Variable Valve Timing (VVTi) in Reducing 2JZ Fuel Consumption

AUG 5, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

VVTi Technology Evolution and Objectives

Variable Valve Timing (VVTi) technology has undergone significant evolution since its inception, revolutionizing engine performance and fuel efficiency. The development of VVTi can be traced back to the late 1980s when automotive manufacturers began exploring ways to optimize engine operation across various driving conditions. The primary objective of VVTi technology has always been to enhance engine efficiency, reduce fuel consumption, and minimize emissions without compromising performance.

In the context of the 2JZ engine, renowned for its robustness and tuning potential, the integration of VVTi technology marks a crucial milestone in its development. The 2JZ engine, initially designed for high performance, faced increasing pressure to meet stricter emission standards and fuel economy requirements. This necessitated the adoption of advanced technologies like VVTi to maintain its performance characteristics while improving efficiency.

The evolution of VVTi technology in the 2JZ engine has been driven by several key objectives. Primarily, it aims to reduce fuel consumption by optimizing valve timing across different engine speeds and load conditions. This optimization allows for better control of the air-fuel mixture, resulting in more complete combustion and improved thermal efficiency. Additionally, VVTi technology seeks to enhance low-end torque and high-end power, providing a broader power band and more responsive engine performance.

Another critical objective of VVTi implementation in the 2JZ engine is the reduction of emissions. By precisely controlling valve timing, the system can minimize overlap between intake and exhaust valve openings, reducing the amount of unburned fuel escaping through the exhaust. This not only improves fuel economy but also significantly reduces harmful emissions, helping the engine meet increasingly stringent environmental regulations.

The development of VVTi technology for the 2JZ engine has also focused on improving cold-start performance and idle stability. By adjusting valve timing during engine warm-up, VVTi can reduce the time required for the engine to reach optimal operating temperature, thereby reducing fuel consumption and emissions during the critical warm-up phase.

As the technology has matured, the objectives have expanded to include more sophisticated control strategies. Modern VVTi systems aim to integrate seamlessly with other engine management technologies, such as direct injection and turbocharging, to further optimize engine performance across a wider range of operating conditions. This holistic approach to engine management has become crucial in achieving the delicate balance between performance, efficiency, and emissions compliance.

Looking forward, the ongoing evolution of VVTi technology in the context of the 2JZ engine continues to push the boundaries of what is possible in internal combustion engine design. Future objectives include even finer control of valve timing, potentially incorporating camless valve actuation systems for ultimate flexibility in engine breathing. These advancements promise to further reduce fuel consumption and emissions while maintaining or even enhancing the legendary performance characteristics of the 2JZ engine.

In the context of the 2JZ engine, renowned for its robustness and tuning potential, the integration of VVTi technology marks a crucial milestone in its development. The 2JZ engine, initially designed for high performance, faced increasing pressure to meet stricter emission standards and fuel economy requirements. This necessitated the adoption of advanced technologies like VVTi to maintain its performance characteristics while improving efficiency.

The evolution of VVTi technology in the 2JZ engine has been driven by several key objectives. Primarily, it aims to reduce fuel consumption by optimizing valve timing across different engine speeds and load conditions. This optimization allows for better control of the air-fuel mixture, resulting in more complete combustion and improved thermal efficiency. Additionally, VVTi technology seeks to enhance low-end torque and high-end power, providing a broader power band and more responsive engine performance.

Another critical objective of VVTi implementation in the 2JZ engine is the reduction of emissions. By precisely controlling valve timing, the system can minimize overlap between intake and exhaust valve openings, reducing the amount of unburned fuel escaping through the exhaust. This not only improves fuel economy but also significantly reduces harmful emissions, helping the engine meet increasingly stringent environmental regulations.

The development of VVTi technology for the 2JZ engine has also focused on improving cold-start performance and idle stability. By adjusting valve timing during engine warm-up, VVTi can reduce the time required for the engine to reach optimal operating temperature, thereby reducing fuel consumption and emissions during the critical warm-up phase.

As the technology has matured, the objectives have expanded to include more sophisticated control strategies. Modern VVTi systems aim to integrate seamlessly with other engine management technologies, such as direct injection and turbocharging, to further optimize engine performance across a wider range of operating conditions. This holistic approach to engine management has become crucial in achieving the delicate balance between performance, efficiency, and emissions compliance.

Looking forward, the ongoing evolution of VVTi technology in the context of the 2JZ engine continues to push the boundaries of what is possible in internal combustion engine design. Future objectives include even finer control of valve timing, potentially incorporating camless valve actuation systems for ultimate flexibility in engine breathing. These advancements promise to further reduce fuel consumption and emissions while maintaining or even enhancing the legendary performance characteristics of the 2JZ engine.

Market Demand for Fuel-Efficient 2JZ Engines

The market demand for fuel-efficient 2JZ engines has been steadily increasing in recent years, driven by several key factors. Rising fuel costs and growing environmental concerns have pushed consumers and manufacturers alike to seek more economical and eco-friendly engine solutions. The 2JZ engine, known for its robustness and performance, has long been a favorite among automotive enthusiasts. However, its fuel consumption has been a point of criticism, especially in an era where fuel efficiency is paramount.

In the performance car segment, where the 2JZ engine is predominantly used, there's a growing trend towards balancing high performance with improved fuel economy. This shift is partly due to stricter emissions regulations in many countries, which are forcing manufacturers to innovate and improve engine efficiency. The demand for fuel-efficient 2JZ engines is not limited to new vehicles; there's also a significant aftermarket interest from owners looking to upgrade their existing engines for better fuel economy without sacrificing performance.

The commercial vehicle sector, where durability and efficiency are crucial, has also shown interest in more fuel-efficient versions of the 2JZ engine. Fleet operators are increasingly looking for ways to reduce their fuel costs, which form a significant portion of their operational expenses. A more fuel-efficient 2JZ engine could offer the reliability these operators need while helping to cut down on fuel expenditure.

In emerging markets, where fuel prices can be volatile and infrastructure for alternative fuel vehicles is still developing, there's a growing demand for conventional engines that offer better fuel efficiency. The 2JZ's reputation for reliability makes it an attractive option in these markets, provided its fuel consumption can be improved.

The racing and motorsport industry, while traditionally focused on performance, is also seeing a shift towards fuel efficiency. Many racing series now incorporate fuel efficiency into their regulations, creating a demand for high-performance engines that can deliver power while conserving fuel. This trend is likely to trickle down to street-legal performance cars, further driving the demand for more efficient 2JZ engines.

Lastly, the classic car restoration market has shown interest in modernizing older vehicles with more fuel-efficient engines. The 2JZ, with its cult status, is a popular choice for such projects. If a more fuel-efficient version becomes available, it could open up new opportunities in this niche but growing market segment.

In the performance car segment, where the 2JZ engine is predominantly used, there's a growing trend towards balancing high performance with improved fuel economy. This shift is partly due to stricter emissions regulations in many countries, which are forcing manufacturers to innovate and improve engine efficiency. The demand for fuel-efficient 2JZ engines is not limited to new vehicles; there's also a significant aftermarket interest from owners looking to upgrade their existing engines for better fuel economy without sacrificing performance.

The commercial vehicle sector, where durability and efficiency are crucial, has also shown interest in more fuel-efficient versions of the 2JZ engine. Fleet operators are increasingly looking for ways to reduce their fuel costs, which form a significant portion of their operational expenses. A more fuel-efficient 2JZ engine could offer the reliability these operators need while helping to cut down on fuel expenditure.

In emerging markets, where fuel prices can be volatile and infrastructure for alternative fuel vehicles is still developing, there's a growing demand for conventional engines that offer better fuel efficiency. The 2JZ's reputation for reliability makes it an attractive option in these markets, provided its fuel consumption can be improved.

The racing and motorsport industry, while traditionally focused on performance, is also seeing a shift towards fuel efficiency. Many racing series now incorporate fuel efficiency into their regulations, creating a demand for high-performance engines that can deliver power while conserving fuel. This trend is likely to trickle down to street-legal performance cars, further driving the demand for more efficient 2JZ engines.

Lastly, the classic car restoration market has shown interest in modernizing older vehicles with more fuel-efficient engines. The 2JZ, with its cult status, is a popular choice for such projects. If a more fuel-efficient version becomes available, it could open up new opportunities in this niche but growing market segment.

VVTi Challenges in 2JZ Fuel Reduction

The implementation of Variable Valve Timing (VVTi) technology in the 2JZ engine to reduce fuel consumption faces several significant challenges. One of the primary obstacles is the integration of VVTi into the existing 2JZ engine architecture without compromising its renowned performance characteristics. The 2JZ engine, known for its robustness and power output, requires careful calibration to maintain its performance while improving fuel efficiency.

A major technical hurdle lies in the precise control of valve timing across the engine's wide operating range. The 2JZ engine, particularly in its turbocharged variants, experiences significant variations in intake and exhaust pressures throughout its rev range. Developing a VVTi system that can respond accurately and quickly to these changing conditions while optimizing fuel consumption is a complex task.

Another challenge is the design and implementation of a durable VVTi mechanism that can withstand the high stresses and temperatures associated with the 2JZ engine's performance capabilities. The system must be robust enough to maintain reliability under various driving conditions, from daily commuting to high-performance applications.

The integration of VVTi also presents challenges in terms of engine management and control systems. The 2JZ's existing engine control unit (ECU) may require significant reprogramming or replacement to accommodate the additional variables introduced by VVTi. This includes developing complex algorithms to determine optimal valve timing based on multiple factors such as engine load, speed, and temperature.

Furthermore, the implementation of VVTi in the 2JZ engine must address the issue of increased mechanical complexity. Additional components such as oil control valves, camshaft phasers, and associated sensors add weight and potential points of failure to the engine. Balancing the benefits of improved fuel efficiency against the increased complexity and potential reliability concerns is a critical consideration.

The challenge of maintaining the 2JZ engine's characteristic sound and feel while implementing VVTi is also significant. Enthusiasts and purists value the engine's distinctive performance attributes, and any modifications must preserve these qualities while achieving the goal of reduced fuel consumption.

Lastly, the cost-effectiveness of implementing VVTi technology in an older engine design like the 2JZ presents economic challenges. The research, development, and production costs associated with adapting VVTi to the 2JZ must be weighed against the potential fuel savings and market demand for such an upgrade.

A major technical hurdle lies in the precise control of valve timing across the engine's wide operating range. The 2JZ engine, particularly in its turbocharged variants, experiences significant variations in intake and exhaust pressures throughout its rev range. Developing a VVTi system that can respond accurately and quickly to these changing conditions while optimizing fuel consumption is a complex task.

Another challenge is the design and implementation of a durable VVTi mechanism that can withstand the high stresses and temperatures associated with the 2JZ engine's performance capabilities. The system must be robust enough to maintain reliability under various driving conditions, from daily commuting to high-performance applications.

The integration of VVTi also presents challenges in terms of engine management and control systems. The 2JZ's existing engine control unit (ECU) may require significant reprogramming or replacement to accommodate the additional variables introduced by VVTi. This includes developing complex algorithms to determine optimal valve timing based on multiple factors such as engine load, speed, and temperature.

Furthermore, the implementation of VVTi in the 2JZ engine must address the issue of increased mechanical complexity. Additional components such as oil control valves, camshaft phasers, and associated sensors add weight and potential points of failure to the engine. Balancing the benefits of improved fuel efficiency against the increased complexity and potential reliability concerns is a critical consideration.

The challenge of maintaining the 2JZ engine's characteristic sound and feel while implementing VVTi is also significant. Enthusiasts and purists value the engine's distinctive performance attributes, and any modifications must preserve these qualities while achieving the goal of reduced fuel consumption.

Lastly, the cost-effectiveness of implementing VVTi technology in an older engine design like the 2JZ presents economic challenges. The research, development, and production costs associated with adapting VVTi to the 2JZ must be weighed against the potential fuel savings and market demand for such an upgrade.

Current VVTi Solutions for 2JZ

01 VVTi system optimization for fuel efficiency

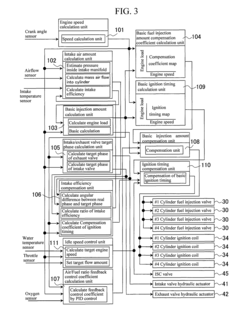

Variable Valve Timing intelligent (VVTi) systems can be optimized to improve fuel consumption by adjusting valve timing based on engine load and speed. This allows for better air-fuel mixture control and combustion efficiency across various operating conditions, resulting in reduced fuel consumption.- VVTi system optimization for fuel efficiency: Variable Valve Timing intelligent (VVTi) systems can be optimized to improve fuel consumption by adjusting valve timing based on engine load and speed. This optimization allows for better air-fuel mixture control, leading to more efficient combustion and reduced fuel consumption across various operating conditions.

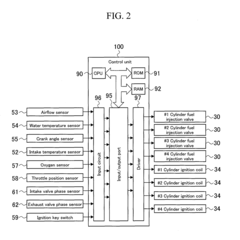

- Integration of VVTi with engine control systems: Integrating VVTi with advanced engine control systems enables real-time adjustments to valve timing based on various parameters such as throttle position, engine temperature, and exhaust gas composition. This integration allows for more precise control of the combustion process, resulting in improved fuel efficiency and reduced emissions.

- VVTi-based combustion optimization strategies: Implementing specific combustion optimization strategies using VVTi technology can significantly reduce fuel consumption. These strategies may include early intake valve closing for partial load conditions, late exhaust valve opening for improved scavenging, or variable valve lift control to optimize air-fuel mixture formation.

- VVTi application in hybrid and alternative fuel systems: Adapting VVTi technology for use in hybrid powertrains and alternative fuel systems can further enhance fuel efficiency. This adaptation involves tailoring valve timing strategies to accommodate the unique characteristics of hybrid operations or alternative fuels, resulting in optimized engine performance and reduced fuel consumption.

- Advanced VVTi control algorithms for fuel economy: Developing and implementing advanced control algorithms for VVTi systems can lead to significant improvements in fuel economy. These algorithms may incorporate machine learning techniques, predictive modeling, or adaptive control strategies to continuously optimize valve timing based on driving conditions and driver behavior.

02 Integration of VVTi with engine control systems

Integrating VVTi with advanced engine control systems enables real-time adjustments to valve timing based on various parameters such as throttle position, engine temperature, and exhaust gas composition. This integration allows for more precise control of the combustion process, leading to improved fuel efficiency.Expand Specific Solutions03 VVTi-based combustion optimization strategies

Implementing specific combustion optimization strategies using VVTi technology can significantly reduce fuel consumption. These strategies may include early intake valve closing for partial load conditions, late exhaust valve opening for improved scavenging, or variable valve lift control to optimize air-fuel mixture formation.Expand Specific Solutions04 VVTi application in hybrid and start-stop systems

Adapting VVTi technology for use in hybrid powertrains and start-stop systems can further enhance fuel efficiency. By optimizing valve timing during engine restart and transitions between electric and combustion power, these systems can minimize fuel consumption in urban driving conditions.Expand Specific Solutions05 Advanced VVTi control algorithms for fuel economy

Developing and implementing sophisticated control algorithms for VVTi systems can maximize fuel economy benefits. These algorithms may incorporate machine learning techniques, predictive modeling, or adaptive control strategies to continuously optimize valve timing based on driving conditions and driver behavior.Expand Specific Solutions

Key Players in VVTi Technology

The Variable Valve Timing (VVTi) technology for reducing 2JZ fuel consumption is in a mature stage of development, with significant market adoption and ongoing refinement. The global automotive VVT system market size is projected to reach several billion dollars by 2025, driven by increasing demand for fuel-efficient vehicles. Major players like Toyota Motor Corp., the pioneer of VVTi, along with BorgWarner, Inc., DENSO Corp., and Mitsubishi Motors Corp., have established strong positions in this field. These companies, along with emerging competitors such as Chery Automobile and Hyundai Motor Co., are continuously innovating to improve VVT efficiency and performance, indicating a highly competitive landscape with ongoing technological advancements.

BorgWarner, Inc.

Technical Solution: BorgWarner has developed a range of VVT technologies applicable to engines like the 2JZ. Their Cam Torque Actuated (CTA) phaser technology uses the existing torsional energy in the valve train to actuate the phaser, reducing oil demand and improving efficiency[4]. For engines like the 2JZ, BorgWarner's dual independent cam phasing system allows for independent control of both intake and exhaust valve timing. This system can achieve a phasing range of up to 70 degrees crank angle, providing greater flexibility in optimizing engine performance and fuel economy[5]. BorgWarner has also introduced their eBooster® electrically driven compressor, which can work in conjunction with VVT systems to further reduce fuel consumption by improving low-end torque and transient response[6].

Strengths: Advanced phaser technology with reduced oil demand, wide phasing range for optimization. Weaknesses: May require significant modifications to existing 2JZ engine architecture for implementation.

Toyota Motor Corp.

Technical Solution: Toyota's VVT-i (Variable Valve Timing with intelligence) system is a pioneering technology in variable valve timing. For the 2JZ engine, Toyota has implemented a dual VVT-i system that controls both intake and exhaust valve timing[1]. This system uses oil pressure to adjust the camshaft position, allowing for optimal valve timing across different engine speeds and loads. The VVT-i system in the 2JZ engine can advance or retard valve timing by up to 60 degrees, significantly improving fuel efficiency, especially at low to mid-range engine speeds[2]. Toyota has also integrated this system with direct fuel injection and their D-4S (Direct injection 4-stroke gasoline engine Superior version) technology, further enhancing combustion efficiency and reducing fuel consumption[3].

Strengths: Proven reliability, seamless integration with other Toyota technologies, and significant improvements in fuel efficiency. Weaknesses: Complexity of the system may lead to higher maintenance costs, and the technology may be reaching its optimization limits.

Core VVTi Innovations for 2JZ

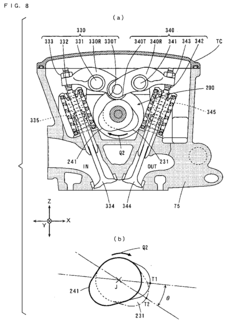

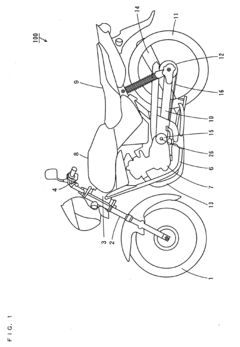

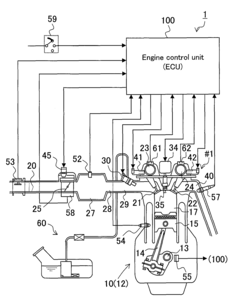

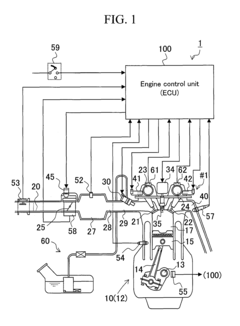

Valve timing controller, engine device having the same, and vehicle

PatentInactiveEP1835134A1

Innovation

- A valve timing control device with a phase changing mechanism that adjusts the phase of the second camshaft relative to the first camshaft at specific engine speeds, using engaging mechanisms biased by centrifugal force to prevent repeated phase changes within a certain engine speed range, thereby stabilizing valve behavior without requiring expensive actuators.

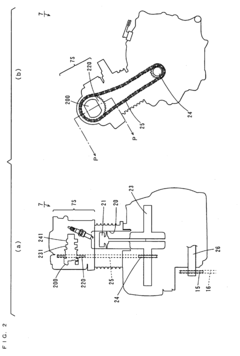

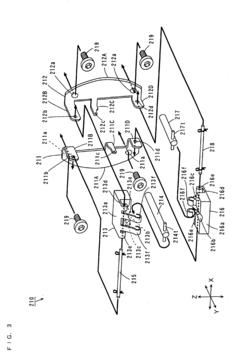

Engine control device

PatentInactiveUS8326516B2

Innovation

- An engine control device that calculates compensation coefficients for transient ignition timing adjustments based on the angular difference between the current and target valve phases, using intake air amount ratios and ideal gas equations, allowing for simpler calculations and reduced errors, and adjusts ignition timing accordingly to maintain optimal engine efficiency and prevent combustion issues.

Emissions Regulations Impact

Emissions regulations have played a significant role in shaping the development and implementation of Variable Valve Timing (VVTi) technology, particularly in the context of reducing fuel consumption in engines like the 2JZ. These regulations, which have become increasingly stringent over the years, have forced automotive manufacturers to innovate and adopt advanced technologies to meet compliance standards while maintaining performance.

The impact of emissions regulations on VVTi research and development can be observed through several key aspects. Firstly, the introduction of stricter emission standards, such as Euro 6 in Europe and Tier 3 in the United States, has necessitated more precise control over engine combustion processes. VVTi technology allows for optimized valve timing across different engine speeds and loads, resulting in improved fuel efficiency and reduced emissions.

Furthermore, the push for lower CO2 emissions has directly influenced the focus on fuel consumption reduction. VVTi systems contribute to this goal by enabling more efficient air-fuel mixture preparation and combustion, leading to better fuel economy. This aligns with regulatory targets for fleet-wide CO2 reductions imposed on automobile manufacturers.

The regulations have also accelerated the adoption of VVTi technology across a wider range of engines and vehicle segments. What was once primarily found in high-performance engines like the 2JZ has now become commonplace in many mainstream vehicles. This widespread implementation has been driven by the need to meet emissions standards across entire product lines.

Additionally, emissions regulations have spurred research into more advanced VVTi systems. Continuous variable valve timing and lift systems have emerged as a response to the demand for even greater precision in engine control. These systems offer finer adjustments to valve operation, further optimizing engine performance and emissions across a broader range of operating conditions.

The regulatory landscape has also influenced the integration of VVTi with other engine technologies. For instance, the combination of VVTi with direct fuel injection and turbocharging has become a popular strategy to meet both emissions and performance targets. This synergy allows for downsized engines that can deliver power when needed while maintaining efficiency during normal operation.

Lastly, the impact of emissions regulations on VVTi technology extends to the development of diagnostic and monitoring systems. On-board diagnostics (OBD) requirements have become more sophisticated, necessitating advanced sensors and control systems to ensure that emissions control technologies, including VVTi, are functioning correctly throughout the vehicle's lifetime.

The impact of emissions regulations on VVTi research and development can be observed through several key aspects. Firstly, the introduction of stricter emission standards, such as Euro 6 in Europe and Tier 3 in the United States, has necessitated more precise control over engine combustion processes. VVTi technology allows for optimized valve timing across different engine speeds and loads, resulting in improved fuel efficiency and reduced emissions.

Furthermore, the push for lower CO2 emissions has directly influenced the focus on fuel consumption reduction. VVTi systems contribute to this goal by enabling more efficient air-fuel mixture preparation and combustion, leading to better fuel economy. This aligns with regulatory targets for fleet-wide CO2 reductions imposed on automobile manufacturers.

The regulations have also accelerated the adoption of VVTi technology across a wider range of engines and vehicle segments. What was once primarily found in high-performance engines like the 2JZ has now become commonplace in many mainstream vehicles. This widespread implementation has been driven by the need to meet emissions standards across entire product lines.

Additionally, emissions regulations have spurred research into more advanced VVTi systems. Continuous variable valve timing and lift systems have emerged as a response to the demand for even greater precision in engine control. These systems offer finer adjustments to valve operation, further optimizing engine performance and emissions across a broader range of operating conditions.

The regulatory landscape has also influenced the integration of VVTi with other engine technologies. For instance, the combination of VVTi with direct fuel injection and turbocharging has become a popular strategy to meet both emissions and performance targets. This synergy allows for downsized engines that can deliver power when needed while maintaining efficiency during normal operation.

Lastly, the impact of emissions regulations on VVTi technology extends to the development of diagnostic and monitoring systems. On-board diagnostics (OBD) requirements have become more sophisticated, necessitating advanced sensors and control systems to ensure that emissions control technologies, including VVTi, are functioning correctly throughout the vehicle's lifetime.

Cost-Benefit Analysis of VVTi Implementation

The implementation of Variable Valve Timing (VVTi) technology in the 2JZ engine presents a significant opportunity for fuel consumption reduction, but it also comes with associated costs and benefits that must be carefully evaluated. This cost-benefit analysis aims to provide a comprehensive overview of the financial implications of integrating VVTi into the 2JZ engine platform.

From a cost perspective, the initial investment for VVTi implementation is substantial. The system requires additional components such as variable camshaft sprockets, oil control valves, and an advanced engine control unit. These hardware upgrades contribute to increased production costs per engine unit. Furthermore, the development and testing phase for adapting VVTi to the 2JZ engine architecture incurs significant research and development expenses.

However, the benefits of VVTi implementation are considerable, particularly in terms of fuel efficiency improvements. Studies have shown that VVTi can reduce fuel consumption by 5-10% under various driving conditions. This translates to substantial savings for end-users over the lifetime of the vehicle, potentially offsetting the higher initial purchase price. Additionally, the improved fuel economy contributes to reduced carbon emissions, aligning with increasingly stringent environmental regulations and potentially avoiding future penalties.

The enhanced performance characteristics offered by VVTi, such as improved low-end torque and high-end power, can also lead to increased market competitiveness. This may result in higher sales volumes or the ability to command premium pricing, further offsetting the implementation costs. Moreover, the adoption of VVTi technology can positively impact brand perception, positioning the manufacturer as technologically advanced and environmentally conscious.

Long-term cost considerations include potential maintenance requirements for the VVTi system. While generally reliable, the additional complexity may lead to increased service costs over the vehicle's lifespan. However, these costs are typically outweighed by the fuel savings and performance benefits.

In conclusion, the cost-benefit analysis suggests that despite the initial investment and potential long-term maintenance considerations, the implementation of VVTi in the 2JZ engine is likely to yield net positive results. The combination of fuel efficiency gains, performance improvements, and market positioning benefits presents a compelling case for VVTi adoption, particularly when considering the long-term financial and environmental impacts.

From a cost perspective, the initial investment for VVTi implementation is substantial. The system requires additional components such as variable camshaft sprockets, oil control valves, and an advanced engine control unit. These hardware upgrades contribute to increased production costs per engine unit. Furthermore, the development and testing phase for adapting VVTi to the 2JZ engine architecture incurs significant research and development expenses.

However, the benefits of VVTi implementation are considerable, particularly in terms of fuel efficiency improvements. Studies have shown that VVTi can reduce fuel consumption by 5-10% under various driving conditions. This translates to substantial savings for end-users over the lifetime of the vehicle, potentially offsetting the higher initial purchase price. Additionally, the improved fuel economy contributes to reduced carbon emissions, aligning with increasingly stringent environmental regulations and potentially avoiding future penalties.

The enhanced performance characteristics offered by VVTi, such as improved low-end torque and high-end power, can also lead to increased market competitiveness. This may result in higher sales volumes or the ability to command premium pricing, further offsetting the implementation costs. Moreover, the adoption of VVTi technology can positively impact brand perception, positioning the manufacturer as technologically advanced and environmentally conscious.

Long-term cost considerations include potential maintenance requirements for the VVTi system. While generally reliable, the additional complexity may lead to increased service costs over the vehicle's lifespan. However, these costs are typically outweighed by the fuel savings and performance benefits.

In conclusion, the cost-benefit analysis suggests that despite the initial investment and potential long-term maintenance considerations, the implementation of VVTi in the 2JZ engine is likely to yield net positive results. The combination of fuel efficiency gains, performance improvements, and market positioning benefits presents a compelling case for VVTi adoption, particularly when considering the long-term financial and environmental impacts.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!