Piston Ring Selection for Enhanced 2JZ Compression Stability

AUG 5, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

2JZ Piston Ring Evolution

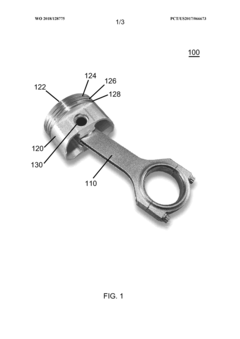

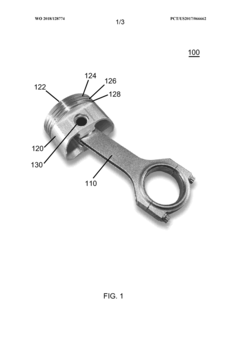

The evolution of piston rings for the 2JZ engine has been a journey of continuous improvement, driven by the pursuit of enhanced compression stability and overall engine performance. In the early stages of 2JZ development, conventional three-piece piston ring sets were commonly used, consisting of a top compression ring, a second compression ring, and an oil control ring. These initial designs provided adequate sealing and oil control for stock applications but left room for improvement in high-performance scenarios.

As tuners and enthusiasts began pushing the 2JZ engine to its limits, the need for more robust piston ring solutions became apparent. This led to the introduction of specialized performance ring sets, often featuring ductile iron or steel top rings with various coatings such as chrome or plasma-moly. These materials and coatings offered improved durability and heat resistance, crucial for withstanding the increased cylinder pressures and temperatures associated with forced induction and high-output builds.

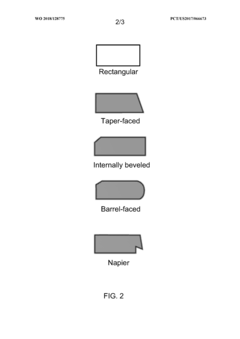

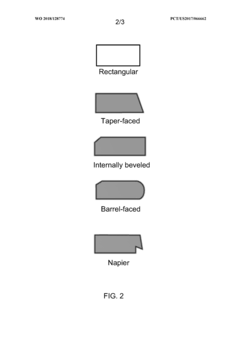

The second compression ring also saw significant evolution. Traditional cast iron rings were gradually replaced by napier-style or taper-faced rings, which provided better oil control and reduced the tendency for ring flutter at high RPMs. This improvement was particularly beneficial for the 2JZ engine, known for its ability to sustain high rotational speeds.

Oil control rings underwent refinement as well, with many high-performance applications adopting three-piece designs featuring two thin steel rails and an expander. This configuration offered superior oil management, crucial for maintaining proper lubrication while minimizing oil consumption in high-stress environments.

Another notable development in 2JZ piston ring technology was the introduction of gapless ring designs. These innovative rings featured interlocking ends that significantly reduced blow-by and improved cylinder sealing, particularly beneficial for forced induction applications where maintaining compression is critical.

The materials used in piston ring manufacturing also evolved. While cast iron remained common for many applications, advanced alloys and coatings became increasingly prevalent. Nitrided steel rings, for instance, offered excellent wear resistance and strength, making them ideal for high-boost applications. PVD (Physical Vapor Deposition) coatings, such as diamond-like carbon (DLC), began to appear on premium ring sets, providing unparalleled surface hardness and reduced friction.

As the 2JZ engine continued to be a popular platform for extreme performance builds, piston ring manufacturers developed application-specific solutions. These tailored ring packages considered factors such as bore size, compression ratio, boost pressure, and intended use (e.g., drag racing, time attack, endurance racing) to optimize ring material, profile, and tension for specific engine configurations.

As tuners and enthusiasts began pushing the 2JZ engine to its limits, the need for more robust piston ring solutions became apparent. This led to the introduction of specialized performance ring sets, often featuring ductile iron or steel top rings with various coatings such as chrome or plasma-moly. These materials and coatings offered improved durability and heat resistance, crucial for withstanding the increased cylinder pressures and temperatures associated with forced induction and high-output builds.

The second compression ring also saw significant evolution. Traditional cast iron rings were gradually replaced by napier-style or taper-faced rings, which provided better oil control and reduced the tendency for ring flutter at high RPMs. This improvement was particularly beneficial for the 2JZ engine, known for its ability to sustain high rotational speeds.

Oil control rings underwent refinement as well, with many high-performance applications adopting three-piece designs featuring two thin steel rails and an expander. This configuration offered superior oil management, crucial for maintaining proper lubrication while minimizing oil consumption in high-stress environments.

Another notable development in 2JZ piston ring technology was the introduction of gapless ring designs. These innovative rings featured interlocking ends that significantly reduced blow-by and improved cylinder sealing, particularly beneficial for forced induction applications where maintaining compression is critical.

The materials used in piston ring manufacturing also evolved. While cast iron remained common for many applications, advanced alloys and coatings became increasingly prevalent. Nitrided steel rings, for instance, offered excellent wear resistance and strength, making them ideal for high-boost applications. PVD (Physical Vapor Deposition) coatings, such as diamond-like carbon (DLC), began to appear on premium ring sets, providing unparalleled surface hardness and reduced friction.

As the 2JZ engine continued to be a popular platform for extreme performance builds, piston ring manufacturers developed application-specific solutions. These tailored ring packages considered factors such as bore size, compression ratio, boost pressure, and intended use (e.g., drag racing, time attack, endurance racing) to optimize ring material, profile, and tension for specific engine configurations.

Market Demand Analysis

The market demand for enhanced 2JZ compression stability through improved piston ring selection has been steadily growing in recent years. This demand is primarily driven by automotive enthusiasts, racing teams, and performance vehicle manufacturers seeking to maximize the potential of the iconic 2JZ engine platform.

In the aftermarket performance sector, there is a significant interest in upgrading 2JZ engines for increased power output and reliability. As enthusiasts push these engines to higher boost levels and more extreme operating conditions, the need for superior compression stability becomes paramount. This has led to a surge in demand for high-quality piston rings that can withstand increased cylinder pressures and temperatures.

The racing industry, particularly in drag racing and time attack events, has been a key driver of this market demand. Teams competing with 2JZ-powered vehicles are constantly seeking ways to extract more power while maintaining engine longevity. The selection of appropriate piston rings plays a crucial role in achieving this balance, leading to increased investment in research and development of advanced ring materials and designs.

Performance vehicle manufacturers, both in the OEM and aftermarket sectors, have also recognized the importance of piston ring selection in enhancing 2JZ compression stability. As they develop high-performance packages and complete engine builds, the demand for precision-engineered piston rings has grown significantly. This has created opportunities for specialized manufacturers to develop and market piston ring sets specifically tailored for high-output 2JZ applications.

The global nature of the automotive performance market has further expanded the demand for these specialized components. With the 2JZ engine's popularity extending beyond its original Japanese market, there is now a worldwide customer base seeking high-quality piston rings for engine builds and upgrades. This international demand has led to increased competition among manufacturers and a broader range of products available to consumers.

Additionally, the rise of online communities and social media platforms dedicated to automotive performance has contributed to market growth. These platforms serve as hubs for information exchange, product reviews, and performance comparisons, driving awareness and demand for advanced piston ring solutions among enthusiasts and professionals alike.

As environmental regulations become stricter, there is also a growing demand for piston rings that can contribute to improved fuel efficiency and reduced emissions without compromising performance. This has led to increased research into materials and designs that can enhance sealing properties while minimizing friction, aligning with both performance and environmental considerations.

In the aftermarket performance sector, there is a significant interest in upgrading 2JZ engines for increased power output and reliability. As enthusiasts push these engines to higher boost levels and more extreme operating conditions, the need for superior compression stability becomes paramount. This has led to a surge in demand for high-quality piston rings that can withstand increased cylinder pressures and temperatures.

The racing industry, particularly in drag racing and time attack events, has been a key driver of this market demand. Teams competing with 2JZ-powered vehicles are constantly seeking ways to extract more power while maintaining engine longevity. The selection of appropriate piston rings plays a crucial role in achieving this balance, leading to increased investment in research and development of advanced ring materials and designs.

Performance vehicle manufacturers, both in the OEM and aftermarket sectors, have also recognized the importance of piston ring selection in enhancing 2JZ compression stability. As they develop high-performance packages and complete engine builds, the demand for precision-engineered piston rings has grown significantly. This has created opportunities for specialized manufacturers to develop and market piston ring sets specifically tailored for high-output 2JZ applications.

The global nature of the automotive performance market has further expanded the demand for these specialized components. With the 2JZ engine's popularity extending beyond its original Japanese market, there is now a worldwide customer base seeking high-quality piston rings for engine builds and upgrades. This international demand has led to increased competition among manufacturers and a broader range of products available to consumers.

Additionally, the rise of online communities and social media platforms dedicated to automotive performance has contributed to market growth. These platforms serve as hubs for information exchange, product reviews, and performance comparisons, driving awareness and demand for advanced piston ring solutions among enthusiasts and professionals alike.

As environmental regulations become stricter, there is also a growing demand for piston rings that can contribute to improved fuel efficiency and reduced emissions without compromising performance. This has led to increased research into materials and designs that can enhance sealing properties while minimizing friction, aligning with both performance and environmental considerations.

Current Challenges

The current challenges in piston ring selection for enhanced 2JZ compression stability are multifaceted and require careful consideration. One of the primary issues is the high-performance nature of the 2JZ engine, which demands exceptional compression control under extreme conditions. The stock piston rings, while adequate for standard applications, often struggle to maintain optimal sealing at higher boost levels and increased cylinder pressures.

Material selection poses another significant challenge. Traditional cast iron rings may not provide the necessary durability and heat resistance required for heavily modified 2JZ engines. The search for advanced materials that can withstand higher temperatures and pressures while maintaining dimensional stability is ongoing. Exotic alloys and coatings show promise but come with increased costs and potential compatibility issues.

Ring design complexity is a further hurdle. The balance between tension, conformability, and wear resistance is delicate. Too much tension can lead to excessive friction and accelerated cylinder wear, while insufficient tension results in blow-by and power loss. Engineers must navigate this fine line to achieve optimal performance without compromising engine longevity.

The dynamic behavior of piston rings under high-speed operation presents another challenge. At extreme RPMs, ring flutter can occur, leading to momentary losses in compression and potential damage. Developing ring designs that maintain stability across a wide range of engine speeds is crucial for maximizing the 2JZ's potential.

Oil control is an additional concern, particularly in forced induction applications. Excessive oil consumption can lead to carbon buildup and reduced performance. Striking the right balance between effective oil scraping and maintaining adequate lubrication is essential for long-term engine health and performance.

Thermal management remains a persistent challenge. The intense heat generated in high-output 2JZ engines can cause ring expansion and potential seizure. Developing rings that can maintain their shape and sealing properties under extreme thermal loads is critical for reliability.

Lastly, the aftermarket nature of many 2JZ modifications introduces variability in engine specifications. Piston ring manufacturers must account for a wide range of bore sizes, compression ratios, and operating conditions. This diversity complicates the development of standardized solutions and often requires custom approaches to achieve optimal results.

Material selection poses another significant challenge. Traditional cast iron rings may not provide the necessary durability and heat resistance required for heavily modified 2JZ engines. The search for advanced materials that can withstand higher temperatures and pressures while maintaining dimensional stability is ongoing. Exotic alloys and coatings show promise but come with increased costs and potential compatibility issues.

Ring design complexity is a further hurdle. The balance between tension, conformability, and wear resistance is delicate. Too much tension can lead to excessive friction and accelerated cylinder wear, while insufficient tension results in blow-by and power loss. Engineers must navigate this fine line to achieve optimal performance without compromising engine longevity.

The dynamic behavior of piston rings under high-speed operation presents another challenge. At extreme RPMs, ring flutter can occur, leading to momentary losses in compression and potential damage. Developing ring designs that maintain stability across a wide range of engine speeds is crucial for maximizing the 2JZ's potential.

Oil control is an additional concern, particularly in forced induction applications. Excessive oil consumption can lead to carbon buildup and reduced performance. Striking the right balance between effective oil scraping and maintaining adequate lubrication is essential for long-term engine health and performance.

Thermal management remains a persistent challenge. The intense heat generated in high-output 2JZ engines can cause ring expansion and potential seizure. Developing rings that can maintain their shape and sealing properties under extreme thermal loads is critical for reliability.

Lastly, the aftermarket nature of many 2JZ modifications introduces variability in engine specifications. Piston ring manufacturers must account for a wide range of bore sizes, compression ratios, and operating conditions. This diversity complicates the development of standardized solutions and often requires custom approaches to achieve optimal results.

Existing Ring Solutions

01 Piston ring design for improved compression stability

Innovative piston ring designs are developed to enhance compression stability in engines. These designs focus on optimizing ring geometry, material selection, and surface treatments to minimize blow-by and maintain consistent compression over time. Advanced manufacturing techniques are employed to achieve precise tolerances and surface finishes, contributing to better sealing and reduced friction.- Piston ring design for improved compression stability: Innovative piston ring designs are developed to enhance compression stability in engines. These designs focus on optimizing ring geometry, material selection, and surface treatments to minimize blow-by and maintain consistent compression over time. Advanced manufacturing techniques are employed to produce rings with precise dimensions and surface finishes, contributing to better sealing and reduced friction.

- Coating and surface treatments for piston rings: Various coating and surface treatment techniques are applied to piston rings to improve their compression stability. These treatments include plasma spraying, physical vapor deposition, and chemical vapor deposition of wear-resistant materials. The coatings enhance the ring's durability, reduce friction, and maintain a consistent seal against the cylinder wall, thereby improving overall compression stability.

- Piston ring tension and gap control: Methods for controlling piston ring tension and gap are developed to optimize compression stability. These techniques involve precise manufacturing processes, heat treatments, and innovative ring designs that allow for controlled expansion and contraction during engine operation. By maintaining proper ring tension and gap, blow-by is minimized, and compression stability is improved throughout the engine's operating range.

- Multi-piece piston ring assemblies: Multi-piece piston ring assemblies are designed to enhance compression stability by combining the benefits of different materials and geometries. These assemblies typically consist of a top compression ring, a second compression ring, and an oil control ring. Each ring is optimized for its specific function, working together to maintain consistent compression and reduce oil consumption while minimizing friction and wear.

- Advanced materials for piston rings: Novel materials are developed and utilized in piston ring manufacturing to improve compression stability. These materials include high-strength alloys, ceramics, and composite materials that offer superior wear resistance, thermal stability, and reduced friction. The use of these advanced materials helps maintain ring geometry and sealing properties over extended periods, contributing to consistent compression performance throughout the engine's lifespan.

02 Coating and surface treatments for piston rings

Various coating and surface treatment technologies are applied to piston rings to improve their compression stability. These treatments enhance wear resistance, reduce friction, and maintain sealing properties under high-temperature and high-pressure conditions. Techniques such as plasma spraying, physical vapor deposition, and nitriding are used to create durable and low-friction surfaces on piston rings.Expand Specific Solutions03 Multi-piece piston ring assemblies

Multi-piece piston ring assemblies are developed to address compression stability issues. These designs typically include separate components for oil control and compression sealing, allowing for optimized performance in each function. The use of multiple pieces also enables better conformability to cylinder walls and improved overall sealing efficiency.Expand Specific Solutions04 Material innovations for piston rings

Advanced materials are being developed and utilized in piston ring manufacturing to enhance compression stability. These materials offer improved thermal properties, wear resistance, and dimensional stability under extreme operating conditions. High-performance alloys, ceramics, and composite materials are being explored to create piston rings that maintain their sealing properties over extended periods.Expand Specific Solutions05 Piston ring groove design and treatment

Innovations in piston ring groove design and treatment contribute to improved compression stability. These advancements focus on optimizing groove geometry, surface finish, and coatings to enhance ring seating and reduce micro-movement. Techniques such as laser hardening, induction hardening, and precision machining are employed to create more durable and efficient ring grooves.Expand Specific Solutions

Key Industry Players

The piston ring selection for enhanced 2JZ compression stability is in a mature stage of development, with a significant market size due to the popularity of high-performance engine modifications. The technology is well-established, with several key players contributing to its advancement. Companies like Federal-Mogul Burscheid GmbH and Riken Corp. have extensive experience in piston ring manufacturing, while MCE-5 Development SA focuses on innovative compression technologies. Materion Corp. and Schaeffler Technologies AG & Co. KG provide advanced materials and engineering solutions, further enhancing the field. The competitive landscape is characterized by a mix of established manufacturers and specialized technology firms, driving continuous improvement in piston ring performance and durability for high-compression applications.

Federal-Mogul Burscheid GmbH

Technical Solution: Federal-Mogul has developed the DuroGlide® piston ring coating technology, which is particularly suitable for enhancing 2JZ compression stability. This advanced coating combines a hard chromium base layer with a soft running-in layer, providing excellent scuff resistance and reduced friction. For the 2JZ engine, Federal-Mogul offers a set of top rings with a PVD coating of chromium nitride, which significantly improves wear resistance and reduces oil consumption[2]. Their second compression ring features a tapered face design with a phosphate coating, optimizing gas sealing and oil control. The oil ring set incorporates a high-tension expander for consistent sealing pressure throughout the engine's lifecycle[4].

Strengths: Excellent scuff resistance, reduced friction, and improved oil control. Weaknesses: May require more frequent replacement in extreme high-performance applications.

Schaeffler Technologies AG & Co. KG

Technical Solution: Schaeffler has developed a range of advanced piston ring technologies applicable to the 2JZ engine for enhanced compression stability. Their "Form-Honed" ring technology creates a precise barrel-shaped profile on the ring face, optimizing contact with the cylinder wall and improving sealing performance. For top rings, Schaeffler offers a PVD coating with chromium nitride and a diamond-like carbon (DLC) layer, providing exceptional wear resistance and reduced friction[5]. The second compression ring features a tapered face with a proprietary "Nanocoat" surface treatment, enhancing oil scraping efficiency. Schaeffler's oil ring set incorporates a high-tension spring expander made from heat-treated stainless steel, ensuring consistent radial force throughout the engine's operating range[6].

Strengths: Precise ring profiles, advanced coating technologies, and consistent sealing performance. Weaknesses: Potentially higher cost and complexity in manufacturing process.

Core Ring Innovations

Piston compression rings of copper-nickel-tin alloys

PatentWO2018128775A1

Innovation

- Piston compression rings made from a copper-nickel-tin alloy with specific weight percentages, offering high thermal conductivity, wear resistance, and thermal stability, which reduces the maximum temperature of the piston crown and minimizes crevice volume, thereby enhancing engine efficiency.

Piston compression rings of copper alloys

PatentWO2018128774A1

Innovation

- Piston compression rings made from a copper-nickel-silicon-chromium alloy with specific weight percentages, offering high thermal conductivity, wear resistance, and thermal stability, allowing the top ring to be positioned closer to the piston crown without compromising material strength.

Material Science Impact

The impact of material science on piston ring selection for enhanced 2JZ compression stability is profound and multifaceted. Advanced materials have revolutionized the performance and durability of piston rings, directly influencing the engine's compression stability and overall efficiency.

High-strength alloys, such as steel-molybdenum and chromium-based materials, have become increasingly prevalent in piston ring manufacturing. These alloys offer superior wear resistance and thermal stability, crucial for maintaining consistent compression in high-performance engines like the 2JZ. The enhanced material properties allow for tighter tolerances and reduced ring gap, effectively minimizing blow-by and improving combustion efficiency.

Ceramic coatings, particularly those utilizing plasma-sprayed molybdenum, have emerged as a game-changing innovation in piston ring technology. These coatings significantly reduce friction between the ring and cylinder wall, leading to improved fuel efficiency and reduced wear. The thermal barrier properties of ceramic coatings also contribute to better heat management, crucial for maintaining compression stability under extreme operating conditions.

Advancements in surface treatment technologies, such as physical vapor deposition (PVD) and diamond-like carbon (DLC) coatings, have further enhanced the tribological properties of piston rings. These treatments create ultra-hard, low-friction surfaces that resist scuffing and micro-welding, ensuring consistent sealing performance throughout the engine's lifecycle.

Composite materials, incorporating carbon fiber or other high-strength fibers, are being explored for their potential in piston ring applications. These materials offer an exceptional strength-to-weight ratio, potentially allowing for thinner, lighter rings that maintain or even improve sealing performance while reducing reciprocating mass.

Nanotechnology has also begun to play a role in piston ring material science. Nanostructured coatings and materials can provide unprecedented levels of hardness, wear resistance, and self-lubrication properties. This emerging field holds promise for developing piston rings that can maintain optimal compression stability under increasingly demanding engine conditions.

The integration of smart materials, such as shape memory alloys, into piston ring design is an area of ongoing research. These materials could potentially allow for adaptive ring tension, optimizing sealing performance across a wide range of operating temperatures and pressures, thereby enhancing compression stability throughout the engine's operating range.

High-strength alloys, such as steel-molybdenum and chromium-based materials, have become increasingly prevalent in piston ring manufacturing. These alloys offer superior wear resistance and thermal stability, crucial for maintaining consistent compression in high-performance engines like the 2JZ. The enhanced material properties allow for tighter tolerances and reduced ring gap, effectively minimizing blow-by and improving combustion efficiency.

Ceramic coatings, particularly those utilizing plasma-sprayed molybdenum, have emerged as a game-changing innovation in piston ring technology. These coatings significantly reduce friction between the ring and cylinder wall, leading to improved fuel efficiency and reduced wear. The thermal barrier properties of ceramic coatings also contribute to better heat management, crucial for maintaining compression stability under extreme operating conditions.

Advancements in surface treatment technologies, such as physical vapor deposition (PVD) and diamond-like carbon (DLC) coatings, have further enhanced the tribological properties of piston rings. These treatments create ultra-hard, low-friction surfaces that resist scuffing and micro-welding, ensuring consistent sealing performance throughout the engine's lifecycle.

Composite materials, incorporating carbon fiber or other high-strength fibers, are being explored for their potential in piston ring applications. These materials offer an exceptional strength-to-weight ratio, potentially allowing for thinner, lighter rings that maintain or even improve sealing performance while reducing reciprocating mass.

Nanotechnology has also begun to play a role in piston ring material science. Nanostructured coatings and materials can provide unprecedented levels of hardness, wear resistance, and self-lubrication properties. This emerging field holds promise for developing piston rings that can maintain optimal compression stability under increasingly demanding engine conditions.

The integration of smart materials, such as shape memory alloys, into piston ring design is an area of ongoing research. These materials could potentially allow for adaptive ring tension, optimizing sealing performance across a wide range of operating temperatures and pressures, thereby enhancing compression stability throughout the engine's operating range.

Emissions Regulations

Emissions regulations play a crucial role in shaping the automotive industry, including the development and selection of piston rings for high-performance engines like the 2JZ. These regulations have become increasingly stringent over the years, driven by global efforts to reduce air pollution and combat climate change.

In the context of piston ring selection for enhanced 2JZ compression stability, emissions regulations have a significant impact on design considerations and material choices. The primary goal of these regulations is to limit the release of harmful pollutants such as carbon monoxide (CO), nitrogen oxides (NOx), and particulate matter (PM) from vehicle exhaust systems.

For the 2JZ engine, which is known for its high-performance capabilities, meeting emissions standards while maintaining optimal compression stability presents a unique challenge. Piston rings must be designed to effectively seal the combustion chamber, preventing blow-by gases from escaping into the crankcase. This not only improves engine efficiency but also reduces emissions of unburned hydrocarbons.

The selection of piston ring materials and coatings is heavily influenced by emissions regulations. Traditional cast iron rings may not provide the necessary sealing and wear resistance required to meet modern emissions standards. As a result, manufacturers are increasingly turning to advanced materials such as steel alloys and ceramic-based coatings that offer improved durability and reduced friction.

Emissions regulations also drive the development of more precise manufacturing techniques for piston rings. Tighter tolerances and improved surface finishes are essential for minimizing oil consumption and reducing particulate emissions. This has led to the adoption of advanced machining processes and quality control measures in piston ring production.

Furthermore, the push for lower emissions has encouraged the integration of piston ring designs with other engine components. For instance, the interaction between piston rings and cylinder liners must be optimized to reduce oil consumption and minimize the formation of harmful emissions. This holistic approach to engine design is crucial for meeting increasingly stringent emissions targets.

As emissions regulations continue to evolve, piston ring manufacturers must stay ahead of the curve by investing in research and development. This includes exploring novel materials, coatings, and designs that can further enhance compression stability while reducing emissions. The ongoing shift towards electrification in the automotive industry may also influence future emissions regulations, potentially impacting the development of high-performance internal combustion engines like the 2JZ.

In the context of piston ring selection for enhanced 2JZ compression stability, emissions regulations have a significant impact on design considerations and material choices. The primary goal of these regulations is to limit the release of harmful pollutants such as carbon monoxide (CO), nitrogen oxides (NOx), and particulate matter (PM) from vehicle exhaust systems.

For the 2JZ engine, which is known for its high-performance capabilities, meeting emissions standards while maintaining optimal compression stability presents a unique challenge. Piston rings must be designed to effectively seal the combustion chamber, preventing blow-by gases from escaping into the crankcase. This not only improves engine efficiency but also reduces emissions of unburned hydrocarbons.

The selection of piston ring materials and coatings is heavily influenced by emissions regulations. Traditional cast iron rings may not provide the necessary sealing and wear resistance required to meet modern emissions standards. As a result, manufacturers are increasingly turning to advanced materials such as steel alloys and ceramic-based coatings that offer improved durability and reduced friction.

Emissions regulations also drive the development of more precise manufacturing techniques for piston rings. Tighter tolerances and improved surface finishes are essential for minimizing oil consumption and reducing particulate emissions. This has led to the adoption of advanced machining processes and quality control measures in piston ring production.

Furthermore, the push for lower emissions has encouraged the integration of piston ring designs with other engine components. For instance, the interaction between piston rings and cylinder liners must be optimized to reduce oil consumption and minimize the formation of harmful emissions. This holistic approach to engine design is crucial for meeting increasingly stringent emissions targets.

As emissions regulations continue to evolve, piston ring manufacturers must stay ahead of the curve by investing in research and development. This includes exploring novel materials, coatings, and designs that can further enhance compression stability while reducing emissions. The ongoing shift towards electrification in the automotive industry may also influence future emissions regulations, potentially impacting the development of high-performance internal combustion engines like the 2JZ.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!