How to Implement AIB Prototypes for Stationary Storage — System Integration Tips

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

AIB Prototype Goals

The primary goal of AIB (Aqueous Ion Battery) prototypes for stationary storage is to develop a safe, cost-effective, and environmentally friendly energy storage solution. These prototypes aim to address the growing demand for large-scale energy storage systems that can support grid stability, integrate renewable energy sources, and provide backup power during outages.

AIB prototypes for stationary storage focus on leveraging the advantages of aqueous electrolytes, which offer improved safety characteristics compared to traditional lithium-ion batteries. The use of non-flammable, water-based electrolytes significantly reduces the risk of fire and thermal runaway, making AIB systems particularly suitable for deployment in densely populated areas or critical infrastructure locations.

Another key objective of AIB prototypes is to achieve high energy density and long cycle life. Researchers and developers are working to optimize electrode materials and electrolyte compositions to maximize the energy storage capacity of AIB systems while ensuring their longevity. This involves exploring various combinations of cathode and anode materials, as well as investigating different aqueous electrolyte formulations to enhance overall performance.

Cost-effectiveness is a crucial goal for AIB prototypes. The development efforts aim to utilize abundant and low-cost materials, simplify manufacturing processes, and reduce the overall system complexity. By focusing on these aspects, AIB technology seeks to offer a competitive alternative to existing energy storage solutions, potentially lowering the total cost of ownership for stationary storage applications.

Scalability and modularity are also important objectives for AIB prototypes. The design of these systems should allow for easy scaling to meet various capacity requirements, from small-scale residential applications to large grid-scale installations. Modular designs facilitate easier maintenance, replacement of components, and system upgrades, enhancing the flexibility and adaptability of AIB storage solutions.

Environmental sustainability is a core goal of AIB prototype development. By using non-toxic, recyclable materials and minimizing the environmental impact throughout the battery lifecycle, AIB technology aims to provide a more eco-friendly alternative to conventional battery systems. This aligns with global efforts to reduce carbon emissions and promote sustainable energy solutions.

Lastly, AIB prototypes for stationary storage aim to demonstrate long-term stability and reliability under various operating conditions. This includes the ability to withstand temperature fluctuations, maintain performance over extended periods, and operate efficiently in different climatic environments. Achieving these goals is crucial for the widespread adoption of AIB technology in diverse stationary storage applications.

AIB prototypes for stationary storage focus on leveraging the advantages of aqueous electrolytes, which offer improved safety characteristics compared to traditional lithium-ion batteries. The use of non-flammable, water-based electrolytes significantly reduces the risk of fire and thermal runaway, making AIB systems particularly suitable for deployment in densely populated areas or critical infrastructure locations.

Another key objective of AIB prototypes is to achieve high energy density and long cycle life. Researchers and developers are working to optimize electrode materials and electrolyte compositions to maximize the energy storage capacity of AIB systems while ensuring their longevity. This involves exploring various combinations of cathode and anode materials, as well as investigating different aqueous electrolyte formulations to enhance overall performance.

Cost-effectiveness is a crucial goal for AIB prototypes. The development efforts aim to utilize abundant and low-cost materials, simplify manufacturing processes, and reduce the overall system complexity. By focusing on these aspects, AIB technology seeks to offer a competitive alternative to existing energy storage solutions, potentially lowering the total cost of ownership for stationary storage applications.

Scalability and modularity are also important objectives for AIB prototypes. The design of these systems should allow for easy scaling to meet various capacity requirements, from small-scale residential applications to large grid-scale installations. Modular designs facilitate easier maintenance, replacement of components, and system upgrades, enhancing the flexibility and adaptability of AIB storage solutions.

Environmental sustainability is a core goal of AIB prototype development. By using non-toxic, recyclable materials and minimizing the environmental impact throughout the battery lifecycle, AIB technology aims to provide a more eco-friendly alternative to conventional battery systems. This aligns with global efforts to reduce carbon emissions and promote sustainable energy solutions.

Lastly, AIB prototypes for stationary storage aim to demonstrate long-term stability and reliability under various operating conditions. This includes the ability to withstand temperature fluctuations, maintain performance over extended periods, and operate efficiently in different climatic environments. Achieving these goals is crucial for the widespread adoption of AIB technology in diverse stationary storage applications.

Market Analysis

The market for stationary energy storage systems, particularly those utilizing Advanced Inorganic Battery (AIB) technology, is experiencing significant growth and transformation. This surge is driven by the increasing demand for reliable, efficient, and sustainable energy storage solutions across various sectors, including utilities, commercial and industrial applications, and residential markets.

The global stationary energy storage market is projected to expand rapidly in the coming years, with AIB technologies playing a crucial role in this growth. Factors contributing to this market expansion include the rising adoption of renewable energy sources, grid modernization initiatives, and the need for enhanced energy reliability and resilience.

In the utility sector, AIB-based stationary storage systems are gaining traction due to their potential to provide grid stabilization, peak shaving, and load shifting capabilities. These systems enable utilities to better manage fluctuations in energy supply and demand, particularly with the increasing integration of intermittent renewable energy sources such as solar and wind power.

Commercial and industrial applications represent another significant market segment for AIB stationary storage. Businesses are increasingly turning to these systems to reduce energy costs, improve power quality, and ensure uninterrupted operations. The ability of AIB technologies to provide high-power output and long cycle life makes them particularly attractive for these applications.

The residential market for stationary storage is also showing promise, driven by factors such as the growing popularity of solar photovoltaic systems, increasing electricity rates, and the desire for energy independence. AIB-based systems offer homeowners the potential to store excess energy generated during peak hours and use it during periods of high demand or grid outages.

Geographically, the market for AIB stationary storage systems is experiencing strong growth in regions with high renewable energy penetration and supportive regulatory environments. Countries such as the United States, Germany, China, and Australia are at the forefront of this market expansion, with significant investments being made in research, development, and deployment of AIB technologies.

However, the market also faces challenges, including high initial costs, competition from other energy storage technologies, and the need for standardization and regulatory frameworks. Overcoming these hurdles will be crucial for the widespread adoption of AIB-based stationary storage systems.

As the technology matures and economies of scale are achieved, the cost of AIB systems is expected to decrease, making them more competitive with alternative storage solutions. This trend, coupled with ongoing improvements in performance and reliability, is likely to drive further market growth and adoption across various sectors and geographical regions.

The global stationary energy storage market is projected to expand rapidly in the coming years, with AIB technologies playing a crucial role in this growth. Factors contributing to this market expansion include the rising adoption of renewable energy sources, grid modernization initiatives, and the need for enhanced energy reliability and resilience.

In the utility sector, AIB-based stationary storage systems are gaining traction due to their potential to provide grid stabilization, peak shaving, and load shifting capabilities. These systems enable utilities to better manage fluctuations in energy supply and demand, particularly with the increasing integration of intermittent renewable energy sources such as solar and wind power.

Commercial and industrial applications represent another significant market segment for AIB stationary storage. Businesses are increasingly turning to these systems to reduce energy costs, improve power quality, and ensure uninterrupted operations. The ability of AIB technologies to provide high-power output and long cycle life makes them particularly attractive for these applications.

The residential market for stationary storage is also showing promise, driven by factors such as the growing popularity of solar photovoltaic systems, increasing electricity rates, and the desire for energy independence. AIB-based systems offer homeowners the potential to store excess energy generated during peak hours and use it during periods of high demand or grid outages.

Geographically, the market for AIB stationary storage systems is experiencing strong growth in regions with high renewable energy penetration and supportive regulatory environments. Countries such as the United States, Germany, China, and Australia are at the forefront of this market expansion, with significant investments being made in research, development, and deployment of AIB technologies.

However, the market also faces challenges, including high initial costs, competition from other energy storage technologies, and the need for standardization and regulatory frameworks. Overcoming these hurdles will be crucial for the widespread adoption of AIB-based stationary storage systems.

As the technology matures and economies of scale are achieved, the cost of AIB systems is expected to decrease, making them more competitive with alternative storage solutions. This trend, coupled with ongoing improvements in performance and reliability, is likely to drive further market growth and adoption across various sectors and geographical regions.

Technical Challenges

The implementation of Advanced Inert Battery (AIB) prototypes for stationary storage faces several significant technical challenges. One of the primary obstacles is the integration of AIB technology with existing power systems and infrastructure. The unique characteristics of AIB, such as its high energy density and long cycle life, require careful consideration when designing the interface between the battery and the power grid.

A major challenge lies in the development of advanced battery management systems (BMS) capable of optimizing AIB performance while ensuring safety and longevity. These systems must accurately monitor and control various parameters, including cell voltage, temperature, and state of charge, across large-scale battery arrays. The complexity of AIB chemistry demands sophisticated algorithms and sensors to maintain optimal operating conditions and prevent degradation.

Thermal management presents another critical challenge in AIB prototype implementation. The heat generated during charging and discharging cycles must be effectively dissipated to prevent thermal runaway and maintain battery efficiency. Designing cooling systems that can scale with larger stationary storage installations while minimizing energy consumption is a significant engineering hurdle.

The integration of AIB prototypes with power electronics and inverters poses additional challenges. Developing efficient and reliable power conversion systems that can handle the high energy density and unique discharge characteristics of AIB technology is crucial for maximizing overall system performance. This includes addressing issues related to voltage regulation, power quality, and grid synchronization.

Scalability and modularity are key considerations in AIB prototype implementation. Designing systems that can be easily scaled up from small prototypes to large-scale stationary storage installations requires careful planning and innovative engineering solutions. This includes addressing challenges related to cell balancing, interconnection, and system redundancy to ensure reliable operation at various scales.

Safety and reliability remain paramount concerns in AIB implementation. Developing robust safety mechanisms, including advanced fire suppression systems and fail-safe protocols, is essential for mitigating potential risks associated with large-scale energy storage. Additionally, ensuring long-term reliability and performance consistency over the expected lifespan of stationary storage systems presents ongoing technical challenges.

Environmental considerations also play a role in AIB prototype implementation. Developing sustainable manufacturing processes, addressing potential environmental impacts of AIB materials, and designing systems for end-of-life recycling or repurposing are important challenges that must be addressed to ensure the long-term viability of this technology in stationary storage applications.

A major challenge lies in the development of advanced battery management systems (BMS) capable of optimizing AIB performance while ensuring safety and longevity. These systems must accurately monitor and control various parameters, including cell voltage, temperature, and state of charge, across large-scale battery arrays. The complexity of AIB chemistry demands sophisticated algorithms and sensors to maintain optimal operating conditions and prevent degradation.

Thermal management presents another critical challenge in AIB prototype implementation. The heat generated during charging and discharging cycles must be effectively dissipated to prevent thermal runaway and maintain battery efficiency. Designing cooling systems that can scale with larger stationary storage installations while minimizing energy consumption is a significant engineering hurdle.

The integration of AIB prototypes with power electronics and inverters poses additional challenges. Developing efficient and reliable power conversion systems that can handle the high energy density and unique discharge characteristics of AIB technology is crucial for maximizing overall system performance. This includes addressing issues related to voltage regulation, power quality, and grid synchronization.

Scalability and modularity are key considerations in AIB prototype implementation. Designing systems that can be easily scaled up from small prototypes to large-scale stationary storage installations requires careful planning and innovative engineering solutions. This includes addressing challenges related to cell balancing, interconnection, and system redundancy to ensure reliable operation at various scales.

Safety and reliability remain paramount concerns in AIB implementation. Developing robust safety mechanisms, including advanced fire suppression systems and fail-safe protocols, is essential for mitigating potential risks associated with large-scale energy storage. Additionally, ensuring long-term reliability and performance consistency over the expected lifespan of stationary storage systems presents ongoing technical challenges.

Environmental considerations also play a role in AIB prototype implementation. Developing sustainable manufacturing processes, addressing potential environmental impacts of AIB materials, and designing systems for end-of-life recycling or repurposing are important challenges that must be addressed to ensure the long-term viability of this technology in stationary storage applications.

Current AIB Solutions

01 Electrode materials and structures for AIBs

Development of novel electrode materials and structures for aluminum-ion batteries, including graphene-based cathodes, nanostructured anodes, and composite electrodes. These advancements aim to improve the battery's energy density, cycling stability, and overall performance.- Electrode materials and structures for AIB: Development of novel electrode materials and structures for aluminum-ion batteries, focusing on improving energy density, cycling stability, and overall performance. This includes the use of graphene-based materials, metal oxides, and composite structures to enhance the electrochemical properties of both cathodes and anodes.

- Electrolyte formulations for AIB: Optimization of electrolyte compositions for aluminum-ion batteries, including ionic liquids and non-aqueous solutions. These formulations aim to improve ion conductivity, reduce corrosion, and enhance the overall efficiency and lifespan of the battery system.

- AIB cell design and assembly: Innovative approaches to AIB cell design and assembly, focusing on optimizing the arrangement of components, improving sealing methods, and enhancing thermal management. These designs aim to increase energy density, improve safety, and facilitate easier integration into various applications.

- AIB system integration and management: Development of integrated AIB systems, including battery management systems (BMS), power control units, and thermal management solutions. These integrated systems aim to optimize battery performance, extend lifespan, and ensure safe operation in various applications such as electric vehicles and grid storage.

- AIB manufacturing processes and scalability: Advancements in manufacturing processes for AIB components and full cells, focusing on scalability, cost reduction, and quality control. This includes innovations in electrode fabrication, cell assembly automation, and quality assurance techniques to enable large-scale production of AIB systems.

02 Electrolyte formulations for AIBs

Research on advanced electrolyte formulations specifically designed for aluminum-ion batteries. This includes ionic liquids, organic solvents, and additives that enhance ion conductivity, reduce corrosion, and improve the overall electrochemical performance of the battery system.Expand Specific Solutions03 AIB cell and pack design

Innovative designs for AIB cells and battery packs, focusing on optimizing the arrangement of components, thermal management systems, and integration with other power systems. These designs aim to enhance the battery's energy density, safety, and compatibility with various applications.Expand Specific Solutions04 AIB charging and management systems

Development of specialized charging protocols and battery management systems for aluminum-ion batteries. These systems are designed to optimize charging efficiency, monitor battery health, and ensure safe operation throughout the battery's lifecycle.Expand Specific Solutions05 Integration of AIBs with renewable energy systems

Exploration of methods to integrate aluminum-ion batteries with renewable energy sources such as solar and wind power. This includes the development of hybrid energy storage systems and smart grid applications that leverage the unique characteristics of AIBs.Expand Specific Solutions

Key Industry Players

The implementation of AIB (Advanced Intelligent Battery) prototypes for stationary storage is in a nascent stage, with the market showing significant growth potential. The industry is transitioning from early development to commercialization, driven by increasing demand for efficient energy storage solutions. Key players like Huawei, Samsung, and State Grid are investing heavily in R&D, indicating a competitive landscape. The technology's maturity varies, with established companies like IBM and Qualcomm bringing advanced expertise, while startups like Lantu Automobile and ChangXin Memory are introducing innovative approaches. The market size is expanding rapidly, fueled by the global push for renewable energy integration and grid stability.

Huawei Technologies Co., Ltd.

Technical Solution: Huawei has developed a comprehensive AIB prototype solution for stationary storage systems, leveraging its expertise in telecommunications and power electronics. The company's approach focuses on high-density energy storage modules with integrated battery management systems (BMS) for enhanced safety and performance[2]. Huawei's AIB prototype incorporates advanced power conversion systems (PCS) with multi-level inverter technology, achieving high efficiency and power quality[4]. The system utilizes AI-driven predictive maintenance algorithms to optimize battery life and system reliability. Huawei has also implemented a cloud-based energy management platform that enables remote monitoring, control, and optimization of distributed storage resources[6].

Strengths: Strong technological capabilities, global presence, and experience in large-scale system integration. Weaknesses: Potential geopolitical challenges in some markets and increased scrutiny on data security.

State Grid Corp. of China

Technical Solution: State Grid Corp. of China has developed an advanced AIB (Advanced Interface Bus) prototype for stationary storage systems, focusing on grid-scale energy storage integration. Their approach utilizes a modular design with standardized interfaces, allowing for seamless integration of various storage technologies. The system incorporates real-time monitoring and control capabilities, enabling dynamic power management and load balancing[1]. State Grid's AIB prototype employs advanced power electronics for efficient DC-AC conversion, minimizing energy losses during charge and discharge cycles[3]. The company has also implemented a sophisticated energy management system (EMS) that optimizes storage utilization based on grid demand forecasts and renewable energy generation patterns[5].

Strengths: Extensive experience in large-scale grid operations, strong R&D capabilities, and access to vast amounts of real-world grid data. Weaknesses: Potential challenges in adapting to rapidly evolving storage technologies and regulatory environments.

Core AIB Technologies

Battery storage device

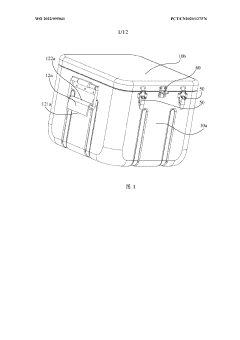

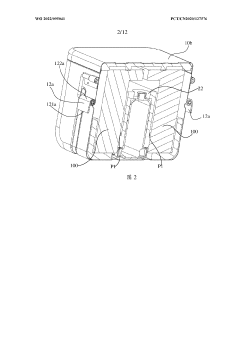

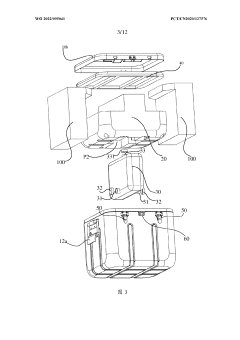

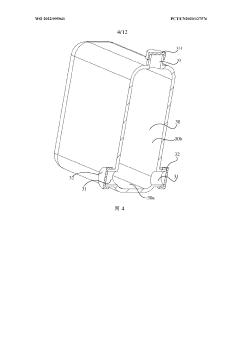

PatentWO2022095041A1

Innovation

- Design a battery storage device by setting a limiter and an inner box of cooling material in the casing. The limiter forms a slot to prevent battery collision. When the temperature rises, the leakage module fails and the cooling material overflows to reduce the temperature. .

Safety Regulations

Safety regulations play a crucial role in the implementation of Advanced Inert Battery (AIB) prototypes for stationary storage systems. These regulations are designed to ensure the safe operation, installation, and maintenance of energy storage systems, protecting both personnel and property from potential hazards.

One of the primary safety considerations for AIB prototypes is fire prevention and suppression. Regulatory bodies require comprehensive fire safety measures, including the use of fire-resistant materials, installation of fire detection and suppression systems, and the implementation of thermal management strategies. These measures are essential to mitigate the risk of thermal runaway, which can lead to catastrophic failures in battery systems.

Electrical safety is another critical aspect addressed by safety regulations. AIB prototypes must comply with stringent electrical standards, including proper insulation, grounding, and protection against short circuits and overloading. The integration of advanced Battery Management Systems (BMS) is often mandated to monitor and control voltage, current, and temperature parameters, ensuring safe operation within specified limits.

Environmental protection regulations also impact the implementation of AIB prototypes. These regulations typically cover aspects such as hazardous material handling, disposal procedures, and containment measures to prevent potential leaks or spills. Manufacturers and integrators must adhere to strict guidelines for the transportation, storage, and end-of-life management of battery components.

Safety regulations often require rigorous testing and certification processes for AIB prototypes. This includes performance testing under various conditions, abuse testing to evaluate system response to abnormal situations, and long-term reliability assessments. Compliance with international standards such as UL 9540 for energy storage systems and IEC 62619 for safety requirements of lithium-ion batteries is typically mandatory.

The integration of AIB prototypes into existing infrastructure necessitates compliance with building codes and local regulations. This may involve specific requirements for system placement, ventilation, access control, and emergency response procedures. Installers and system integrators must work closely with local authorities to ensure all safety requirements are met during the implementation process.

Occupational safety regulations also come into play, mandating proper training for personnel involved in the installation, operation, and maintenance of AIB systems. This includes the use of appropriate personal protective equipment (PPE), implementation of lockout/tagout procedures, and establishment of emergency response protocols.

As the technology evolves, safety regulations for AIB prototypes are likely to undergo continuous updates. Manufacturers and integrators must stay informed about the latest regulatory changes and adapt their designs and implementation strategies accordingly. This ongoing process ensures that safety standards keep pace with technological advancements, maintaining a balance between innovation and risk mitigation in the field of stationary energy storage.

One of the primary safety considerations for AIB prototypes is fire prevention and suppression. Regulatory bodies require comprehensive fire safety measures, including the use of fire-resistant materials, installation of fire detection and suppression systems, and the implementation of thermal management strategies. These measures are essential to mitigate the risk of thermal runaway, which can lead to catastrophic failures in battery systems.

Electrical safety is another critical aspect addressed by safety regulations. AIB prototypes must comply with stringent electrical standards, including proper insulation, grounding, and protection against short circuits and overloading. The integration of advanced Battery Management Systems (BMS) is often mandated to monitor and control voltage, current, and temperature parameters, ensuring safe operation within specified limits.

Environmental protection regulations also impact the implementation of AIB prototypes. These regulations typically cover aspects such as hazardous material handling, disposal procedures, and containment measures to prevent potential leaks or spills. Manufacturers and integrators must adhere to strict guidelines for the transportation, storage, and end-of-life management of battery components.

Safety regulations often require rigorous testing and certification processes for AIB prototypes. This includes performance testing under various conditions, abuse testing to evaluate system response to abnormal situations, and long-term reliability assessments. Compliance with international standards such as UL 9540 for energy storage systems and IEC 62619 for safety requirements of lithium-ion batteries is typically mandatory.

The integration of AIB prototypes into existing infrastructure necessitates compliance with building codes and local regulations. This may involve specific requirements for system placement, ventilation, access control, and emergency response procedures. Installers and system integrators must work closely with local authorities to ensure all safety requirements are met during the implementation process.

Occupational safety regulations also come into play, mandating proper training for personnel involved in the installation, operation, and maintenance of AIB systems. This includes the use of appropriate personal protective equipment (PPE), implementation of lockout/tagout procedures, and establishment of emergency response protocols.

As the technology evolves, safety regulations for AIB prototypes are likely to undergo continuous updates. Manufacturers and integrators must stay informed about the latest regulatory changes and adapt their designs and implementation strategies accordingly. This ongoing process ensures that safety standards keep pace with technological advancements, maintaining a balance between innovation and risk mitigation in the field of stationary energy storage.

Cost-Benefit Analysis

Implementing AIB (Anode-free Lithium-metal Battery) prototypes for stationary storage systems requires a comprehensive cost-benefit analysis to determine the economic viability and potential advantages over existing technologies. The initial investment in AIB technology may be higher due to the novelty of the approach and the need for specialized manufacturing processes. However, the long-term benefits could outweigh these upfront costs.

One of the primary advantages of AIB systems is their potential for higher energy density compared to traditional lithium-ion batteries. This increased energy storage capacity per unit volume or weight can lead to significant space savings and reduced infrastructure requirements for stationary storage applications. The cost savings associated with smaller footprints and simplified installation processes should be factored into the overall economic assessment.

Longevity is another crucial factor in the cost-benefit equation. AIB prototypes have shown promising results in terms of cycle life and capacity retention, which could translate to extended operational lifespans for stationary storage systems. This increased durability may result in lower replacement and maintenance costs over time, potentially offsetting the higher initial investment.

Safety considerations also play a role in the cost-benefit analysis. AIB technology's potential for improved safety characteristics, such as reduced risk of thermal runaway, could lead to lower insurance premiums and reduced need for extensive safety measures. These factors contribute to overall cost savings and operational benefits.

The scalability of AIB technology is another important aspect to consider. As production volumes increase and manufacturing processes are optimized, economies of scale are likely to drive down costs. This could make AIB systems increasingly competitive with established battery technologies in the stationary storage market.

Environmental benefits should also be factored into the analysis. AIB systems may offer advantages in terms of reduced environmental impact during production and end-of-life recycling. These benefits could translate into tangible cost savings through compliance with environmental regulations and potential government incentives for clean energy technologies.

It is essential to consider the integration costs associated with implementing AIB prototypes into existing energy infrastructure. While there may be initial challenges and expenses related to system compatibility and control integration, the long-term benefits of improved performance and efficiency could justify these investments.

In conclusion, a thorough cost-benefit analysis of AIB prototypes for stationary storage should weigh the initial higher costs against the potential long-term advantages in energy density, longevity, safety, scalability, and environmental impact. As the technology matures and production scales up, the economic benefits are likely to become increasingly favorable, positioning AIB systems as a competitive option in the stationary storage market.

One of the primary advantages of AIB systems is their potential for higher energy density compared to traditional lithium-ion batteries. This increased energy storage capacity per unit volume or weight can lead to significant space savings and reduced infrastructure requirements for stationary storage applications. The cost savings associated with smaller footprints and simplified installation processes should be factored into the overall economic assessment.

Longevity is another crucial factor in the cost-benefit equation. AIB prototypes have shown promising results in terms of cycle life and capacity retention, which could translate to extended operational lifespans for stationary storage systems. This increased durability may result in lower replacement and maintenance costs over time, potentially offsetting the higher initial investment.

Safety considerations also play a role in the cost-benefit analysis. AIB technology's potential for improved safety characteristics, such as reduced risk of thermal runaway, could lead to lower insurance premiums and reduced need for extensive safety measures. These factors contribute to overall cost savings and operational benefits.

The scalability of AIB technology is another important aspect to consider. As production volumes increase and manufacturing processes are optimized, economies of scale are likely to drive down costs. This could make AIB systems increasingly competitive with established battery technologies in the stationary storage market.

Environmental benefits should also be factored into the analysis. AIB systems may offer advantages in terms of reduced environmental impact during production and end-of-life recycling. These benefits could translate into tangible cost savings through compliance with environmental regulations and potential government incentives for clean energy technologies.

It is essential to consider the integration costs associated with implementing AIB prototypes into existing energy infrastructure. While there may be initial challenges and expenses related to system compatibility and control integration, the long-term benefits of improved performance and efficiency could justify these investments.

In conclusion, a thorough cost-benefit analysis of AIB prototypes for stationary storage should weigh the initial higher costs against the potential long-term advantages in energy density, longevity, safety, scalability, and environmental impact. As the technology matures and production scales up, the economic benefits are likely to become increasingly favorable, positioning AIB systems as a competitive option in the stationary storage market.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!