AIB vs Li-ion: Where Aluminum Batteries Could Make Economic Sense (Use Cases)

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

AIB vs Li-ion Background

The development of energy storage technologies has been a critical focus in the quest for sustainable and efficient power solutions. Among these, lithium-ion (Li-ion) batteries have dominated the market for decades, powering everything from smartphones to electric vehicles. However, the search for alternatives has led to the emergence of aluminum-ion batteries (AIBs) as a potential competitor.

Li-ion batteries, first commercialized in the early 1990s, have undergone significant improvements in energy density, cycle life, and cost reduction. Their success stems from the high energy density, relatively low self-discharge, and lack of memory effect. Despite these advantages, Li-ion batteries face challenges such as limited lithium resources, safety concerns, and environmental impact.

In contrast, AIBs have gained attention due to aluminum's abundance, low cost, and high theoretical capacity. Aluminum is the third most abundant element in the Earth's crust, making it a potentially more sustainable option for large-scale energy storage. The development of AIBs began in the 1970s but has seen renewed interest in recent years due to advancements in materials science and nanotechnology.

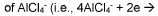

The core difference between Li-ion and AIB technologies lies in their chemistry. Li-ion batteries typically use a lithium cobalt oxide cathode and a graphite anode, while AIBs employ an aluminum anode and various cathode materials, often based on graphite or other carbon structures. This fundamental difference results in distinct performance characteristics and potential applications.

AIBs offer several theoretical advantages over Li-ion batteries, including higher energy density, faster charging rates, and improved safety due to the non-flammable nature of aluminum-based electrolytes. However, they also face significant challenges, particularly in terms of cycle life and overall performance stability, which have hindered their widespread adoption.

The economic implications of AIBs versus Li-ion batteries are complex and multifaceted. While the raw materials for AIBs are generally less expensive, the manufacturing processes and infrastructure are less developed compared to the well-established Li-ion industry. This creates a scenario where AIBs may have long-term cost advantages but face short-term economic hurdles in scaling up production and achieving market penetration.

As research continues, the potential use cases for AIBs are becoming clearer. They show promise in applications where their unique characteristics, such as rapid charging and enhanced safety, outweigh their current limitations. These could include grid-scale energy storage, electric vehicle fast-charging stations, and certain portable electronics.

Li-ion batteries, first commercialized in the early 1990s, have undergone significant improvements in energy density, cycle life, and cost reduction. Their success stems from the high energy density, relatively low self-discharge, and lack of memory effect. Despite these advantages, Li-ion batteries face challenges such as limited lithium resources, safety concerns, and environmental impact.

In contrast, AIBs have gained attention due to aluminum's abundance, low cost, and high theoretical capacity. Aluminum is the third most abundant element in the Earth's crust, making it a potentially more sustainable option for large-scale energy storage. The development of AIBs began in the 1970s but has seen renewed interest in recent years due to advancements in materials science and nanotechnology.

The core difference between Li-ion and AIB technologies lies in their chemistry. Li-ion batteries typically use a lithium cobalt oxide cathode and a graphite anode, while AIBs employ an aluminum anode and various cathode materials, often based on graphite or other carbon structures. This fundamental difference results in distinct performance characteristics and potential applications.

AIBs offer several theoretical advantages over Li-ion batteries, including higher energy density, faster charging rates, and improved safety due to the non-flammable nature of aluminum-based electrolytes. However, they also face significant challenges, particularly in terms of cycle life and overall performance stability, which have hindered their widespread adoption.

The economic implications of AIBs versus Li-ion batteries are complex and multifaceted. While the raw materials for AIBs are generally less expensive, the manufacturing processes and infrastructure are less developed compared to the well-established Li-ion industry. This creates a scenario where AIBs may have long-term cost advantages but face short-term economic hurdles in scaling up production and achieving market penetration.

As research continues, the potential use cases for AIBs are becoming clearer. They show promise in applications where their unique characteristics, such as rapid charging and enhanced safety, outweigh their current limitations. These could include grid-scale energy storage, electric vehicle fast-charging stations, and certain portable electronics.

Market Demand Analysis

The market demand for aluminum-ion batteries (AIBs) is rapidly evolving, driven by the increasing need for sustainable and efficient energy storage solutions. As the world transitions towards renewable energy sources and electrification of various sectors, the limitations of lithium-ion batteries (LIBs) have become more apparent, creating opportunities for alternative technologies like AIBs.

In the automotive industry, there is a growing demand for batteries with higher energy density, faster charging capabilities, and improved safety profiles. AIBs show promise in these areas, potentially offering faster charging times and enhanced safety compared to LIBs. This could make them particularly attractive for electric vehicles (EVs) in urban environments where rapid charging is crucial.

The renewable energy sector presents another significant market opportunity for AIBs. As wind and solar power generation increases, the need for large-scale energy storage systems grows. AIBs' potential for longer cycle life and lower cost could make them an attractive option for grid-scale storage, helping to balance supply and demand in renewable energy systems.

Consumer electronics represent a third major market for AIBs. With the continuous growth of portable devices and the increasing power demands of smartphones, laptops, and wearables, there is a constant push for batteries that can charge faster and last longer. AIBs' potential for rapid charging could address this need, potentially revolutionizing the consumer electronics landscape.

In the industrial sector, there is a growing demand for safer and more durable battery technologies. AIBs' non-flammable nature and potential for longer cycle life could make them ideal for applications in harsh environments or where safety is paramount, such as in mining equipment or offshore installations.

The market size for advanced battery technologies is projected to grow significantly in the coming years. While specific figures for AIBs are not yet available due to their emerging status, the global advanced battery market is expected to expand rapidly, driven by the electrification of transportation and the growth of renewable energy.

However, it's important to note that the market demand for AIBs is still speculative and depends heavily on the technology's ability to overcome current limitations and achieve commercial viability. Factors such as production scalability, raw material availability, and cost competitiveness with established LIB technology will play crucial roles in determining AIBs' market penetration and growth trajectory.

In the automotive industry, there is a growing demand for batteries with higher energy density, faster charging capabilities, and improved safety profiles. AIBs show promise in these areas, potentially offering faster charging times and enhanced safety compared to LIBs. This could make them particularly attractive for electric vehicles (EVs) in urban environments where rapid charging is crucial.

The renewable energy sector presents another significant market opportunity for AIBs. As wind and solar power generation increases, the need for large-scale energy storage systems grows. AIBs' potential for longer cycle life and lower cost could make them an attractive option for grid-scale storage, helping to balance supply and demand in renewable energy systems.

Consumer electronics represent a third major market for AIBs. With the continuous growth of portable devices and the increasing power demands of smartphones, laptops, and wearables, there is a constant push for batteries that can charge faster and last longer. AIBs' potential for rapid charging could address this need, potentially revolutionizing the consumer electronics landscape.

In the industrial sector, there is a growing demand for safer and more durable battery technologies. AIBs' non-flammable nature and potential for longer cycle life could make them ideal for applications in harsh environments or where safety is paramount, such as in mining equipment or offshore installations.

The market size for advanced battery technologies is projected to grow significantly in the coming years. While specific figures for AIBs are not yet available due to their emerging status, the global advanced battery market is expected to expand rapidly, driven by the electrification of transportation and the growth of renewable energy.

However, it's important to note that the market demand for AIBs is still speculative and depends heavily on the technology's ability to overcome current limitations and achieve commercial viability. Factors such as production scalability, raw material availability, and cost competitiveness with established LIB technology will play crucial roles in determining AIBs' market penetration and growth trajectory.

Current AIB Challenges

Aluminum-ion batteries (AIBs) face several significant challenges that currently limit their widespread adoption and commercialization. One of the primary obstacles is the relatively low energy density compared to lithium-ion batteries (LIBs). While AIBs offer potential advantages in terms of safety, cost, and environmental impact, their energy storage capacity lags behind that of LIBs, making them less competitive for many applications where high energy density is crucial.

Another major challenge is the limited cycle life of AIBs. The repeated charging and discharging processes can lead to degradation of the electrode materials, particularly the cathode. This degradation results in capacity fade over time, reducing the battery's overall lifespan and performance. Improving the stability of electrode materials and developing more robust electrolytes are key areas of focus for researchers aiming to enhance AIB longevity.

The development of suitable cathode materials presents a significant hurdle for AIB advancement. Many potential cathode materials suffer from poor reversibility or low voltage, which directly impacts the battery's energy density and efficiency. Researchers are exploring various materials, including graphene-based structures and metal oxides, to overcome these limitations and improve overall battery performance.

Electrolyte challenges also pose a considerable obstacle for AIB development. The highly corrosive nature of some aluminum-based electrolytes can lead to degradation of other battery components, affecting both performance and safety. Finding electrolyte formulations that balance conductivity, stability, and compatibility with electrode materials is crucial for advancing AIB technology.

Manufacturing scalability remains a significant challenge for AIBs. While the raw materials for AIBs are generally more abundant and less expensive than those for LIBs, the production processes for AIB components are not yet optimized for large-scale manufacturing. Developing cost-effective and efficient production methods is essential for AIBs to compete economically with established battery technologies.

Lastly, the lack of standardization and limited real-world performance data hinder the widespread adoption of AIBs. As a relatively new technology, AIBs have not undergone the same level of extensive testing and optimization as LIBs. This lack of long-term performance data and established industry standards makes it difficult for potential users and manufacturers to assess the reliability and suitability of AIBs for various applications.

Another major challenge is the limited cycle life of AIBs. The repeated charging and discharging processes can lead to degradation of the electrode materials, particularly the cathode. This degradation results in capacity fade over time, reducing the battery's overall lifespan and performance. Improving the stability of electrode materials and developing more robust electrolytes are key areas of focus for researchers aiming to enhance AIB longevity.

The development of suitable cathode materials presents a significant hurdle for AIB advancement. Many potential cathode materials suffer from poor reversibility or low voltage, which directly impacts the battery's energy density and efficiency. Researchers are exploring various materials, including graphene-based structures and metal oxides, to overcome these limitations and improve overall battery performance.

Electrolyte challenges also pose a considerable obstacle for AIB development. The highly corrosive nature of some aluminum-based electrolytes can lead to degradation of other battery components, affecting both performance and safety. Finding electrolyte formulations that balance conductivity, stability, and compatibility with electrode materials is crucial for advancing AIB technology.

Manufacturing scalability remains a significant challenge for AIBs. While the raw materials for AIBs are generally more abundant and less expensive than those for LIBs, the production processes for AIB components are not yet optimized for large-scale manufacturing. Developing cost-effective and efficient production methods is essential for AIBs to compete economically with established battery technologies.

Lastly, the lack of standardization and limited real-world performance data hinder the widespread adoption of AIBs. As a relatively new technology, AIBs have not undergone the same level of extensive testing and optimization as LIBs. This lack of long-term performance data and established industry standards makes it difficult for potential users and manufacturers to assess the reliability and suitability of AIBs for various applications.

Li-ion vs AIB Solutions

01 Cost-effective production methods

Developing economically viable production methods for aluminum batteries is crucial for their commercial success. This includes optimizing manufacturing processes, reducing material costs, and improving scalability. Innovations in electrode fabrication, electrolyte formulation, and cell assembly techniques contribute to lowering production costs and enhancing economic feasibility.- Cost-effective production methods: Developing economically viable production methods for aluminum batteries is crucial for their commercial success. This includes optimizing manufacturing processes, reducing material costs, and improving scalability. Innovations in electrode fabrication, electrolyte formulation, and cell assembly techniques contribute to lowering production costs and enhancing economic feasibility.

- Performance improvements: Enhancing the performance of aluminum batteries is essential for their economic viability. This involves increasing energy density, improving cycle life, and enhancing charge/discharge rates. Research focuses on developing advanced electrode materials, electrolyte compositions, and cell designs to achieve performance levels competitive with existing battery technologies.

- Integration with renewable energy systems: The economic viability of aluminum batteries can be improved by integrating them with renewable energy systems. This includes developing battery management systems, grid integration technologies, and energy storage solutions tailored for solar and wind power applications. Such integration can enhance the overall efficiency and cost-effectiveness of renewable energy systems.

- Recycling and sustainability: Implementing efficient recycling processes and ensuring sustainability in the production and use of aluminum batteries are crucial for their long-term economic viability. This involves developing environmentally friendly manufacturing methods, creating closed-loop recycling systems, and minimizing the environmental impact of battery production and disposal.

- Market analysis and commercialization strategies: Conducting comprehensive market analyses and developing effective commercialization strategies are essential for the economic viability of aluminum batteries. This includes identifying target markets, assessing competition, developing pricing strategies, and creating partnerships for production and distribution. Understanding regulatory requirements and consumer preferences is also crucial for successful market entry.

02 Performance enhancement for market competitiveness

Improving the performance of aluminum batteries is essential for their economic viability. This involves enhancing energy density, power output, cycle life, and charging efficiency. Advanced materials and designs that address these aspects can make aluminum batteries more competitive with existing battery technologies in various applications.Expand Specific Solutions03 Integration with renewable energy systems

The economic viability of aluminum batteries can be improved by integrating them with renewable energy systems. This integration can provide efficient energy storage solutions for solar and wind power, enhancing grid stability and reducing reliance on fossil fuels. The synergy between aluminum batteries and renewable energy sources can create new market opportunities.Expand Specific Solutions04 Recycling and sustainability considerations

Developing efficient recycling processes for aluminum batteries is crucial for their long-term economic viability. Sustainable production and end-of-life management can reduce environmental impact and raw material costs. Implementing circular economy principles in the aluminum battery lifecycle can enhance their overall economic and ecological value proposition.Expand Specific Solutions05 Market analysis and commercialization strategies

Conducting comprehensive market analyses and developing effective commercialization strategies are vital for the economic success of aluminum batteries. This includes identifying target markets, assessing competition, and creating business models that leverage the unique advantages of aluminum battery technology. Strategic partnerships and investment in research and development can accelerate market adoption and improve economic viability.Expand Specific Solutions

Key Players in AIB

The competition landscape for aluminum-ion batteries (AIBs) versus lithium-ion batteries (Li-ion) is in an early development stage, with the market still dominated by Li-ion technology. While the global battery market is projected to reach $310 billion by 2027, AIBs currently occupy a niche segment. The technology is still maturing, with research institutions like Beijing Institute of Technology and William Marsh Rice University leading advancements. Companies such as StoreDot and Ningde Amperex Technology are exploring AIB potential, but commercial viability remains limited. AIBs show promise in specific use cases where their fast charging capabilities and improved safety could outweigh Li-ion's energy density advantages, particularly in grid storage and electric vehicle applications.

Beijing Institute of Technology

Technical Solution: Beijing Institute of Technology has been at the forefront of aluminum-ion battery (AIB) research, developing a novel graphene-based cathode material that significantly enhances the battery's performance. Their AIB design utilizes an aluminum foil anode, a graphene cathode, and an AlCl3/EMIMCl ionic liquid electrolyte. This configuration has demonstrated a high capacity of 123 mAh/g and excellent cycling stability, retaining 88% capacity after 10,000 cycles [1]. The institute has also explored the use of 3D graphene foam as a cathode material, which provides a large surface area and facilitates rapid ion transport, resulting in improved power density and cycle life [2].

Strengths: High cycling stability, improved power density, and potential for fast charging. Weaknesses: Lower energy density compared to Li-ion batteries, challenges in large-scale production of graphene-based materials.

StoreDot Ltd.

Technical Solution: StoreDot, while primarily known for its extreme fast-charging (XFC) lithium-ion batteries, has also been exploring aluminum-ion technology as a potential alternative. Their approach focuses on developing silicon-dominant anode materials that could be adapted for use in AIBs. StoreDot's technology aims to address the energy density limitations of traditional AIBs by incorporating nanostructured silicon, which could potentially increase the battery's capacity [3]. The company's research suggests that their silicon-based anodes could enable AIBs to achieve energy densities closer to those of lithium-ion batteries while maintaining the safety and abundance advantages of aluminum [4].

Strengths: Potential for higher energy density AIBs, leveraging existing silicon anode technology. Weaknesses: Still in early research stages for AIB applications, may face challenges in electrolyte compatibility.

AIB Core Innovations

Aluminum-ion battery using aluminum chloride/amide-based deep eutectic solvents

PatentWO2020056514A1

Innovation

- The development of aluminum-ion batteries using aluminum chloride/amide-based deep eutectic solvents as electrolytes, combined with inexpensive graphitic materials and other cathode active materials, such as pyrolytic and natural graphite, to create a cost-effective and safer battery technology.

Economic Viability

The economic viability of Aluminum-Ion Batteries (AIBs) compared to Lithium-Ion Batteries (LIBs) is a critical factor in determining their potential for widespread adoption. While AIBs offer several advantages, their economic feasibility depends on various factors, including production costs, performance characteristics, and market dynamics.

One of the primary economic advantages of AIBs is the abundance and low cost of aluminum as a raw material. Aluminum is the third most abundant element in the Earth's crust, making it significantly cheaper and more accessible than lithium. This abundance could potentially lead to lower production costs for AIBs, especially as manufacturing processes are optimized and scaled up.

However, the current production costs of AIBs are still higher than those of LIBs due to the nascent state of the technology and the lack of established manufacturing infrastructure. As research and development progress and production scales increase, it is anticipated that the cost per kWh of AIBs will decrease, potentially reaching parity with or even undercutting LIBs in the future.

The economic viability of AIBs is also influenced by their performance characteristics. AIBs have shown promising results in terms of fast charging capabilities, with some prototypes demonstrating charging times as low as one minute. This rapid charging ability could provide significant economic benefits in applications where minimizing downtime is crucial, such as in electric vehicles or grid energy storage systems.

Furthermore, AIBs have demonstrated excellent cycle life, with some experimental cells maintaining high capacity retention even after thousands of charge-discharge cycles. This longevity could translate to lower total cost of ownership over the battery's lifetime, potentially offsetting higher initial costs.

The safety profile of AIBs is another factor contributing to their economic potential. Unlike LIBs, AIBs are non-flammable and do not pose the same risk of thermal runaway. This enhanced safety could lead to reduced costs associated with safety measures, transportation, and insurance, particularly in large-scale energy storage applications.

Market dynamics will play a crucial role in determining the economic viability of AIBs. As environmental regulations become more stringent and the demand for sustainable energy storage solutions grows, AIBs could gain a competitive edge due to their use of more abundant and environmentally friendly materials.

In conclusion, while AIBs currently face economic challenges due to their early stage of development, they show promising potential for economic viability in the future. As technology advances and production scales up, AIBs could become increasingly competitive with LIBs, particularly in applications that benefit from their unique characteristics such as fast charging, long cycle life, and enhanced safety.

One of the primary economic advantages of AIBs is the abundance and low cost of aluminum as a raw material. Aluminum is the third most abundant element in the Earth's crust, making it significantly cheaper and more accessible than lithium. This abundance could potentially lead to lower production costs for AIBs, especially as manufacturing processes are optimized and scaled up.

However, the current production costs of AIBs are still higher than those of LIBs due to the nascent state of the technology and the lack of established manufacturing infrastructure. As research and development progress and production scales increase, it is anticipated that the cost per kWh of AIBs will decrease, potentially reaching parity with or even undercutting LIBs in the future.

The economic viability of AIBs is also influenced by their performance characteristics. AIBs have shown promising results in terms of fast charging capabilities, with some prototypes demonstrating charging times as low as one minute. This rapid charging ability could provide significant economic benefits in applications where minimizing downtime is crucial, such as in electric vehicles or grid energy storage systems.

Furthermore, AIBs have demonstrated excellent cycle life, with some experimental cells maintaining high capacity retention even after thousands of charge-discharge cycles. This longevity could translate to lower total cost of ownership over the battery's lifetime, potentially offsetting higher initial costs.

The safety profile of AIBs is another factor contributing to their economic potential. Unlike LIBs, AIBs are non-flammable and do not pose the same risk of thermal runaway. This enhanced safety could lead to reduced costs associated with safety measures, transportation, and insurance, particularly in large-scale energy storage applications.

Market dynamics will play a crucial role in determining the economic viability of AIBs. As environmental regulations become more stringent and the demand for sustainable energy storage solutions grows, AIBs could gain a competitive edge due to their use of more abundant and environmentally friendly materials.

In conclusion, while AIBs currently face economic challenges due to their early stage of development, they show promising potential for economic viability in the future. As technology advances and production scales up, AIBs could become increasingly competitive with LIBs, particularly in applications that benefit from their unique characteristics such as fast charging, long cycle life, and enhanced safety.

Environmental Impact

The environmental impact of battery technologies is a critical consideration in the ongoing transition towards sustainable energy systems. When comparing Aluminum-ion Batteries (AIBs) with Lithium-ion Batteries (LIBs), several key factors come into play that highlight the potential ecological advantages of AIBs.

Firstly, the raw material sourcing for AIBs presents a more environmentally friendly profile. Aluminum is the third most abundant element in the Earth's crust, making it readily available and reducing the need for extensive mining operations. In contrast, lithium extraction often involves water-intensive processes and can lead to soil degradation and water pollution, particularly in sensitive ecosystems where lithium deposits are found.

The production process of AIBs also offers potential environmental benefits. The energy requirements for manufacturing aluminum-based batteries are generally lower than those for lithium-ion batteries, resulting in a reduced carbon footprint during the production phase. Additionally, the materials used in AIBs are typically less toxic and easier to handle safely, minimizing the risk of environmental contamination during manufacturing and transportation.

In terms of lifecycle performance, AIBs show promise in longevity and recyclability. The theoretical cycle life of AIBs is higher than that of LIBs, which could lead to reduced waste generation over time. Moreover, the recycling process for aluminum is well-established and more efficient compared to lithium recycling, potentially creating a more circular economy for battery materials.

The end-of-life management of AIBs also presents environmental advantages. The components of AIBs are generally easier to separate and recycle, with aluminum being infinitely recyclable without loss of quality. This characteristic could significantly reduce the environmental burden associated with battery disposal and promote the reuse of materials in new battery production.

However, it's important to note that the environmental impact of AIBs is not uniformly positive. The production of aluminum itself is energy-intensive, primarily due to the electrolysis process used to refine bauxite ore. This energy demand could offset some of the environmental gains if not sourced from renewable energy. Additionally, the full-scale production and widespread adoption of AIBs would require the development of new supply chains and manufacturing processes, which could have short-term environmental impacts.

In conclusion, while AIBs show promising environmental benefits compared to LIBs, particularly in terms of raw material availability, recyclability, and reduced toxicity, a comprehensive life cycle assessment is necessary to fully quantify their ecological advantages. As the technology matures and production scales up, ongoing research and development efforts should focus on further optimizing the environmental performance of AIBs to maximize their potential as a sustainable energy storage solution.

Firstly, the raw material sourcing for AIBs presents a more environmentally friendly profile. Aluminum is the third most abundant element in the Earth's crust, making it readily available and reducing the need for extensive mining operations. In contrast, lithium extraction often involves water-intensive processes and can lead to soil degradation and water pollution, particularly in sensitive ecosystems where lithium deposits are found.

The production process of AIBs also offers potential environmental benefits. The energy requirements for manufacturing aluminum-based batteries are generally lower than those for lithium-ion batteries, resulting in a reduced carbon footprint during the production phase. Additionally, the materials used in AIBs are typically less toxic and easier to handle safely, minimizing the risk of environmental contamination during manufacturing and transportation.

In terms of lifecycle performance, AIBs show promise in longevity and recyclability. The theoretical cycle life of AIBs is higher than that of LIBs, which could lead to reduced waste generation over time. Moreover, the recycling process for aluminum is well-established and more efficient compared to lithium recycling, potentially creating a more circular economy for battery materials.

The end-of-life management of AIBs also presents environmental advantages. The components of AIBs are generally easier to separate and recycle, with aluminum being infinitely recyclable without loss of quality. This characteristic could significantly reduce the environmental burden associated with battery disposal and promote the reuse of materials in new battery production.

However, it's important to note that the environmental impact of AIBs is not uniformly positive. The production of aluminum itself is energy-intensive, primarily due to the electrolysis process used to refine bauxite ore. This energy demand could offset some of the environmental gains if not sourced from renewable energy. Additionally, the full-scale production and widespread adoption of AIBs would require the development of new supply chains and manufacturing processes, which could have short-term environmental impacts.

In conclusion, while AIBs show promising environmental benefits compared to LIBs, particularly in terms of raw material availability, recyclability, and reduced toxicity, a comprehensive life cycle assessment is necessary to fully quantify their ecological advantages. As the technology matures and production scales up, ongoing research and development efforts should focus on further optimizing the environmental performance of AIBs to maximize their potential as a sustainable energy storage solution.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!