How to Measure Rate Capability for AIBs Under Realistic Load Profiles

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

AIB Rate Capability Background and Objectives

Aluminum-ion batteries (AIBs) have emerged as a promising alternative to lithium-ion batteries due to their potential for higher energy density, improved safety, and lower cost. The rate capability of AIBs, which refers to their ability to deliver energy at different discharge rates, is a critical factor in determining their performance and suitability for various applications. Understanding and measuring the rate capability of AIBs under realistic load profiles is essential for advancing their development and implementation in real-world scenarios.

The evolution of AIB technology can be traced back to the early 2000s when researchers began exploring aluminum as a potential electrode material. Since then, significant progress has been made in improving the performance and stability of AIBs. The primary goal of measuring rate capability under realistic load profiles is to assess the practical performance of AIBs in conditions that closely mimic their intended applications, such as in electric vehicles, grid energy storage, or portable electronics.

Realistic load profiles are crucial for evaluating AIB performance because they account for the dynamic and variable nature of energy demand in real-world applications. Unlike constant-current discharge tests commonly used in laboratory settings, realistic load profiles incorporate fluctuations in power demand, intermittent usage patterns, and varying environmental conditions. This approach provides a more accurate representation of how AIBs would perform in actual use cases.

The objectives of measuring rate capability under realistic load profiles are multifaceted. Firstly, it aims to quantify the AIB's ability to maintain consistent performance across a range of discharge rates that reflect real-world usage patterns. Secondly, it seeks to identify potential limitations or degradation mechanisms that may occur under dynamic loading conditions. Thirdly, it enables researchers and engineers to optimize AIB designs and materials to better meet the demands of specific applications.

Furthermore, this research direction aligns with the broader trend in energy storage technology towards more application-specific testing and development. By focusing on realistic load profiles, researchers can bridge the gap between laboratory results and real-world performance, leading to more reliable and efficient AIB systems. This approach also facilitates the comparison of AIBs with other energy storage technologies under comparable conditions, providing valuable insights for technology selection and integration in various sectors.

In conclusion, the measurement of rate capability for AIBs under realistic load profiles represents a critical step in advancing AIB technology. It combines the historical context of AIB development with the current need for practical performance metrics, setting the stage for future innovations in this promising field of energy storage.

The evolution of AIB technology can be traced back to the early 2000s when researchers began exploring aluminum as a potential electrode material. Since then, significant progress has been made in improving the performance and stability of AIBs. The primary goal of measuring rate capability under realistic load profiles is to assess the practical performance of AIBs in conditions that closely mimic their intended applications, such as in electric vehicles, grid energy storage, or portable electronics.

Realistic load profiles are crucial for evaluating AIB performance because they account for the dynamic and variable nature of energy demand in real-world applications. Unlike constant-current discharge tests commonly used in laboratory settings, realistic load profiles incorporate fluctuations in power demand, intermittent usage patterns, and varying environmental conditions. This approach provides a more accurate representation of how AIBs would perform in actual use cases.

The objectives of measuring rate capability under realistic load profiles are multifaceted. Firstly, it aims to quantify the AIB's ability to maintain consistent performance across a range of discharge rates that reflect real-world usage patterns. Secondly, it seeks to identify potential limitations or degradation mechanisms that may occur under dynamic loading conditions. Thirdly, it enables researchers and engineers to optimize AIB designs and materials to better meet the demands of specific applications.

Furthermore, this research direction aligns with the broader trend in energy storage technology towards more application-specific testing and development. By focusing on realistic load profiles, researchers can bridge the gap between laboratory results and real-world performance, leading to more reliable and efficient AIB systems. This approach also facilitates the comparison of AIBs with other energy storage technologies under comparable conditions, providing valuable insights for technology selection and integration in various sectors.

In conclusion, the measurement of rate capability for AIBs under realistic load profiles represents a critical step in advancing AIB technology. It combines the historical context of AIB development with the current need for practical performance metrics, setting the stage for future innovations in this promising field of energy storage.

Market Demand for AIB Performance Assessment

The market demand for accurate and reliable performance assessment of Aqueous Ion Batteries (AIBs) under realistic load profiles is rapidly growing. As AIBs emerge as a promising energy storage solution for various applications, including grid-scale storage, electric vehicles, and portable electronics, the need for standardized and comprehensive testing methodologies becomes increasingly critical.

Industry stakeholders, including battery manufacturers, researchers, and end-users, are seeking robust methods to evaluate AIB rate capability under conditions that closely mimic real-world usage scenarios. This demand is driven by the necessity to understand and predict battery performance in diverse operational environments, ranging from intermittent renewable energy integration to high-power demand applications in electric transportation.

The market for AIB performance assessment tools and services is expected to expand significantly in the coming years, paralleling the growth of the AIB market itself. This growth is fueled by the increasing adoption of AIBs in various sectors, particularly in regions prioritizing sustainable energy solutions and electrification of transportation.

Battery manufacturers require accurate rate capability measurements to optimize their products, differentiate them in the market, and meet the evolving needs of their customers. These assessments are crucial for product development, quality control, and marketing efforts. Additionally, third-party testing laboratories and certification bodies are experiencing increased demand for their services as the AIB market matures and standardization efforts progress.

End-users, such as utility companies and electric vehicle manufacturers, are particularly interested in AIB performance data under realistic load profiles. This information is essential for system design, integration planning, and long-term operational strategy. The ability to accurately predict AIB behavior under varying load conditions directly impacts the efficiency, reliability, and cost-effectiveness of energy storage systems.

Research institutions and academic organizations are also contributing to the market demand for advanced AIB performance assessment methodologies. Their work in developing new testing protocols and improving existing ones drives innovation in the field and supports the broader adoption of AIBs across industries.

The market is also seeing a rise in demand for software solutions and data analytics platforms that can process and interpret the complex data generated from AIB performance tests under realistic load profiles. These tools are becoming essential for battery designers, system integrators, and operators to make informed decisions and optimize AIB deployment strategies.

Industry stakeholders, including battery manufacturers, researchers, and end-users, are seeking robust methods to evaluate AIB rate capability under conditions that closely mimic real-world usage scenarios. This demand is driven by the necessity to understand and predict battery performance in diverse operational environments, ranging from intermittent renewable energy integration to high-power demand applications in electric transportation.

The market for AIB performance assessment tools and services is expected to expand significantly in the coming years, paralleling the growth of the AIB market itself. This growth is fueled by the increasing adoption of AIBs in various sectors, particularly in regions prioritizing sustainable energy solutions and electrification of transportation.

Battery manufacturers require accurate rate capability measurements to optimize their products, differentiate them in the market, and meet the evolving needs of their customers. These assessments are crucial for product development, quality control, and marketing efforts. Additionally, third-party testing laboratories and certification bodies are experiencing increased demand for their services as the AIB market matures and standardization efforts progress.

End-users, such as utility companies and electric vehicle manufacturers, are particularly interested in AIB performance data under realistic load profiles. This information is essential for system design, integration planning, and long-term operational strategy. The ability to accurately predict AIB behavior under varying load conditions directly impacts the efficiency, reliability, and cost-effectiveness of energy storage systems.

Research institutions and academic organizations are also contributing to the market demand for advanced AIB performance assessment methodologies. Their work in developing new testing protocols and improving existing ones drives innovation in the field and supports the broader adoption of AIBs across industries.

The market is also seeing a rise in demand for software solutions and data analytics platforms that can process and interpret the complex data generated from AIB performance tests under realistic load profiles. These tools are becoming essential for battery designers, system integrators, and operators to make informed decisions and optimize AIB deployment strategies.

Current Challenges in AIB Rate Capability Measurement

Measuring the rate capability of Aqueous Ion Batteries (AIBs) under realistic load profiles presents several significant challenges that researchers and engineers must address. One of the primary difficulties lies in accurately simulating real-world usage scenarios, which often involve complex and variable current demands. Traditional testing methods, such as constant current discharge, fail to capture the dynamic nature of actual battery applications, leading to potential discrepancies between laboratory results and real-world performance.

The development of standardized testing protocols for AIBs under realistic load profiles is another major hurdle. Unlike lithium-ion batteries, which have well-established testing procedures, AIBs lack universally accepted methodologies for rate capability assessment. This absence of standardization makes it challenging to compare results across different research groups and hinders the broader adoption of AIB technology in various applications.

Furthermore, the unique characteristics of AIBs, such as their aqueous electrolyte and specific electrode materials, introduce additional complexities in rate capability measurement. The high ionic conductivity of aqueous electrolytes can lead to rapid charge transfer, potentially masking rate-limiting steps in the battery system. Consequently, conventional testing approaches may not adequately capture the true rate capabilities of AIBs, necessitating the development of specialized measurement techniques.

Another challenge is the accurate determination of state-of-charge (SOC) during dynamic cycling. Unlike constant current tests, realistic load profiles involve frequent changes in current direction and magnitude, making it difficult to precisely track the battery's SOC. This uncertainty can lead to inaccuracies in rate capability assessments and complicate the interpretation of performance data.

The impact of temperature fluctuations on AIB rate capability measurements is also a significant concern. Real-world applications often involve varying thermal conditions, which can substantially affect battery performance. Developing testing protocols that account for these temperature variations while maintaining consistency and reproducibility is a complex task that requires careful consideration.

Lastly, the long-term stability and cycle life of AIBs under realistic load profiles pose additional challenges for rate capability measurements. Assessing how repeated exposure to dynamic current profiles affects the battery's rate performance over extended periods is crucial for understanding the practical viability of AIBs in various applications. However, conducting such long-term studies while maintaining realistic operating conditions is both time-consuming and resource-intensive, presenting a significant barrier to comprehensive rate capability evaluations.

The development of standardized testing protocols for AIBs under realistic load profiles is another major hurdle. Unlike lithium-ion batteries, which have well-established testing procedures, AIBs lack universally accepted methodologies for rate capability assessment. This absence of standardization makes it challenging to compare results across different research groups and hinders the broader adoption of AIB technology in various applications.

Furthermore, the unique characteristics of AIBs, such as their aqueous electrolyte and specific electrode materials, introduce additional complexities in rate capability measurement. The high ionic conductivity of aqueous electrolytes can lead to rapid charge transfer, potentially masking rate-limiting steps in the battery system. Consequently, conventional testing approaches may not adequately capture the true rate capabilities of AIBs, necessitating the development of specialized measurement techniques.

Another challenge is the accurate determination of state-of-charge (SOC) during dynamic cycling. Unlike constant current tests, realistic load profiles involve frequent changes in current direction and magnitude, making it difficult to precisely track the battery's SOC. This uncertainty can lead to inaccuracies in rate capability assessments and complicate the interpretation of performance data.

The impact of temperature fluctuations on AIB rate capability measurements is also a significant concern. Real-world applications often involve varying thermal conditions, which can substantially affect battery performance. Developing testing protocols that account for these temperature variations while maintaining consistency and reproducibility is a complex task that requires careful consideration.

Lastly, the long-term stability and cycle life of AIBs under realistic load profiles pose additional challenges for rate capability measurements. Assessing how repeated exposure to dynamic current profiles affects the battery's rate performance over extended periods is crucial for understanding the practical viability of AIBs in various applications. However, conducting such long-term studies while maintaining realistic operating conditions is both time-consuming and resource-intensive, presenting a significant barrier to comprehensive rate capability evaluations.

Existing AIB Rate Capability Measurement Techniques

01 Electrode materials for improved rate capability

Advanced electrode materials are crucial for enhancing the rate capability of aluminum-ion batteries. These materials, such as graphene-based composites or nanostructured metal oxides, offer increased surface area and improved ion diffusion pathways, allowing for faster charge and discharge rates.- Electrode materials for improved rate capability: Advanced electrode materials are crucial for enhancing the rate capability of aluminum-ion batteries. These materials, such as graphene-based composites or nanostructured metal oxides, can facilitate faster ion transport and electron transfer, leading to improved charge/discharge rates and overall battery performance.

- Electrolyte optimization for high-rate performance: The composition and properties of the electrolyte play a significant role in determining the rate capability of AIBs. Developing novel electrolyte formulations or additives can enhance ionic conductivity, reduce interfacial resistance, and improve the stability of the electrode-electrolyte interface, thereby enabling faster charge/discharge rates.

- Battery design and architecture for enhanced rate capability: Innovative battery designs and architectures can significantly improve the rate capability of AIBs. This includes optimizing electrode thickness, porosity, and surface area, as well as developing novel cell configurations that minimize internal resistance and enhance ion diffusion pathways.

- Advanced current collectors for high-rate AIBs: Developing advanced current collectors with improved conductivity and stability can enhance the rate capability of aluminum-ion batteries. These may include 3D structured current collectors, conductive coatings, or novel materials that facilitate faster electron transfer and maintain structural integrity during high-rate cycling.

- Nanostructured materials for improved rate performance: Incorporating nanostructured materials in AIB components can significantly enhance rate capability. These materials, such as nanoparticles, nanowires, or nanocomposites, offer increased surface area, shortened diffusion paths, and improved kinetics, leading to faster charge/discharge rates and better overall battery performance.

02 Electrolyte optimization for high-rate performance

The composition and properties of the electrolyte significantly impact the rate capability of AIBs. Developing electrolytes with high ionic conductivity, wide electrochemical windows, and good compatibility with electrode materials can lead to improved rate performance and overall battery efficiency.Expand Specific Solutions03 Novel cell designs for enhanced rate capability

Innovative cell architectures and designs can contribute to improved rate capability in AIBs. This includes optimizing electrode thickness, separator properties, and current collector designs to facilitate rapid ion transport and minimize internal resistance.Expand Specific Solutions04 Advanced manufacturing techniques for high-performance AIBs

Employing cutting-edge manufacturing processes can lead to AIBs with superior rate capability. These techniques may include precision coating methods, advanced electrode fabrication processes, or novel assembly techniques that ensure optimal electrode-electrolyte interfaces and uniform current distribution.Expand Specific Solutions05 Integration of smart battery management systems

Incorporating intelligent battery management systems can optimize the performance and rate capability of AIBs. These systems can monitor and control charging/discharging processes, manage thermal conditions, and implement adaptive algorithms to maximize battery efficiency and longevity while maintaining high rate capabilities.Expand Specific Solutions

Key Players in AIB Development and Testing

The competition landscape for measuring rate capability of AIBs under realistic load profiles is evolving rapidly, reflecting the growing importance of advanced battery technologies. The market is in an early growth stage, with significant potential for expansion as electric vehicles and renewable energy storage solutions gain traction. Key players like Contemporary Amperex Technology, LG Energy Solution, and Sunwoda Electronic are driving innovation in this field. Academic institutions such as Beijing Institute of Technology and Tsinghua Shenzhen International Graduate School are contributing valuable research. The technology is progressing but still maturing, with companies focusing on improving accuracy, reliability, and real-world applicability of measurement techniques for AIB performance under various load conditions.

Contemporary Amperex Technology Co., Ltd.

Technical Solution: CATL has developed an advanced Battery Management System (BMS) that incorporates real-time monitoring and adaptive control algorithms to measure and optimize the rate capability of their AIBs (Automotive Intelligence Batteries) under realistic load profiles. The system utilizes machine learning techniques to predict battery performance and degradation based on historical data and current operating conditions[1]. CATL's approach includes the implementation of high-precision current and voltage sensors, coupled with temperature monitoring at multiple points within the battery pack. This comprehensive data collection allows for accurate state estimation and dynamic adjustment of charging and discharging strategies to maintain optimal performance and longevity[2].

Strengths: Industry-leading battery technology, extensive R&D capabilities, and large-scale production capacity. Weaknesses: Potential overreliance on specific battery chemistries and vulnerability to supply chain disruptions.

LG Energy Solution Ltd.

Technical Solution: LG Energy Solution has implemented a sophisticated Battery Monitoring System (BMS) that utilizes advanced algorithms to measure and analyze the rate capability of their AIBs under various load profiles. Their approach incorporates a combination of electrochemical impedance spectroscopy (EIS) and pulse power characterization techniques to assess battery performance in real-time[3]. The system employs a network of sensors to monitor key parameters such as current, voltage, and temperature across different cells and modules within the battery pack. LG's solution also includes predictive modeling capabilities that leverage artificial intelligence to forecast battery behavior under different usage scenarios, enabling proactive management of battery health and performance[4].

Strengths: Strong R&D capabilities, diverse product portfolio, and global manufacturing presence. Weaknesses: Potential quality control issues and intense competition in the EV battery market.

Core Innovations in Realistic Load Profile Simulation

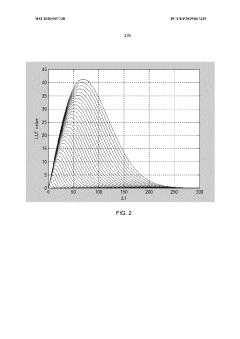

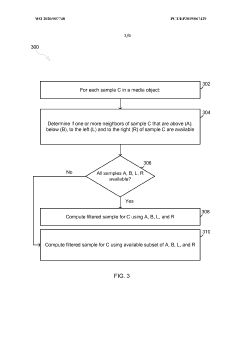

Bilateral filter with LUT avoiding unnecessary multiplication and minimizing the lut

PatentWO2020007748A1

Innovation

- The implementation reduces the complexity of the bilateral filter by using a two-dimensional look-up table instead of a three-dimensional one, avoiding unnecessary multiplications, and applying a scaling transformation to approximate rows, thereby minimizing the number of stored values and required multipliers.

Standardization Efforts for AIB Testing Protocols

Efforts to standardize testing protocols for Aqueous Ion Batteries (AIBs) are gaining momentum as the technology advances and approaches commercial viability. These standardization initiatives aim to establish consistent methods for evaluating AIB performance, particularly in terms of rate capability under realistic load profiles. Such efforts are crucial for enabling fair comparisons between different AIB systems and facilitating their integration into various applications.

Several organizations and research institutions are leading the charge in developing standardized testing protocols for AIBs. The International Electrotechnical Commission (IEC) has formed a working group dedicated to energy storage systems, which includes a focus on AIB testing standards. This group is collaborating with industry experts and academic researchers to define key performance metrics and testing procedures specific to AIBs.

One of the primary challenges in standardizing AIB testing protocols is accounting for the unique characteristics of aqueous electrolytes and their interactions with electrode materials. Unlike lithium-ion batteries, AIBs exhibit different kinetics and transport mechanisms, necessitating tailored testing approaches. To address this, researchers are developing specialized cycling protocols that simulate real-world usage patterns while considering the specific electrochemical behavior of AIBs.

The standardization efforts also encompass the development of reference electrodes and control samples for AIBs. These reference materials are essential for ensuring consistency across different testing facilities and enabling reproducible results. Efforts are underway to establish a set of benchmark AIB systems that can serve as performance baselines for evaluating new materials and designs.

Another critical aspect of the standardization process is the creation of guidelines for reporting AIB performance data. This includes specifying the minimum required information, such as electrolyte composition, electrode materials, and cell construction details, to ensure transparency and facilitate meaningful comparisons between different studies. Additionally, standardized formats for presenting rate capability data under various load profiles are being developed to improve clarity and ease of interpretation.

As the field of AIBs continues to evolve, these standardization efforts will play a crucial role in accelerating technology development and commercialization. By providing a common framework for evaluating AIB performance, these protocols will enable more effective collaboration between researchers, manufacturers, and end-users, ultimately driving innovation and improving the overall quality of AIB technology.

Several organizations and research institutions are leading the charge in developing standardized testing protocols for AIBs. The International Electrotechnical Commission (IEC) has formed a working group dedicated to energy storage systems, which includes a focus on AIB testing standards. This group is collaborating with industry experts and academic researchers to define key performance metrics and testing procedures specific to AIBs.

One of the primary challenges in standardizing AIB testing protocols is accounting for the unique characteristics of aqueous electrolytes and their interactions with electrode materials. Unlike lithium-ion batteries, AIBs exhibit different kinetics and transport mechanisms, necessitating tailored testing approaches. To address this, researchers are developing specialized cycling protocols that simulate real-world usage patterns while considering the specific electrochemical behavior of AIBs.

The standardization efforts also encompass the development of reference electrodes and control samples for AIBs. These reference materials are essential for ensuring consistency across different testing facilities and enabling reproducible results. Efforts are underway to establish a set of benchmark AIB systems that can serve as performance baselines for evaluating new materials and designs.

Another critical aspect of the standardization process is the creation of guidelines for reporting AIB performance data. This includes specifying the minimum required information, such as electrolyte composition, electrode materials, and cell construction details, to ensure transparency and facilitate meaningful comparisons between different studies. Additionally, standardized formats for presenting rate capability data under various load profiles are being developed to improve clarity and ease of interpretation.

As the field of AIBs continues to evolve, these standardization efforts will play a crucial role in accelerating technology development and commercialization. By providing a common framework for evaluating AIB performance, these protocols will enable more effective collaboration between researchers, manufacturers, and end-users, ultimately driving innovation and improving the overall quality of AIB technology.

Environmental Impact of AIB Testing Procedures

The environmental impact of AIB (Aqueous Ion Battery) testing procedures is a critical consideration in the development and implementation of sustainable energy storage solutions. As the demand for high-performance batteries continues to grow, it is essential to evaluate the ecological footprint of testing methodologies used to assess rate capability under realistic load profiles.

AIB testing procedures typically involve repeated charge-discharge cycles, which consume significant amounts of energy and resources. The environmental impact of these processes can be substantial, particularly when conducted on a large scale or over extended periods. One of the primary concerns is the energy consumption associated with testing equipment, such as battery cyclers, environmental chambers, and data acquisition systems. These devices often operate continuously for days or weeks, contributing to increased electricity usage and associated carbon emissions.

Furthermore, the materials used in AIB testing can have environmental implications. Electrolytes, separators, and electrode materials may contain potentially harmful substances that require careful handling and disposal. Improper management of these materials can lead to soil and water contamination, posing risks to local ecosystems and human health.

The production of test samples and prototype batteries also generates waste, including discarded electrodes, electrolytes, and packaging materials. While some of these components may be recyclable, others may require specialized disposal methods to minimize environmental impact. Additionally, the manufacturing processes for test materials and equipment can contribute to resource depletion and greenhouse gas emissions.

Water usage is another significant factor to consider in AIB testing procedures. Aqueous electrolytes require purified water, and the production and treatment of this water can have substantial environmental implications, particularly in water-scarce regions. Moreover, the disposal of used electrolytes must be carefully managed to prevent contamination of water sources.

To mitigate the environmental impact of AIB testing procedures, researchers and manufacturers are exploring various strategies. These include optimizing test protocols to reduce energy consumption, implementing more efficient equipment designs, and developing closed-loop systems for electrolyte recycling. Additionally, there is a growing emphasis on using renewable energy sources to power testing facilities, further reducing the carbon footprint of these operations.

As the field of AIB technology advances, it is crucial to balance the need for comprehensive testing with environmental responsibility. This may involve developing standardized testing procedures that minimize resource consumption while still providing accurate and reliable data on rate capability under realistic load profiles. By addressing the environmental impact of testing procedures, the AIB industry can contribute to the overall sustainability of energy storage solutions and support the transition to a greener energy landscape.

AIB testing procedures typically involve repeated charge-discharge cycles, which consume significant amounts of energy and resources. The environmental impact of these processes can be substantial, particularly when conducted on a large scale or over extended periods. One of the primary concerns is the energy consumption associated with testing equipment, such as battery cyclers, environmental chambers, and data acquisition systems. These devices often operate continuously for days or weeks, contributing to increased electricity usage and associated carbon emissions.

Furthermore, the materials used in AIB testing can have environmental implications. Electrolytes, separators, and electrode materials may contain potentially harmful substances that require careful handling and disposal. Improper management of these materials can lead to soil and water contamination, posing risks to local ecosystems and human health.

The production of test samples and prototype batteries also generates waste, including discarded electrodes, electrolytes, and packaging materials. While some of these components may be recyclable, others may require specialized disposal methods to minimize environmental impact. Additionally, the manufacturing processes for test materials and equipment can contribute to resource depletion and greenhouse gas emissions.

Water usage is another significant factor to consider in AIB testing procedures. Aqueous electrolytes require purified water, and the production and treatment of this water can have substantial environmental implications, particularly in water-scarce regions. Moreover, the disposal of used electrolytes must be carefully managed to prevent contamination of water sources.

To mitigate the environmental impact of AIB testing procedures, researchers and manufacturers are exploring various strategies. These include optimizing test protocols to reduce energy consumption, implementing more efficient equipment designs, and developing closed-loop systems for electrolyte recycling. Additionally, there is a growing emphasis on using renewable energy sources to power testing facilities, further reducing the carbon footprint of these operations.

As the field of AIB technology advances, it is crucial to balance the need for comprehensive testing with environmental responsibility. This may involve developing standardized testing procedures that minimize resource consumption while still providing accurate and reliable data on rate capability under realistic load profiles. By addressing the environmental impact of testing procedures, the AIB industry can contribute to the overall sustainability of energy storage solutions and support the transition to a greener energy landscape.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!