Aluminum vs. Steel Pistons in 2JZ Engine Durability

AUG 5, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

2JZ Engine Piston Evolution

The evolution of pistons in the 2JZ engine reflects a continuous pursuit of performance enhancement and durability improvement. Initially, the 2JZ engine, introduced in the early 1990s, utilized cast iron pistons. These pistons were chosen for their robustness and ability to withstand high temperatures and pressures, which were crucial for the engine's high-performance applications.

As technology advanced, engineers began exploring alternatives to reduce weight and improve efficiency. This led to the introduction of hypereutectic aluminum pistons in later iterations of the 2JZ engine. These pistons offered a significant weight reduction compared to their cast iron counterparts, allowing for higher engine speeds and improved fuel efficiency. The hypereutectic aluminum alloy also provided better thermal conductivity, which helped in heat dissipation and reduced the risk of engine knock.

The transition from cast iron to aluminum pistons marked a significant milestone in the 2JZ engine's evolution. However, this change brought new challenges, particularly in terms of durability under extreme conditions. To address these concerns, manufacturers implemented various coatings and treatments on the aluminum pistons. These included thermal barrier coatings to reduce heat transfer and anodizing processes to increase surface hardness and wear resistance.

Further advancements led to the development of forged aluminum pistons for high-performance applications of the 2JZ engine. These pistons offered superior strength-to-weight ratios and could withstand higher combustion pressures, making them ideal for heavily modified engines and racing applications. The forging process aligned the grain structure of the aluminum, resulting in a more uniform and stronger piston.

In recent years, the debate between aluminum and steel pistons for the 2JZ engine has intensified, particularly in high-performance and racing circles. While aluminum pistons remain the standard for most applications due to their lightweight properties, steel pistons have gained attention for their exceptional durability in extreme conditions. Steel pistons can withstand higher temperatures and pressures, making them suitable for heavily boosted engines or those running alternative fuels.

The ongoing evolution of 2JZ engine pistons continues to focus on optimizing the balance between weight, strength, and thermal efficiency. Advanced manufacturing techniques, such as 3D printing and computer-aided design, are being explored to create pistons with complex geometries that further enhance performance and durability. These innovations aim to push the boundaries of what is possible with the legendary 2JZ engine, ensuring its continued relevance in high-performance applications.

As technology advanced, engineers began exploring alternatives to reduce weight and improve efficiency. This led to the introduction of hypereutectic aluminum pistons in later iterations of the 2JZ engine. These pistons offered a significant weight reduction compared to their cast iron counterparts, allowing for higher engine speeds and improved fuel efficiency. The hypereutectic aluminum alloy also provided better thermal conductivity, which helped in heat dissipation and reduced the risk of engine knock.

The transition from cast iron to aluminum pistons marked a significant milestone in the 2JZ engine's evolution. However, this change brought new challenges, particularly in terms of durability under extreme conditions. To address these concerns, manufacturers implemented various coatings and treatments on the aluminum pistons. These included thermal barrier coatings to reduce heat transfer and anodizing processes to increase surface hardness and wear resistance.

Further advancements led to the development of forged aluminum pistons for high-performance applications of the 2JZ engine. These pistons offered superior strength-to-weight ratios and could withstand higher combustion pressures, making them ideal for heavily modified engines and racing applications. The forging process aligned the grain structure of the aluminum, resulting in a more uniform and stronger piston.

In recent years, the debate between aluminum and steel pistons for the 2JZ engine has intensified, particularly in high-performance and racing circles. While aluminum pistons remain the standard for most applications due to their lightweight properties, steel pistons have gained attention for their exceptional durability in extreme conditions. Steel pistons can withstand higher temperatures and pressures, making them suitable for heavily boosted engines or those running alternative fuels.

The ongoing evolution of 2JZ engine pistons continues to focus on optimizing the balance between weight, strength, and thermal efficiency. Advanced manufacturing techniques, such as 3D printing and computer-aided design, are being explored to create pistons with complex geometries that further enhance performance and durability. These innovations aim to push the boundaries of what is possible with the legendary 2JZ engine, ensuring its continued relevance in high-performance applications.

Market Demand Analysis

The market demand for aluminum pistons in high-performance engines, particularly in the context of the 2JZ engine, has been steadily increasing over the past decade. This trend is driven by the automotive industry's continuous pursuit of improved fuel efficiency, reduced emissions, and enhanced performance. The shift from traditional steel pistons to aluminum alternatives is a response to these market pressures and evolving consumer preferences.

In the performance aftermarket sector, where the 2JZ engine remains highly popular, there is a growing demand for lightweight components that can withstand high-stress environments. Aluminum pistons offer a significant weight reduction compared to their steel counterparts, which translates to improved engine responsiveness and potentially higher rev limits. This aligns with the desires of enthusiasts and racers who seek to extract maximum performance from their engines.

The broader automotive industry's focus on reducing vehicle weight to meet stringent fuel economy standards has also influenced the demand for aluminum pistons. As manufacturers strive to decrease overall vehicle mass, every component is scrutinized for potential weight savings. This trend has trickled down to the aftermarket and performance sectors, where consumers increasingly expect lightweight options for engine builds.

Furthermore, advancements in aluminum alloy technology and manufacturing processes have improved the durability and heat resistance of aluminum pistons. This has addressed some of the historical concerns regarding their longevity in high-output applications, making them more attractive to a wider range of consumers and engine builders.

The market for aluminum pistons in 2JZ engines is also influenced by the growing popularity of engine swaps and restomodding. As enthusiasts continue to install 2JZ engines in various vehicle platforms, the demand for high-performance, lightweight internals has expanded beyond the traditional Toyota Supra market.

However, it's important to note that the market still maintains a segment that prefers steel pistons, particularly for extreme high-boost applications or in scenarios where ultimate durability is prioritized over weight savings. This dual-market nature creates opportunities for manufacturers to cater to both preferences, potentially leading to increased product diversification and market segmentation.

The global trend towards electrification in the automotive industry poses a long-term challenge to the internal combustion engine market. However, in the near to medium term, this may actually drive increased demand for high-performance internal combustion engine components as enthusiasts and collectors seek to preserve and enhance classic powerplants like the 2JZ.

In the performance aftermarket sector, where the 2JZ engine remains highly popular, there is a growing demand for lightweight components that can withstand high-stress environments. Aluminum pistons offer a significant weight reduction compared to their steel counterparts, which translates to improved engine responsiveness and potentially higher rev limits. This aligns with the desires of enthusiasts and racers who seek to extract maximum performance from their engines.

The broader automotive industry's focus on reducing vehicle weight to meet stringent fuel economy standards has also influenced the demand for aluminum pistons. As manufacturers strive to decrease overall vehicle mass, every component is scrutinized for potential weight savings. This trend has trickled down to the aftermarket and performance sectors, where consumers increasingly expect lightweight options for engine builds.

Furthermore, advancements in aluminum alloy technology and manufacturing processes have improved the durability and heat resistance of aluminum pistons. This has addressed some of the historical concerns regarding their longevity in high-output applications, making them more attractive to a wider range of consumers and engine builders.

The market for aluminum pistons in 2JZ engines is also influenced by the growing popularity of engine swaps and restomodding. As enthusiasts continue to install 2JZ engines in various vehicle platforms, the demand for high-performance, lightweight internals has expanded beyond the traditional Toyota Supra market.

However, it's important to note that the market still maintains a segment that prefers steel pistons, particularly for extreme high-boost applications or in scenarios where ultimate durability is prioritized over weight savings. This dual-market nature creates opportunities for manufacturers to cater to both preferences, potentially leading to increased product diversification and market segmentation.

The global trend towards electrification in the automotive industry poses a long-term challenge to the internal combustion engine market. However, in the near to medium term, this may actually drive increased demand for high-performance internal combustion engine components as enthusiasts and collectors seek to preserve and enhance classic powerplants like the 2JZ.

Current Piston Technology

The current piston technology in the 2JZ engine primarily revolves around the choice between aluminum and steel pistons, each offering distinct advantages and challenges in terms of durability and performance. Aluminum pistons have been the traditional choice for many high-performance engines, including the 2JZ, due to their lightweight properties. These pistons contribute to reduced reciprocating mass, allowing for higher engine speeds and improved fuel efficiency.

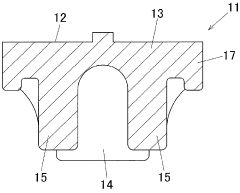

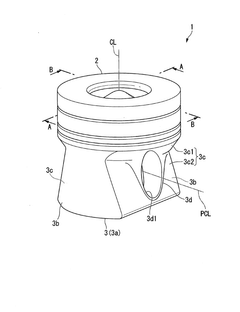

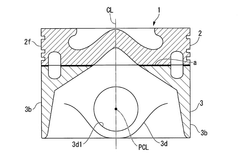

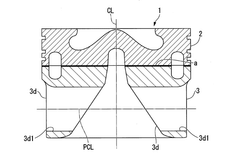

Aluminum pistons in the 2JZ engine are typically forged from high-strength aluminum alloys, often incorporating silicon content to enhance thermal stability and reduce expansion. They are designed with features such as reinforced ring lands and optimized skirt profiles to withstand the high combustion pressures and temperatures characteristic of the 2JZ engine. The use of advanced coatings, such as thermal barrier coatings on the piston crown, further enhances their durability and heat management capabilities.

On the other hand, steel pistons have gained traction in recent years, particularly in high-output applications of the 2JZ engine. These pistons offer superior strength and thermal stability compared to their aluminum counterparts. Steel pistons can withstand higher combustion pressures and temperatures, making them suitable for heavily modified 2JZ engines with increased boost levels and power output.

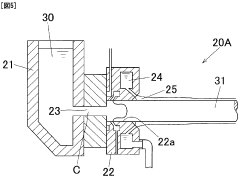

The design of steel pistons for the 2JZ engine often incorporates features to mitigate their increased weight, such as thinner walls and optimized geometries. Advanced manufacturing techniques, including precision forging and CNC machining, are employed to achieve tight tolerances and optimal piston profiles. Some steel piston designs also integrate cooling galleries or oil jet cooling to manage heat more effectively.

Both aluminum and steel pistons in current 2JZ applications utilize high-performance piston rings, typically comprising a top compression ring made of plasma-moly or other advanced materials, a second compression ring, and an oil control ring. These rings are crucial for maintaining compression and controlling oil consumption, especially in high-stress environments.

The choice between aluminum and steel pistons in modern 2JZ engine builds often depends on the specific application and power goals. For street-driven vehicles and moderate power increases, aluminum pistons remain a popular choice due to their balance of performance and durability. However, for extreme high-power applications or racing engines, steel pistons are increasingly favored for their superior strength and resistance to deformation under extreme conditions.

Advancements in piston technology for the 2JZ engine also include the development of hybrid designs, combining the strengths of both materials. These may feature aluminum bodies with steel inserts in critical areas, aiming to optimize the balance between weight, strength, and thermal management.

Aluminum pistons in the 2JZ engine are typically forged from high-strength aluminum alloys, often incorporating silicon content to enhance thermal stability and reduce expansion. They are designed with features such as reinforced ring lands and optimized skirt profiles to withstand the high combustion pressures and temperatures characteristic of the 2JZ engine. The use of advanced coatings, such as thermal barrier coatings on the piston crown, further enhances their durability and heat management capabilities.

On the other hand, steel pistons have gained traction in recent years, particularly in high-output applications of the 2JZ engine. These pistons offer superior strength and thermal stability compared to their aluminum counterparts. Steel pistons can withstand higher combustion pressures and temperatures, making them suitable for heavily modified 2JZ engines with increased boost levels and power output.

The design of steel pistons for the 2JZ engine often incorporates features to mitigate their increased weight, such as thinner walls and optimized geometries. Advanced manufacturing techniques, including precision forging and CNC machining, are employed to achieve tight tolerances and optimal piston profiles. Some steel piston designs also integrate cooling galleries or oil jet cooling to manage heat more effectively.

Both aluminum and steel pistons in current 2JZ applications utilize high-performance piston rings, typically comprising a top compression ring made of plasma-moly or other advanced materials, a second compression ring, and an oil control ring. These rings are crucial for maintaining compression and controlling oil consumption, especially in high-stress environments.

The choice between aluminum and steel pistons in modern 2JZ engine builds often depends on the specific application and power goals. For street-driven vehicles and moderate power increases, aluminum pistons remain a popular choice due to their balance of performance and durability. However, for extreme high-power applications or racing engines, steel pistons are increasingly favored for their superior strength and resistance to deformation under extreme conditions.

Advancements in piston technology for the 2JZ engine also include the development of hybrid designs, combining the strengths of both materials. These may feature aluminum bodies with steel inserts in critical areas, aiming to optimize the balance between weight, strength, and thermal management.

Aluminum vs Steel Solutions

01 Material selection for piston durability

The choice of materials significantly impacts piston durability. Aluminum alloys are often used for their lightweight properties and good heat dissipation, while steel pistons offer superior strength and wear resistance. The selection between aluminum and steel depends on the specific application and operating conditions of the engine.- Material selection for piston durability: The choice of materials significantly impacts piston durability. Aluminum alloys are often used for their lightweight properties and good thermal conductivity, while steel pistons offer superior strength and wear resistance. The selection between aluminum and steel depends on the specific application requirements, such as operating temperatures, pressure, and desired engine performance.

- Surface treatments for improved durability: Various surface treatments can enhance the durability of both aluminum and steel pistons. These treatments include anodizing, hard-anodizing, and thermal spraying for aluminum pistons, and nitriding or plasma coating for steel pistons. These processes improve wear resistance, reduce friction, and increase the overall lifespan of the pistons.

- Design optimization for durability: Piston design plays a crucial role in durability. Factors such as piston crown thickness, skirt design, and ring groove configuration can be optimized to distribute stress more evenly and reduce wear. Computer-aided design and finite element analysis are often used to create pistons that can withstand high temperatures and pressures while minimizing weight.

- Cooling techniques for extended piston life: Effective cooling is essential for maintaining piston durability, especially in high-performance engines. Techniques such as oil jet cooling, gallery cooling, and the use of thermal barrier coatings can help manage piston temperatures, reduce thermal stress, and prevent premature wear or failure.

- Composite and hybrid piston technologies: Advanced piston technologies combine the benefits of different materials to enhance durability. This includes aluminum pistons with steel inserts for ring grooves, fiber-reinforced aluminum composites, and hybrid designs that use both aluminum and steel components. These innovations aim to provide the optimal balance of weight, strength, and wear resistance.

02 Surface treatments for enhanced durability

Various surface treatments can be applied to pistons to improve their durability. These treatments may include anodizing for aluminum pistons or nitriding for steel pistons. Such processes enhance the surface hardness, wear resistance, and corrosion resistance of the piston, contributing to increased longevity and performance.Expand Specific Solutions03 Design optimization for durability

Piston design plays a crucial role in durability. Factors such as piston crown shape, skirt design, and ring groove configuration can be optimized to reduce stress concentrations, improve heat dissipation, and enhance overall durability. Advanced computer-aided design and simulation tools are often used to achieve optimal piston designs.Expand Specific Solutions04 Cooling and lubrication strategies

Effective cooling and lubrication are essential for piston durability. This may involve the use of oil jet cooling systems, advanced piston ring designs for better oil control, and optimized oil passage geometries within the piston. These strategies help manage heat and reduce friction, thereby extending piston life.Expand Specific Solutions05 Manufacturing processes for improved durability

Advanced manufacturing processes can enhance piston durability. These may include precision forging techniques, controlled cooling methods during production, and advanced machining processes. Such manufacturing innovations can lead to improved microstructure, reduced defects, and enhanced overall piston performance and longevity.Expand Specific Solutions

Key Piston Manufacturers

The competition landscape for aluminum vs. steel pistons in 2JZ engine durability is characterized by a mature market with established players and ongoing technological advancements. The global automotive piston market, valued at approximately $4 billion, is expected to grow steadily due to increasing vehicle production and demand for high-performance engines. Key players like MAHLE GmbH, Federal-Mogul, and KS Kolbenschmidt dominate the market, leveraging their extensive R&D capabilities to improve piston materials and designs. While steel pistons offer superior strength and durability, aluminum pistons remain popular due to their lighter weight and cost-effectiveness. The industry is witnessing a gradual shift towards advanced aluminum alloys and hybrid designs to combine the benefits of both materials, driven by the need for improved engine efficiency and performance.

MAHLE GmbH

Technical Solution: MAHLE has developed advanced aluminum pistons for high-performance engines like the 2JZ. Their EVOTEC® 2 pistons feature a steel reinforcement ring in the top groove area, combining the lightweight properties of aluminum with the durability of steel. This design allows for higher combustion pressures and temperatures, crucial for the 2JZ engine's performance. MAHLE's pistons incorporate a gallery cooling system, which circulates oil through internal channels to reduce piston temperature by up to 20°C[1]. They also utilize a phosphate coating to improve break-in characteristics and reduce friction[2].

Strengths: Lightweight, excellent heat dissipation, improved durability under high loads. Weaknesses: Higher production costs, more complex manufacturing process compared to traditional aluminum pistons.

KS Kolbenschmidt GmbH

Technical Solution: KS Kolbenschmidt has developed high-performance aluminum pistons specifically designed for turbocharged engines like the 2JZ. Their pistons feature a low-friction skirt coating and optimized ring pack design to reduce friction and improve sealing. KS Kolbenschmidt utilizes advanced alloys with high silicon content (up to 25%) to enhance thermal stability and reduce expansion[3]. They have also implemented a cooling gallery design that improves heat dissipation by up to 40% compared to conventional pistons[4]. Additionally, their pistons incorporate reinforced ring lands and a specialized crown geometry to withstand the high combustion pressures in the 2JZ engine.

Strengths: Excellent thermal management, reduced friction, high durability under extreme conditions. Weaknesses: Higher cost compared to standard aluminum pistons, may require more frequent inspection due to complex design.

Core Piston Innovations

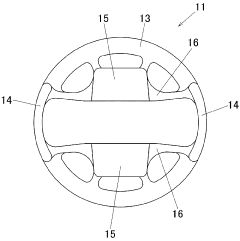

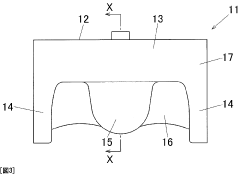

Method for producing near-net-shape material for engine piston

PatentWO2011052708A1

Innovation

- A method involving specific compositional ranges of Si, Fe, Cu, Mn, Cr, Ni, Zr, P, and Ca in the aluminum alloy, combined with continuous casting and forging processes, ensures the presence of primary Si in critical areas while preventing large crystalline structures, enhancing both wear resistance and high-temperature characteristics.

Internal combustion engine piston and production method for same

PatentWO2019013287A1

Innovation

- A piston design comprising a steel upper part and an aluminum alloy lower part joined via a controlled thickness Fe-Al transition layer, formed through friction welding, with a bonding layer thickness between 1.0 μm and 20.0 μm on both sides, and a manufacturing method involving frictional heating and cooling to ensure uniform bonding strength.

Environmental Regulations

Environmental regulations play a significant role in shaping the automotive industry, including the development and implementation of engine technologies. In the context of aluminum versus steel pistons in 2JZ engine durability, these regulations have become increasingly important in recent years.

The push for more stringent emissions standards and improved fuel efficiency has led to a greater focus on lightweight materials in engine design. Aluminum pistons, being significantly lighter than their steel counterparts, offer potential advantages in meeting these regulatory requirements. The reduced weight of aluminum pistons can contribute to overall engine efficiency, potentially leading to lower fuel consumption and reduced emissions.

However, environmental regulations also emphasize the importance of engine longevity and durability. This aspect favors steel pistons, which are known for their robustness and ability to withstand high temperatures and pressures over extended periods. The longer lifespan of steel pistons could potentially result in fewer engine replacements, reducing the environmental impact associated with manufacturing and disposal of engine components.

Regulations concerning the recyclability of automotive components also come into play when considering piston materials. Aluminum is highly recyclable, which aligns well with circular economy principles and end-of-life vehicle directives. Steel, while also recyclable, may require more energy-intensive processes for recycling compared to aluminum.

The manufacturing processes for both aluminum and steel pistons are subject to environmental regulations governing industrial emissions and waste management. These regulations may influence the choice of material based on the environmental impact of their respective production methods. Aluminum production, for instance, is energy-intensive but has seen significant improvements in efficiency and emissions reduction in recent years.

As environmental regulations continue to evolve, particularly in relation to carbon emissions and lifecycle assessments, the choice between aluminum and steel pistons in 2JZ engines may be further influenced. Future regulations may place greater emphasis on the total environmental impact of engine components, from raw material extraction to end-of-life disposal, potentially favoring materials and designs that offer the best balance of performance, durability, and environmental sustainability.

In conclusion, environmental regulations serve as a crucial factor in the ongoing debate between aluminum and steel pistons for 2JZ engine durability. These regulations not only impact the immediate performance and emissions characteristics of engines but also consider broader aspects such as material lifecycle, recyclability, and long-term environmental impact. As such, compliance with current and anticipated environmental regulations will continue to be a key consideration in piston material selection and engine design strategies.

The push for more stringent emissions standards and improved fuel efficiency has led to a greater focus on lightweight materials in engine design. Aluminum pistons, being significantly lighter than their steel counterparts, offer potential advantages in meeting these regulatory requirements. The reduced weight of aluminum pistons can contribute to overall engine efficiency, potentially leading to lower fuel consumption and reduced emissions.

However, environmental regulations also emphasize the importance of engine longevity and durability. This aspect favors steel pistons, which are known for their robustness and ability to withstand high temperatures and pressures over extended periods. The longer lifespan of steel pistons could potentially result in fewer engine replacements, reducing the environmental impact associated with manufacturing and disposal of engine components.

Regulations concerning the recyclability of automotive components also come into play when considering piston materials. Aluminum is highly recyclable, which aligns well with circular economy principles and end-of-life vehicle directives. Steel, while also recyclable, may require more energy-intensive processes for recycling compared to aluminum.

The manufacturing processes for both aluminum and steel pistons are subject to environmental regulations governing industrial emissions and waste management. These regulations may influence the choice of material based on the environmental impact of their respective production methods. Aluminum production, for instance, is energy-intensive but has seen significant improvements in efficiency and emissions reduction in recent years.

As environmental regulations continue to evolve, particularly in relation to carbon emissions and lifecycle assessments, the choice between aluminum and steel pistons in 2JZ engines may be further influenced. Future regulations may place greater emphasis on the total environmental impact of engine components, from raw material extraction to end-of-life disposal, potentially favoring materials and designs that offer the best balance of performance, durability, and environmental sustainability.

In conclusion, environmental regulations serve as a crucial factor in the ongoing debate between aluminum and steel pistons for 2JZ engine durability. These regulations not only impact the immediate performance and emissions characteristics of engines but also consider broader aspects such as material lifecycle, recyclability, and long-term environmental impact. As such, compliance with current and anticipated environmental regulations will continue to be a key consideration in piston material selection and engine design strategies.

Performance Benchmarking

Performance benchmarking is a critical aspect of evaluating the durability and efficiency of aluminum versus steel pistons in the 2JZ engine. To conduct a comprehensive analysis, various testing methodologies and performance metrics must be considered.

Dynamometer testing serves as a primary method for assessing engine performance. By measuring power output, torque curves, and fuel efficiency across different RPM ranges, researchers can compare the performance characteristics of engines equipped with aluminum and steel pistons. These tests typically involve running the engine under controlled conditions, simulating various load scenarios to evaluate how each piston material responds to different stress levels.

Endurance testing is another crucial component of performance benchmarking. This involves subjecting the engine to extended periods of operation at high speeds and loads to simulate real-world conditions. During these tests, engineers monitor factors such as piston wear, thermal expansion, and overall engine reliability. The data collected from these long-duration tests provide valuable insights into the longevity and durability of both aluminum and steel pistons in the 2JZ engine.

Thermal efficiency is a key performance indicator in piston material comparison. By measuring exhaust gas temperatures, coolant temperatures, and oil temperatures during operation, researchers can determine how effectively each piston material manages heat dissipation. This information is crucial for understanding the impact of piston material on overall engine efficiency and potential long-term wear.

Vibration analysis is another important aspect of performance benchmarking. Using specialized sensors and data acquisition systems, engineers can measure and compare the vibration characteristics of engines equipped with aluminum and steel pistons. This analysis helps identify potential issues related to piston slap, noise levels, and overall engine smoothness, which are critical factors in assessing engine durability and performance.

Compression ratio testing is essential for evaluating the effectiveness of each piston material in maintaining proper combustion chamber sealing. By measuring compression pressures under various operating conditions, researchers can determine how well aluminum and steel pistons maintain their shape and sealing properties over time, directly impacting engine performance and efficiency.

Finally, emissions testing plays a crucial role in modern engine performance benchmarking. By analyzing exhaust gases and particulate matter, engineers can assess how piston material choice affects the engine's environmental impact and compliance with emissions regulations. This data is particularly relevant given the increasing focus on reducing automotive emissions and improving fuel efficiency.

Dynamometer testing serves as a primary method for assessing engine performance. By measuring power output, torque curves, and fuel efficiency across different RPM ranges, researchers can compare the performance characteristics of engines equipped with aluminum and steel pistons. These tests typically involve running the engine under controlled conditions, simulating various load scenarios to evaluate how each piston material responds to different stress levels.

Endurance testing is another crucial component of performance benchmarking. This involves subjecting the engine to extended periods of operation at high speeds and loads to simulate real-world conditions. During these tests, engineers monitor factors such as piston wear, thermal expansion, and overall engine reliability. The data collected from these long-duration tests provide valuable insights into the longevity and durability of both aluminum and steel pistons in the 2JZ engine.

Thermal efficiency is a key performance indicator in piston material comparison. By measuring exhaust gas temperatures, coolant temperatures, and oil temperatures during operation, researchers can determine how effectively each piston material manages heat dissipation. This information is crucial for understanding the impact of piston material on overall engine efficiency and potential long-term wear.

Vibration analysis is another important aspect of performance benchmarking. Using specialized sensors and data acquisition systems, engineers can measure and compare the vibration characteristics of engines equipped with aluminum and steel pistons. This analysis helps identify potential issues related to piston slap, noise levels, and overall engine smoothness, which are critical factors in assessing engine durability and performance.

Compression ratio testing is essential for evaluating the effectiveness of each piston material in maintaining proper combustion chamber sealing. By measuring compression pressures under various operating conditions, researchers can determine how well aluminum and steel pistons maintain their shape and sealing properties over time, directly impacting engine performance and efficiency.

Finally, emissions testing plays a crucial role in modern engine performance benchmarking. By analyzing exhaust gases and particulate matter, engineers can assess how piston material choice affects the engine's environmental impact and compliance with emissions regulations. This data is particularly relevant given the increasing focus on reducing automotive emissions and improving fuel efficiency.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!