Dual Overhead Camshaft Implementation in 2JZ Power Delivery

AUG 5, 20258 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

2JZ DOHC Background

The 2JZ engine, developed by Toyota in the early 1990s, has become an iconic powerplant in the automotive world. Originally designed for the Toyota Supra, this inline-six engine has gained a reputation for its robustness, reliability, and immense tuning potential. The 2JZ-GE and 2JZ-GTE variants, in particular, have been at the forefront of high-performance applications for decades.

The Dual Overhead Camshaft (DOHC) configuration in the 2JZ engine plays a crucial role in its power delivery and overall performance. This design features two camshafts located above the cylinder head, with one controlling the intake valves and the other managing the exhaust valves. This arrangement allows for more precise control over valve timing and lift, resulting in improved engine breathing and increased power output.

The implementation of DOHC in the 2JZ engine was a significant advancement over its predecessor, the 1JZ engine, which utilized a Single Overhead Camshaft (SOHC) design. The transition to DOHC allowed for higher rev limits, increased volumetric efficiency, and better overall engine performance across a wider range of operating conditions.

One of the key features of the 2JZ DOHC system is its use of four valves per cylinder, with two intake and two exhaust valves. This configuration enhances airflow into and out of the combustion chamber, contributing to the engine's ability to produce high power outputs, especially when modified. The DOHC layout also facilitates the implementation of variable valve timing systems, such as Toyota's VVT-i (Variable Valve Timing with intelligence), which further optimizes engine performance and efficiency.

The 2JZ engine's DOHC design has proven to be exceptionally durable, even under high-stress conditions. This robustness has made it a favorite among tuners and racing enthusiasts, who often push the engine far beyond its stock power levels. The DOHC configuration's ability to maintain valve control at high RPMs has been instrumental in achieving these impressive power figures while maintaining reliability.

Over the years, the 2JZ DOHC system has undergone various refinements and modifications by both Toyota and aftermarket tuners. These improvements have focused on areas such as camshaft profiles, valve spring rates, and timing gear designs, all aimed at extracting even more performance from this already capable engine architecture.

The Dual Overhead Camshaft (DOHC) configuration in the 2JZ engine plays a crucial role in its power delivery and overall performance. This design features two camshafts located above the cylinder head, with one controlling the intake valves and the other managing the exhaust valves. This arrangement allows for more precise control over valve timing and lift, resulting in improved engine breathing and increased power output.

The implementation of DOHC in the 2JZ engine was a significant advancement over its predecessor, the 1JZ engine, which utilized a Single Overhead Camshaft (SOHC) design. The transition to DOHC allowed for higher rev limits, increased volumetric efficiency, and better overall engine performance across a wider range of operating conditions.

One of the key features of the 2JZ DOHC system is its use of four valves per cylinder, with two intake and two exhaust valves. This configuration enhances airflow into and out of the combustion chamber, contributing to the engine's ability to produce high power outputs, especially when modified. The DOHC layout also facilitates the implementation of variable valve timing systems, such as Toyota's VVT-i (Variable Valve Timing with intelligence), which further optimizes engine performance and efficiency.

The 2JZ engine's DOHC design has proven to be exceptionally durable, even under high-stress conditions. This robustness has made it a favorite among tuners and racing enthusiasts, who often push the engine far beyond its stock power levels. The DOHC configuration's ability to maintain valve control at high RPMs has been instrumental in achieving these impressive power figures while maintaining reliability.

Over the years, the 2JZ DOHC system has undergone various refinements and modifications by both Toyota and aftermarket tuners. These improvements have focused on areas such as camshaft profiles, valve spring rates, and timing gear designs, all aimed at extracting even more performance from this already capable engine architecture.

Market Demand Analysis

The market demand for dual overhead camshaft (DOHC) implementation in the 2JZ engine, particularly in the context of power delivery, has seen a significant surge in recent years. This demand is primarily driven by automotive enthusiasts, racing teams, and performance-oriented manufacturers seeking to extract maximum potential from the iconic 2JZ platform.

The 2JZ engine, originally developed by Toyota, has gained a cult following in the automotive world due to its robust design and high-performance capabilities. As the aftermarket performance industry continues to grow, there is an increasing demand for advanced engine technologies that can enhance power output, efficiency, and overall engine performance. The implementation of DOHC in the 2JZ engine addresses these market needs by offering improved valve control, higher rev limits, and increased power potential.

In the performance automotive sector, the global market for engine upgrades and modifications has been steadily expanding. This growth is fueled by a combination of factors, including the rising popularity of motorsports, the increasing number of car enthusiasts engaging in vehicle customization, and the continuous pursuit of improved engine performance across various automotive applications.

The demand for DOHC implementation in the 2JZ engine is not limited to a single geographic region. While traditionally strong in Japan and North America, there is a growing interest in Europe, Australia, and emerging markets in Southeast Asia. This global demand is reflected in the increasing number of aftermarket companies offering DOHC conversion kits and related components for the 2JZ engine.

Furthermore, the market demand extends beyond individual consumers and racing teams. There is a growing interest from niche vehicle manufacturers and restomodding companies looking to incorporate advanced engine technologies into their builds. These companies cater to high-end customers seeking unique, high-performance vehicles that combine classic aesthetics with modern engineering.

The demand for DOHC implementation in the 2JZ engine is also influenced by broader industry trends. As emissions regulations become stricter worldwide, there is an increasing focus on improving engine efficiency while maintaining or enhancing performance. DOHC technology, when properly implemented, can contribute to better fuel economy and reduced emissions without sacrificing power output, aligning with these industry-wide objectives.

In conclusion, the market demand for dual overhead camshaft implementation in 2JZ power delivery is robust and multifaceted. It is driven by a combination of enthusiast interest, racing applications, aftermarket industry growth, and the need for advanced engine technologies that can meet both performance and efficiency requirements. As the automotive landscape continues to evolve, the demand for such engine enhancements is expected to remain strong, presenting opportunities for further research, development, and innovation in this field.

The 2JZ engine, originally developed by Toyota, has gained a cult following in the automotive world due to its robust design and high-performance capabilities. As the aftermarket performance industry continues to grow, there is an increasing demand for advanced engine technologies that can enhance power output, efficiency, and overall engine performance. The implementation of DOHC in the 2JZ engine addresses these market needs by offering improved valve control, higher rev limits, and increased power potential.

In the performance automotive sector, the global market for engine upgrades and modifications has been steadily expanding. This growth is fueled by a combination of factors, including the rising popularity of motorsports, the increasing number of car enthusiasts engaging in vehicle customization, and the continuous pursuit of improved engine performance across various automotive applications.

The demand for DOHC implementation in the 2JZ engine is not limited to a single geographic region. While traditionally strong in Japan and North America, there is a growing interest in Europe, Australia, and emerging markets in Southeast Asia. This global demand is reflected in the increasing number of aftermarket companies offering DOHC conversion kits and related components for the 2JZ engine.

Furthermore, the market demand extends beyond individual consumers and racing teams. There is a growing interest from niche vehicle manufacturers and restomodding companies looking to incorporate advanced engine technologies into their builds. These companies cater to high-end customers seeking unique, high-performance vehicles that combine classic aesthetics with modern engineering.

The demand for DOHC implementation in the 2JZ engine is also influenced by broader industry trends. As emissions regulations become stricter worldwide, there is an increasing focus on improving engine efficiency while maintaining or enhancing performance. DOHC technology, when properly implemented, can contribute to better fuel economy and reduced emissions without sacrificing power output, aligning with these industry-wide objectives.

In conclusion, the market demand for dual overhead camshaft implementation in 2JZ power delivery is robust and multifaceted. It is driven by a combination of enthusiast interest, racing applications, aftermarket industry growth, and the need for advanced engine technologies that can meet both performance and efficiency requirements. As the automotive landscape continues to evolve, the demand for such engine enhancements is expected to remain strong, presenting opportunities for further research, development, and innovation in this field.

DOHC Tech Challenges

The implementation of Dual Overhead Camshaft (DOHC) technology in the 2JZ engine presents several significant technical challenges. One of the primary hurdles is the complex design and manufacturing process required for the cylinder head. The DOHC configuration necessitates a more intricate casting process to accommodate two separate camshafts, resulting in increased production costs and potential quality control issues.

Another challenge lies in the precise timing and synchronization of the two camshafts. The 2JZ engine's high-performance nature demands extremely accurate valve timing to optimize power delivery across a wide RPM range. Achieving this level of precision with two camshafts requires advanced engineering solutions, such as sophisticated cam phasing systems and robust timing chains or belts.

The increased weight of the DOHC system compared to a single overhead camshaft (SOHC) design poses challenges for overall engine balance and efficiency. Engineers must carefully consider weight distribution and its impact on the engine's center of gravity, potentially affecting vehicle handling characteristics. Additionally, the added weight can slightly reduce fuel efficiency, necessitating careful optimization of other engine components to maintain overall performance.

Thermal management presents another significant challenge in DOHC implementation. The presence of two camshafts and additional moving parts in the cylinder head increases heat generation. Effective cooling strategies must be developed to prevent overheating and ensure consistent performance, particularly under high-load conditions typical of the 2JZ's applications.

Maintenance and serviceability also become more complex with a DOHC system. The increased number of components, such as additional camshafts, lifters, and timing mechanisms, can lead to higher maintenance costs and more frequent service intervals. Ensuring easy access for routine maintenance and repairs without compromising the engine's compact design is a significant engineering challenge.

Lastly, integrating advanced technologies like variable valve timing (VVT) with a DOHC system adds another layer of complexity. While VVT can significantly enhance performance and efficiency, its implementation on both intake and exhaust camshafts requires sophisticated control systems and actuators, further complicating the engine's design and potentially increasing production costs.

Another challenge lies in the precise timing and synchronization of the two camshafts. The 2JZ engine's high-performance nature demands extremely accurate valve timing to optimize power delivery across a wide RPM range. Achieving this level of precision with two camshafts requires advanced engineering solutions, such as sophisticated cam phasing systems and robust timing chains or belts.

The increased weight of the DOHC system compared to a single overhead camshaft (SOHC) design poses challenges for overall engine balance and efficiency. Engineers must carefully consider weight distribution and its impact on the engine's center of gravity, potentially affecting vehicle handling characteristics. Additionally, the added weight can slightly reduce fuel efficiency, necessitating careful optimization of other engine components to maintain overall performance.

Thermal management presents another significant challenge in DOHC implementation. The presence of two camshafts and additional moving parts in the cylinder head increases heat generation. Effective cooling strategies must be developed to prevent overheating and ensure consistent performance, particularly under high-load conditions typical of the 2JZ's applications.

Maintenance and serviceability also become more complex with a DOHC system. The increased number of components, such as additional camshafts, lifters, and timing mechanisms, can lead to higher maintenance costs and more frequent service intervals. Ensuring easy access for routine maintenance and repairs without compromising the engine's compact design is a significant engineering challenge.

Lastly, integrating advanced technologies like variable valve timing (VVT) with a DOHC system adds another layer of complexity. While VVT can significantly enhance performance and efficiency, its implementation on both intake and exhaust camshafts requires sophisticated control systems and actuators, further complicating the engine's design and potentially increasing production costs.

Current DOHC Solutions

01 DOHC design for improved power delivery

The Dual Overhead Camshaft (DOHC) design in the 2JZ engine enhances power delivery by allowing for more precise control of valve timing and lift. This configuration enables better airflow management, resulting in improved engine performance across a wider RPM range.- DOHC configuration in 2JZ engine: The Dual Overhead Camshaft (DOHC) configuration in the 2JZ engine allows for improved valve control and timing, resulting in enhanced power delivery. This setup features two camshafts per cylinder bank, one controlling the intake valves and the other controlling the exhaust valves, enabling more precise valve actuation and higher engine speeds.

- Variable valve timing system: The 2JZ engine with DOHC may incorporate a variable valve timing system, which adjusts the timing of valve opening and closing based on engine speed and load. This technology optimizes power delivery across a wide range of operating conditions, improving both low-end torque and high-end power output.

- Intake and exhaust system design: The DOHC configuration in the 2JZ engine allows for optimized intake and exhaust port designs, enhancing airflow and exhaust gas evacuation. This improved breathing capability contributes to increased power output and better overall engine performance across the rev range.

- Camshaft profile and lift optimization: The DOHC layout in the 2JZ engine enables the use of specialized camshaft profiles and lift characteristics for both intake and exhaust valves. This optimization allows for improved valve control, resulting in enhanced combustion efficiency and power delivery throughout the engine's operating range.

- Engine management and tuning: The DOHC configuration in the 2JZ engine provides greater flexibility for engine management and tuning. Advanced engine control units can precisely adjust valve timing, fuel injection, and ignition timing to maximize power delivery and efficiency based on driving conditions and performance requirements.

02 Variable valve timing implementation

Incorporating variable valve timing (VVT) systems with the DOHC setup in the 2JZ engine further optimizes power delivery. VVT allows for dynamic adjustment of valve timing based on engine speed and load, enhancing both low-end torque and high-end power output.Expand Specific Solutions03 Camshaft profile optimization

Optimizing the camshaft profiles in the DOHC system of the 2JZ engine contributes to improved power delivery. Carefully designed lobe profiles can enhance valve lift characteristics, duration, and overlap, resulting in better combustion efficiency and increased power output across the engine's operating range.Expand Specific Solutions04 Integration of advanced materials

The use of advanced materials in the DOHC system of the 2JZ engine, such as lightweight alloys for camshafts and valve train components, reduces inertia and friction. This allows for higher engine speeds and quicker valve actuation, contributing to improved power delivery and overall engine efficiency.Expand Specific Solutions05 Optimized intake and exhaust systems

The DOHC configuration in the 2JZ engine allows for optimized intake and exhaust port designs, as well as improved manifold layouts. This enhances airflow efficiency, reduces pumping losses, and contributes to better cylinder filling and scavenging, ultimately improving power delivery across the engine's operating range.Expand Specific Solutions

Key Engine Manufacturers

The research on Dual Overhead Camshaft (DOHC) implementation in 2JZ power delivery is in a mature stage of development, with the technology widely adopted across the automotive industry. The market for DOHC engines is substantial, driven by the demand for high-performance and fuel-efficient vehicles. Key players in this field include Toyota Motor Corp., the original developer of the 2JZ engine, along with other major automotive manufacturers such as Honda Motor Co., Ltd., Ford Motor Co., and Mercedes-Benz Group AG. These companies have extensively refined DOHC technology, improving power output, efficiency, and reliability. The competitive landscape is characterized by ongoing innovation in materials, design, and integration with advanced engine management systems.

Honda Motor Co., Ltd.

Technical Solution: Honda's research on DOHC implementation focuses on their VTEC (Variable Valve Timing and Lift Electronic Control) technology, which has been adapted for various engine configurations. In the context of power delivery similar to the 2JZ, Honda's approach involves a DOHC system with three cam lobes per cylinder - two standard lobes for low-RPM operation and one high-performance lobe for high-RPM use[3]. This system allows for optimal valve timing and lift across the entire RPM range, enhancing both low-end torque and high-end power. Honda's implementation also includes advanced engine management systems that control valve timing, fuel injection, and ignition timing to maximize efficiency and power output. Recent developments have seen Honda integrate direct injection and turbocharging with their DOHC VTEC systems, further improving power density and fuel efficiency[4].

Strengths: Excellent balance of efficiency and performance, smooth power delivery across the RPM range. Weaknesses: Complexity of the VTEC system can increase production costs and potential for mechanical issues.

Toyota Motor Corp.

Technical Solution: Toyota, as the creator of the 2JZ engine, has pioneered the Dual Overhead Camshaft (DOHC) implementation in the 2JZ power delivery system. Their approach involves using two separate camshafts for intake and exhaust valves, allowing for more precise valve timing and higher rev limits. Toyota's DOHC design in the 2JZ features VVT-i (Variable Valve Timing with intelligence) technology, which adjusts valve timing based on engine speed and load, optimizing performance across the RPM range[1]. The 2JZ-GTE variant, in particular, utilizes a twin-turbo setup combined with the DOHC system, resulting in a robust and highly tunable engine capable of producing over 1,000 horsepower with modifications[2]. Toyota's implementation also includes a coil-on-plug ignition system and sequential fuel injection, further enhancing the engine's efficiency and power output.

Strengths: Exceptional durability, high tuning potential, and smooth power delivery. Weaknesses: Complexity of the DOHC system can lead to higher maintenance costs and potential timing issues if not properly maintained.

2JZ DOHC Innovations

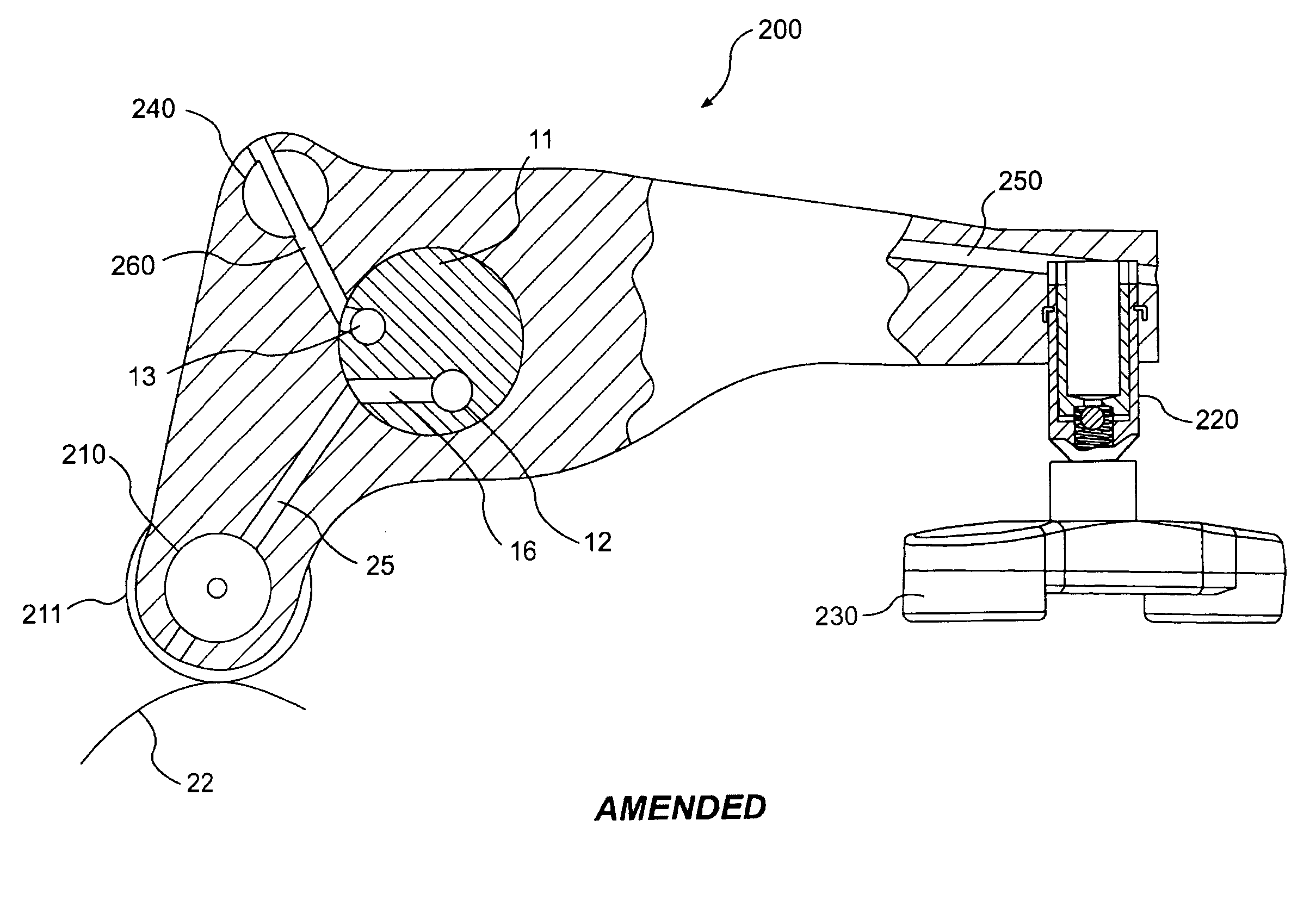

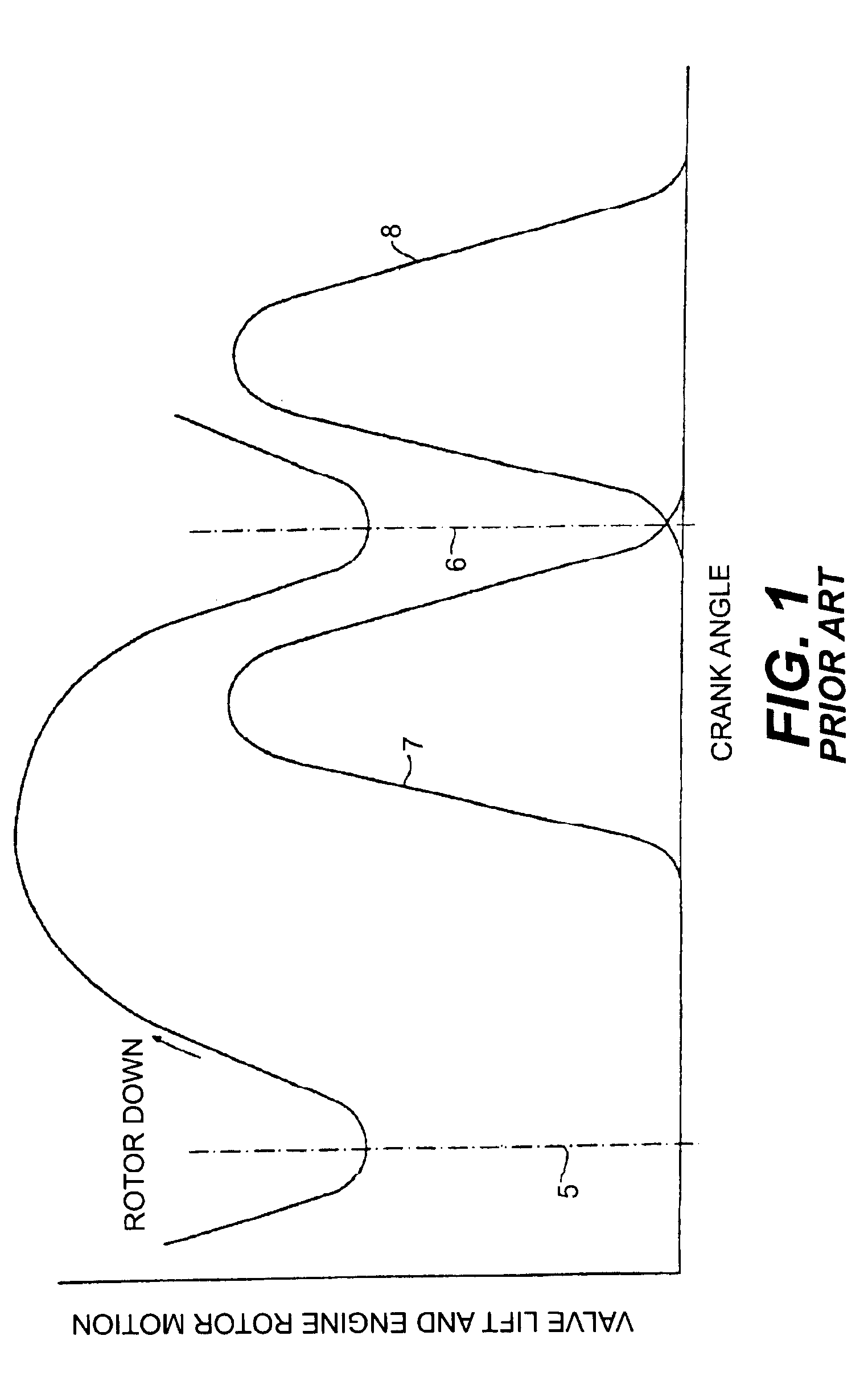

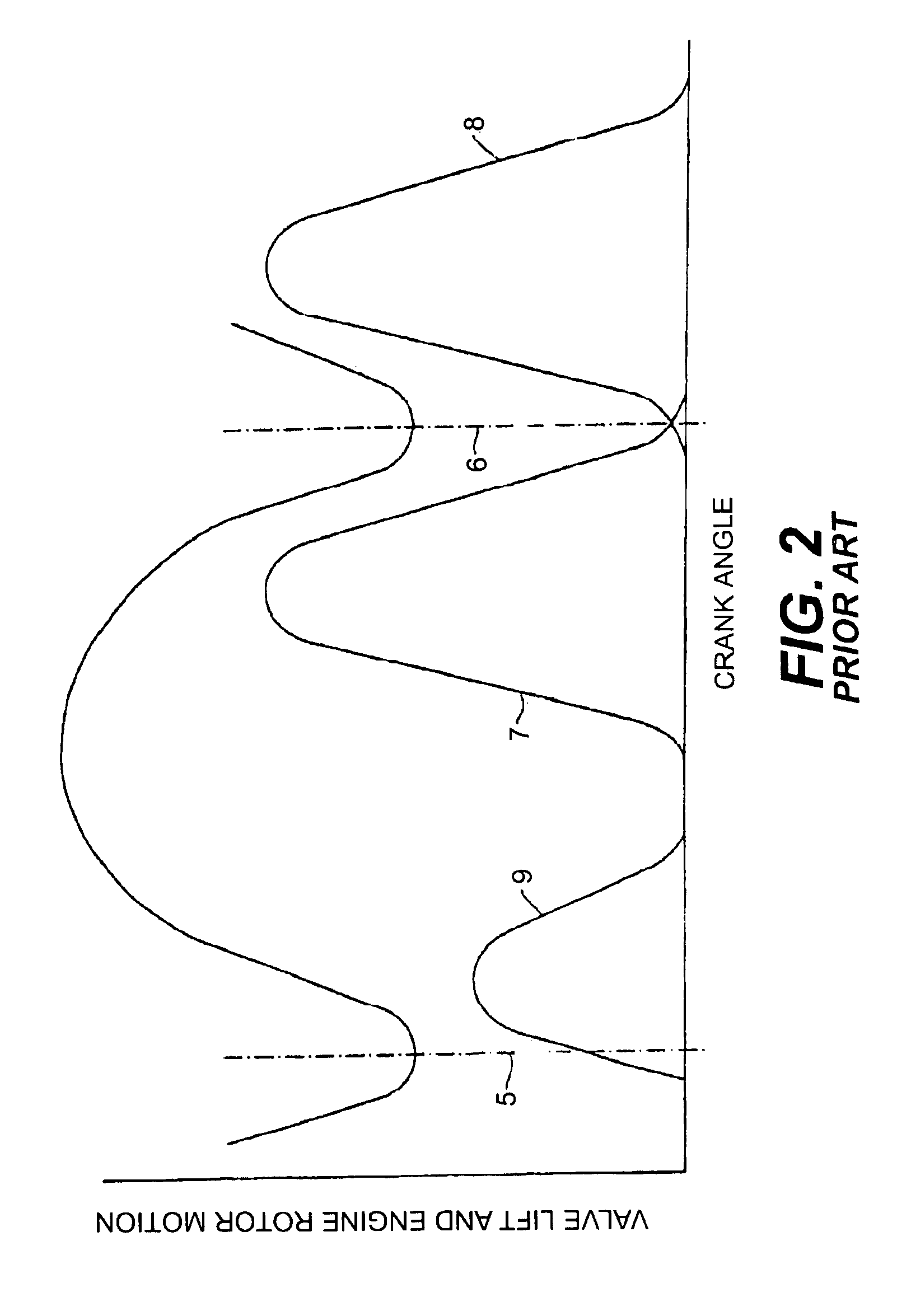

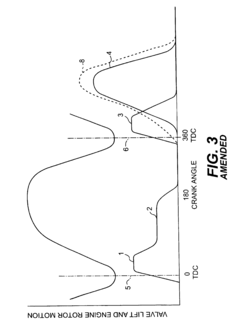

Multi-cycle, engine braking with positive power valve actuation control system and process for using the same

PatentInactiveUSRE39258E1

Innovation

- The system modifies the cam and rocker arms of an overhead cam engine to provide a dedicated cam lobe for braking, eliminating the classic compression release retarder housing and integrating the compression release retarder with the rocker arms, allowing for two braking events per engine revolution and incorporating exhaust gas recirculation to enhance retarding power.

Emissions Regulations

Emissions regulations have become increasingly stringent in recent years, significantly impacting the automotive industry and engine design. These regulations aim to reduce harmful emissions and improve air quality, forcing manufacturers to adapt their technologies, including those related to dual overhead camshaft (DOHC) implementations in engines like the 2JZ.

The implementation of DOHC in the 2JZ engine must comply with various emission standards, such as the Euro 6 in Europe, Tier 3 in the United States, and China 6 in China. These standards set limits on pollutants like carbon monoxide (CO), nitrogen oxides (NOx), and particulate matter (PM). To meet these requirements, manufacturers must optimize combustion efficiency and integrate advanced aftertreatment systems.

One of the key advantages of DOHC in the context of emissions regulations is its ability to provide precise control over valve timing and lift. This allows for better management of the air-fuel mixture and exhaust gas recirculation (EGR), which are crucial for reducing emissions. Variable valve timing (VVT) systems, often used in conjunction with DOHC, can further enhance emissions control by adjusting valve operation based on engine load and speed.

However, the complexity of DOHC systems can present challenges in meeting emissions targets. The increased number of moving parts and potential for oil consumption through valve stem seals may lead to higher particulate emissions over time. Manufacturers must address these issues through improved materials and design to ensure long-term compliance with emissions regulations.

The integration of direct fuel injection systems with DOHC engines has become a common strategy to meet emissions standards. This combination allows for more precise fuel metering and improved combustion efficiency, resulting in lower emissions and better fuel economy. In the case of the 2JZ engine, adapting direct injection technology to work with its DOHC layout would be a significant step towards meeting modern emissions requirements.

Emissions regulations also drive the development of hybrid and electrification technologies. While the 2JZ is primarily known as a conventional internal combustion engine, future iterations or derivatives may need to incorporate hybrid elements to comply with increasingly strict standards. This could involve integrating electric motors and advanced energy recovery systems to work in tandem with the DOHC configuration.

As emissions regulations continue to evolve, the future of DOHC implementations in engines like the 2JZ will likely involve a combination of advanced combustion strategies, sophisticated engine management systems, and integration with electrification technologies. Manufacturers will need to balance performance objectives with emissions compliance, potentially leading to innovative solutions that push the boundaries of internal combustion engine design.

The implementation of DOHC in the 2JZ engine must comply with various emission standards, such as the Euro 6 in Europe, Tier 3 in the United States, and China 6 in China. These standards set limits on pollutants like carbon monoxide (CO), nitrogen oxides (NOx), and particulate matter (PM). To meet these requirements, manufacturers must optimize combustion efficiency and integrate advanced aftertreatment systems.

One of the key advantages of DOHC in the context of emissions regulations is its ability to provide precise control over valve timing and lift. This allows for better management of the air-fuel mixture and exhaust gas recirculation (EGR), which are crucial for reducing emissions. Variable valve timing (VVT) systems, often used in conjunction with DOHC, can further enhance emissions control by adjusting valve operation based on engine load and speed.

However, the complexity of DOHC systems can present challenges in meeting emissions targets. The increased number of moving parts and potential for oil consumption through valve stem seals may lead to higher particulate emissions over time. Manufacturers must address these issues through improved materials and design to ensure long-term compliance with emissions regulations.

The integration of direct fuel injection systems with DOHC engines has become a common strategy to meet emissions standards. This combination allows for more precise fuel metering and improved combustion efficiency, resulting in lower emissions and better fuel economy. In the case of the 2JZ engine, adapting direct injection technology to work with its DOHC layout would be a significant step towards meeting modern emissions requirements.

Emissions regulations also drive the development of hybrid and electrification technologies. While the 2JZ is primarily known as a conventional internal combustion engine, future iterations or derivatives may need to incorporate hybrid elements to comply with increasingly strict standards. This could involve integrating electric motors and advanced energy recovery systems to work in tandem with the DOHC configuration.

As emissions regulations continue to evolve, the future of DOHC implementations in engines like the 2JZ will likely involve a combination of advanced combustion strategies, sophisticated engine management systems, and integration with electrification technologies. Manufacturers will need to balance performance objectives with emissions compliance, potentially leading to innovative solutions that push the boundaries of internal combustion engine design.

Performance Testing

Performance testing is a critical aspect of evaluating the effectiveness of the Dual Overhead Camshaft (DOHC) implementation in the 2JZ engine's power delivery system. This process involves a series of rigorous tests designed to measure and analyze various performance parameters under different operating conditions.

The testing methodology typically begins with dyno testing, where the engine is mounted on a dynamometer to measure its power output and torque curves across the entire RPM range. This provides baseline data for comparison with single overhead camshaft configurations and helps quantify the improvements achieved through the DOHC implementation.

Acceleration tests are conducted to assess the engine's responsiveness and power delivery characteristics. These tests include 0-60 mph, quarter-mile, and in-gear acceleration measurements. The data collected helps evaluate the DOHC system's impact on low-end torque, mid-range power, and top-end performance.

Fuel efficiency testing is another crucial component of the performance evaluation. This involves measuring fuel consumption under various driving conditions, including city, highway, and combined cycles. The results are compared with single overhead camshaft configurations to determine if the DOHC system offers any improvements in fuel economy.

Thermal management tests are conducted to assess the engine's ability to maintain optimal operating temperatures under high-load conditions. This is particularly important for the 2JZ engine, known for its high-performance capabilities. Temperature sensors are strategically placed to monitor critical components, ensuring the DOHC implementation does not introduce any cooling challenges.

Durability testing is performed to evaluate the long-term reliability of the DOHC system. This involves extended running periods under various load conditions, simulating real-world usage scenarios. The engine is periodically inspected for wear and tear, with particular attention paid to the camshaft lobes, valve train components, and timing chain system.

Noise, Vibration, and Harshness (NVH) testing is carried out to assess the acoustic and vibrational characteristics of the DOHC implementation. This ensures that the new configuration does not introduce undesirable noise or vibrations that could negatively impact the driving experience.

Finally, emissions testing is conducted to verify that the DOHC system meets or exceeds current environmental regulations. This involves measuring exhaust gases under various operating conditions and comparing the results with regulatory standards and single overhead camshaft configurations.

The testing methodology typically begins with dyno testing, where the engine is mounted on a dynamometer to measure its power output and torque curves across the entire RPM range. This provides baseline data for comparison with single overhead camshaft configurations and helps quantify the improvements achieved through the DOHC implementation.

Acceleration tests are conducted to assess the engine's responsiveness and power delivery characteristics. These tests include 0-60 mph, quarter-mile, and in-gear acceleration measurements. The data collected helps evaluate the DOHC system's impact on low-end torque, mid-range power, and top-end performance.

Fuel efficiency testing is another crucial component of the performance evaluation. This involves measuring fuel consumption under various driving conditions, including city, highway, and combined cycles. The results are compared with single overhead camshaft configurations to determine if the DOHC system offers any improvements in fuel economy.

Thermal management tests are conducted to assess the engine's ability to maintain optimal operating temperatures under high-load conditions. This is particularly important for the 2JZ engine, known for its high-performance capabilities. Temperature sensors are strategically placed to monitor critical components, ensuring the DOHC implementation does not introduce any cooling challenges.

Durability testing is performed to evaluate the long-term reliability of the DOHC system. This involves extended running periods under various load conditions, simulating real-world usage scenarios. The engine is periodically inspected for wear and tear, with particular attention paid to the camshaft lobes, valve train components, and timing chain system.

Noise, Vibration, and Harshness (NVH) testing is carried out to assess the acoustic and vibrational characteristics of the DOHC implementation. This ensures that the new configuration does not introduce undesirable noise or vibrations that could negatively impact the driving experience.

Finally, emissions testing is conducted to verify that the DOHC system meets or exceeds current environmental regulations. This involves measuring exhaust gases under various operating conditions and comparing the results with regulatory standards and single overhead camshaft configurations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!