Aluminum-Ion Battery Thermal Management: Testing and Design Considerations

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Al-Ion Battery Background

Aluminum-ion batteries (AIBs) have emerged as a promising alternative to conventional lithium-ion batteries, offering potential advantages in terms of safety, cost, and environmental impact. The development of AIBs can be traced back to the early 2000s, with significant progress made in recent years. These batteries utilize aluminum as the anode material, which is abundant, low-cost, and has a high theoretical capacity.

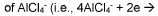

The core components of an aluminum-ion battery include an aluminum anode, a graphite cathode, and an electrolyte typically composed of aluminum chloride (AlCl3) and an organic solvent. The electrochemical reactions involve the reversible intercalation and de-intercalation of aluminum ions between the anode and cathode. This process is fundamentally different from lithium-ion batteries, resulting in unique characteristics and challenges.

One of the key advantages of AIBs is their potential for fast charging. Some prototypes have demonstrated charging times as low as one minute, significantly outperforming conventional lithium-ion batteries. Additionally, AIBs exhibit excellent cycling stability, with some research showing over 7,500 charge-discharge cycles without significant capacity loss.

However, AIBs face several technical challenges that have hindered their widespread adoption. The primary issue is their relatively low energy density compared to lithium-ion batteries. Current AIB prototypes typically achieve energy densities of 40-70 Wh/kg, whereas commercial lithium-ion batteries can reach 200-300 Wh/kg. This limitation is primarily due to the lower voltage of AIBs and challenges in developing high-capacity cathode materials.

Another significant challenge is the corrosive nature of the electrolyte used in AIBs. The highly acidic aluminum chloride-based electrolytes can cause degradation of cell components over time, affecting the battery's long-term performance and safety. Researchers are actively exploring alternative electrolyte formulations to mitigate this issue.

Thermal management is a critical aspect of AIB development, as it directly impacts the battery's performance, safety, and lifespan. The electrochemical reactions in AIBs generate heat during charging and discharging, which can lead to temperature increases within the cell. Effective thermal management strategies are essential to maintain optimal operating temperatures, prevent thermal runaway, and ensure uniform heat distribution across the battery pack.

As research in AIBs progresses, addressing these challenges and optimizing thermal management systems will be crucial for realizing their full potential. The development of advanced materials, improved cell designs, and innovative cooling strategies will play a vital role in enhancing the overall performance and safety of aluminum-ion batteries, paving the way for their integration into various applications, from portable electronics to electric vehicles and grid-scale energy storage systems.

The core components of an aluminum-ion battery include an aluminum anode, a graphite cathode, and an electrolyte typically composed of aluminum chloride (AlCl3) and an organic solvent. The electrochemical reactions involve the reversible intercalation and de-intercalation of aluminum ions between the anode and cathode. This process is fundamentally different from lithium-ion batteries, resulting in unique characteristics and challenges.

One of the key advantages of AIBs is their potential for fast charging. Some prototypes have demonstrated charging times as low as one minute, significantly outperforming conventional lithium-ion batteries. Additionally, AIBs exhibit excellent cycling stability, with some research showing over 7,500 charge-discharge cycles without significant capacity loss.

However, AIBs face several technical challenges that have hindered their widespread adoption. The primary issue is their relatively low energy density compared to lithium-ion batteries. Current AIB prototypes typically achieve energy densities of 40-70 Wh/kg, whereas commercial lithium-ion batteries can reach 200-300 Wh/kg. This limitation is primarily due to the lower voltage of AIBs and challenges in developing high-capacity cathode materials.

Another significant challenge is the corrosive nature of the electrolyte used in AIBs. The highly acidic aluminum chloride-based electrolytes can cause degradation of cell components over time, affecting the battery's long-term performance and safety. Researchers are actively exploring alternative electrolyte formulations to mitigate this issue.

Thermal management is a critical aspect of AIB development, as it directly impacts the battery's performance, safety, and lifespan. The electrochemical reactions in AIBs generate heat during charging and discharging, which can lead to temperature increases within the cell. Effective thermal management strategies are essential to maintain optimal operating temperatures, prevent thermal runaway, and ensure uniform heat distribution across the battery pack.

As research in AIBs progresses, addressing these challenges and optimizing thermal management systems will be crucial for realizing their full potential. The development of advanced materials, improved cell designs, and innovative cooling strategies will play a vital role in enhancing the overall performance and safety of aluminum-ion batteries, paving the way for their integration into various applications, from portable electronics to electric vehicles and grid-scale energy storage systems.

Market Demand Analysis

The market demand for aluminum-ion battery thermal management solutions is experiencing significant growth, driven by the increasing adoption of electric vehicles (EVs) and renewable energy storage systems. As the automotive industry shifts towards electrification, the need for efficient and safe battery technologies has become paramount. Aluminum-ion batteries have emerged as a promising alternative to lithium-ion batteries, offering potential advantages in terms of safety, cost, and environmental impact.

The global electric vehicle market is projected to expand rapidly in the coming years, with major automotive manufacturers committing to electrifying their product lines. This transition is creating a substantial demand for advanced battery technologies, including aluminum-ion batteries. The thermal management of these batteries is crucial for ensuring optimal performance, longevity, and safety, thus driving the need for innovative testing and design solutions.

In the renewable energy sector, the push for grid-scale energy storage solutions is also contributing to the market demand for aluminum-ion battery thermal management. As countries worldwide aim to increase their renewable energy capacity, the need for efficient and reliable energy storage systems becomes more pressing. Aluminum-ion batteries, with proper thermal management, could play a significant role in addressing this demand.

The industrial and consumer electronics sectors are also showing interest in aluminum-ion battery technology. The potential for faster charging times and improved safety characteristics makes these batteries attractive for a wide range of applications, from power tools to portable electronic devices. As a result, the market for thermal management solutions in these sectors is expected to grow alongside the adoption of aluminum-ion batteries.

Regulatory pressures and environmental concerns are further driving the demand for advanced battery technologies and their associated thermal management systems. Governments worldwide are implementing stricter emissions standards and offering incentives for clean energy technologies, which is indirectly boosting the market for aluminum-ion batteries and their thermal management solutions.

The market demand is not limited to the batteries themselves but extends to the entire ecosystem of testing equipment, design tools, and thermal management systems. Companies specializing in battery thermal management are likely to see increased opportunities as the aluminum-ion battery market matures. This includes providers of thermal imaging equipment, cooling systems, and simulation software for battery design and testing.

As research and development in aluminum-ion battery technology progresses, the demand for sophisticated thermal management solutions is expected to intensify. The ability to effectively manage heat generation and dissipation in these batteries will be critical for their widespread adoption across various industries. This creates a significant market opportunity for companies that can develop and provide innovative thermal management technologies tailored to the unique characteristics of aluminum-ion batteries.

The global electric vehicle market is projected to expand rapidly in the coming years, with major automotive manufacturers committing to electrifying their product lines. This transition is creating a substantial demand for advanced battery technologies, including aluminum-ion batteries. The thermal management of these batteries is crucial for ensuring optimal performance, longevity, and safety, thus driving the need for innovative testing and design solutions.

In the renewable energy sector, the push for grid-scale energy storage solutions is also contributing to the market demand for aluminum-ion battery thermal management. As countries worldwide aim to increase their renewable energy capacity, the need for efficient and reliable energy storage systems becomes more pressing. Aluminum-ion batteries, with proper thermal management, could play a significant role in addressing this demand.

The industrial and consumer electronics sectors are also showing interest in aluminum-ion battery technology. The potential for faster charging times and improved safety characteristics makes these batteries attractive for a wide range of applications, from power tools to portable electronic devices. As a result, the market for thermal management solutions in these sectors is expected to grow alongside the adoption of aluminum-ion batteries.

Regulatory pressures and environmental concerns are further driving the demand for advanced battery technologies and their associated thermal management systems. Governments worldwide are implementing stricter emissions standards and offering incentives for clean energy technologies, which is indirectly boosting the market for aluminum-ion batteries and their thermal management solutions.

The market demand is not limited to the batteries themselves but extends to the entire ecosystem of testing equipment, design tools, and thermal management systems. Companies specializing in battery thermal management are likely to see increased opportunities as the aluminum-ion battery market matures. This includes providers of thermal imaging equipment, cooling systems, and simulation software for battery design and testing.

As research and development in aluminum-ion battery technology progresses, the demand for sophisticated thermal management solutions is expected to intensify. The ability to effectively manage heat generation and dissipation in these batteries will be critical for their widespread adoption across various industries. This creates a significant market opportunity for companies that can develop and provide innovative thermal management technologies tailored to the unique characteristics of aluminum-ion batteries.

Thermal Challenges

Aluminum-ion batteries face significant thermal challenges that must be addressed to ensure their safe and efficient operation. One of the primary concerns is the high heat generation during charging and discharging cycles. This heat production is primarily due to the rapid ion transfer between electrodes and the internal resistance of the battery components. If not properly managed, this excess heat can lead to thermal runaway, potentially causing battery failure or even safety hazards.

The thermal conductivity of battery materials plays a crucial role in heat dissipation. Aluminum, while having excellent electrical conductivity, also possesses high thermal conductivity. This characteristic presents both advantages and challenges in thermal management. On one hand, it allows for faster heat dissipation from the core of the battery to its surface. On the other hand, it can lead to uneven temperature distribution within the battery pack, potentially causing localized hot spots.

Another thermal challenge is the impact of ambient temperature on battery performance. Aluminum-ion batteries, like many other battery technologies, are sensitive to extreme temperatures. High ambient temperatures can accelerate chemical reactions within the battery, potentially leading to faster degradation of electrode materials and electrolytes. Conversely, low temperatures can significantly reduce the battery's capacity and power output due to increased internal resistance and slower ion mobility.

The design of the battery pack and its cooling system must account for these thermal challenges. Effective thermal management strategies may include active cooling systems, such as liquid cooling or forced air circulation, to maintain optimal operating temperatures. Passive cooling techniques, like the use of phase change materials or heat spreaders, can also be employed to regulate temperature distribution within the battery pack.

Furthermore, the thermal expansion and contraction of battery components during temperature fluctuations pose additional challenges. This can lead to mechanical stress on the battery structure, potentially causing deformation or damage to cell components. Designers must consider these thermal expansion effects when selecting materials and designing the battery enclosure to ensure long-term structural integrity.

Thermal modeling and simulation play a crucial role in addressing these challenges. Advanced computational fluid dynamics (CFD) and finite element analysis (FEA) techniques can help predict temperature distributions, identify potential hot spots, and optimize cooling system designs. These tools are essential for developing effective thermal management solutions that can maintain battery performance and longevity across a wide range of operating conditions.

The thermal conductivity of battery materials plays a crucial role in heat dissipation. Aluminum, while having excellent electrical conductivity, also possesses high thermal conductivity. This characteristic presents both advantages and challenges in thermal management. On one hand, it allows for faster heat dissipation from the core of the battery to its surface. On the other hand, it can lead to uneven temperature distribution within the battery pack, potentially causing localized hot spots.

Another thermal challenge is the impact of ambient temperature on battery performance. Aluminum-ion batteries, like many other battery technologies, are sensitive to extreme temperatures. High ambient temperatures can accelerate chemical reactions within the battery, potentially leading to faster degradation of electrode materials and electrolytes. Conversely, low temperatures can significantly reduce the battery's capacity and power output due to increased internal resistance and slower ion mobility.

The design of the battery pack and its cooling system must account for these thermal challenges. Effective thermal management strategies may include active cooling systems, such as liquid cooling or forced air circulation, to maintain optimal operating temperatures. Passive cooling techniques, like the use of phase change materials or heat spreaders, can also be employed to regulate temperature distribution within the battery pack.

Furthermore, the thermal expansion and contraction of battery components during temperature fluctuations pose additional challenges. This can lead to mechanical stress on the battery structure, potentially causing deformation or damage to cell components. Designers must consider these thermal expansion effects when selecting materials and designing the battery enclosure to ensure long-term structural integrity.

Thermal modeling and simulation play a crucial role in addressing these challenges. Advanced computational fluid dynamics (CFD) and finite element analysis (FEA) techniques can help predict temperature distributions, identify potential hot spots, and optimize cooling system designs. These tools are essential for developing effective thermal management solutions that can maintain battery performance and longevity across a wide range of operating conditions.

Current Thermal Solutions

01 Thermal management systems for aluminum-ion batteries

Advanced thermal management systems are developed specifically for aluminum-ion batteries to maintain optimal operating temperatures, enhance performance, and extend battery life. These systems may include active cooling mechanisms, heat dissipation structures, and temperature monitoring devices to prevent overheating and ensure efficient operation.- Thermal management systems for aluminum-ion batteries: Advanced thermal management systems are developed specifically for aluminum-ion batteries to maintain optimal operating temperatures. These systems may include cooling channels, heat exchangers, or phase change materials to regulate battery temperature during charging and discharging cycles, enhancing performance and longevity.

- Battery pack design for improved heat dissipation: Innovative battery pack designs are implemented to enhance heat dissipation in aluminum-ion batteries. These designs may incorporate specialized materials, structural modifications, or air flow patterns to efficiently remove excess heat from the battery cells, preventing overheating and maintaining stable performance.

- Smart thermal management control systems: Intelligent control systems are developed to actively monitor and manage the thermal conditions of aluminum-ion batteries. These systems utilize sensors, algorithms, and predictive models to optimize cooling strategies, adjust charging rates, and maintain ideal temperature ranges for maximum battery efficiency and safety.

- Integration of thermal management with battery management systems: Thermal management functionalities are integrated into comprehensive battery management systems for aluminum-ion batteries. This integration allows for coordinated control of temperature, state of charge, and other critical parameters, ensuring optimal performance and prolonging battery life through adaptive thermal regulation strategies.

- Novel cooling technologies for aluminum-ion batteries: Innovative cooling technologies are developed specifically for aluminum-ion batteries, addressing their unique thermal characteristics. These may include advanced liquid cooling systems, thermoelectric cooling devices, or nanomaterial-based heat spreaders, designed to efficiently manage heat generation and dissipation in high-performance battery applications.

02 Battery pack design for improved heat distribution

Innovative battery pack designs are implemented to improve heat distribution in aluminum-ion batteries. These designs may incorporate heat-conductive materials, strategic cell arrangement, and thermal interfaces to facilitate uniform heat dissipation and prevent localized hot spots within the battery pack.Expand Specific Solutions03 Cooling systems for aluminum-ion battery modules

Specialized cooling systems are developed for aluminum-ion battery modules to maintain optimal operating temperatures. These may include liquid cooling circuits, air cooling channels, or phase-change materials to efficiently remove excess heat and prevent thermal runaway in high-power applications.Expand Specific Solutions04 Thermal interface materials for enhanced heat transfer

Advanced thermal interface materials are utilized to enhance heat transfer between aluminum-ion battery cells and cooling systems. These materials may include high-conductivity compounds, phase-change materials, or nanostructured interfaces to improve thermal management efficiency and reduce thermal resistance.Expand Specific Solutions05 Smart thermal management algorithms and control systems

Intelligent thermal management algorithms and control systems are developed to optimize the performance of aluminum-ion batteries. These systems may use real-time temperature monitoring, predictive modeling, and adaptive control strategies to dynamically adjust cooling parameters and maintain ideal operating conditions.Expand Specific Solutions

Key Industry Players

The aluminum-ion battery thermal management market is in its early growth stage, with increasing interest due to the potential advantages over lithium-ion batteries. The market size is expanding as research and development efforts intensify, though commercial applications remain limited. Technologically, aluminum-ion batteries are still evolving, with key players like Contemporary Amperex Technology, Samsung SDI, and GM Global Technology Operations leading advancements. Universities such as China Three Gorges University and Huazhong University of Science & Technology are contributing to fundamental research. While not yet mature, the technology shows promise for improved safety, faster charging, and lower costs compared to current battery options.

GM Global Technology Operations LLC

Technical Solution: GM has developed a comprehensive thermal management system for aluminum-ion batteries, focusing on vehicle integration and overall efficiency. Their approach combines active and passive cooling methods, utilizing a dual-circuit liquid cooling system. The primary circuit manages battery temperature during normal operation, while the secondary circuit provides additional cooling capacity during fast charging or high-performance driving scenarios[7]. GM's system also incorporates thermal preconditioning, which optimizes battery temperature before charging or during cold starts. This preconditioning can improve charging speeds by up to 50% in cold weather conditions[8]. Additionally, GM has integrated their thermal management system with the vehicle's overall HVAC system, allowing for heat recovery and cabin climate control optimization. The company reports that this integrated approach has led to a 15% increase in overall vehicle energy efficiency[9].

Strengths: Comprehensive vehicle integration, efficient dual-circuit cooling, thermal preconditioning for improved performance. Weaknesses: Potentially higher system complexity, increased vehicle integration challenges.

Robert Bosch GmbH

Technical Solution: Bosch has engineered an innovative thermal management solution for aluminum-ion batteries, focusing on scalability and adaptability across various vehicle platforms. Their system utilizes a modular approach with standardized cooling modules that can be easily configured for different battery sizes and vehicle types. The core of Bosch's solution is a high-efficiency heat pump system that can both cool and heat the battery pack as needed[10]. This bi-directional thermal management allows for optimal battery performance in both hot and cold climates. Bosch has also developed advanced thermal modeling software that enables rapid optimization of cooling system designs for specific vehicle applications. The company claims that their modular approach can reduce development time for new vehicle thermal management systems by up to 40%[11]. Additionally, Bosch's system incorporates predictive thermal management algorithms that use route information and driving patterns to optimize battery temperature proactively.

Strengths: Highly scalable and adaptable, efficient bi-directional thermal management, reduced development time. Weaknesses: Potential for higher initial costs due to modular components, may require more space in vehicle design.

Innovative Cooling Tech

Battery Module, Battery Device, and Battery System Having Thermal Management Design

PatentPendingUS20240429488A1

Innovation

- A battery module and system design incorporating a thermal management system with a temperature control medium circulated through a system fluid circulation device, utilizing a heat exchange pipe that acts as both a heat exchange medium and current path, and an enclosure with high thermal insulation capabilities to maintain temperature uniformity and efficiency across battery cells.

Aluminum-ion battery using aluminum chloride/amide-based deep eutectic solvents

PatentWO2020056514A1

Innovation

- The development of aluminum-ion batteries using aluminum chloride/amide-based deep eutectic solvents as electrolytes, combined with inexpensive graphitic materials and other cathode active materials, such as pyrolytic and natural graphite, to create a cost-effective and safer battery technology.

Safety Regulations

Safety regulations play a crucial role in the development and implementation of aluminum-ion battery thermal management systems. These regulations are designed to ensure the safe operation of batteries and protect users from potential hazards associated with thermal runaway, overheating, and other temperature-related issues.

One of the primary safety standards governing aluminum-ion batteries is the IEC 62133, which outlines safety requirements for portable sealed secondary cells and batteries. This standard covers various aspects of battery safety, including thermal management considerations. It specifies temperature limits for normal operation and sets guidelines for thermal abuse testing to evaluate battery performance under extreme conditions.

The UN Manual of Tests and Criteria, specifically UN 38.3, is another important regulation that addresses the transportation safety of lithium-ion batteries. While primarily focused on lithium-ion batteries, many of its principles are applicable to aluminum-ion batteries as well. This regulation mandates a series of tests, including thermal cycling and external short circuit tests, to ensure batteries can withstand various environmental conditions during transport.

In the United States, the Consumer Product Safety Commission (CPSC) has established guidelines for battery safety, which include thermal management considerations. These guidelines emphasize the importance of proper thermal design to prevent overheating and potential fire hazards in consumer electronics.

The automotive industry has its own set of safety regulations for battery systems, such as the ISO 6469 series for electrically propelled road vehicles. These standards address safety specifications for rechargeable energy storage systems (RESS) and include requirements for thermal management and protection against thermal runaway.

For aerospace applications, the DO-311A standard, developed by RTCA, provides guidelines for rechargeable lithium batteries and battery systems in aerospace. While specific to lithium batteries, many of its thermal management principles can be adapted for aluminum-ion batteries in aerospace applications.

Regulatory bodies such as the European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) also impact battery thermal management by regulating the use of certain materials in battery construction. This can influence the choice of thermal management materials and strategies.

As aluminum-ion battery technology continues to evolve, it is likely that new safety regulations specific to this battery chemistry will be developed. In the meantime, manufacturers and researchers must adapt existing standards and best practices from lithium-ion and other battery technologies to ensure the safe design and operation of aluminum-ion battery thermal management systems.

One of the primary safety standards governing aluminum-ion batteries is the IEC 62133, which outlines safety requirements for portable sealed secondary cells and batteries. This standard covers various aspects of battery safety, including thermal management considerations. It specifies temperature limits for normal operation and sets guidelines for thermal abuse testing to evaluate battery performance under extreme conditions.

The UN Manual of Tests and Criteria, specifically UN 38.3, is another important regulation that addresses the transportation safety of lithium-ion batteries. While primarily focused on lithium-ion batteries, many of its principles are applicable to aluminum-ion batteries as well. This regulation mandates a series of tests, including thermal cycling and external short circuit tests, to ensure batteries can withstand various environmental conditions during transport.

In the United States, the Consumer Product Safety Commission (CPSC) has established guidelines for battery safety, which include thermal management considerations. These guidelines emphasize the importance of proper thermal design to prevent overheating and potential fire hazards in consumer electronics.

The automotive industry has its own set of safety regulations for battery systems, such as the ISO 6469 series for electrically propelled road vehicles. These standards address safety specifications for rechargeable energy storage systems (RESS) and include requirements for thermal management and protection against thermal runaway.

For aerospace applications, the DO-311A standard, developed by RTCA, provides guidelines for rechargeable lithium batteries and battery systems in aerospace. While specific to lithium batteries, many of its thermal management principles can be adapted for aluminum-ion batteries in aerospace applications.

Regulatory bodies such as the European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) also impact battery thermal management by regulating the use of certain materials in battery construction. This can influence the choice of thermal management materials and strategies.

As aluminum-ion battery technology continues to evolve, it is likely that new safety regulations specific to this battery chemistry will be developed. In the meantime, manufacturers and researchers must adapt existing standards and best practices from lithium-ion and other battery technologies to ensure the safe design and operation of aluminum-ion battery thermal management systems.

Environmental Impact

The environmental impact of aluminum-ion battery thermal management systems is a critical consideration in the development and implementation of this technology. As the demand for sustainable energy storage solutions grows, it is essential to evaluate the ecological footprint of these systems throughout their lifecycle.

Aluminum-ion batteries offer several environmental advantages over traditional lithium-ion batteries. The abundance of aluminum as a raw material reduces the environmental strain associated with resource extraction. Additionally, aluminum is highly recyclable, potentially leading to a more circular economy in battery production and disposal.

However, the thermal management systems for aluminum-ion batteries present their own set of environmental challenges. The production of cooling systems, heat exchangers, and thermal interface materials requires energy and resources. The manufacturing processes involved may contribute to greenhouse gas emissions and water pollution if not properly managed.

During operation, the energy consumption of thermal management systems must be considered. While these systems are crucial for maintaining battery performance and longevity, they also contribute to the overall energy demand of the battery system. Optimizing the efficiency of thermal management can help reduce this environmental impact.

The choice of coolants used in thermal management systems is another important environmental factor. Some coolants may have high global warming potential or pose risks to ecosystems if leaked. Developing and implementing environmentally friendly coolants is essential for minimizing the ecological impact of these systems.

End-of-life considerations for thermal management components are also crucial. The disposal or recycling of heat sinks, cooling plates, and other thermal management materials must be carefully managed to prevent environmental contamination. Designing these components with recyclability in mind can significantly reduce their long-term environmental impact.

As research and development in aluminum-ion battery thermal management progresses, there is an opportunity to integrate eco-design principles from the outset. This approach can lead to the development of more sustainable thermal management solutions, such as passive cooling systems or the use of waste heat for other applications, further reducing the environmental footprint of these technologies.

Aluminum-ion batteries offer several environmental advantages over traditional lithium-ion batteries. The abundance of aluminum as a raw material reduces the environmental strain associated with resource extraction. Additionally, aluminum is highly recyclable, potentially leading to a more circular economy in battery production and disposal.

However, the thermal management systems for aluminum-ion batteries present their own set of environmental challenges. The production of cooling systems, heat exchangers, and thermal interface materials requires energy and resources. The manufacturing processes involved may contribute to greenhouse gas emissions and water pollution if not properly managed.

During operation, the energy consumption of thermal management systems must be considered. While these systems are crucial for maintaining battery performance and longevity, they also contribute to the overall energy demand of the battery system. Optimizing the efficiency of thermal management can help reduce this environmental impact.

The choice of coolants used in thermal management systems is another important environmental factor. Some coolants may have high global warming potential or pose risks to ecosystems if leaked. Developing and implementing environmentally friendly coolants is essential for minimizing the ecological impact of these systems.

End-of-life considerations for thermal management components are also crucial. The disposal or recycling of heat sinks, cooling plates, and other thermal management materials must be carefully managed to prevent environmental contamination. Designing these components with recyclability in mind can significantly reduce their long-term environmental impact.

As research and development in aluminum-ion battery thermal management progresses, there is an opportunity to integrate eco-design principles from the outset. This approach can lead to the development of more sustainable thermal management solutions, such as passive cooling systems or the use of waste heat for other applications, further reducing the environmental footprint of these technologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!