Reversible Al Intercalation Mechanisms: How to Characterize and Optimize Cathodes

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Al Intercalation Background and Objectives

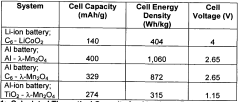

Aluminum-ion batteries have emerged as a promising alternative to lithium-ion batteries due to their potential for higher energy density, improved safety, and lower cost. The concept of aluminum intercalation, where aluminum ions are reversibly inserted into and extracted from cathode materials, forms the cornerstone of this technology. This process is crucial for the development of high-performance aluminum-ion batteries.

The evolution of aluminum intercalation technology can be traced back to the early 2000s when researchers began exploring aluminum as a potential charge carrier in rechargeable batteries. Initial studies focused on understanding the fundamental mechanisms of aluminum ion transport in various host materials. Over the past two decades, significant progress has been made in identifying suitable cathode materials and optimizing their structures for efficient aluminum intercalation.

The primary objective of research in this field is to develop cathode materials that can accommodate reversible aluminum intercalation with high capacity, fast kinetics, and long cycle life. This goal encompasses several key aspects, including the design of materials with appropriate crystal structures, optimization of electronic conductivity, and enhancement of aluminum ion diffusion pathways.

One of the main challenges in aluminum intercalation is the strong electrostatic interaction between the trivalent aluminum ions and the host lattice. This interaction can lead to structural distortions and slow diffusion kinetics, limiting the practical application of many cathode materials. Consequently, a significant focus of current research is on developing strategies to mitigate these issues and improve the overall performance of aluminum-ion batteries.

Recent technological trends in this field include the exploration of novel cathode materials such as transition metal oxides, sulfides, and organic compounds. Additionally, there is growing interest in the use of advanced characterization techniques, including in situ and operando methods, to gain deeper insights into the aluminum intercalation mechanisms at the atomic and molecular levels.

The development of aluminum intercalation technology is driven by the increasing demand for sustainable and high-performance energy storage solutions. As global energy needs continue to grow and the transition towards renewable energy sources accelerates, the importance of efficient and cost-effective battery technologies becomes ever more critical. Aluminum-ion batteries, with their potential for high energy density and use of abundant materials, are well-positioned to play a significant role in this evolving energy landscape.

The evolution of aluminum intercalation technology can be traced back to the early 2000s when researchers began exploring aluminum as a potential charge carrier in rechargeable batteries. Initial studies focused on understanding the fundamental mechanisms of aluminum ion transport in various host materials. Over the past two decades, significant progress has been made in identifying suitable cathode materials and optimizing their structures for efficient aluminum intercalation.

The primary objective of research in this field is to develop cathode materials that can accommodate reversible aluminum intercalation with high capacity, fast kinetics, and long cycle life. This goal encompasses several key aspects, including the design of materials with appropriate crystal structures, optimization of electronic conductivity, and enhancement of aluminum ion diffusion pathways.

One of the main challenges in aluminum intercalation is the strong electrostatic interaction between the trivalent aluminum ions and the host lattice. This interaction can lead to structural distortions and slow diffusion kinetics, limiting the practical application of many cathode materials. Consequently, a significant focus of current research is on developing strategies to mitigate these issues and improve the overall performance of aluminum-ion batteries.

Recent technological trends in this field include the exploration of novel cathode materials such as transition metal oxides, sulfides, and organic compounds. Additionally, there is growing interest in the use of advanced characterization techniques, including in situ and operando methods, to gain deeper insights into the aluminum intercalation mechanisms at the atomic and molecular levels.

The development of aluminum intercalation technology is driven by the increasing demand for sustainable and high-performance energy storage solutions. As global energy needs continue to grow and the transition towards renewable energy sources accelerates, the importance of efficient and cost-effective battery technologies becomes ever more critical. Aluminum-ion batteries, with their potential for high energy density and use of abundant materials, are well-positioned to play a significant role in this evolving energy landscape.

Market Analysis for Al-ion Batteries

The market for aluminum-ion batteries is experiencing significant growth and attracting increasing attention from both industry and academia. This emerging technology offers several advantages over traditional lithium-ion batteries, including potentially lower costs, improved safety, and faster charging capabilities. The global energy storage market, which encompasses various battery technologies, is projected to reach substantial value in the coming years, with aluminum-ion batteries poised to capture a growing share.

Key drivers for the adoption of aluminum-ion batteries include the rising demand for sustainable energy storage solutions, the need for safer battery technologies, and the increasing focus on rapid charging capabilities. Industries such as electric vehicles, renewable energy storage, and consumer electronics are showing particular interest in this technology due to its potential to address current limitations of lithium-ion batteries.

The market for aluminum-ion batteries is still in its early stages, with ongoing research and development efforts focused on improving performance and scalability. Several start-ups and established companies are investing in this technology, recognizing its potential to disrupt the energy storage landscape. However, the market faces challenges, including the need for further technological advancements to enhance energy density and cycle life.

Geographically, North America and Asia-Pacific regions are leading in aluminum-ion battery research and development. China, in particular, has shown strong interest in this technology, with several companies and research institutions actively working on commercialization efforts. Europe is also emerging as a significant player, driven by its focus on sustainable energy solutions and electric vehicle adoption.

The automotive sector represents a major potential market for aluminum-ion batteries, as manufacturers seek alternatives to lithium-ion technology to address range anxiety and charging time concerns. The grid storage market also presents significant opportunities, particularly in regions with high renewable energy penetration. Additionally, the consumer electronics industry is exploring aluminum-ion batteries as a safer and faster-charging alternative for portable devices.

While the market for aluminum-ion batteries is promising, it is important to note that the technology is still evolving. Continued investment in research and development, as well as scaling up manufacturing processes, will be crucial for realizing the full market potential of this technology. As advancements in cathode materials and electrolyte formulations progress, the market is expected to see increased adoption and diversification of applications in the coming years.

Key drivers for the adoption of aluminum-ion batteries include the rising demand for sustainable energy storage solutions, the need for safer battery technologies, and the increasing focus on rapid charging capabilities. Industries such as electric vehicles, renewable energy storage, and consumer electronics are showing particular interest in this technology due to its potential to address current limitations of lithium-ion batteries.

The market for aluminum-ion batteries is still in its early stages, with ongoing research and development efforts focused on improving performance and scalability. Several start-ups and established companies are investing in this technology, recognizing its potential to disrupt the energy storage landscape. However, the market faces challenges, including the need for further technological advancements to enhance energy density and cycle life.

Geographically, North America and Asia-Pacific regions are leading in aluminum-ion battery research and development. China, in particular, has shown strong interest in this technology, with several companies and research institutions actively working on commercialization efforts. Europe is also emerging as a significant player, driven by its focus on sustainable energy solutions and electric vehicle adoption.

The automotive sector represents a major potential market for aluminum-ion batteries, as manufacturers seek alternatives to lithium-ion technology to address range anxiety and charging time concerns. The grid storage market also presents significant opportunities, particularly in regions with high renewable energy penetration. Additionally, the consumer electronics industry is exploring aluminum-ion batteries as a safer and faster-charging alternative for portable devices.

While the market for aluminum-ion batteries is promising, it is important to note that the technology is still evolving. Continued investment in research and development, as well as scaling up manufacturing processes, will be crucial for realizing the full market potential of this technology. As advancements in cathode materials and electrolyte formulations progress, the market is expected to see increased adoption and diversification of applications in the coming years.

Current Challenges in Al Intercalation Cathodes

Aluminum-ion batteries have emerged as a promising alternative to lithium-ion batteries due to their potential for higher energy density, lower cost, and improved safety. However, the development of efficient and stable cathode materials for reversible Al intercalation remains a significant challenge in the field.

One of the primary obstacles is the limited understanding of Al intercalation mechanisms in various cathode materials. The trivalent nature of Al ions results in strong electrostatic interactions with host lattices, often leading to slow kinetics and structural instability. This challenge is further compounded by the lack of suitable characterization techniques that can accurately probe the Al intercalation process in real-time.

Another major hurdle is the development of cathode materials with high capacity and long cycle life. Many potential cathode materials suffer from rapid capacity fading due to irreversible structural changes during repeated Al insertion and extraction. This issue is particularly pronounced in layered materials, where the host structure may collapse or undergo phase transitions during cycling.

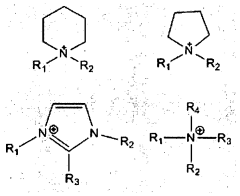

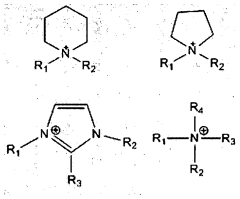

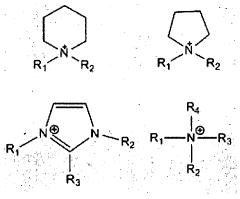

The choice of electrolyte also presents a significant challenge in optimizing Al intercalation cathodes. Most Al-ion batteries rely on chloroaluminate ionic liquids as electrolytes, which are corrosive and moisture-sensitive. These properties limit the selection of cathode materials and complicate cell assembly and long-term stability.

Furthermore, the multivalent nature of Al ions often leads to the formation of strong Al-O bonds in oxide-based cathodes, resulting in sluggish diffusion kinetics and poor rate capability. This challenge necessitates the exploration of novel cathode architectures and compositions that can facilitate rapid Al ion transport while maintaining structural integrity.

The development of in situ and operando characterization techniques specifically tailored for Al-ion systems is crucial for advancing our understanding of intercalation mechanisms. Current methods often fall short in providing detailed insights into the structural and chemical changes occurring during Al insertion and extraction, hindering the rational design of improved cathode materials.

Lastly, the scalability and practical implementation of Al intercalation cathodes pose significant challenges. Many promising materials developed in laboratory settings face obstacles in scaling up for commercial production, including issues related to synthesis complexity, cost, and environmental impact.

Addressing these challenges requires a multidisciplinary approach, combining advanced materials science, electrochemistry, and characterization techniques. Overcoming these hurdles will be critical in realizing the full potential of Al-ion batteries as a viable energy storage technology.

One of the primary obstacles is the limited understanding of Al intercalation mechanisms in various cathode materials. The trivalent nature of Al ions results in strong electrostatic interactions with host lattices, often leading to slow kinetics and structural instability. This challenge is further compounded by the lack of suitable characterization techniques that can accurately probe the Al intercalation process in real-time.

Another major hurdle is the development of cathode materials with high capacity and long cycle life. Many potential cathode materials suffer from rapid capacity fading due to irreversible structural changes during repeated Al insertion and extraction. This issue is particularly pronounced in layered materials, where the host structure may collapse or undergo phase transitions during cycling.

The choice of electrolyte also presents a significant challenge in optimizing Al intercalation cathodes. Most Al-ion batteries rely on chloroaluminate ionic liquids as electrolytes, which are corrosive and moisture-sensitive. These properties limit the selection of cathode materials and complicate cell assembly and long-term stability.

Furthermore, the multivalent nature of Al ions often leads to the formation of strong Al-O bonds in oxide-based cathodes, resulting in sluggish diffusion kinetics and poor rate capability. This challenge necessitates the exploration of novel cathode architectures and compositions that can facilitate rapid Al ion transport while maintaining structural integrity.

The development of in situ and operando characterization techniques specifically tailored for Al-ion systems is crucial for advancing our understanding of intercalation mechanisms. Current methods often fall short in providing detailed insights into the structural and chemical changes occurring during Al insertion and extraction, hindering the rational design of improved cathode materials.

Lastly, the scalability and practical implementation of Al intercalation cathodes pose significant challenges. Many promising materials developed in laboratory settings face obstacles in scaling up for commercial production, including issues related to synthesis complexity, cost, and environmental impact.

Addressing these challenges requires a multidisciplinary approach, combining advanced materials science, electrochemistry, and characterization techniques. Overcoming these hurdles will be critical in realizing the full potential of Al-ion batteries as a viable energy storage technology.

Existing Cathode Characterization Methods

01 Aluminum intercalation cathode materials

Various materials are being developed as cathodes for aluminum intercalation batteries. These materials are designed to allow reversible insertion and extraction of aluminum ions, improving the overall performance and cycle life of the battery. Research focuses on optimizing the structure and composition of these cathode materials to enhance their intercalation properties and stability.- Aluminum intercalation cathode materials: Various materials are being explored as cathodes for aluminum intercalation batteries. These materials are designed to allow reversible insertion and extraction of aluminum ions, which is crucial for the battery's rechargeability. Research focuses on improving the structural stability and electrochemical performance of these cathodes to enhance overall battery efficiency and lifespan.

- Electrolyte composition for Al-ion batteries: The electrolyte composition plays a vital role in the reversibility of aluminum intercalation cathodes. Researchers are developing novel electrolyte formulations that facilitate efficient aluminum ion transport while minimizing side reactions. These electrolytes aim to improve the cycling stability and coulombic efficiency of Al-ion batteries.

- Nanostructured cathode designs: Nanostructured cathode designs are being investigated to enhance the reversibility of aluminum intercalation. These designs aim to increase the surface area and reduce diffusion distances for aluminum ions, leading to improved kinetics and cycling performance. Various nanostructures, such as nanoparticles, nanowires, and nanocomposites, are being explored.

- Surface modification of cathode materials: Surface modification techniques are being employed to improve the reversibility of aluminum intercalation cathodes. These modifications aim to stabilize the cathode-electrolyte interface, reduce side reactions, and enhance the overall electrochemical performance. Various coating materials and surface treatments are being investigated to achieve these goals.

- In-situ characterization techniques: Advanced in-situ characterization techniques are being developed to study the aluminum intercalation process in real-time. These techniques allow researchers to observe structural changes, ion transport mechanisms, and interfacial reactions during battery operation. This information is crucial for understanding and improving the reversibility of aluminum intercalation cathodes.

02 Electrolyte composition for Al-ion batteries

The electrolyte composition plays a crucial role in the reversibility of aluminum intercalation cathodes. Researchers are developing novel electrolyte formulations that facilitate efficient aluminum ion transport and minimize side reactions. These electrolytes aim to improve the overall performance, stability, and cycle life of aluminum-ion batteries.Expand Specific Solutions03 Nanostructured cathode materials

Nanostructured cathode materials are being explored to enhance the reversibility of aluminum intercalation. These materials offer increased surface area and shorter diffusion paths for aluminum ions, leading to improved intercalation kinetics and overall battery performance. Various synthesis methods and nanostructure designs are being investigated to optimize these cathode materials.Expand Specific Solutions04 Coating and surface modification techniques

Surface modification and coating techniques are being employed to improve the stability and reversibility of aluminum intercalation cathodes. These methods aim to protect the cathode material from unwanted side reactions, enhance the interfacial properties, and maintain the structural integrity of the cathode during repeated cycling.Expand Specific Solutions05 In-situ characterization of Al intercalation

Advanced in-situ characterization techniques are being developed to study the aluminum intercalation process in real-time. These methods provide valuable insights into the structural and chemical changes occurring during battery operation, helping researchers optimize cathode materials and improve the overall reversibility of aluminum intercalation batteries.Expand Specific Solutions

Key Players in Al-ion Battery Research

The reversible Al intercalation mechanisms for cathode optimization represent an emerging field in energy storage technology. The industry is in its early development stage, with significant potential for growth as demand for high-performance batteries increases. The market size is expanding, driven by the need for more efficient and sustainable energy storage solutions. Technologically, the field is still maturing, with ongoing research to improve cathode materials and characterization methods. Key players like Massachusetts Institute of Technology, Northwestern University, and Shell are actively contributing to advancements. Universities and research institutions are at the forefront of innovation, while established companies are investing in R&D to commercialize promising technologies. The competitive landscape is dynamic, with collaborations between academia and industry accelerating progress in this crucial area of battery technology.

Massachusetts Institute of Technology

Technical Solution: MIT has developed advanced characterization techniques for studying reversible Al intercalation mechanisms in cathode materials. They utilize in-situ X-ray diffraction (XRD) and X-ray absorption spectroscopy (XAS) to track structural changes during Al insertion/extraction[1]. Their approach combines computational modeling with experimental data to elucidate the atomic-scale processes occurring during cycling. MIT researchers have also explored novel cathode materials like transition metal oxides and sulfides with layered structures that can accommodate Al ions[2]. They focus on optimizing the interlayer spacing and electronic structure to enhance Al mobility and storage capacity.

Strengths: Cutting-edge characterization techniques, combined experimental-computational approach. Weaknesses: May be more focused on fundamental research rather than commercial applications.

Northwestern University

Technical Solution: Northwestern University has made significant strides in developing and optimizing cathode materials for reversible Al intercalation. Their research focuses on layered double hydroxides (LDHs) as promising cathode materials[3]. They have developed a novel synthesis method to create LDHs with controlled composition and morphology, resulting in improved Al intercalation kinetics and cycling stability. Northwestern's team has also investigated the use of graphene-based materials as conductive additives to enhance the electronic conductivity of cathode materials[4]. Their approach combines advanced material synthesis techniques with in-depth electrochemical characterization to optimize cathode performance.

Strengths: Innovative material design, focus on practical improvements in cathode performance. Weaknesses: May face challenges in scaling up novel materials for commercial production.

Core Innovations in Al Intercalation Mechanisms

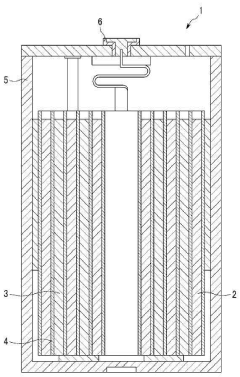

A high energy density aluminum battery

PatentWO2012044678A2

Innovation

- Development of high energy density aluminum batteries with an aluminum anode, a cathode capable of intercalating aluminum or lithium ions, and an electrolyte that supports reversible deposition and stripping of aluminum, utilizing materials like Ti(AICI4)2, MnCI(AICI4), Co(AICI4)2, and ionic liquids with specific compositions to maintain stability and performance.

Positive active material for rechargeable lithium battery, method of preparing the same, and rechargeable lithium battery including the same

PatentActiveKR1020140118860A

Innovation

- A cathode active material with a coating layer containing a metal (M) like Al, Zr, Ti, Mg, Ca, V, Zn, Mo, Ni, Co, or Mn, applied to the surface of lithium cobalt or nickel cobalt manganese composite oxides, reduces surface free energy, suppressing electrolyte wetting and enhancing high-rate and long-life characteristics.

Environmental Impact of Al-ion Batteries

The environmental impact of Al-ion batteries is a crucial consideration in their development and potential widespread adoption. These batteries offer several environmental advantages over traditional lithium-ion batteries, primarily due to the abundance and recyclability of aluminum.

Aluminum is the third most abundant element in the Earth's crust, making it a more sustainable choice for large-scale battery production compared to lithium. The extraction and processing of aluminum have a lower environmental footprint than lithium, reducing the overall ecological impact of battery manufacturing.

One of the key environmental benefits of Al-ion batteries is their potential for improved recyclability. The aluminum components can be more easily recovered and reused compared to lithium-ion batteries, leading to a more circular economy approach in battery production and disposal. This recyclability can significantly reduce waste and the need for new raw material extraction.

Al-ion batteries also have the potential to be safer than lithium-ion batteries, with a lower risk of thermal runaway and fire. This increased safety profile not only benefits users but also reduces the environmental risks associated with battery accidents and disposal.

The production process of Al-ion batteries may require less energy compared to lithium-ion batteries, potentially reducing greenhouse gas emissions associated with battery manufacturing. However, more research is needed to quantify these energy savings accurately across the entire production chain.

Water usage in Al-ion battery production is another area where environmental benefits may be realized. The extraction and processing of aluminum typically require less water compared to lithium, potentially reducing the strain on water resources in battery production regions.

Despite these advantages, it's important to note that Al-ion battery technology is still in its early stages, and large-scale production and use may reveal unforeseen environmental challenges. Ongoing research is needed to fully understand and mitigate any potential negative impacts as the technology matures.

The development of Al-ion batteries also presents an opportunity to design for sustainability from the outset. Incorporating principles of green chemistry and engineering into the research and development process can help minimize environmental impacts throughout the battery lifecycle.

As the technology progresses, life cycle assessments will be crucial in comparing the overall environmental impact of Al-ion batteries to other energy storage solutions. These assessments should consider raw material extraction, manufacturing processes, use phase efficiency, and end-of-life management to provide a comprehensive view of the environmental implications.

Aluminum is the third most abundant element in the Earth's crust, making it a more sustainable choice for large-scale battery production compared to lithium. The extraction and processing of aluminum have a lower environmental footprint than lithium, reducing the overall ecological impact of battery manufacturing.

One of the key environmental benefits of Al-ion batteries is their potential for improved recyclability. The aluminum components can be more easily recovered and reused compared to lithium-ion batteries, leading to a more circular economy approach in battery production and disposal. This recyclability can significantly reduce waste and the need for new raw material extraction.

Al-ion batteries also have the potential to be safer than lithium-ion batteries, with a lower risk of thermal runaway and fire. This increased safety profile not only benefits users but also reduces the environmental risks associated with battery accidents and disposal.

The production process of Al-ion batteries may require less energy compared to lithium-ion batteries, potentially reducing greenhouse gas emissions associated with battery manufacturing. However, more research is needed to quantify these energy savings accurately across the entire production chain.

Water usage in Al-ion battery production is another area where environmental benefits may be realized. The extraction and processing of aluminum typically require less water compared to lithium, potentially reducing the strain on water resources in battery production regions.

Despite these advantages, it's important to note that Al-ion battery technology is still in its early stages, and large-scale production and use may reveal unforeseen environmental challenges. Ongoing research is needed to fully understand and mitigate any potential negative impacts as the technology matures.

The development of Al-ion batteries also presents an opportunity to design for sustainability from the outset. Incorporating principles of green chemistry and engineering into the research and development process can help minimize environmental impacts throughout the battery lifecycle.

As the technology progresses, life cycle assessments will be crucial in comparing the overall environmental impact of Al-ion batteries to other energy storage solutions. These assessments should consider raw material extraction, manufacturing processes, use phase efficiency, and end-of-life management to provide a comprehensive view of the environmental implications.

Scalability and Manufacturing Considerations

The scalability and manufacturing considerations for reversible Al intercalation cathodes are crucial for their practical implementation in large-scale energy storage systems. One of the primary challenges is the development of cost-effective and scalable production methods for cathode materials. Current laboratory-scale synthesis techniques, such as hydrothermal or sol-gel methods, may not be suitable for industrial-scale production. Therefore, research efforts should focus on adapting these processes or developing new ones that can maintain material quality while increasing production volume.

Another important aspect is the optimization of cathode composition and structure for improved performance and durability. This includes fine-tuning the particle size distribution, porosity, and surface area of the cathode materials to enhance Al ion diffusion and overall electrochemical performance. Additionally, the development of advanced coating technologies and surface modification techniques can help improve the stability and cycling performance of the cathodes at scale.

The selection of appropriate binders and conductive additives is also critical for large-scale manufacturing. These components must be compatible with the cathode material and the aluminum-based electrolyte while maintaining their functionality over extended cycling. Furthermore, the optimization of electrode formulation and coating processes is essential to ensure uniform distribution of active materials and additives, as well as to achieve the desired thickness and porosity of the cathode layer.

Scalability considerations extend to the cell and battery pack design as well. The development of efficient and cost-effective cell assembly processes, including electrode stacking or winding techniques, must be addressed. Moreover, the integration of these cells into larger battery packs requires careful thermal management and safety considerations, particularly given the potential for dendrite formation in aluminum-based systems.

Environmental and sustainability aspects should also be taken into account when scaling up production. This includes the development of eco-friendly synthesis routes, the use of abundant and non-toxic materials, and the implementation of recycling strategies for end-of-life batteries. These considerations are crucial for ensuring the long-term viability and market acceptance of Al-ion battery technology.

Lastly, quality control and testing procedures must be established to maintain consistent performance across large-scale production batches. This involves the development of in-line monitoring techniques, standardized testing protocols, and automated inspection systems to ensure that the manufactured cathodes meet the required specifications and performance criteria.

Another important aspect is the optimization of cathode composition and structure for improved performance and durability. This includes fine-tuning the particle size distribution, porosity, and surface area of the cathode materials to enhance Al ion diffusion and overall electrochemical performance. Additionally, the development of advanced coating technologies and surface modification techniques can help improve the stability and cycling performance of the cathodes at scale.

The selection of appropriate binders and conductive additives is also critical for large-scale manufacturing. These components must be compatible with the cathode material and the aluminum-based electrolyte while maintaining their functionality over extended cycling. Furthermore, the optimization of electrode formulation and coating processes is essential to ensure uniform distribution of active materials and additives, as well as to achieve the desired thickness and porosity of the cathode layer.

Scalability considerations extend to the cell and battery pack design as well. The development of efficient and cost-effective cell assembly processes, including electrode stacking or winding techniques, must be addressed. Moreover, the integration of these cells into larger battery packs requires careful thermal management and safety considerations, particularly given the potential for dendrite formation in aluminum-based systems.

Environmental and sustainability aspects should also be taken into account when scaling up production. This includes the development of eco-friendly synthesis routes, the use of abundant and non-toxic materials, and the implementation of recycling strategies for end-of-life batteries. These considerations are crucial for ensuring the long-term viability and market acceptance of Al-ion battery technology.

Lastly, quality control and testing procedures must be established to maintain consistent performance across large-scale production batches. This involves the development of in-line monitoring techniques, standardized testing protocols, and automated inspection systems to ensure that the manufactured cathodes meet the required specifications and performance criteria.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!