact compared to LFP batteries, which contain lithium and phosphate.

Grid operators and utilities are subject to regulatory frameworks that influence energy storage deployment. For instance, FERC Order 841 in the United States requires grid operators to facilitate the participation of energy storage resources in wholesale electricity markets. Such regulations create opportunities for both AIB and LFP technologies to demonstrate their value in grid applications.

Performance metrics for energy storage systems are often defined by regulatory bodies. These metrics, including round-trip efficiency, cycle life, and response time, form the basis for comparing AIBs and LFP batteries. Regulatory agencies may also set targets for energy storage deployment, influencing the market potential for these technologies.

The regulatory landscape for energy storage is evolving rapidly. Policymakers are increasingly recognizing the role of energy storage in achieving renewable energy integration and grid stability goals. This has led to the development of specific energy storage policies and incentives in many regions, which can impact the competitiveness of AIBs versus LFP batteries.

Lastly, regulations surrounding the sourcing of raw materials and supply chain transparency are becoming more stringent. This aspect of the regulatory framework may influence the adoption of AIBs and LFP batteries differently, depending on the availability and sustainability of their respective raw materials.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!