How Augmented Reality Revamps 2JZ Engine DIY Repairs

AUG 6, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

AR in 2JZ Engine Repair: Background and Objectives

Augmented Reality (AR) technology has been rapidly evolving over the past decade, revolutionizing various industries, including automotive repair. The integration of AR into the realm of DIY engine repairs, particularly for the iconic 2JZ engine, marks a significant milestone in the convergence of cutting-edge technology and traditional mechanical expertise.

The 2JZ engine, renowned for its robustness and tuning potential, has long been a favorite among automotive enthusiasts. However, its complexity has often posed challenges for DIY mechanics. The application of AR in this context aims to bridge the gap between expert knowledge and amateur skills, making intricate repairs more accessible to a broader audience.

The primary objective of implementing AR in 2JZ engine repairs is to enhance the efficiency, accuracy, and safety of DIY maintenance procedures. By overlaying digital information onto the physical engine components, AR technology provides real-time guidance, reducing the likelihood of errors and potentially hazardous situations.

This technological advancement is driven by the increasing demand for more intuitive and user-friendly repair solutions. As the automotive industry continues to evolve, there is a growing need for tools that can keep pace with the complexity of modern engines while empowering individual enthusiasts to maintain and modify their vehicles.

The development of AR applications for 2JZ engine repairs is part of a broader trend in the automotive sector towards digitalization and smart maintenance solutions. This trend is fueled by advancements in computer vision, machine learning, and mobile computing, which have made AR technology more accessible and practical for everyday use.

From a historical perspective, the journey of AR in automotive repair began with simple digital manuals and has progressed to sophisticated, interactive 3D models that can be superimposed on real-world objects. The application to the 2JZ engine represents a significant step forward in this evolution, given the engine's cult status and technical complexity.

Looking ahead, the integration of AR in 2JZ engine repairs is expected to pave the way for wider adoption of this technology across various engine types and vehicle models. This could potentially transform the landscape of DIY automotive maintenance, making it more accessible to a new generation of car enthusiasts while preserving the hands-on nature of mechanical work.

The 2JZ engine, renowned for its robustness and tuning potential, has long been a favorite among automotive enthusiasts. However, its complexity has often posed challenges for DIY mechanics. The application of AR in this context aims to bridge the gap between expert knowledge and amateur skills, making intricate repairs more accessible to a broader audience.

The primary objective of implementing AR in 2JZ engine repairs is to enhance the efficiency, accuracy, and safety of DIY maintenance procedures. By overlaying digital information onto the physical engine components, AR technology provides real-time guidance, reducing the likelihood of errors and potentially hazardous situations.

This technological advancement is driven by the increasing demand for more intuitive and user-friendly repair solutions. As the automotive industry continues to evolve, there is a growing need for tools that can keep pace with the complexity of modern engines while empowering individual enthusiasts to maintain and modify their vehicles.

The development of AR applications for 2JZ engine repairs is part of a broader trend in the automotive sector towards digitalization and smart maintenance solutions. This trend is fueled by advancements in computer vision, machine learning, and mobile computing, which have made AR technology more accessible and practical for everyday use.

From a historical perspective, the journey of AR in automotive repair began with simple digital manuals and has progressed to sophisticated, interactive 3D models that can be superimposed on real-world objects. The application to the 2JZ engine represents a significant step forward in this evolution, given the engine's cult status and technical complexity.

Looking ahead, the integration of AR in 2JZ engine repairs is expected to pave the way for wider adoption of this technology across various engine types and vehicle models. This could potentially transform the landscape of DIY automotive maintenance, making it more accessible to a new generation of car enthusiasts while preserving the hands-on nature of mechanical work.

Market Analysis for AR-Enhanced DIY Auto Repair

The market for AR-enhanced DIY auto repair, particularly focusing on the 2JZ engine, shows significant potential for growth and innovation. This niche combines the enduring popularity of the 2JZ engine among automotive enthusiasts with the cutting-edge technology of augmented reality, creating a unique value proposition in the automotive aftermarket sector.

The 2JZ engine, renowned for its robustness and tuning potential, continues to have a dedicated following despite being out of production. This sustained interest creates a steady demand for repair and modification solutions, especially among DIY enthusiasts. The introduction of AR technology to this market addresses several key pain points in the DIY repair process, potentially expanding the market to include less experienced mechanics.

Market research indicates that the global automotive AR market is expected to grow substantially in the coming years. While specific data for 2JZ engine repairs is limited, the broader trend suggests a receptive market for AR-enhanced repair solutions. The DIY auto repair market, valued at billions globally, represents a significant portion of the overall automotive aftermarket. AR technology's integration into this space could drive further growth by making complex repairs more accessible.

Consumer trends show an increasing preference for self-service options across various industries, including automotive repair. This shift is partly driven by the desire to reduce costs and the satisfaction derived from personal accomplishment. AR technology aligns well with these trends, offering a middle ground between professional service and unaided DIY attempts.

The target demographic for AR-enhanced 2JZ engine repairs primarily consists of automotive enthusiasts aged 25-45, with a mix of professional mechanics and hobbyists. This group typically has higher disposable income and is more likely to invest in advanced tools and technologies to support their passion. The market also includes a growing segment of younger enthusiasts who are digital natives and more readily adopt new technologies.

Geographically, the market shows strong potential in regions with a high concentration of import tuner culture and motorsports activities. North America, particularly the United States, represents a significant market due to the popularity of Japanese sports cars and the 2JZ engine. Europe and parts of Asia, especially Japan, also show promising market potential.

The competitive landscape for AR-enhanced DIY auto repair solutions is still developing, with few direct competitors specifically targeting 2JZ engine repairs. This presents an opportunity for early movers to establish market leadership. However, the broader automotive AR market is seeing increased activity from both established automotive companies and tech startups, indicating growing recognition of the technology's potential.

The 2JZ engine, renowned for its robustness and tuning potential, continues to have a dedicated following despite being out of production. This sustained interest creates a steady demand for repair and modification solutions, especially among DIY enthusiasts. The introduction of AR technology to this market addresses several key pain points in the DIY repair process, potentially expanding the market to include less experienced mechanics.

Market research indicates that the global automotive AR market is expected to grow substantially in the coming years. While specific data for 2JZ engine repairs is limited, the broader trend suggests a receptive market for AR-enhanced repair solutions. The DIY auto repair market, valued at billions globally, represents a significant portion of the overall automotive aftermarket. AR technology's integration into this space could drive further growth by making complex repairs more accessible.

Consumer trends show an increasing preference for self-service options across various industries, including automotive repair. This shift is partly driven by the desire to reduce costs and the satisfaction derived from personal accomplishment. AR technology aligns well with these trends, offering a middle ground between professional service and unaided DIY attempts.

The target demographic for AR-enhanced 2JZ engine repairs primarily consists of automotive enthusiasts aged 25-45, with a mix of professional mechanics and hobbyists. This group typically has higher disposable income and is more likely to invest in advanced tools and technologies to support their passion. The market also includes a growing segment of younger enthusiasts who are digital natives and more readily adopt new technologies.

Geographically, the market shows strong potential in regions with a high concentration of import tuner culture and motorsports activities. North America, particularly the United States, represents a significant market due to the popularity of Japanese sports cars and the 2JZ engine. Europe and parts of Asia, especially Japan, also show promising market potential.

The competitive landscape for AR-enhanced DIY auto repair solutions is still developing, with few direct competitors specifically targeting 2JZ engine repairs. This presents an opportunity for early movers to establish market leadership. However, the broader automotive AR market is seeing increased activity from both established automotive companies and tech startups, indicating growing recognition of the technology's potential.

Current AR Technologies in Automotive Maintenance

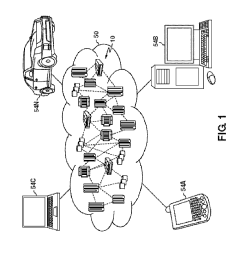

Augmented Reality (AR) has made significant strides in the automotive maintenance sector, revolutionizing the way mechanics and DIY enthusiasts approach engine repairs, particularly for complex powerplants like the 2JZ engine. Current AR technologies in this field primarily focus on enhancing visual information, providing real-time guidance, and improving the overall efficiency of maintenance procedures.

One of the most prominent AR applications in automotive maintenance is the use of smart glasses or head-mounted displays (HMDs). These devices overlay digital information onto the user's field of view, allowing them to access repair manuals, schematics, and step-by-step instructions without taking their hands off the task. For 2JZ engine repairs, this means mechanics can visualize intricate components and their relationships within the engine block, making disassembly and reassembly processes more intuitive and less error-prone.

Mobile devices, such as smartphones and tablets, also play a crucial role in AR-assisted engine repairs. Advanced AR apps utilize the device's camera to recognize engine parts and provide contextual information. When working on a 2JZ engine, these apps can identify specific components, highlight potential problem areas, and offer diagnostic suggestions based on visual cues. This technology is particularly beneficial for DIY enthusiasts who may lack extensive experience with high-performance engines.

Projection-based AR systems are gaining traction in professional automotive workshops. These systems project repair instructions, torque specifications, and wiring diagrams directly onto the engine or work surface. For 2JZ engine maintenance, this means critical information about timing belt alignment, fuel injector placement, or turbocharger installation can be displayed precisely where it's needed, reducing the likelihood of mistakes during complex procedures.

AR-enabled tools and equipment are also emerging as valuable assets in engine maintenance. Smart tools equipped with sensors and AR displays can provide real-time feedback on torque applications, ensuring that critical fasteners on the 2JZ engine are tightened to exact specifications. Similarly, AR-enhanced diagnostic tools can overlay fault codes and sensor data directly onto the engine, helping technicians quickly identify and address issues.

Collaborative AR platforms are transforming remote assistance capabilities in automotive maintenance. These systems allow expert mechanics to guide less experienced technicians or DIY enthusiasts through complex 2JZ engine repairs from a distance. By sharing their view and providing real-time annotations and instructions, experts can effectively troubleshoot issues and offer guidance as if they were present in person.

As AR technology continues to evolve, we're seeing the integration of artificial intelligence and machine learning algorithms to enhance its capabilities. These advancements enable AR systems to learn from past repair data, predict potential issues, and offer increasingly accurate and context-aware guidance for 2JZ engine maintenance. This fusion of AR and AI promises to further streamline the repair process and reduce the learning curve for complex engine work.

One of the most prominent AR applications in automotive maintenance is the use of smart glasses or head-mounted displays (HMDs). These devices overlay digital information onto the user's field of view, allowing them to access repair manuals, schematics, and step-by-step instructions without taking their hands off the task. For 2JZ engine repairs, this means mechanics can visualize intricate components and their relationships within the engine block, making disassembly and reassembly processes more intuitive and less error-prone.

Mobile devices, such as smartphones and tablets, also play a crucial role in AR-assisted engine repairs. Advanced AR apps utilize the device's camera to recognize engine parts and provide contextual information. When working on a 2JZ engine, these apps can identify specific components, highlight potential problem areas, and offer diagnostic suggestions based on visual cues. This technology is particularly beneficial for DIY enthusiasts who may lack extensive experience with high-performance engines.

Projection-based AR systems are gaining traction in professional automotive workshops. These systems project repair instructions, torque specifications, and wiring diagrams directly onto the engine or work surface. For 2JZ engine maintenance, this means critical information about timing belt alignment, fuel injector placement, or turbocharger installation can be displayed precisely where it's needed, reducing the likelihood of mistakes during complex procedures.

AR-enabled tools and equipment are also emerging as valuable assets in engine maintenance. Smart tools equipped with sensors and AR displays can provide real-time feedback on torque applications, ensuring that critical fasteners on the 2JZ engine are tightened to exact specifications. Similarly, AR-enhanced diagnostic tools can overlay fault codes and sensor data directly onto the engine, helping technicians quickly identify and address issues.

Collaborative AR platforms are transforming remote assistance capabilities in automotive maintenance. These systems allow expert mechanics to guide less experienced technicians or DIY enthusiasts through complex 2JZ engine repairs from a distance. By sharing their view and providing real-time annotations and instructions, experts can effectively troubleshoot issues and offer guidance as if they were present in person.

As AR technology continues to evolve, we're seeing the integration of artificial intelligence and machine learning algorithms to enhance its capabilities. These advancements enable AR systems to learn from past repair data, predict potential issues, and offer increasingly accurate and context-aware guidance for 2JZ engine maintenance. This fusion of AR and AI promises to further streamline the repair process and reduce the learning curve for complex engine work.

Existing AR Solutions for 2JZ Engine Maintenance

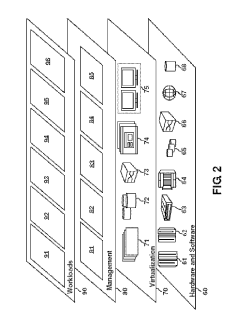

01 AR-assisted repair guidance systems

Augmented Reality (AR) systems provide step-by-step visual guidance for DIY repairs. These systems overlay digital instructions, diagrams, and 3D models onto the real-world view of the object being repaired, helping users identify parts and follow repair procedures accurately.- AR-assisted repair guidance: Augmented Reality (AR) technology is used to provide step-by-step repair instructions and visual guidance for DIY repairs. This includes overlaying digital information onto real-world objects, helping users identify parts, understand repair procedures, and perform maintenance tasks more efficiently.

- Remote expert assistance: AR systems enable remote experts to provide real-time guidance for DIY repairs. Users can share their view with experts who can then annotate the real-world environment or provide visual instructions, allowing for more effective troubleshooting and repair assistance without the need for on-site presence.

- Interactive 3D modeling for repairs: AR technology incorporates interactive 3D models of devices or machinery to aid in DIY repairs. Users can manipulate these models, view exploded diagrams, and understand the internal components, making it easier to diagnose issues and perform repairs accurately.

- AR-enhanced tool guidance: Augmented Reality is used to guide users in the proper use of tools during DIY repairs. This includes showing correct tool placement, demonstrating proper techniques, and providing real-time feedback on user actions to ensure repairs are carried out correctly and safely.

- AR safety features for DIY repairs: AR systems incorporate safety features for DIY repairs, such as highlighting potential hazards, providing warnings about dangerous components, and ensuring users follow proper safety protocols. This helps prevent accidents and improves the overall safety of DIY repair processes.

02 Remote expert assistance in AR

AR platforms enable remote experts to provide real-time guidance for DIY repairs. Users can share their view through AR devices, allowing experts to annotate the real-world environment and provide instructions, enhancing the efficiency and accuracy of complex repair tasks.Expand Specific Solutions03 AR-enhanced repair manuals and documentation

Traditional repair manuals are enhanced with AR capabilities, allowing users to access interactive 3D models, animations, and contextual information by scanning parts or QR codes. This integration improves comprehension and reduces errors during DIY repair processes.Expand Specific Solutions04 AR tools for diagnostics and measurement

AR applications incorporate diagnostic tools and measurement capabilities, enabling users to perform accurate assessments of repair needs. These tools can include virtual rulers, level indicators, and component analyzers, aiding in precise DIY repairs.Expand Specific Solutions05 Gesture and voice control in AR repair interfaces

AR repair systems utilize gesture recognition and voice commands to provide hands-free operation during DIY tasks. This allows users to navigate instructions, access additional information, and control the AR interface while keeping their hands free for the actual repair work.Expand Specific Solutions

Key Players in AR Automotive Repair Solutions

The augmented reality (AR) market for 2JZ engine DIY repairs is in its early growth stage, with significant potential for expansion. The global AR market size is projected to reach $97.76 billion by 2028, growing at a CAGR of 48.6% from 2021 to 2028. While the technology is still evolving, companies like Apple, Niantic, and Magic Leap are driving innovation in AR hardware and software. The automotive repair sector, including applications for the 2JZ engine, represents a niche but promising area for AR implementation. As the technology matures, we can expect increased adoption and more sophisticated AR solutions for engine repair and maintenance tasks.

Apple, Inc.

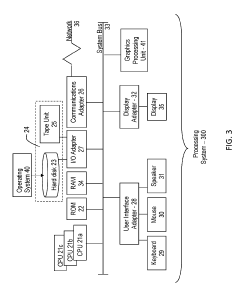

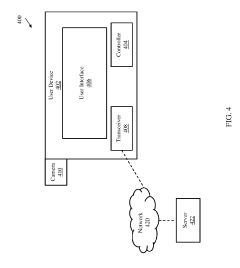

Technical Solution: Apple's AR approach for 2JZ engine repairs leverages their ARKit platform, which utilizes advanced computer vision and machine learning algorithms to provide precise object recognition and tracking[1]. The system overlays 3D models of engine components onto the real-world view, guiding users through complex repair procedures. It incorporates spatial audio cues and haptic feedback for an immersive experience[2]. Apple's solution also integrates with their LiDAR scanner-equipped devices to create detailed 3D maps of the engine, enabling accurate measurements and part identification[3]. The AR application can recognize specific engine parts and provide real-time information on their condition, maintenance history, and optimal replacement timing[4].

Strengths: Seamless integration with Apple ecosystem, high-quality graphics, and precise object tracking. Weaknesses: Limited to Apple devices, potentially higher cost for implementation.

Niantic, Inc.

Technical Solution: Niantic's AR solution for 2JZ engine repairs builds upon their expertise in location-based AR technology. Their system utilizes computer vision and machine learning to recognize engine components and overlay step-by-step repair instructions in real-time[5]. The platform incorporates collaborative features, allowing multiple users to share AR views and annotations, facilitating remote expert assistance[6]. Niantic's solution also leverages their Lightship ARDK to provide persistent AR experiences, enabling users to save and resume repair progress across sessions[7]. The system includes a gamified element, rewarding users for completing repair tasks and sharing knowledge, fostering a community-driven repair ecosystem[8].

Strengths: Strong multiplayer and location-based AR capabilities, gamification elements for user engagement. Weaknesses: May require more robust internet connectivity for optimal performance.

Core AR Innovations for Engine Repair Guidance

System for maintenance and repair using augmented reality

PatentInactiveUS20190278992A1

Innovation

- An augmented reality system using a device with a camera and controller that captures and analyzes media associated with a repair item to determine a candidate repair component and provide a repair method through a user interface, leveraging image recognition and cloud computing to guide users in real-time troubleshooting.

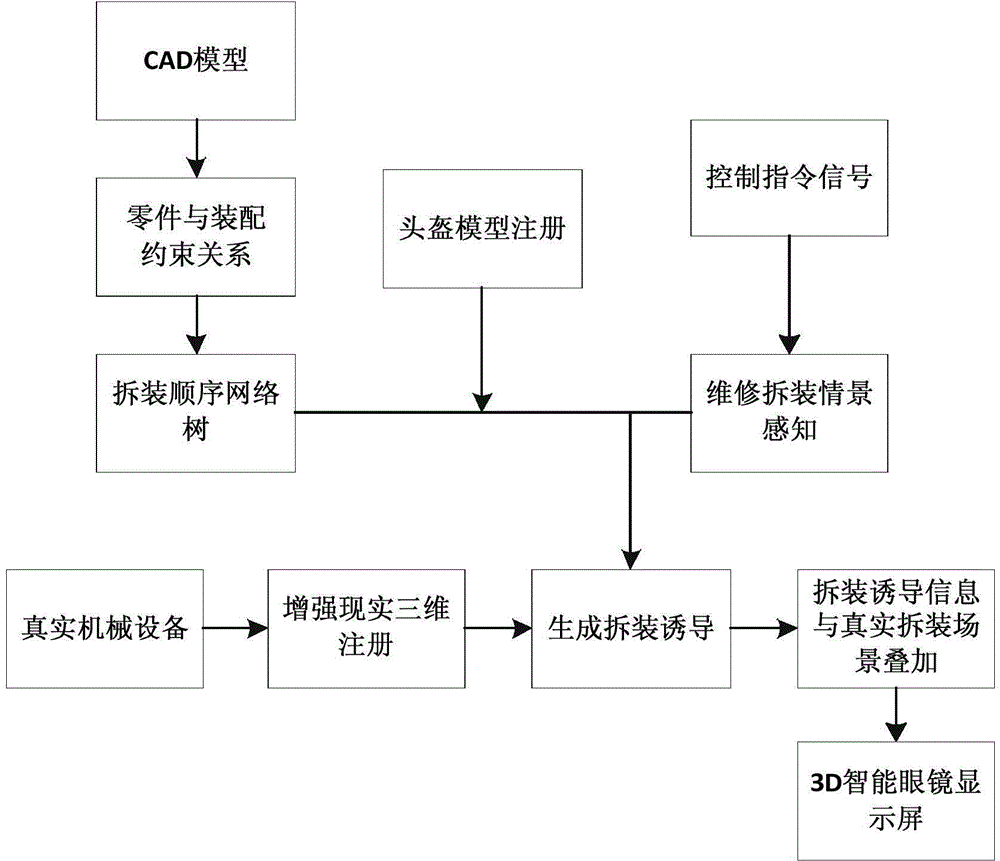

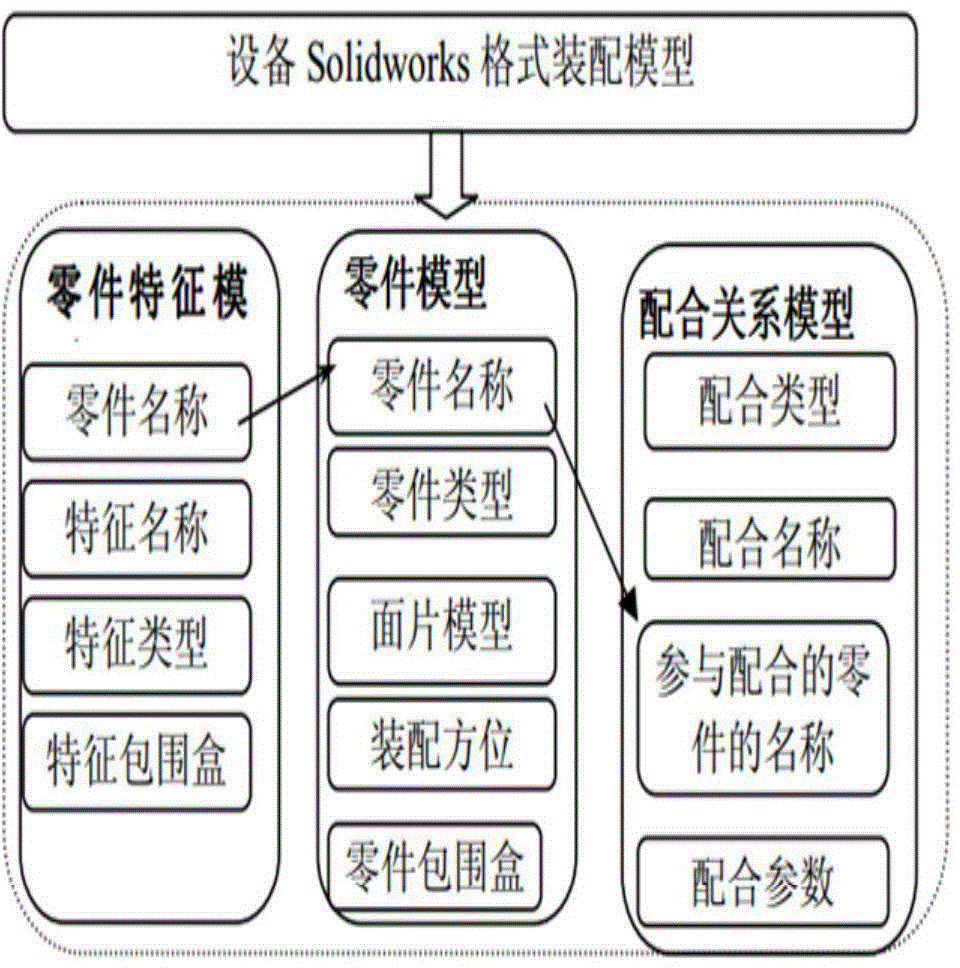

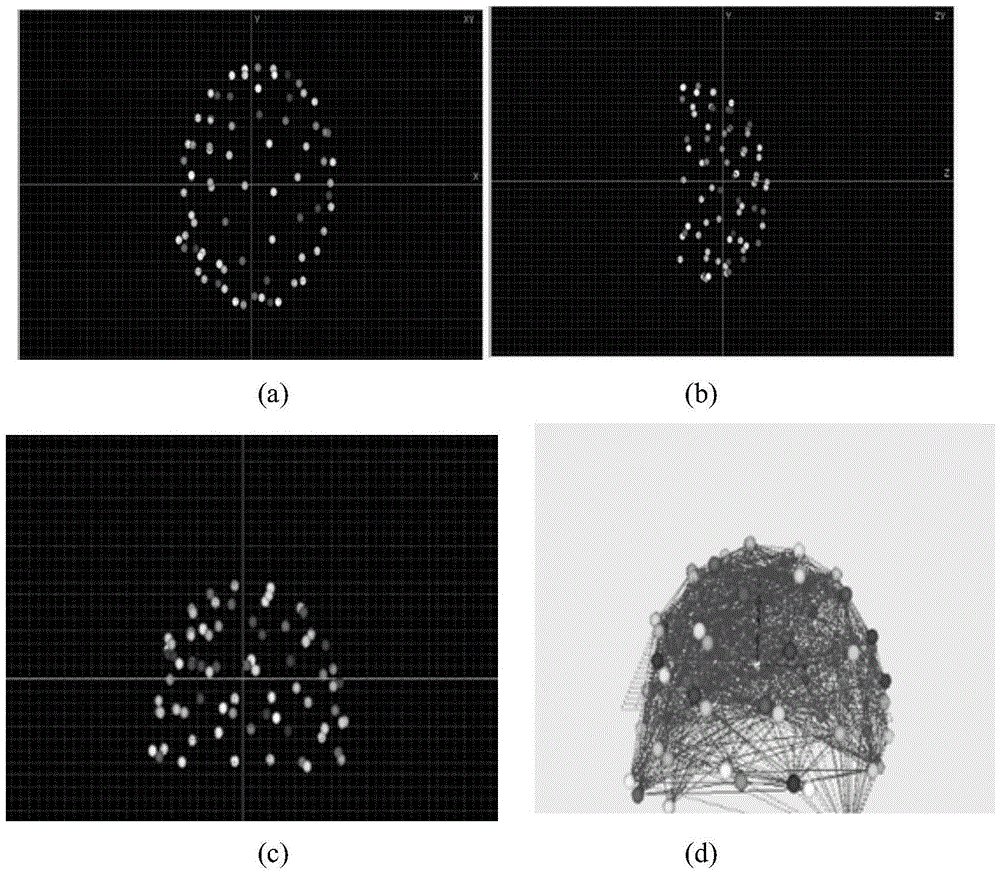

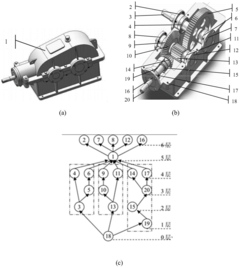

Equipment and method for realizing augmented reality induced maintenance system

PatentActiveCN104484523A

Innovation

- A portable augmented reality induction maintenance system is adopted, including 3D smart glasses, optical position trackers and computers, which provide virtual induction information through wireless interaction technology to help operators complete disassembly and assembly operations in real scenes.

Safety Considerations in AR-Guided DIY Repairs

Safety considerations are paramount when implementing augmented reality (AR) for DIY repairs on complex engines like the 2JZ. While AR technology offers significant benefits in guiding users through intricate repair processes, it also introduces new risks that must be carefully managed.

One primary concern is the potential for distraction. AR overlays can provide valuable information, but they may also divert attention from immediate physical hazards. To mitigate this risk, AR systems for engine repairs should incorporate intelligent safety alerts that warn users of nearby dangers, such as hot surfaces or moving parts. These alerts should be designed to be noticeable without being overly intrusive or distracting.

Another critical safety aspect is ensuring that AR instructions are always up-to-date and accurate. Incorrect or outdated information could lead to dangerous mistakes during repairs. Implementing a robust system for verifying and updating AR content is essential. This may involve regular reviews by experienced mechanics and engineers, as well as a feedback mechanism for users to report any discrepancies or issues they encounter.

The physical interaction between the user and the AR device itself presents additional safety challenges. Hands-free AR devices, such as smart glasses, are preferable for engine repairs as they allow users to keep their hands free for tools and components. However, these devices must be designed to withstand the harsh environment of an engine bay, including resistance to oil, heat, and potential impacts.

Electrical safety is another crucial consideration, particularly when working with hybrid or electric vehicle components. AR systems should include clear warnings about high-voltage areas and provide guidance on proper insulation and grounding procedures. Additionally, the AR device itself must be designed to operate safely in potentially explosive environments, adhering to relevant safety standards for electronic equipment in such conditions.

Data privacy and security also play a role in safety considerations. AR systems may collect and process sensitive information about the vehicle and its owner. Ensuring this data is securely stored and transmitted is vital to prevent unauthorized access or malicious exploitation.

Lastly, it's important to recognize that AR should complement, not replace, proper training and experience. Users should be required to demonstrate a basic understanding of engine mechanics and safety procedures before relying on AR-guided repairs. This could be implemented through introductory modules or safety quizzes within the AR application itself.

By addressing these safety considerations comprehensively, AR technology can significantly enhance the DIY repair experience for 2JZ engines while minimizing potential risks. Continuous evaluation and improvement of safety measures will be crucial as this technology evolves and becomes more widely adopted in automotive maintenance.

One primary concern is the potential for distraction. AR overlays can provide valuable information, but they may also divert attention from immediate physical hazards. To mitigate this risk, AR systems for engine repairs should incorporate intelligent safety alerts that warn users of nearby dangers, such as hot surfaces or moving parts. These alerts should be designed to be noticeable without being overly intrusive or distracting.

Another critical safety aspect is ensuring that AR instructions are always up-to-date and accurate. Incorrect or outdated information could lead to dangerous mistakes during repairs. Implementing a robust system for verifying and updating AR content is essential. This may involve regular reviews by experienced mechanics and engineers, as well as a feedback mechanism for users to report any discrepancies or issues they encounter.

The physical interaction between the user and the AR device itself presents additional safety challenges. Hands-free AR devices, such as smart glasses, are preferable for engine repairs as they allow users to keep their hands free for tools and components. However, these devices must be designed to withstand the harsh environment of an engine bay, including resistance to oil, heat, and potential impacts.

Electrical safety is another crucial consideration, particularly when working with hybrid or electric vehicle components. AR systems should include clear warnings about high-voltage areas and provide guidance on proper insulation and grounding procedures. Additionally, the AR device itself must be designed to operate safely in potentially explosive environments, adhering to relevant safety standards for electronic equipment in such conditions.

Data privacy and security also play a role in safety considerations. AR systems may collect and process sensitive information about the vehicle and its owner. Ensuring this data is securely stored and transmitted is vital to prevent unauthorized access or malicious exploitation.

Lastly, it's important to recognize that AR should complement, not replace, proper training and experience. Users should be required to demonstrate a basic understanding of engine mechanics and safety procedures before relying on AR-guided repairs. This could be implemented through introductory modules or safety quizzes within the AR application itself.

By addressing these safety considerations comprehensively, AR technology can significantly enhance the DIY repair experience for 2JZ engines while minimizing potential risks. Continuous evaluation and improvement of safety measures will be crucial as this technology evolves and becomes more widely adopted in automotive maintenance.

User Experience Design for AR Repair Interfaces

The user experience design for augmented reality (AR) repair interfaces in the context of 2JZ engine DIY repairs represents a critical intersection of technology and practical application. This design approach focuses on creating intuitive, user-friendly interfaces that enhance the repair process for both novice and experienced mechanics.

At the core of effective AR repair interfaces is the principle of seamless integration with the physical environment. The interface must provide clear, real-time visual overlays that accurately align with the engine components, offering step-by-step guidance without obstructing the user's view or impeding manual work. This requires precise spatial mapping and object recognition capabilities to ensure that AR elements are correctly positioned relative to the engine.

The interface design should prioritize clarity and simplicity, presenting information in a hierarchical manner that allows users to access detailed instructions or additional resources as needed. This can be achieved through a combination of visual cues, such as color-coded highlights for different engine parts, and interactive elements that respond to user gestures or voice commands.

Customization is another key aspect of AR repair interfaces. The system should be adaptable to different skill levels, allowing users to adjust the level of detail and complexity in the instructions. For instance, a beginner might require more comprehensive guidance, while an experienced mechanic might prefer a streamlined interface that focuses on specific, complex procedures.

Ergonomics play a crucial role in the design process. The interface must be optimized for prolonged use in various repair scenarios, considering factors such as lighting conditions, user posture, and the physical constraints of working on an engine. This may involve developing interfaces that can be easily viewed from multiple angles and distances, as well as incorporating features that reduce eye strain and fatigue.

Feedback mechanisms are essential for enhancing user confidence and ensuring accurate repairs. The interface should provide real-time confirmation of completed steps, alert users to potential errors, and offer troubleshooting guidance when unexpected issues arise. This can be achieved through a combination of visual, auditory, and haptic feedback, tailored to the specific repair task at hand.

Lastly, the AR repair interface should facilitate collaboration and knowledge sharing. Features such as remote expert assistance, where an experienced mechanic can guide a user through complex procedures in real-time, or the ability to record and share repair sessions, can significantly enhance the learning experience and foster a community of DIY enthusiasts.

At the core of effective AR repair interfaces is the principle of seamless integration with the physical environment. The interface must provide clear, real-time visual overlays that accurately align with the engine components, offering step-by-step guidance without obstructing the user's view or impeding manual work. This requires precise spatial mapping and object recognition capabilities to ensure that AR elements are correctly positioned relative to the engine.

The interface design should prioritize clarity and simplicity, presenting information in a hierarchical manner that allows users to access detailed instructions or additional resources as needed. This can be achieved through a combination of visual cues, such as color-coded highlights for different engine parts, and interactive elements that respond to user gestures or voice commands.

Customization is another key aspect of AR repair interfaces. The system should be adaptable to different skill levels, allowing users to adjust the level of detail and complexity in the instructions. For instance, a beginner might require more comprehensive guidance, while an experienced mechanic might prefer a streamlined interface that focuses on specific, complex procedures.

Ergonomics play a crucial role in the design process. The interface must be optimized for prolonged use in various repair scenarios, considering factors such as lighting conditions, user posture, and the physical constraints of working on an engine. This may involve developing interfaces that can be easily viewed from multiple angles and distances, as well as incorporating features that reduce eye strain and fatigue.

Feedback mechanisms are essential for enhancing user confidence and ensuring accurate repairs. The interface should provide real-time confirmation of completed steps, alert users to potential errors, and offer troubleshooting guidance when unexpected issues arise. This can be achieved through a combination of visual, auditory, and haptic feedback, tailored to the specific repair task at hand.

Lastly, the AR repair interface should facilitate collaboration and knowledge sharing. Features such as remote expert assistance, where an experienced mechanic can guide a user through complex procedures in real-time, or the ability to record and share repair sessions, can significantly enhance the learning experience and foster a community of DIY enthusiasts.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!