How to Measure Coulombic Efficiency and Cycle Life for Aluminum-Ion Cells — Standard Protocols

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Al-Ion Cell Testing Goals

The primary goal of testing aluminum-ion cells is to accurately assess their performance, particularly in terms of Coulombic efficiency and cycle life. These metrics are crucial for evaluating the viability and potential of aluminum-ion technology as a promising alternative to lithium-ion batteries. Coulombic efficiency, which measures the ratio of charge extracted from the cell to the charge input during charging, provides insights into the reversibility of electrochemical reactions and the overall efficiency of the energy storage system.

Cycle life testing aims to determine the longevity and durability of aluminum-ion cells under repeated charge-discharge cycles. This is essential for understanding the practical applicability of these cells in various applications, from portable electronics to grid-scale energy storage. The goal is to establish standardized protocols that enable consistent and comparable measurements across different research groups and industry players.

Another key objective is to identify and quantify the factors affecting the performance and degradation of aluminum-ion cells. This includes investigating the impact of various operating conditions, such as temperature, current rates, and depth of discharge, on the cell's efficiency and lifespan. By systematically studying these parameters, researchers can optimize cell design and operating conditions to enhance overall performance.

Furthermore, the testing goals encompass the development of accelerated aging techniques that can provide reliable predictions of long-term cell behavior within a shorter timeframe. This is particularly important for expediting the research and development process, allowing for faster iterations and improvements in cell chemistry and design.

Lastly, the testing aims to establish a comprehensive understanding of the failure modes and degradation mechanisms specific to aluminum-ion cells. This knowledge is crucial for developing strategies to mitigate performance decline and extend the useful life of these cells. By identifying the root causes of capacity fade and efficiency loss, researchers can work towards innovative solutions that address these challenges and push the boundaries of aluminum-ion technology.

Cycle life testing aims to determine the longevity and durability of aluminum-ion cells under repeated charge-discharge cycles. This is essential for understanding the practical applicability of these cells in various applications, from portable electronics to grid-scale energy storage. The goal is to establish standardized protocols that enable consistent and comparable measurements across different research groups and industry players.

Another key objective is to identify and quantify the factors affecting the performance and degradation of aluminum-ion cells. This includes investigating the impact of various operating conditions, such as temperature, current rates, and depth of discharge, on the cell's efficiency and lifespan. By systematically studying these parameters, researchers can optimize cell design and operating conditions to enhance overall performance.

Furthermore, the testing goals encompass the development of accelerated aging techniques that can provide reliable predictions of long-term cell behavior within a shorter timeframe. This is particularly important for expediting the research and development process, allowing for faster iterations and improvements in cell chemistry and design.

Lastly, the testing aims to establish a comprehensive understanding of the failure modes and degradation mechanisms specific to aluminum-ion cells. This knowledge is crucial for developing strategies to mitigate performance decline and extend the useful life of these cells. By identifying the root causes of capacity fade and efficiency loss, researchers can work towards innovative solutions that address these challenges and push the boundaries of aluminum-ion technology.

Market Demand Analysis

The market demand for aluminum-ion cells and their associated measurement protocols is driven by the growing need for sustainable and high-performance energy storage solutions. As the world transitions towards renewable energy sources and electrification of transportation, there is an increasing focus on developing alternative battery technologies to complement and potentially surpass lithium-ion batteries.

Aluminum-ion cells have garnered significant attention due to their potential advantages, including higher energy density, faster charging capabilities, improved safety, and lower cost compared to traditional lithium-ion batteries. These characteristics make them particularly attractive for applications in electric vehicles, grid energy storage, and portable electronics.

The demand for standardized protocols to measure Coulombic efficiency and cycle life of aluminum-ion cells stems from the need for accurate and comparable performance data across different research groups and manufacturers. As the technology progresses from laboratory-scale experiments to commercial production, reliable and consistent measurement methods become crucial for assessing the viability and competitiveness of aluminum-ion cells in the market.

Investors and industry stakeholders require robust performance metrics to make informed decisions about funding and resource allocation. Standardized protocols enable fair comparisons between different cell designs and chemistries, facilitating the identification of promising research directions and accelerating the overall development of aluminum-ion technology.

The automotive industry, in particular, has shown keen interest in aluminum-ion cells as a potential solution for next-generation electric vehicles. The ability to accurately measure and predict battery performance over extended periods is essential for meeting the stringent requirements of this sector, including long-range capabilities and fast charging times.

Grid energy storage represents another significant market opportunity for aluminum-ion cells. As renewable energy sources become more prevalent, there is a growing need for large-scale, cost-effective energy storage solutions. Standardized measurement protocols are crucial for evaluating the long-term reliability and efficiency of aluminum-ion cells in these applications.

Consumer electronics manufacturers are also exploring aluminum-ion technology as a potential replacement for lithium-ion batteries in portable devices. The demand for longer-lasting and faster-charging batteries continues to drive innovation in this sector, with standardized performance metrics playing a key role in product development and marketing.

As research and development in aluminum-ion technology intensify, the market for specialized testing equipment and services is expected to grow. This includes the development of advanced battery testing systems capable of implementing standardized protocols for measuring Coulombic efficiency and cycle life.

Aluminum-ion cells have garnered significant attention due to their potential advantages, including higher energy density, faster charging capabilities, improved safety, and lower cost compared to traditional lithium-ion batteries. These characteristics make them particularly attractive for applications in electric vehicles, grid energy storage, and portable electronics.

The demand for standardized protocols to measure Coulombic efficiency and cycle life of aluminum-ion cells stems from the need for accurate and comparable performance data across different research groups and manufacturers. As the technology progresses from laboratory-scale experiments to commercial production, reliable and consistent measurement methods become crucial for assessing the viability and competitiveness of aluminum-ion cells in the market.

Investors and industry stakeholders require robust performance metrics to make informed decisions about funding and resource allocation. Standardized protocols enable fair comparisons between different cell designs and chemistries, facilitating the identification of promising research directions and accelerating the overall development of aluminum-ion technology.

The automotive industry, in particular, has shown keen interest in aluminum-ion cells as a potential solution for next-generation electric vehicles. The ability to accurately measure and predict battery performance over extended periods is essential for meeting the stringent requirements of this sector, including long-range capabilities and fast charging times.

Grid energy storage represents another significant market opportunity for aluminum-ion cells. As renewable energy sources become more prevalent, there is a growing need for large-scale, cost-effective energy storage solutions. Standardized measurement protocols are crucial for evaluating the long-term reliability and efficiency of aluminum-ion cells in these applications.

Consumer electronics manufacturers are also exploring aluminum-ion technology as a potential replacement for lithium-ion batteries in portable devices. The demand for longer-lasting and faster-charging batteries continues to drive innovation in this sector, with standardized performance metrics playing a key role in product development and marketing.

As research and development in aluminum-ion technology intensify, the market for specialized testing equipment and services is expected to grow. This includes the development of advanced battery testing systems capable of implementing standardized protocols for measuring Coulombic efficiency and cycle life.

Current Challenges

The measurement of Coulombic efficiency and cycle life for aluminum-ion cells presents several significant challenges that researchers and industry professionals must address. One of the primary obstacles is the lack of standardized protocols specifically tailored for aluminum-ion cells. Unlike lithium-ion batteries, which have well-established testing procedures, aluminum-ion technology is relatively new and lacks universally accepted measurement standards.

The unique chemistry of aluminum-ion cells introduces complexities in accurately determining Coulombic efficiency. The trivalent nature of aluminum ions and their interaction with electrolytes and electrode materials can lead to side reactions and irreversible capacity loss, making it difficult to isolate and quantify the true Coulombic efficiency. Additionally, the potential for aluminum plating and stripping during cycling further complicates the measurement process.

Cycle life assessment for aluminum-ion cells faces its own set of challenges. The relatively limited understanding of degradation mechanisms in these cells makes it challenging to develop accelerated testing methods that accurately predict long-term performance. The potential for electrolyte decomposition, electrode material degradation, and interfacial instabilities over extended cycling periods adds layers of complexity to cycle life measurements.

Another significant hurdle is the variability in cell designs and materials used across different research groups and manufacturers. This diversity makes it challenging to establish standardized testing conditions that are applicable across the board. Factors such as electrode composition, electrolyte formulation, and cell architecture can significantly influence performance metrics, necessitating careful consideration in protocol development.

The sensitivity of aluminum-ion cells to environmental conditions poses additional challenges. Temperature fluctuations, humidity levels, and even atmospheric exposure can impact cell performance and measurement accuracy. Controlling these variables consistently across different testing facilities and ensuring reproducibility of results is a major concern in developing reliable measurement protocols.

Furthermore, the limited availability of commercial aluminum-ion cells and specialized testing equipment tailored for this technology hinders widespread adoption of standardized measurement techniques. Many researchers rely on custom-built cells and adapted testing setups, which can introduce variability and make cross-comparison of results challenging.

Lastly, the rapid pace of innovation in aluminum-ion technology means that measurement protocols must be flexible enough to accommodate emerging materials and cell designs while maintaining consistency and comparability of results. Striking this balance between standardization and adaptability remains a key challenge in the development of robust measurement protocols for Coulombic efficiency and cycle life in aluminum-ion cells.

The unique chemistry of aluminum-ion cells introduces complexities in accurately determining Coulombic efficiency. The trivalent nature of aluminum ions and their interaction with electrolytes and electrode materials can lead to side reactions and irreversible capacity loss, making it difficult to isolate and quantify the true Coulombic efficiency. Additionally, the potential for aluminum plating and stripping during cycling further complicates the measurement process.

Cycle life assessment for aluminum-ion cells faces its own set of challenges. The relatively limited understanding of degradation mechanisms in these cells makes it challenging to develop accelerated testing methods that accurately predict long-term performance. The potential for electrolyte decomposition, electrode material degradation, and interfacial instabilities over extended cycling periods adds layers of complexity to cycle life measurements.

Another significant hurdle is the variability in cell designs and materials used across different research groups and manufacturers. This diversity makes it challenging to establish standardized testing conditions that are applicable across the board. Factors such as electrode composition, electrolyte formulation, and cell architecture can significantly influence performance metrics, necessitating careful consideration in protocol development.

The sensitivity of aluminum-ion cells to environmental conditions poses additional challenges. Temperature fluctuations, humidity levels, and even atmospheric exposure can impact cell performance and measurement accuracy. Controlling these variables consistently across different testing facilities and ensuring reproducibility of results is a major concern in developing reliable measurement protocols.

Furthermore, the limited availability of commercial aluminum-ion cells and specialized testing equipment tailored for this technology hinders widespread adoption of standardized measurement techniques. Many researchers rely on custom-built cells and adapted testing setups, which can introduce variability and make cross-comparison of results challenging.

Lastly, the rapid pace of innovation in aluminum-ion technology means that measurement protocols must be flexible enough to accommodate emerging materials and cell designs while maintaining consistency and comparability of results. Striking this balance between standardization and adaptability remains a key challenge in the development of robust measurement protocols for Coulombic efficiency and cycle life in aluminum-ion cells.

Existing Test Protocols

01 Electrode materials for improved Coulombic efficiency

Novel electrode materials, such as modified graphene or carbon-based composites, are developed to enhance the Coulombic efficiency of aluminum-ion cells. These materials provide better ion storage and transport, reducing capacity loss during charge-discharge cycles.- Electrolyte composition for improved efficiency: Optimizing the electrolyte composition in aluminum-ion cells can significantly enhance Coulombic efficiency and cycle life. This includes using ionic liquids, organic solvents, or their mixtures with carefully selected additives to improve the stability of the electrode-electrolyte interface and reduce side reactions.

- Cathode material engineering: Developing advanced cathode materials, such as graphene-based structures, transition metal oxides, or organic compounds, can lead to improved Coulombic efficiency and extended cycle life in aluminum-ion cells. These materials offer enhanced ion storage capacity and structural stability during repeated charge-discharge cycles.

- Anode material optimization: Enhancing the anode material, typically aluminum, by alloying or surface modification can improve the Coulombic efficiency and cycle life of aluminum-ion cells. These modifications aim to reduce dendrite formation, enhance ion diffusion, and maintain structural integrity during cycling.

- Cell design and architecture: Innovative cell designs, including optimized electrode configurations, separator materials, and current collector structures, can significantly impact the Coulombic efficiency and cycle life of aluminum-ion cells. These design improvements focus on enhancing ion transport, reducing internal resistance, and maintaining electrode integrity.

- Advanced charging protocols: Implementing sophisticated charging protocols and battery management systems can improve the Coulombic efficiency and extend the cycle life of aluminum-ion cells. These strategies may include pulse charging, temperature-controlled charging, or adaptive charging algorithms that optimize the charge-discharge process based on cell conditions.

02 Electrolyte optimization for cycle life extension

Advanced electrolyte formulations, including ionic liquids or organic solvents with additives, are designed to improve the stability of the electrode-electrolyte interface. This reduces side reactions and electrolyte decomposition, leading to extended cycle life of aluminum-ion cells.Expand Specific Solutions03 Nanostructured cathode materials for enhanced performance

Nanostructured cathode materials, such as metal oxides or sulfides, are engineered to provide higher specific capacity and better structural stability. These materials contribute to improved Coulombic efficiency and longer cycle life by facilitating faster ion diffusion and minimizing structural degradation during cycling.Expand Specific Solutions04 Protective coatings and surface modifications

Protective coatings and surface modifications are applied to electrode materials to enhance their stability and prevent unwanted side reactions. These treatments help maintain the electrode integrity over multiple cycles, leading to improved Coulombic efficiency and extended cycle life of aluminum-ion cells.Expand Specific Solutions05 Advanced cell design and engineering

Innovative cell designs and engineering approaches are implemented to optimize the overall performance of aluminum-ion cells. These include improved current collectors, separator materials, and cell packaging techniques that enhance ion transport, reduce internal resistance, and minimize capacity fading, resulting in higher Coulombic efficiency and longer cycle life.Expand Specific Solutions

Key Industry Players

The development of aluminum-ion cell technology is in its early stages, with the market still emerging and significant potential for growth. The technology's maturity is progressing, but it remains less advanced compared to established lithium-ion batteries. Key players like Samsung SDI, Robert Bosch, and Siemens are investing in research and development, while specialized companies such as Pacific Industrial Development Corp. and Sicona Battery Technologies are focusing on innovative materials and manufacturing processes. Academic institutions like Cornell University and the California Institute of Technology are contributing to fundamental research, potentially accelerating technological advancements. The involvement of diverse players, from established electronics giants to startups and research institutions, indicates a competitive and dynamic landscape poised for future breakthroughs in aluminum-ion cell technology.

Cornell University

Technical Solution: Cornell University has developed a standardized protocol for measuring Coulombic efficiency and cycle life of aluminum-ion cells. Their approach involves using a three-electrode cell configuration with aluminum as the working electrode, activated carbon as the counter electrode, and a reference electrode[1]. The protocol includes precise control of charge/discharge rates, cutoff voltages, and temperature. They employ potentiostatic intermittent titration technique (PITT) to accurately determine the state of charge and depth of discharge[2]. The university has also pioneered the use of in situ techniques such as X-ray diffraction and Raman spectroscopy to monitor structural changes during cycling, providing insights into degradation mechanisms[3].

Strengths: Comprehensive approach combining electrochemical and spectroscopic techniques for in-depth analysis. Weaknesses: May require specialized equipment not readily available in all labs, potentially limiting widespread adoption.

California Institute of Technology

Technical Solution: Caltech has developed an advanced protocol for measuring Coulombic efficiency and cycle life of aluminum-ion cells using high-precision coulometry. Their method employs a custom-built high-precision charger-cycler capable of measuring current with nano-ampere resolution[4]. This allows for accurate quantification of side reactions and self-discharge processes. The institute has also implemented machine learning algorithms to analyze cycling data and predict cell degradation patterns[5]. Additionally, they use synchrotron-based X-ray techniques to study the evolution of the aluminum anode and cathode materials during cycling, providing atomic-level insights into performance limitations[6].

Strengths: Extremely high precision measurements and advanced data analysis techniques. Weaknesses: Highly specialized equipment and expertise required, which may limit accessibility for smaller research groups.

Core Measurement Tech

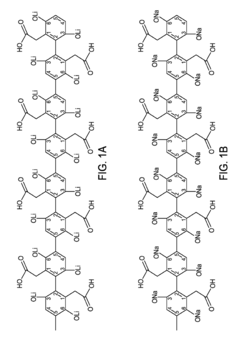

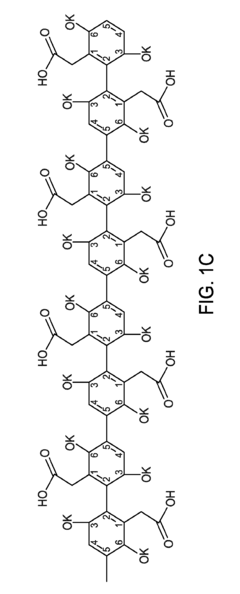

Method for producing lithium-ion, sodium-ion and potassium-ion batteries with increased safety

PatentInactiveUS20190058193A1

Innovation

- The production of lithiated pyomelanin (LPM), sodiated pyomelanin (SPM), and potassiated pyomelanin (PPM) through dissolving melanin in alkaline solutions, reducing, titrating, dialyzing, and lyophilizing to create stable, non-aqueous battery components that control lithium ion release and reduce the risk of metallic lithium formation, thereby enhancing safety.

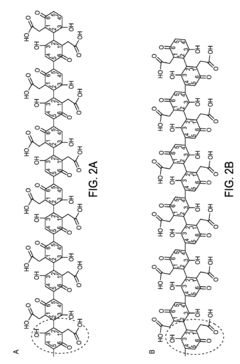

System and method for initializing and operating metal-air cell

PatentWO2018109767A1

Innovation

- A method to create a modified passivation layer on the aluminum anode by using a low-corrosion anodic alloy and an alkaline electrolyte with a metal oxoanion additive, such as sodium or potassium stannate, while controlling operational parameters like temperature, anode potential, and current density to induce a 'peak event' that reduces corrosion and enhances energy and power density.

Safety Considerations

Safety considerations are paramount when measuring Coulombic efficiency and cycle life for aluminum-ion cells. The handling and testing of these cells require strict adherence to safety protocols to mitigate potential risks associated with their operation and potential failure modes.

Firstly, it is crucial to conduct all measurements in a controlled environment with proper ventilation. Aluminum-ion cells may release gases during cycling, particularly if they experience thermal runaway or other failure modes. Adequate ventilation helps prevent the accumulation of potentially hazardous gases and reduces the risk of fire or explosion.

Protective equipment is essential for personnel involved in the testing process. This includes wearing safety goggles, gloves resistant to chemical exposure, and flame-resistant lab coats. These measures protect against potential electrolyte leakage or cell rupture, which could cause chemical burns or other injuries.

The testing area should be equipped with appropriate fire suppression systems, including Class D fire extinguishers suitable for metal fires. Aluminum-ion cells can pose unique fire risks due to the reactivity of aluminum, and standard fire extinguishers may be ineffective or even exacerbate the situation.

Electrical safety is another critical aspect. The testing equipment should be properly grounded and insulated to prevent electrical shocks. Current limiting devices and circuit breakers should be incorporated into the testing setup to prevent overcurrent situations that could lead to cell damage or safety hazards.

Temperature monitoring and control are essential during the measurement process. Aluminum-ion cells can be sensitive to temperature fluctuations, and excessive heat generation during cycling could lead to thermal runaway. Implementing temperature sensors and cutoff mechanisms helps maintain safe operating conditions and prevents potential cell failures.

Proper disposal procedures for used or damaged aluminum-ion cells must be established and followed. These cells may contain reactive materials and should not be disposed of in regular waste streams. Partnering with specialized recycling facilities ensures environmentally responsible and safe disposal of spent cells.

Regular safety training and emergency response drills should be conducted for all personnel involved in the testing procedures. This ensures that everyone is aware of potential hazards, knows how to use safety equipment, and can respond effectively in case of an emergency.

Lastly, maintaining detailed safety documentation, including Material Safety Data Sheets (MSDS) for all materials used in the cells and testing process, is crucial. This information should be readily accessible to all personnel and emergency responders in case of incidents.

Firstly, it is crucial to conduct all measurements in a controlled environment with proper ventilation. Aluminum-ion cells may release gases during cycling, particularly if they experience thermal runaway or other failure modes. Adequate ventilation helps prevent the accumulation of potentially hazardous gases and reduces the risk of fire or explosion.

Protective equipment is essential for personnel involved in the testing process. This includes wearing safety goggles, gloves resistant to chemical exposure, and flame-resistant lab coats. These measures protect against potential electrolyte leakage or cell rupture, which could cause chemical burns or other injuries.

The testing area should be equipped with appropriate fire suppression systems, including Class D fire extinguishers suitable for metal fires. Aluminum-ion cells can pose unique fire risks due to the reactivity of aluminum, and standard fire extinguishers may be ineffective or even exacerbate the situation.

Electrical safety is another critical aspect. The testing equipment should be properly grounded and insulated to prevent electrical shocks. Current limiting devices and circuit breakers should be incorporated into the testing setup to prevent overcurrent situations that could lead to cell damage or safety hazards.

Temperature monitoring and control are essential during the measurement process. Aluminum-ion cells can be sensitive to temperature fluctuations, and excessive heat generation during cycling could lead to thermal runaway. Implementing temperature sensors and cutoff mechanisms helps maintain safe operating conditions and prevents potential cell failures.

Proper disposal procedures for used or damaged aluminum-ion cells must be established and followed. These cells may contain reactive materials and should not be disposed of in regular waste streams. Partnering with specialized recycling facilities ensures environmentally responsible and safe disposal of spent cells.

Regular safety training and emergency response drills should be conducted for all personnel involved in the testing procedures. This ensures that everyone is aware of potential hazards, knows how to use safety equipment, and can respond effectively in case of an emergency.

Lastly, maintaining detailed safety documentation, including Material Safety Data Sheets (MSDS) for all materials used in the cells and testing process, is crucial. This information should be readily accessible to all personnel and emergency responders in case of incidents.

Environmental Impact

The environmental impact of aluminum-ion cells is a crucial consideration in the development and implementation of this emerging battery technology. As the world shifts towards more sustainable energy solutions, it is essential to evaluate the ecological footprint of aluminum-ion cells throughout their lifecycle, from production to disposal.

One of the primary advantages of aluminum-ion cells is their potential for reduced environmental impact compared to traditional lithium-ion batteries. Aluminum is the third most abundant element in the Earth's crust, making it a more sustainable and readily available resource. The extraction and processing of aluminum generally have a lower environmental impact than lithium, which often requires extensive mining operations in sensitive ecosystems.

The production of aluminum-ion cells also presents opportunities for reduced energy consumption and greenhouse gas emissions. The manufacturing process for these cells can be less energy-intensive than that of lithium-ion batteries, potentially leading to a lower carbon footprint. Additionally, the use of non-toxic and non-flammable electrolytes in aluminum-ion cells reduces the risk of environmental contamination in case of accidents or improper disposal.

Recycling and end-of-life management are critical aspects of the environmental impact assessment for aluminum-ion cells. The recyclability of aluminum is well-established, with existing infrastructure and processes in place for reclaiming and reusing the metal. This presents a significant advantage over lithium-ion batteries, which often face challenges in recycling due to the complexity of their components and the high cost of lithium recovery.

However, it is important to note that the environmental impact of aluminum-ion cells is not entirely benign. The production of aluminum still requires significant energy input, primarily in the form of electricity for the electrolysis process. The source of this electricity plays a crucial role in determining the overall environmental footprint of aluminum production and, by extension, aluminum-ion cells.

Furthermore, the development of standardized protocols for measuring Coulombic efficiency and cycle life of aluminum-ion cells can indirectly contribute to their environmental impact. By establishing reliable methods for assessing battery performance and longevity, researchers and manufacturers can optimize cell design and production processes to maximize efficiency and lifespan. This, in turn, can lead to reduced waste generation and more efficient use of resources over the battery's lifecycle.

In conclusion, while aluminum-ion cells show promise for reduced environmental impact compared to current battery technologies, a comprehensive lifecycle assessment is necessary to fully understand their ecological implications. This assessment should consider factors such as resource extraction, manufacturing processes, energy consumption, recyclability, and potential for environmental contamination. As research in this field progresses, it is crucial to maintain a focus on sustainability and environmental stewardship alongside performance improvements.

One of the primary advantages of aluminum-ion cells is their potential for reduced environmental impact compared to traditional lithium-ion batteries. Aluminum is the third most abundant element in the Earth's crust, making it a more sustainable and readily available resource. The extraction and processing of aluminum generally have a lower environmental impact than lithium, which often requires extensive mining operations in sensitive ecosystems.

The production of aluminum-ion cells also presents opportunities for reduced energy consumption and greenhouse gas emissions. The manufacturing process for these cells can be less energy-intensive than that of lithium-ion batteries, potentially leading to a lower carbon footprint. Additionally, the use of non-toxic and non-flammable electrolytes in aluminum-ion cells reduces the risk of environmental contamination in case of accidents or improper disposal.

Recycling and end-of-life management are critical aspects of the environmental impact assessment for aluminum-ion cells. The recyclability of aluminum is well-established, with existing infrastructure and processes in place for reclaiming and reusing the metal. This presents a significant advantage over lithium-ion batteries, which often face challenges in recycling due to the complexity of their components and the high cost of lithium recovery.

However, it is important to note that the environmental impact of aluminum-ion cells is not entirely benign. The production of aluminum still requires significant energy input, primarily in the form of electricity for the electrolysis process. The source of this electricity plays a crucial role in determining the overall environmental footprint of aluminum production and, by extension, aluminum-ion cells.

Furthermore, the development of standardized protocols for measuring Coulombic efficiency and cycle life of aluminum-ion cells can indirectly contribute to their environmental impact. By establishing reliable methods for assessing battery performance and longevity, researchers and manufacturers can optimize cell design and production processes to maximize efficiency and lifespan. This, in turn, can lead to reduced waste generation and more efficient use of resources over the battery's lifecycle.

In conclusion, while aluminum-ion cells show promise for reduced environmental impact compared to current battery technologies, a comprehensive lifecycle assessment is necessary to fully understand their ecological implications. This assessment should consider factors such as resource extraction, manufacturing processes, energy consumption, recyclability, and potential for environmental contamination. As research in this field progresses, it is crucial to maintain a focus on sustainability and environmental stewardship alongside performance improvements.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!