Aluminum-Ion Batteries: Fundamentals, Promises and Current Limitations

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Al-Ion Battery Evolution and Objectives

Aluminum-ion batteries have emerged as a promising alternative to traditional lithium-ion batteries, driven by the increasing demand for sustainable and high-performance energy storage solutions. The evolution of Al-ion batteries can be traced back to the early 2000s when researchers began exploring aluminum as a potential electrode material due to its abundance, low cost, and high theoretical capacity.

The initial research focused on understanding the fundamental electrochemistry of aluminum in battery systems. Scientists investigated various electrolyte compositions and cathode materials to overcome the challenges associated with aluminum's trivalent nature and the formation of passivation layers. These early studies laid the groundwork for subsequent developments in Al-ion battery technology.

As research progressed, the objectives of Al-ion battery development became more defined. The primary goals included achieving higher energy density, improved cycling stability, and faster charging rates compared to existing battery technologies. Researchers aimed to leverage aluminum's theoretical capacity of 2980 mAh/g, which is significantly higher than that of lithium (3860 mAh/g), while addressing the limitations of aluminum's low diffusion rate in solid electrodes.

One of the key milestones in Al-ion battery evolution was the development of graphite-based cathodes in the mid-2010s. This breakthrough demonstrated the feasibility of reversible aluminum intercalation and paved the way for further advancements in cathode materials. Subsequent research focused on optimizing the cathode structure and composition to enhance capacity and cycling performance.

Parallel to cathode development, significant efforts were directed towards improving electrolyte formulations. The discovery of room-temperature ionic liquids as suitable electrolytes for Al-ion batteries marked another crucial step in their evolution. These electrolytes enabled stable aluminum plating and stripping, addressing one of the major challenges in Al-ion battery technology.

Recent objectives in Al-ion battery research have expanded to include the development of flexible and wearable energy storage devices. This shift reflects the growing demand for portable and adaptable power sources in various applications, from consumer electronics to electric vehicles.

Looking ahead, the objectives for Al-ion battery technology continue to evolve. Researchers are now focusing on scaling up production processes, improving the overall energy efficiency of the battery systems, and exploring novel materials and architectures to push the boundaries of performance. The ultimate goal is to create Al-ion batteries that can compete with or surpass the capabilities of current lithium-ion technologies while offering advantages in terms of cost, safety, and environmental impact.

The initial research focused on understanding the fundamental electrochemistry of aluminum in battery systems. Scientists investigated various electrolyte compositions and cathode materials to overcome the challenges associated with aluminum's trivalent nature and the formation of passivation layers. These early studies laid the groundwork for subsequent developments in Al-ion battery technology.

As research progressed, the objectives of Al-ion battery development became more defined. The primary goals included achieving higher energy density, improved cycling stability, and faster charging rates compared to existing battery technologies. Researchers aimed to leverage aluminum's theoretical capacity of 2980 mAh/g, which is significantly higher than that of lithium (3860 mAh/g), while addressing the limitations of aluminum's low diffusion rate in solid electrodes.

One of the key milestones in Al-ion battery evolution was the development of graphite-based cathodes in the mid-2010s. This breakthrough demonstrated the feasibility of reversible aluminum intercalation and paved the way for further advancements in cathode materials. Subsequent research focused on optimizing the cathode structure and composition to enhance capacity and cycling performance.

Parallel to cathode development, significant efforts were directed towards improving electrolyte formulations. The discovery of room-temperature ionic liquids as suitable electrolytes for Al-ion batteries marked another crucial step in their evolution. These electrolytes enabled stable aluminum plating and stripping, addressing one of the major challenges in Al-ion battery technology.

Recent objectives in Al-ion battery research have expanded to include the development of flexible and wearable energy storage devices. This shift reflects the growing demand for portable and adaptable power sources in various applications, from consumer electronics to electric vehicles.

Looking ahead, the objectives for Al-ion battery technology continue to evolve. Researchers are now focusing on scaling up production processes, improving the overall energy efficiency of the battery systems, and exploring novel materials and architectures to push the boundaries of performance. The ultimate goal is to create Al-ion batteries that can compete with or surpass the capabilities of current lithium-ion technologies while offering advantages in terms of cost, safety, and environmental impact.

Market Potential for Al-Ion Energy Storage

The market potential for aluminum-ion (Al-ion) energy storage is rapidly expanding as the global demand for sustainable and efficient energy solutions continues to grow. Al-ion batteries are emerging as a promising alternative to traditional lithium-ion batteries, offering several advantages that could disrupt the energy storage market.

One of the key drivers for Al-ion battery market potential is the abundance and low cost of aluminum. As the third most abundant element in the Earth's crust, aluminum is significantly more accessible and cheaper than lithium. This factor alone positions Al-ion batteries as a potentially more cost-effective solution for large-scale energy storage applications, particularly in grid storage and renewable energy integration.

The safety profile of Al-ion batteries also contributes to their market appeal. Unlike lithium-ion batteries, which have faced scrutiny due to thermal runaway risks, Al-ion batteries are inherently safer due to their non-flammable nature. This characteristic makes them particularly attractive for use in electric vehicles and portable electronics, where safety is a paramount concern.

Environmental considerations further enhance the market potential of Al-ion batteries. The recyclability of aluminum and the lower environmental impact of its production compared to lithium extraction align well with the growing emphasis on sustainable technologies. As governments and industries worldwide push for greener solutions, Al-ion batteries could gain significant traction in the market.

The fast-charging capabilities of Al-ion batteries present another compelling advantage. With the potential to charge significantly faster than lithium-ion batteries, Al-ion technology could address one of the major pain points in electric vehicle adoption and mobile device usage. This feature opens up new market opportunities in sectors where rapid charging is critical.

However, the market potential is not without challenges. The current energy density limitations of Al-ion batteries compared to lithium-ion counterparts may initially restrict their application in certain high-energy demand sectors. Overcoming this hurdle through ongoing research and development will be crucial for expanding market reach.

The industrial and stationary energy storage sectors represent significant market opportunities for Al-ion batteries. Their potential for long cycle life and high power output makes them well-suited for grid stabilization, peak shaving, and renewable energy storage applications. As the renewable energy sector continues to grow, the demand for efficient and cost-effective energy storage solutions is expected to surge, potentially creating a substantial market for Al-ion technology.

One of the key drivers for Al-ion battery market potential is the abundance and low cost of aluminum. As the third most abundant element in the Earth's crust, aluminum is significantly more accessible and cheaper than lithium. This factor alone positions Al-ion batteries as a potentially more cost-effective solution for large-scale energy storage applications, particularly in grid storage and renewable energy integration.

The safety profile of Al-ion batteries also contributes to their market appeal. Unlike lithium-ion batteries, which have faced scrutiny due to thermal runaway risks, Al-ion batteries are inherently safer due to their non-flammable nature. This characteristic makes them particularly attractive for use in electric vehicles and portable electronics, where safety is a paramount concern.

Environmental considerations further enhance the market potential of Al-ion batteries. The recyclability of aluminum and the lower environmental impact of its production compared to lithium extraction align well with the growing emphasis on sustainable technologies. As governments and industries worldwide push for greener solutions, Al-ion batteries could gain significant traction in the market.

The fast-charging capabilities of Al-ion batteries present another compelling advantage. With the potential to charge significantly faster than lithium-ion batteries, Al-ion technology could address one of the major pain points in electric vehicle adoption and mobile device usage. This feature opens up new market opportunities in sectors where rapid charging is critical.

However, the market potential is not without challenges. The current energy density limitations of Al-ion batteries compared to lithium-ion counterparts may initially restrict their application in certain high-energy demand sectors. Overcoming this hurdle through ongoing research and development will be crucial for expanding market reach.

The industrial and stationary energy storage sectors represent significant market opportunities for Al-ion batteries. Their potential for long cycle life and high power output makes them well-suited for grid stabilization, peak shaving, and renewable energy storage applications. As the renewable energy sector continues to grow, the demand for efficient and cost-effective energy storage solutions is expected to surge, potentially creating a substantial market for Al-ion technology.

Current Al-Ion Battery Tech Challenges

Aluminum-ion batteries face several significant technical challenges that currently limit their widespread adoption and commercialization. One of the primary issues is the lack of suitable cathode materials that can withstand repeated intercalation and de-intercalation of aluminum ions. The large size and high charge density of Al3+ ions often lead to structural degradation of cathode materials over multiple charge-discharge cycles, resulting in poor cycling stability and reduced battery lifespan.

Another major challenge is the development of electrolytes that can effectively facilitate aluminum ion transport while maintaining stability over a wide electrochemical window. Current electrolytes often suffer from corrosion issues, limited electrochemical stability, and low ionic conductivity, which hinder the overall performance of Al-ion batteries.

The anode material also presents challenges, as aluminum metal anodes are prone to dendrite formation during cycling. This can lead to short circuits and safety concerns, necessitating the development of strategies to mitigate dendrite growth or alternative anode materials that maintain high capacity and stability.

Furthermore, the energy density of Al-ion batteries is currently lower than that of commercial lithium-ion batteries. This is partly due to the limited specific capacity of available cathode materials and the challenges in achieving high operating voltages. Improving energy density while maintaining other performance metrics remains a critical area of research.

The rate capability of Al-ion batteries is another area requiring improvement. The slow kinetics of aluminum ion insertion and extraction in many electrode materials result in limited power density, restricting their application in high-power devices.

Scalability and manufacturing processes for Al-ion batteries also present challenges. Many of the promising materials and architectures developed in laboratory settings are difficult to scale up for mass production, hindering the transition from research to commercial applications.

Lastly, there is a need for comprehensive understanding of the fundamental reaction mechanisms and degradation processes in Al-ion batteries. This knowledge gap hampers the rational design of improved materials and cell architectures, necessitating further in-depth studies of the electrochemistry and materials science involved in Al-ion systems.

Another major challenge is the development of electrolytes that can effectively facilitate aluminum ion transport while maintaining stability over a wide electrochemical window. Current electrolytes often suffer from corrosion issues, limited electrochemical stability, and low ionic conductivity, which hinder the overall performance of Al-ion batteries.

The anode material also presents challenges, as aluminum metal anodes are prone to dendrite formation during cycling. This can lead to short circuits and safety concerns, necessitating the development of strategies to mitigate dendrite growth or alternative anode materials that maintain high capacity and stability.

Furthermore, the energy density of Al-ion batteries is currently lower than that of commercial lithium-ion batteries. This is partly due to the limited specific capacity of available cathode materials and the challenges in achieving high operating voltages. Improving energy density while maintaining other performance metrics remains a critical area of research.

The rate capability of Al-ion batteries is another area requiring improvement. The slow kinetics of aluminum ion insertion and extraction in many electrode materials result in limited power density, restricting their application in high-power devices.

Scalability and manufacturing processes for Al-ion batteries also present challenges. Many of the promising materials and architectures developed in laboratory settings are difficult to scale up for mass production, hindering the transition from research to commercial applications.

Lastly, there is a need for comprehensive understanding of the fundamental reaction mechanisms and degradation processes in Al-ion batteries. This knowledge gap hampers the rational design of improved materials and cell architectures, necessitating further in-depth studies of the electrochemistry and materials science involved in Al-ion systems.

Existing Al-Ion Battery Designs

01 Electrode materials for aluminum-ion batteries

Various materials are being explored for use as electrodes in aluminum-ion batteries. These include carbon-based materials, metal oxides, and composite structures. The choice of electrode material significantly affects the battery's performance, including its capacity, cycling stability, and charge-discharge rates.- Electrode materials for aluminum-ion batteries: Various materials are being explored for use as electrodes in aluminum-ion batteries. These include carbon-based materials, metal oxides, and composite structures. The choice of electrode material significantly affects the battery's performance, including its capacity, cycling stability, and charge-discharge rates.

- Electrolyte compositions for aluminum-ion batteries: The development of suitable electrolytes is crucial for aluminum-ion batteries. Research focuses on ionic liquids, organic solvents, and their combinations to create electrolytes that enable efficient aluminum ion transport while maintaining stability and safety. The electrolyte composition affects the battery's conductivity, voltage window, and overall performance.

- Structural design of aluminum-ion batteries: Innovative structural designs are being explored to enhance the performance of aluminum-ion batteries. This includes the development of 3D electrode architectures, nanostructured materials, and novel cell configurations. These designs aim to improve ion diffusion, increase active surface area, and enhance the overall energy density of the battery.

- Improving cycling stability and lifespan: Enhancing the cycling stability and lifespan of aluminum-ion batteries is a key focus area. Researchers are developing strategies to mitigate issues such as electrode degradation, electrolyte decomposition, and capacity fading. This includes surface modifications, protective coatings, and the use of additives to stabilize the electrode-electrolyte interface.

- Integration and application of aluminum-ion batteries: Research is ongoing to integrate aluminum-ion batteries into various applications and to scale up their production. This includes developing battery management systems, exploring their use in grid storage and electric vehicles, and addressing challenges related to manufacturing and commercialization. The focus is on leveraging the potential advantages of aluminum-ion technology, such as low cost and high theoretical capacity.

02 Electrolyte compositions for aluminum-ion batteries

The development of suitable electrolytes is crucial for aluminum-ion batteries. Research focuses on ionic liquids, organic solvents, and their combinations to create electrolytes that enable efficient aluminum ion transport while maintaining stability and safety. The electrolyte composition affects the battery's conductivity, voltage window, and overall performance.Expand Specific Solutions03 Battery structure and design innovations

Innovations in the structural design of aluminum-ion batteries aim to improve their performance and practicality. This includes novel cell architectures, packaging methods, and integration of components. These design improvements can enhance energy density, reduce internal resistance, and improve thermal management.Expand Specific Solutions04 Manufacturing processes for aluminum-ion batteries

Advancements in manufacturing techniques for aluminum-ion batteries focus on scalability, cost-effectiveness, and quality control. This includes methods for electrode preparation, electrolyte filling, and cell assembly. Improved manufacturing processes can lead to more consistent performance and reduced production costs.Expand Specific Solutions05 Performance optimization and characterization

Research efforts are directed towards optimizing the performance of aluminum-ion batteries and developing methods for their characterization. This includes improving cycling stability, increasing energy density, and enhancing rate capability. Advanced characterization techniques are employed to understand degradation mechanisms and guide further improvements.Expand Specific Solutions

Key Players in Al-Ion Battery Research

The aluminum-ion battery market is in its early development stage, with significant potential for growth due to increasing demand for sustainable energy storage solutions. While the market size is currently limited, it is expected to expand rapidly as the technology matures. The competitive landscape is characterized by a mix of academic institutions, research organizations, and private companies working on advancing the technology. Key players like Industrial Technology Research Institute, Ionic Materials Inc., and Alsym Energy are at the forefront of research and development, focusing on overcoming current limitations such as low energy density and cycle life. Universities, including Beijing Institute of Technology and Washington State University, are contributing to fundamental research. As the technology progresses, established battery manufacturers and automotive companies may increasingly enter the market, potentially accelerating commercialization efforts.

Beijing Institute of Technology

Technical Solution: Beijing Institute of Technology has made significant strides in aluminum-ion battery research, focusing on developing high-performance cathode materials. Their approach involves using graphene-based materials as cathodes, which have shown promising results in terms of energy density and cycling stability. The institute has reported achieving a specific capacity of over 100 mAh/g and a cycling life of more than 1000 cycles[1]. They have also explored the use of three-dimensional graphene networks to enhance the ion diffusion and electron transfer processes, leading to improved rate capability and long-term stability[2]. Additionally, the institute has investigated the use of organic compounds as cathode materials, which offer the potential for sustainable and low-cost aluminum-ion batteries[3].

Strengths: High cycling stability, improved energy density, and potential for sustainable materials. Weaknesses: Still facing challenges in achieving commercial-level energy density comparable to lithium-ion batteries.

Ionic Materials Inc.

Technical Solution: Ionic Materials Inc. has developed a novel solid polymer electrolyte that could potentially revolutionize aluminum-ion battery technology. Their proprietary polymer allows for the efficient transport of aluminum ions, addressing one of the key challenges in aluminum-ion battery development. The company's electrolyte is reported to be stable at high voltages and compatible with high-capacity electrode materials[4]. This innovation potentially enables the use of aluminum metal anodes, which could significantly increase the energy density of the batteries. Ionic Materials' technology also aims to improve safety by eliminating the need for flammable liquid electrolytes commonly used in conventional batteries[5].

Strengths: Enhanced safety, potential for high energy density, and compatibility with various electrode materials. Weaknesses: Relatively new technology with limited large-scale production experience.

Breakthrough Al-Ion Battery Patents

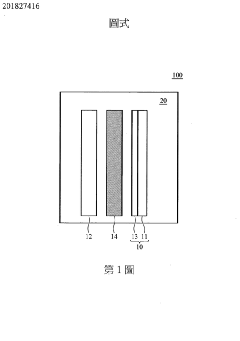

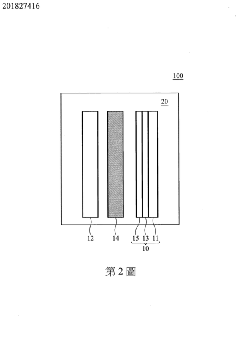

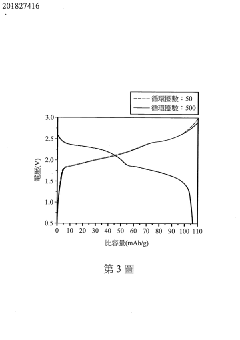

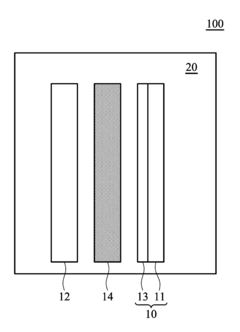

Aluminum-ion battery

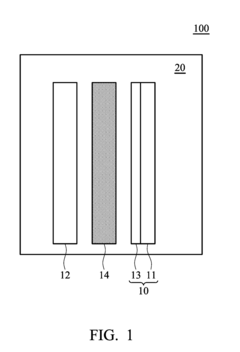

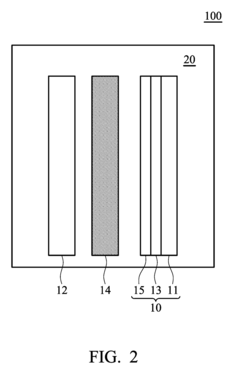

PatentActiveTW201827416A

Innovation

- Incorporation of a compound with formula (I) (C1-8 alkyl or C1-8 fluoroalkyl) in the electrolyte composition, along with aluminum halide and solvent, enhances electrolyte stability and conductivity, preventing decomposition during charging and discharging, and adding an amphoteric compound layer on the positive electrode further improves charge retention and energy density.

Aluminum-ion battery

PatentInactiveUS20180219257A1

Innovation

- The aluminum-ion battery incorporates an electrolyte composition comprising an aluminum halide, a solvent, and a zwitterionic compound of Formula (I), with specific weight ratios, and a zwitterionic compound layer on the positive electrode to enhance stability and conductivity, preventing decomposition and improving charge retention and power density.

Environmental Impact of Al-Ion Batteries

The environmental impact of Al-ion batteries is a crucial consideration in their development and potential widespread adoption. These batteries offer several environmental advantages over traditional lithium-ion batteries, primarily due to the abundance and recyclability of aluminum.

Aluminum is the third most abundant element in the Earth's crust, making it a more sustainable choice for large-scale battery production compared to lithium. The extraction and processing of aluminum have a lower environmental footprint than lithium, reducing the overall ecological impact of battery manufacturing. Additionally, the existing infrastructure for aluminum recycling can be leveraged to create a more circular economy for Al-ion batteries.

The production of Al-ion batteries generally requires less energy and generates fewer greenhouse gas emissions compared to lithium-ion batteries. This is partly due to the lower processing temperatures needed for aluminum-based materials. The reduced energy consumption during manufacturing contributes to a lower carbon footprint over the battery's lifecycle.

Al-ion batteries also present fewer safety concerns than lithium-ion batteries. They are less prone to thermal runaway and have a lower risk of fire or explosion. This increased safety profile not only benefits users but also reduces the potential environmental hazards associated with battery accidents or improper disposal.

The recyclability of Al-ion batteries is a significant environmental advantage. Aluminum can be recycled indefinitely without losing its properties, allowing for a more sustainable battery lifecycle. The recycling process for aluminum is well-established and more energy-efficient than mining new materials, further reducing the environmental impact of battery production.

However, it's important to note that the environmental benefits of Al-ion batteries are not without challenges. The production of high-purity aluminum for battery applications still requires significant energy input. Additionally, the development of efficient recycling processes specifically tailored for Al-ion batteries is necessary to fully realize their environmental potential.

The use of organic electrolytes in some Al-ion battery designs may pose environmental risks if not properly managed. Research into aqueous electrolytes and other environmentally friendly alternatives is ongoing to address this concern and further improve the ecological profile of Al-ion batteries.

In conclusion, while Al-ion batteries show promise for reduced environmental impact compared to current battery technologies, ongoing research and development are crucial to optimize their production, performance, and end-of-life management. As the technology matures, comprehensive life cycle assessments will be essential to fully quantify and validate the environmental benefits of Al-ion batteries across various applications and scenarios.

Aluminum is the third most abundant element in the Earth's crust, making it a more sustainable choice for large-scale battery production compared to lithium. The extraction and processing of aluminum have a lower environmental footprint than lithium, reducing the overall ecological impact of battery manufacturing. Additionally, the existing infrastructure for aluminum recycling can be leveraged to create a more circular economy for Al-ion batteries.

The production of Al-ion batteries generally requires less energy and generates fewer greenhouse gas emissions compared to lithium-ion batteries. This is partly due to the lower processing temperatures needed for aluminum-based materials. The reduced energy consumption during manufacturing contributes to a lower carbon footprint over the battery's lifecycle.

Al-ion batteries also present fewer safety concerns than lithium-ion batteries. They are less prone to thermal runaway and have a lower risk of fire or explosion. This increased safety profile not only benefits users but also reduces the potential environmental hazards associated with battery accidents or improper disposal.

The recyclability of Al-ion batteries is a significant environmental advantage. Aluminum can be recycled indefinitely without losing its properties, allowing for a more sustainable battery lifecycle. The recycling process for aluminum is well-established and more energy-efficient than mining new materials, further reducing the environmental impact of battery production.

However, it's important to note that the environmental benefits of Al-ion batteries are not without challenges. The production of high-purity aluminum for battery applications still requires significant energy input. Additionally, the development of efficient recycling processes specifically tailored for Al-ion batteries is necessary to fully realize their environmental potential.

The use of organic electrolytes in some Al-ion battery designs may pose environmental risks if not properly managed. Research into aqueous electrolytes and other environmentally friendly alternatives is ongoing to address this concern and further improve the ecological profile of Al-ion batteries.

In conclusion, while Al-ion batteries show promise for reduced environmental impact compared to current battery technologies, ongoing research and development are crucial to optimize their production, performance, and end-of-life management. As the technology matures, comprehensive life cycle assessments will be essential to fully quantify and validate the environmental benefits of Al-ion batteries across various applications and scenarios.

Al-Ion vs Li-Ion Performance Comparison

Aluminum-ion batteries (AIBs) have emerged as a promising alternative to lithium-ion batteries (LIBs) due to their potential advantages in safety, cost, and environmental impact. To assess the viability of AIBs as a replacement for LIBs, it is crucial to compare their performance across various metrics.

In terms of energy density, LIBs currently outperform AIBs. Commercial LIBs typically achieve energy densities of 100-265 Wh/kg, while AIBs are still in the early stages of development with reported energy densities ranging from 40-70 Wh/kg. This disparity is primarily due to the higher specific capacity and operating voltage of LIBs.

Power density is an area where AIBs show significant promise. AIBs have demonstrated excellent rate capabilities, with some prototypes achieving full charge in less than one minute. This rapid charging ability surpasses that of most commercial LIBs, which typically require 30 minutes to several hours for a full charge.

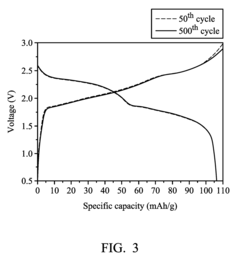

Cycle life is another critical factor in battery performance. While LIBs can achieve 500-1000 cycles before significant capacity loss, some AIB prototypes have shown remarkable stability, maintaining over 90% capacity after 7500 cycles. This extended cycle life could potentially reduce the need for frequent battery replacements in various applications.

Safety is a key advantage of AIBs over LIBs. Aluminum is non-flammable and less reactive than lithium, reducing the risk of thermal runaway and fire hazards associated with LIBs. Additionally, AIBs can be manufactured using aqueous electrolytes, further enhancing their safety profile.

Cost considerations favor AIBs due to the abundance and low price of aluminum compared to lithium. The raw material cost for AIBs is estimated to be significantly lower than that of LIBs, potentially leading to more affordable energy storage solutions.

Environmental impact is another area where AIBs may have an edge. Aluminum is more abundant and easier to recycle than lithium, potentially reducing the environmental footprint of battery production and disposal.

However, it is important to note that AIB technology is still in its infancy compared to the mature LIB industry. Significant research and development efforts are required to overcome current limitations and fully realize the potential of AIBs. As the technology progresses, the performance gap between AIBs and LIBs is expected to narrow, potentially leading to a shift in the energy storage landscape.

In terms of energy density, LIBs currently outperform AIBs. Commercial LIBs typically achieve energy densities of 100-265 Wh/kg, while AIBs are still in the early stages of development with reported energy densities ranging from 40-70 Wh/kg. This disparity is primarily due to the higher specific capacity and operating voltage of LIBs.

Power density is an area where AIBs show significant promise. AIBs have demonstrated excellent rate capabilities, with some prototypes achieving full charge in less than one minute. This rapid charging ability surpasses that of most commercial LIBs, which typically require 30 minutes to several hours for a full charge.

Cycle life is another critical factor in battery performance. While LIBs can achieve 500-1000 cycles before significant capacity loss, some AIB prototypes have shown remarkable stability, maintaining over 90% capacity after 7500 cycles. This extended cycle life could potentially reduce the need for frequent battery replacements in various applications.

Safety is a key advantage of AIBs over LIBs. Aluminum is non-flammable and less reactive than lithium, reducing the risk of thermal runaway and fire hazards associated with LIBs. Additionally, AIBs can be manufactured using aqueous electrolytes, further enhancing their safety profile.

Cost considerations favor AIBs due to the abundance and low price of aluminum compared to lithium. The raw material cost for AIBs is estimated to be significantly lower than that of LIBs, potentially leading to more affordable energy storage solutions.

Environmental impact is another area where AIBs may have an edge. Aluminum is more abundant and easier to recycle than lithium, potentially reducing the environmental footprint of battery production and disposal.

However, it is important to note that AIB technology is still in its infancy compared to the mature LIB industry. Significant research and development efforts are required to overcome current limitations and fully realize the potential of AIBs. As the technology progresses, the performance gap between AIBs and LIBs is expected to narrow, potentially leading to a shift in the energy storage landscape.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!