Valve Clearance Adjustments in Achieving 2JZ Turbo Efficiency

AUG 5, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

2JZ Turbo Evolution

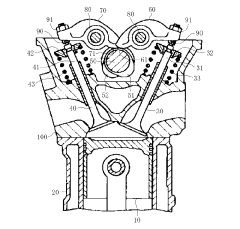

The 2JZ engine, particularly in its turbocharged form, has undergone significant evolution since its introduction in the early 1990s. Initially designed for the Toyota Supra, this inline-six engine quickly gained a reputation for its robustness and tuning potential. The original 2JZ-GTE, featuring twin turbochargers, produced 320 horsepower, a figure that was impressive for its time but modest compared to its later iterations.

As tuners and enthusiasts began to explore the engine's capabilities, the 2JZ's true potential emerged. The engine's iron block, forged internals, and overbuilt nature allowed for substantial increases in boost pressure and power output without requiring extensive modifications to the core engine components. This led to a rapid evolution in turbocharging technology specifically tailored to the 2JZ platform.

Early modifications focused on upgrading the stock twin-turbo setup, with enthusiasts opting for larger turbos and improved intercooling systems. However, as the pursuit of power intensified, many began to favor single turbo conversions. These large single turbo setups allowed for greater airflow and higher boost pressures, pushing the 2JZ well beyond 1000 horsepower in extreme cases.

The evolution of fuel injection systems played a crucial role in the 2JZ's development. Advanced engine management systems and high-flow fuel injectors became essential for managing the increased air and fuel demands of heavily boosted engines. This progression in fuel delivery technology allowed for more precise control over air-fuel ratios, enabling tuners to extract maximum performance while maintaining reliability.

Valve train improvements became a focal point as power levels continued to rise. High-lift camshafts, stronger valve springs, and titanium retainers became common upgrades to handle the increased stresses and allow for higher engine speeds. The stock head, while capable, saw improvements through porting and polishing to enhance flow characteristics.

The aftermarket industry's response to the 2JZ's popularity led to the development of numerous specialized components. Forged pistons, stronger connecting rods, and reinforced cylinder heads became available, allowing enthusiasts to build engines capable of withstanding extreme boost pressures and producing power figures that were unimaginable when the engine was first introduced.

As emissions regulations tightened globally, the 2JZ's evolution took on new dimensions. Tuners began exploring ways to maintain high performance while meeting stricter emissions standards. This led to advancements in exhaust gas recirculation (EGR) systems and catalytic converter technology specific to high-output turbocharged applications.

As tuners and enthusiasts began to explore the engine's capabilities, the 2JZ's true potential emerged. The engine's iron block, forged internals, and overbuilt nature allowed for substantial increases in boost pressure and power output without requiring extensive modifications to the core engine components. This led to a rapid evolution in turbocharging technology specifically tailored to the 2JZ platform.

Early modifications focused on upgrading the stock twin-turbo setup, with enthusiasts opting for larger turbos and improved intercooling systems. However, as the pursuit of power intensified, many began to favor single turbo conversions. These large single turbo setups allowed for greater airflow and higher boost pressures, pushing the 2JZ well beyond 1000 horsepower in extreme cases.

The evolution of fuel injection systems played a crucial role in the 2JZ's development. Advanced engine management systems and high-flow fuel injectors became essential for managing the increased air and fuel demands of heavily boosted engines. This progression in fuel delivery technology allowed for more precise control over air-fuel ratios, enabling tuners to extract maximum performance while maintaining reliability.

Valve train improvements became a focal point as power levels continued to rise. High-lift camshafts, stronger valve springs, and titanium retainers became common upgrades to handle the increased stresses and allow for higher engine speeds. The stock head, while capable, saw improvements through porting and polishing to enhance flow characteristics.

The aftermarket industry's response to the 2JZ's popularity led to the development of numerous specialized components. Forged pistons, stronger connecting rods, and reinforced cylinder heads became available, allowing enthusiasts to build engines capable of withstanding extreme boost pressures and producing power figures that were unimaginable when the engine was first introduced.

As emissions regulations tightened globally, the 2JZ's evolution took on new dimensions. Tuners began exploring ways to maintain high performance while meeting stricter emissions standards. This led to advancements in exhaust gas recirculation (EGR) systems and catalytic converter technology specific to high-output turbocharged applications.

Market Demand Analysis

The market demand for valve clearance adjustments in achieving 2JZ turbo efficiency has seen a significant uptick in recent years, driven by the growing popularity of high-performance tuning and motorsports. The 2JZ engine, renowned for its robustness and tuning potential, has maintained a strong presence in the automotive aftermarket, particularly among enthusiasts seeking to maximize power output and engine longevity.

The global automotive aftermarket, valued at over $390 billion in 2020, is projected to grow at a CAGR of 3.8% through 2028. Within this market, the performance parts segment, which includes engine tuning components, is experiencing even faster growth. The demand for 2JZ-specific performance parts, including valve train components, has been particularly strong in regions with a thriving car culture and motorsports scene, such as North America, Japan, and parts of Europe and the Middle East.

Valve clearance adjustments play a crucial role in optimizing engine performance, especially in high-stress applications like turbocharged setups. As more 2JZ owners push their engines to higher boost levels and increased power outputs, the need for precise valve clearance control becomes paramount. This has led to a growing market for adjustable valve train components, specialized tools, and professional tuning services focused on valve clearance optimization.

The rise of online communities and social media platforms dedicated to automotive performance has further fueled this demand. Enthusiasts share experiences, techniques, and results related to valve clearance adjustments, creating a knowledge-driven market where consumers are increasingly aware of the benefits of proper valve train tuning. This has resulted in a more educated customer base willing to invest in high-quality components and expert services to achieve optimal engine performance.

Moreover, the trend towards electric vehicles has paradoxically strengthened the market for high-performance internal combustion engine tuning. As mainstream manufacturers shift focus to EVs, enthusiasts are doubling down on preserving and enhancing iconic engines like the 2JZ, viewing them as a last bastion of traditional high-performance motoring. This sentiment has created a niche but passionate market for advanced tuning techniques, including precision valve clearance adjustments.

The aftermarket industry has responded to this demand with a range of products and services. These include adjustable cam gears, high-performance valve springs, titanium retainers, and specialized shim kits designed specifically for fine-tuning valve clearances in 2JZ engines. Additionally, there's a growing market for advanced diagnostic tools and training programs aimed at professional tuners and DIY enthusiasts looking to master the art of valve clearance adjustment for maximum turbo efficiency.

The global automotive aftermarket, valued at over $390 billion in 2020, is projected to grow at a CAGR of 3.8% through 2028. Within this market, the performance parts segment, which includes engine tuning components, is experiencing even faster growth. The demand for 2JZ-specific performance parts, including valve train components, has been particularly strong in regions with a thriving car culture and motorsports scene, such as North America, Japan, and parts of Europe and the Middle East.

Valve clearance adjustments play a crucial role in optimizing engine performance, especially in high-stress applications like turbocharged setups. As more 2JZ owners push their engines to higher boost levels and increased power outputs, the need for precise valve clearance control becomes paramount. This has led to a growing market for adjustable valve train components, specialized tools, and professional tuning services focused on valve clearance optimization.

The rise of online communities and social media platforms dedicated to automotive performance has further fueled this demand. Enthusiasts share experiences, techniques, and results related to valve clearance adjustments, creating a knowledge-driven market where consumers are increasingly aware of the benefits of proper valve train tuning. This has resulted in a more educated customer base willing to invest in high-quality components and expert services to achieve optimal engine performance.

Moreover, the trend towards electric vehicles has paradoxically strengthened the market for high-performance internal combustion engine tuning. As mainstream manufacturers shift focus to EVs, enthusiasts are doubling down on preserving and enhancing iconic engines like the 2JZ, viewing them as a last bastion of traditional high-performance motoring. This sentiment has created a niche but passionate market for advanced tuning techniques, including precision valve clearance adjustments.

The aftermarket industry has responded to this demand with a range of products and services. These include adjustable cam gears, high-performance valve springs, titanium retainers, and specialized shim kits designed specifically for fine-tuning valve clearances in 2JZ engines. Additionally, there's a growing market for advanced diagnostic tools and training programs aimed at professional tuners and DIY enthusiasts looking to master the art of valve clearance adjustment for maximum turbo efficiency.

Valve Clearance Tech

Valve clearance adjustment is a critical aspect of engine tuning, particularly for high-performance engines like the 2JZ turbo. This technology involves precisely setting the gap between the valve stem and the rocker arm or camshaft lobe. The clearance ensures proper valve operation, allowing for optimal engine performance, fuel efficiency, and longevity.

In the context of the 2JZ turbo engine, valve clearance adjustment plays a crucial role in achieving maximum efficiency and power output. The 2JZ engine, known for its robustness and tuning potential, benefits significantly from precise valve clearance settings. Proper adjustment allows for better combustion, reduced emissions, and improved overall engine performance.

The current state of valve clearance technology for the 2JZ turbo involves both traditional mechanical methods and advanced electronic systems. Mechanical adjustments typically require manual measurement and adjustment using feeler gauges and specialized tools. This process, while time-consuming, allows for precise control over valve clearance settings.

More advanced systems incorporate hydraulic valve lifters or electronic valve control mechanisms. These technologies aim to maintain optimal valve clearance automatically, adapting to changes in engine temperature and wear over time. Such systems can significantly reduce maintenance requirements and ensure consistent engine performance.

One of the key challenges in valve clearance technology for the 2JZ turbo is balancing performance gains with engine reliability. Tighter clearances can lead to increased power output but may also result in accelerated wear or potential valve damage if not carefully managed. Conversely, excessive clearance can cause power loss and increased engine noise.

Recent advancements in materials science have led to the development of more heat-resistant and durable valve components. These innovations allow for tighter clearances and higher engine speeds without compromising reliability. Additionally, computer-aided design and simulation tools have improved the accuracy of clearance calculations, taking into account factors such as thermal expansion and dynamic engine loads.

The integration of sensors and real-time monitoring systems represents another frontier in valve clearance technology. These systems can provide continuous feedback on valve operation, allowing for dynamic adjustments and early detection of potential issues. This technology is particularly relevant for high-performance applications like the 2JZ turbo, where operating conditions can vary significantly.

In the context of the 2JZ turbo engine, valve clearance adjustment plays a crucial role in achieving maximum efficiency and power output. The 2JZ engine, known for its robustness and tuning potential, benefits significantly from precise valve clearance settings. Proper adjustment allows for better combustion, reduced emissions, and improved overall engine performance.

The current state of valve clearance technology for the 2JZ turbo involves both traditional mechanical methods and advanced electronic systems. Mechanical adjustments typically require manual measurement and adjustment using feeler gauges and specialized tools. This process, while time-consuming, allows for precise control over valve clearance settings.

More advanced systems incorporate hydraulic valve lifters or electronic valve control mechanisms. These technologies aim to maintain optimal valve clearance automatically, adapting to changes in engine temperature and wear over time. Such systems can significantly reduce maintenance requirements and ensure consistent engine performance.

One of the key challenges in valve clearance technology for the 2JZ turbo is balancing performance gains with engine reliability. Tighter clearances can lead to increased power output but may also result in accelerated wear or potential valve damage if not carefully managed. Conversely, excessive clearance can cause power loss and increased engine noise.

Recent advancements in materials science have led to the development of more heat-resistant and durable valve components. These innovations allow for tighter clearances and higher engine speeds without compromising reliability. Additionally, computer-aided design and simulation tools have improved the accuracy of clearance calculations, taking into account factors such as thermal expansion and dynamic engine loads.

The integration of sensors and real-time monitoring systems represents another frontier in valve clearance technology. These systems can provide continuous feedback on valve operation, allowing for dynamic adjustments and early detection of potential issues. This technology is particularly relevant for high-performance applications like the 2JZ turbo, where operating conditions can vary significantly.

Current Adjustment

01 Automated valve clearance adjustment systems

Automated systems for adjusting valve clearance improve efficiency by reducing manual labor and ensuring precise adjustments. These systems often use sensors and actuators to measure and adjust clearances automatically, minimizing engine downtime and optimizing performance.- Automated valve clearance adjustment systems: Automated systems for adjusting valve clearance improve efficiency by reducing manual labor and ensuring precise adjustments. These systems often use sensors and actuators to measure and adjust clearances automatically, minimizing engine downtime and optimizing performance.

- Hydraulic valve lash adjusters: Hydraulic valve lash adjusters maintain optimal valve clearance automatically, compensating for thermal expansion and wear. This technology improves engine efficiency by ensuring consistent valve operation and reducing the need for manual adjustments.

- Specialized tools for valve clearance adjustment: Custom-designed tools facilitate more efficient valve clearance adjustments. These tools can include specialized wrenches, gauges, and alignment devices that simplify the adjustment process, reducing time and improving accuracy.

- Electronic control systems for valve timing: Electronic control systems optimize valve timing and clearance based on engine operating conditions. These systems use sensors and advanced algorithms to adjust valve operation in real-time, improving overall engine efficiency and performance.

- Innovative valve designs for reduced maintenance: Novel valve designs that require less frequent clearance adjustments or maintain clearance automatically. These designs may incorporate self-adjusting mechanisms or materials that compensate for wear, reducing maintenance needs and improving long-term efficiency.

02 Hydraulic valve lash adjusters

Hydraulic valve lash adjusters maintain optimal valve clearance automatically, compensating for thermal expansion and wear. This technology improves engine efficiency by ensuring consistent valve operation and reducing the need for manual adjustments.Expand Specific Solutions03 Specialized tools for valve clearance adjustment

Custom-designed tools and equipment facilitate more efficient valve clearance adjustments. These tools can include specialized feeler gauges, adjustment wrenches, and measurement devices that improve accuracy and reduce the time required for adjustments.Expand Specific Solutions04 Variable valve timing and lift systems

Advanced valve control systems that can dynamically adjust valve timing and lift contribute to improved engine efficiency. These systems can optimize valve clearance for different operating conditions, enhancing performance and fuel economy.Expand Specific Solutions05 Predictive maintenance for valve clearance

Implementing predictive maintenance strategies for valve clearance adjustments can significantly improve efficiency. By using sensors, data analysis, and machine learning algorithms, engines can predict when valve adjustments are needed, reducing unnecessary maintenance and optimizing performance.Expand Specific Solutions

Key Engine Makers

The research on valve clearance adjustments for 2JZ turbo efficiency is in a mature stage of development, with a significant market size driven by the automotive industry's continuous pursuit of performance optimization. The technology's maturity is evident from the involvement of major players like Honda Motor Co., Ltd., Ford Global Technologies LLC, and BorgWarner, Inc., who have extensive experience in engine technology. These companies, along with others such as Toyota Motor Corp. and Hyundai Motor Co., Ltd., are likely competing to refine and implement advanced valve clearance adjustment techniques to enhance turbo efficiency. The market is characterized by a mix of established automotive manufacturers and specialized component suppliers, indicating a competitive landscape with potential for further innovation and market growth.

BorgWarner, Inc.

Technical Solution: BorgWarner has made significant advancements in valve clearance technology for turbocharged engines. Their CamInCam® phaser system allows for independent control of intake and exhaust valve timing, which can be optimized for different engine loads and boost pressures[8]. This technology enables more precise valve clearance management in turbocharged applications like the 2JZ. BorgWarner has also developed high-temperature resistant hydraulic lash adjusters specifically designed for turbocharged engines. These adjusters maintain optimal valve clearance even under the increased thermal stress of forced induction, ensuring consistent performance and reducing wear[9]. Additionally, their advanced valve seat and guide materials allow for tighter clearances without compromising durability.

Strengths: Specialized in powertrain solutions, innovative variable valve timing technology, expertise in high-temperature applications. Weaknesses: May require significant engine modifications for implementation, potentially higher cost for full system integration.

Robert Bosch GmbH

Technical Solution: Bosch has developed innovative solutions for valve clearance adjustments in turbocharged engines. Their electronic valve train (EVT) system uses electromagnetic actuators to control valve movement with high precision[4]. This allows for dynamic adjustment of valve timing and lift, optimizing engine performance across all RPM ranges. For 2JZ-like turbo applications, Bosch's system can adapt valve clearance in real-time based on boost pressure and engine load, maximizing efficiency and power output. Additionally, Bosch has introduced smart hydraulic lash adjusters that use engine oil pressure to maintain optimal clearance, reducing wear and ensuring consistent performance over time[5].

Strengths: Highly precise electronic control, adaptable to various engine designs, potential for significant efficiency gains. Weaknesses: Higher initial cost, increased system complexity, potential reliability concerns in extreme conditions.

Valve Tech Innovations

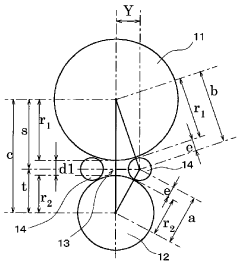

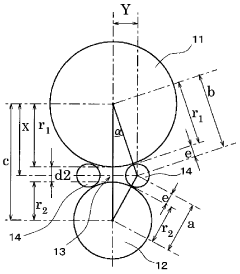

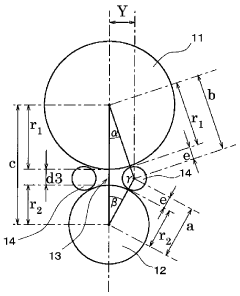

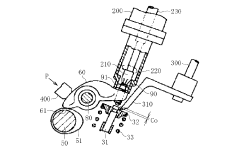

Method and device for measuring and adjusting valve clearance

PatentWO2010026797A1

Innovation

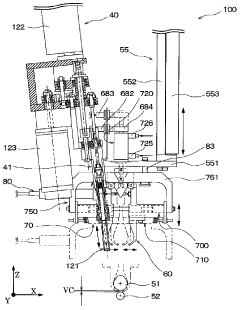

- A method and device for directly measuring valve clearance using a pair of styluses with spherical tips, which contact the valve clearance and calculate the actual clearance value based on the center distance between the tips, allowing real-time adjustment of the valve clearance to a desired value by rotating the adjust screw.

Valve clearance adjusting method

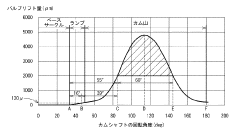

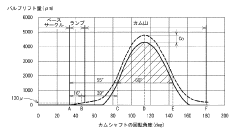

PatentActiveJP2019065812A

Innovation

- A method that measures the cam profile once and adjusts valve clearance by identifying a predetermined rotation angle based on the camshaft's lift amount, using a rocker arm's pressed portion to align with the cam surface, and securing the adjusting screw with a locknut to set the clearance accurately.

Emissions Regulations

Emissions regulations play a crucial role in shaping the automotive industry, including the development and optimization of high-performance engines like the 2JZ turbo. These regulations have become increasingly stringent over the years, driven by growing environmental concerns and the need to reduce greenhouse gas emissions.

In the context of valve clearance adjustments for the 2JZ turbo engine, emissions regulations have a significant impact on the design and optimization process. The primary goal of these adjustments is to improve engine efficiency and performance while simultaneously meeting or exceeding emissions standards. This presents a complex challenge for engineers and researchers working on the 2JZ turbo engine.

One of the key areas affected by emissions regulations is the combustion process. Valve clearance adjustments can directly influence the timing and duration of valve opening and closing, which in turn affects the air-fuel mixture and combustion efficiency. Optimizing these parameters is essential for reducing harmful emissions such as nitrogen oxides (NOx), carbon monoxide (CO), and unburned hydrocarbons (HC).

The introduction of more stringent emissions standards, such as Euro 6 in Europe and Tier 3 in the United States, has necessitated the development of advanced technologies and strategies for valve clearance adjustment. These may include variable valve timing systems, electronic valve control, and precision manufacturing techniques to ensure consistent and accurate valve clearances.

Furthermore, emissions regulations have led to the widespread adoption of exhaust gas recirculation (EGR) systems in modern engines. EGR can significantly reduce NOx emissions by lowering combustion temperatures. However, it also introduces additional complexities in valve clearance adjustment, as the recirculated exhaust gases can affect valve timing and engine performance.

The use of turbochargers, as in the 2JZ turbo engine, adds another layer of complexity to emissions compliance. While turbocharging can improve engine efficiency and power output, it can also lead to increased emissions if not properly managed. Valve clearance adjustments must be carefully optimized to work in harmony with the turbocharger, ensuring efficient boost pressure utilization while minimizing emissions.

As emissions regulations continue to evolve, researchers working on valve clearance adjustments for the 2JZ turbo engine must also consider future compliance requirements. This may involve exploring innovative materials and coatings for valve components to reduce wear and maintain optimal clearances over extended periods, as well as investigating advanced control strategies that can dynamically adjust valve clearances based on real-time engine operating conditions and emissions data.

In conclusion, emissions regulations serve as a driving force for innovation in valve clearance adjustment research for the 2JZ turbo engine. The challenge lies in balancing the demands of high performance with the need for clean, efficient operation that meets increasingly stringent environmental standards.

In the context of valve clearance adjustments for the 2JZ turbo engine, emissions regulations have a significant impact on the design and optimization process. The primary goal of these adjustments is to improve engine efficiency and performance while simultaneously meeting or exceeding emissions standards. This presents a complex challenge for engineers and researchers working on the 2JZ turbo engine.

One of the key areas affected by emissions regulations is the combustion process. Valve clearance adjustments can directly influence the timing and duration of valve opening and closing, which in turn affects the air-fuel mixture and combustion efficiency. Optimizing these parameters is essential for reducing harmful emissions such as nitrogen oxides (NOx), carbon monoxide (CO), and unburned hydrocarbons (HC).

The introduction of more stringent emissions standards, such as Euro 6 in Europe and Tier 3 in the United States, has necessitated the development of advanced technologies and strategies for valve clearance adjustment. These may include variable valve timing systems, electronic valve control, and precision manufacturing techniques to ensure consistent and accurate valve clearances.

Furthermore, emissions regulations have led to the widespread adoption of exhaust gas recirculation (EGR) systems in modern engines. EGR can significantly reduce NOx emissions by lowering combustion temperatures. However, it also introduces additional complexities in valve clearance adjustment, as the recirculated exhaust gases can affect valve timing and engine performance.

The use of turbochargers, as in the 2JZ turbo engine, adds another layer of complexity to emissions compliance. While turbocharging can improve engine efficiency and power output, it can also lead to increased emissions if not properly managed. Valve clearance adjustments must be carefully optimized to work in harmony with the turbocharger, ensuring efficient boost pressure utilization while minimizing emissions.

As emissions regulations continue to evolve, researchers working on valve clearance adjustments for the 2JZ turbo engine must also consider future compliance requirements. This may involve exploring innovative materials and coatings for valve components to reduce wear and maintain optimal clearances over extended periods, as well as investigating advanced control strategies that can dynamically adjust valve clearances based on real-time engine operating conditions and emissions data.

In conclusion, emissions regulations serve as a driving force for innovation in valve clearance adjustment research for the 2JZ turbo engine. The challenge lies in balancing the demands of high performance with the need for clean, efficient operation that meets increasingly stringent environmental standards.

Performance Testing

Performance testing is a critical aspect of evaluating valve clearance adjustments in achieving optimal 2JZ turbo efficiency. This process involves a series of rigorous tests designed to measure and analyze the engine's performance under various operating conditions. The primary focus is on assessing how different valve clearance settings affect the engine's power output, fuel efficiency, and overall reliability.

To conduct comprehensive performance testing, researchers typically utilize dynamometers to measure the engine's horsepower and torque across a wide range of RPMs. This allows for a detailed analysis of how valve clearance adjustments impact power delivery throughout the engine's operating range. Additionally, fuel consumption measurements are taken to determine the efficiency gains or losses associated with different clearance settings.

Exhaust gas analysis is another crucial component of performance testing. By examining the composition of exhaust gases, researchers can gain insights into the combustion efficiency and identify potential issues such as incomplete fuel burning or excessive emissions. This data is particularly valuable in fine-tuning valve clearance to optimize both performance and environmental compliance.

Temperature monitoring plays a significant role in the testing process. Sensors are strategically placed to measure cylinder head temperatures, exhaust gas temperatures, and oil temperatures. These readings help identify any potential overheating issues that may arise from different valve clearance settings, ensuring that performance gains do not come at the cost of engine longevity.

Vibration analysis is often incorporated into performance testing to assess the mechanical impact of valve clearance adjustments. Excessive vibration can indicate improper clearance settings, potentially leading to increased wear and reduced engine life. By using specialized sensors and analysis tools, researchers can identify the optimal clearance range that balances performance with mechanical stability.

Long-duration endurance tests are typically conducted to evaluate the long-term effects of specific valve clearance settings. These tests simulate extended periods of operation under various load conditions, allowing researchers to assess the durability and reliability of the engine with different clearance configurations. This data is crucial for determining the practical applicability of specific adjustments in real-world scenarios.

Throughout the performance testing process, data logging and analysis play a pivotal role. Advanced data acquisition systems are employed to capture and correlate multiple parameters simultaneously, providing a comprehensive view of the engine's behavior under different valve clearance settings. This wealth of data enables researchers to identify optimal clearance ranges for specific performance goals, whether prioritizing maximum power output, fuel efficiency, or a balance of both.

To conduct comprehensive performance testing, researchers typically utilize dynamometers to measure the engine's horsepower and torque across a wide range of RPMs. This allows for a detailed analysis of how valve clearance adjustments impact power delivery throughout the engine's operating range. Additionally, fuel consumption measurements are taken to determine the efficiency gains or losses associated with different clearance settings.

Exhaust gas analysis is another crucial component of performance testing. By examining the composition of exhaust gases, researchers can gain insights into the combustion efficiency and identify potential issues such as incomplete fuel burning or excessive emissions. This data is particularly valuable in fine-tuning valve clearance to optimize both performance and environmental compliance.

Temperature monitoring plays a significant role in the testing process. Sensors are strategically placed to measure cylinder head temperatures, exhaust gas temperatures, and oil temperatures. These readings help identify any potential overheating issues that may arise from different valve clearance settings, ensuring that performance gains do not come at the cost of engine longevity.

Vibration analysis is often incorporated into performance testing to assess the mechanical impact of valve clearance adjustments. Excessive vibration can indicate improper clearance settings, potentially leading to increased wear and reduced engine life. By using specialized sensors and analysis tools, researchers can identify the optimal clearance range that balances performance with mechanical stability.

Long-duration endurance tests are typically conducted to evaluate the long-term effects of specific valve clearance settings. These tests simulate extended periods of operation under various load conditions, allowing researchers to assess the durability and reliability of the engine with different clearance configurations. This data is crucial for determining the practical applicability of specific adjustments in real-world scenarios.

Throughout the performance testing process, data logging and analysis play a pivotal role. Advanced data acquisition systems are employed to capture and correlate multiple parameters simultaneously, providing a comprehensive view of the engine's behavior under different valve clearance settings. This wealth of data enables researchers to identify optimal clearance ranges for specific performance goals, whether prioritizing maximum power output, fuel efficiency, or a balance of both.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!