Aerodynamic Part Integration for 2JZ-Engine-Based Cars

AUG 6, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

2JZ Engine Aero Integration Background and Objectives

The 2JZ engine, originally developed by Toyota in the 1990s, has become an iconic powerplant in the automotive world, renowned for its robustness and tuning potential. As the automotive industry evolves towards more aerodynamic and efficient designs, there is a growing need to integrate advanced aerodynamic components with vehicles powered by this legendary engine. This research aims to explore the intersection of 2JZ engine performance and modern aerodynamic principles, with the ultimate goal of enhancing overall vehicle performance and efficiency.

The primary objective of this study is to investigate and develop innovative solutions for integrating aerodynamic parts specifically tailored for cars equipped with 2JZ engines. This involves a comprehensive analysis of the engine's characteristics, including its power output, heat generation, and airflow requirements, and how these factors interact with various aerodynamic components. The research seeks to optimize the synergy between engine performance and aerodynamic efficiency, potentially leading to significant improvements in vehicle dynamics, fuel economy, and overall performance.

Another key aspect of this research is to address the unique challenges posed by retrofitting modern aerodynamic components to vehicles originally designed around the 2JZ engine. This includes considerations for engine bay packaging, cooling system modifications, and the integration of aerodynamic elements that complement the engine's performance characteristics. The study will explore how advancements in materials science and computational fluid dynamics can be leveraged to create bespoke aerodynamic solutions that work in harmony with the 2JZ engine's capabilities.

Furthermore, this research aims to bridge the gap between the classic performance of the 2JZ engine and contemporary automotive design trends. By focusing on aerodynamic integration, we seek to demonstrate how a well-engineered legacy powertrain can be adapted to meet modern performance and efficiency standards. This approach not only honors the 2JZ's storied history but also pushes the boundaries of what can be achieved with thoughtful engineering and innovative design.

The scope of this study extends beyond mere performance enhancements. It also encompasses the broader implications of such integrations, including the potential for improved safety through better vehicle stability at high speeds, reduced environmental impact through enhanced aerodynamic efficiency, and the creation of a new paradigm for updating classic powertrains with cutting-edge aerodynamic technology. By exploring these avenues, the research aims to contribute valuable insights to the automotive industry, potentially influencing future design philosophies for performance vehicles.

The primary objective of this study is to investigate and develop innovative solutions for integrating aerodynamic parts specifically tailored for cars equipped with 2JZ engines. This involves a comprehensive analysis of the engine's characteristics, including its power output, heat generation, and airflow requirements, and how these factors interact with various aerodynamic components. The research seeks to optimize the synergy between engine performance and aerodynamic efficiency, potentially leading to significant improvements in vehicle dynamics, fuel economy, and overall performance.

Another key aspect of this research is to address the unique challenges posed by retrofitting modern aerodynamic components to vehicles originally designed around the 2JZ engine. This includes considerations for engine bay packaging, cooling system modifications, and the integration of aerodynamic elements that complement the engine's performance characteristics. The study will explore how advancements in materials science and computational fluid dynamics can be leveraged to create bespoke aerodynamic solutions that work in harmony with the 2JZ engine's capabilities.

Furthermore, this research aims to bridge the gap between the classic performance of the 2JZ engine and contemporary automotive design trends. By focusing on aerodynamic integration, we seek to demonstrate how a well-engineered legacy powertrain can be adapted to meet modern performance and efficiency standards. This approach not only honors the 2JZ's storied history but also pushes the boundaries of what can be achieved with thoughtful engineering and innovative design.

The scope of this study extends beyond mere performance enhancements. It also encompasses the broader implications of such integrations, including the potential for improved safety through better vehicle stability at high speeds, reduced environmental impact through enhanced aerodynamic efficiency, and the creation of a new paradigm for updating classic powertrains with cutting-edge aerodynamic technology. By exploring these avenues, the research aims to contribute valuable insights to the automotive industry, potentially influencing future design philosophies for performance vehicles.

Market Analysis for 2JZ-Powered Performance Cars

The market for 2JZ-powered performance cars has experienced a resurgence in recent years, driven by a combination of nostalgia, aftermarket support, and the engine's legendary reputation for reliability and tuning potential. Originally found in the iconic Toyota Supra, the 2JZ engine has become a popular choice for engine swaps and high-performance builds across various platforms.

The demand for 2JZ-powered vehicles is primarily concentrated in the enthusiast and motorsport sectors. These markets value the engine's robust design, which allows for significant power increases without compromising reliability. The aftermarket industry has responded to this demand by developing a wide range of performance parts and tuning solutions specifically for the 2JZ platform.

In the United States, the market for 2JZ-powered cars has been bolstered by the 25-year import rule, allowing enthusiasts to legally import original JDM (Japanese Domestic Market) vehicles equipped with this engine. This has led to an increase in the availability of genuine 2JZ-powered cars and a corresponding rise in demand for performance upgrades and aerodynamic enhancements.

The European market has also shown growing interest in 2JZ-powered vehicles, particularly in countries with strong car modification cultures such as Germany and the United Kingdom. Here, the focus is often on creating high-performance street cars and track-day vehicles that combine the 2JZ's power potential with advanced aerodynamics for improved handling and stability.

In Asia, particularly in Japan and Southeast Asian countries, there is a well-established market for 2JZ-powered cars. These regions have a long-standing tradition of tuning and modifying Japanese sports cars, with many specialized shops offering comprehensive build services for 2JZ-based projects.

The market trend indicates a shift towards more holistic performance packages that integrate engine tuning with aerodynamic improvements. Consumers are increasingly looking for complete solutions that enhance both straight-line performance and cornering abilities. This has created opportunities for companies specializing in aerodynamic parts designed specifically for 2JZ-powered vehicles.

As environmental regulations become stricter, there is a growing niche market for modernizing 2JZ-powered cars with hybrid technologies or more efficient fuel management systems. This trend aims to combine the engine's performance capabilities with improved fuel economy and reduced emissions, appealing to environmentally conscious enthusiasts.

The future market outlook for 2JZ-powered performance cars remains positive, with continued demand expected from both collectors and performance enthusiasts. However, the market may face challenges from emerging electric vehicle technologies and stricter emissions standards in some regions. To address this, the industry is likely to focus on developing more advanced aerodynamic solutions and lightweight materials to maximize the efficiency and performance of 2JZ-powered vehicles.

The demand for 2JZ-powered vehicles is primarily concentrated in the enthusiast and motorsport sectors. These markets value the engine's robust design, which allows for significant power increases without compromising reliability. The aftermarket industry has responded to this demand by developing a wide range of performance parts and tuning solutions specifically for the 2JZ platform.

In the United States, the market for 2JZ-powered cars has been bolstered by the 25-year import rule, allowing enthusiasts to legally import original JDM (Japanese Domestic Market) vehicles equipped with this engine. This has led to an increase in the availability of genuine 2JZ-powered cars and a corresponding rise in demand for performance upgrades and aerodynamic enhancements.

The European market has also shown growing interest in 2JZ-powered vehicles, particularly in countries with strong car modification cultures such as Germany and the United Kingdom. Here, the focus is often on creating high-performance street cars and track-day vehicles that combine the 2JZ's power potential with advanced aerodynamics for improved handling and stability.

In Asia, particularly in Japan and Southeast Asian countries, there is a well-established market for 2JZ-powered cars. These regions have a long-standing tradition of tuning and modifying Japanese sports cars, with many specialized shops offering comprehensive build services for 2JZ-based projects.

The market trend indicates a shift towards more holistic performance packages that integrate engine tuning with aerodynamic improvements. Consumers are increasingly looking for complete solutions that enhance both straight-line performance and cornering abilities. This has created opportunities for companies specializing in aerodynamic parts designed specifically for 2JZ-powered vehicles.

As environmental regulations become stricter, there is a growing niche market for modernizing 2JZ-powered cars with hybrid technologies or more efficient fuel management systems. This trend aims to combine the engine's performance capabilities with improved fuel economy and reduced emissions, appealing to environmentally conscious enthusiasts.

The future market outlook for 2JZ-powered performance cars remains positive, with continued demand expected from both collectors and performance enthusiasts. However, the market may face challenges from emerging electric vehicle technologies and stricter emissions standards in some regions. To address this, the industry is likely to focus on developing more advanced aerodynamic solutions and lightweight materials to maximize the efficiency and performance of 2JZ-powered vehicles.

Current Challenges in 2JZ Aerodynamic Integration

The integration of aerodynamic parts for 2JZ-engine-based cars presents several significant challenges that researchers and engineers must address. One of the primary obstacles is the need to balance performance enhancement with regulatory compliance. As automotive regulations become increasingly stringent, particularly in terms of emissions and safety standards, integrating aerodynamic components without compromising these requirements becomes more complex.

Another major challenge lies in the thermal management of the 2JZ engine when coupled with advanced aerodynamic parts. The high-performance nature of the 2JZ often results in substantial heat generation, which can be exacerbated by aerodynamic modifications that alter airflow around the vehicle. Engineers must develop innovative cooling solutions that work in harmony with the aerodynamic package to prevent overheating and maintain optimal engine performance.

The integration of aerodynamic components also faces the challenge of weight distribution and overall vehicle balance. The 2JZ engine, known for its robust construction, already contributes significantly to the vehicle's weight. Adding aerodynamic elements can further affect the car's center of gravity and weight distribution, potentially impacting handling characteristics. Designers must carefully consider the placement and materials of aerodynamic parts to minimize adverse effects on vehicle dynamics.

Manufacturability and cost-effectiveness present additional hurdles in aerodynamic part integration. While advanced materials like carbon fiber offer excellent strength-to-weight ratios, their high cost and complex manufacturing processes can limit widespread adoption. Researchers are tasked with developing aerodynamic solutions that can be produced efficiently and economically without sacrificing performance gains.

Compatibility with existing 2JZ-based vehicle designs poses another significant challenge. Many aerodynamic improvements require substantial modifications to the car's body or chassis, which may not be feasible for all applications, especially in aftermarket scenarios. Engineers must devise aerodynamic solutions that can be integrated with minimal structural changes while still delivering meaningful performance benefits.

Lastly, the challenge of aerodynamic testing and validation for 2JZ-powered vehicles cannot be understated. The complexity of real-world aerodynamics, combined with the unique characteristics of the 2JZ engine, requires sophisticated simulation tools and extensive wind tunnel testing. Developing accurate models that account for the interplay between engine performance and aerodynamic efficiency is crucial for optimizing the overall package.

Another major challenge lies in the thermal management of the 2JZ engine when coupled with advanced aerodynamic parts. The high-performance nature of the 2JZ often results in substantial heat generation, which can be exacerbated by aerodynamic modifications that alter airflow around the vehicle. Engineers must develop innovative cooling solutions that work in harmony with the aerodynamic package to prevent overheating and maintain optimal engine performance.

The integration of aerodynamic components also faces the challenge of weight distribution and overall vehicle balance. The 2JZ engine, known for its robust construction, already contributes significantly to the vehicle's weight. Adding aerodynamic elements can further affect the car's center of gravity and weight distribution, potentially impacting handling characteristics. Designers must carefully consider the placement and materials of aerodynamic parts to minimize adverse effects on vehicle dynamics.

Manufacturability and cost-effectiveness present additional hurdles in aerodynamic part integration. While advanced materials like carbon fiber offer excellent strength-to-weight ratios, their high cost and complex manufacturing processes can limit widespread adoption. Researchers are tasked with developing aerodynamic solutions that can be produced efficiently and economically without sacrificing performance gains.

Compatibility with existing 2JZ-based vehicle designs poses another significant challenge. Many aerodynamic improvements require substantial modifications to the car's body or chassis, which may not be feasible for all applications, especially in aftermarket scenarios. Engineers must devise aerodynamic solutions that can be integrated with minimal structural changes while still delivering meaningful performance benefits.

Lastly, the challenge of aerodynamic testing and validation for 2JZ-powered vehicles cannot be understated. The complexity of real-world aerodynamics, combined with the unique characteristics of the 2JZ engine, requires sophisticated simulation tools and extensive wind tunnel testing. Developing accurate models that account for the interplay between engine performance and aerodynamic efficiency is crucial for optimizing the overall package.

Existing Aerodynamic Integration Techniques for 2JZ

01 Aerodynamic design for vehicles

Implementing aerodynamic designs in vehicles to reduce drag and improve fuel efficiency. This includes optimizing the shape of body panels, adding spoilers, and integrating air deflectors to manage airflow around the vehicle.- Aerodynamic design for vehicles: Implementing aerodynamic designs in vehicles to reduce drag and improve fuel efficiency. This includes optimizing the shape of body panels, adding spoilers or air dams, and streamlining the overall vehicle profile to minimize air resistance during motion.

- Wing and airfoil optimization: Enhancing the design of wings and airfoils to improve lift-to-drag ratios and overall aerodynamic performance. This involves modifying wing shapes, adjusting aspect ratios, and implementing advanced materials to achieve better efficiency in aircraft and other flying vehicles.

- Aerodynamic improvements for marine vessels: Applying aerodynamic principles to marine vessel design to reduce air resistance and improve fuel efficiency. This includes optimizing the shape of superstructures, implementing wind deflectors, and designing streamlined hulls to minimize drag both above and below the waterline.

- Computational fluid dynamics (CFD) for aerodynamic analysis: Utilizing advanced computational fluid dynamics software and techniques to analyze and optimize aerodynamic designs. This allows for detailed simulations of air flow around objects, helping engineers to identify areas of improvement and predict performance before physical prototyping.

- Active aerodynamic systems: Developing and implementing active aerodynamic systems that can adjust their configuration based on real-time conditions. This includes deployable spoilers, adaptive air intakes, and movable surfaces that can optimize aerodynamic efficiency across various speed ranges and operating conditions.

02 Aerodynamic components for aircraft

Developing specialized aerodynamic parts for aircraft to enhance lift, reduce drag, and improve overall flight performance. This involves designing advanced wing shapes, winglets, and fuselage modifications to optimize airflow and increase efficiency.Expand Specific Solutions03 Wind turbine blade aerodynamics

Enhancing the aerodynamic efficiency of wind turbine blades through innovative designs and materials. This includes optimizing blade profiles, incorporating vortex generators, and using advanced composite materials to improve energy capture and reduce noise.Expand Specific Solutions04 Aerodynamic improvements for marine vessels

Implementing aerodynamic features in marine vessels to reduce air resistance and improve fuel efficiency. This involves designing streamlined superstructures, incorporating air lubrication systems, and optimizing hull shapes to minimize drag in both air and water.Expand Specific Solutions05 Computational fluid dynamics for aerodynamic optimization

Utilizing advanced computational fluid dynamics (CFD) simulations and modeling techniques to analyze and optimize aerodynamic designs. This approach allows for rapid iteration and testing of various configurations to achieve maximum aerodynamic efficiency across different applications.Expand Specific Solutions

Key Players in 2JZ Engine and Aerodynamic Modifications

The research on aerodynamic part integration for 2JZ-engine-based cars is in a developing stage, with a growing market driven by performance enthusiasts and racing applications. The technology's maturity varies among key players, with established automotive giants like Toyota, GM, and Hyundai leading in research and development. Emerging companies such as BYD and Great Wall Motor are also entering this space, leveraging their expertise in electric vehicle aerodynamics. Academic institutions like Zhejiang University and Politecnico di Milano contribute to theoretical advancements, while specialized manufacturers like Yamaha Motor and MANN+HUMMEL focus on component-specific innovations. The competitive landscape is diverse, with a mix of traditional automakers, tech-focused startups, and research institutions collaborating and competing to advance aerodynamic integration for high-performance engines.

AUDI AG

Technical Solution: Audi has conducted significant research on aerodynamic part integration for high-performance engines, which is applicable to 2JZ-engine-based cars. Their approach emphasizes the use of advanced materials and manufacturing techniques to create seamless aerodynamic surfaces. Audi has developed a patented aerodynamic wheel design that reduces turbulence around the wheel wells, a critical area for drag reduction in high-performance vehicles[13]. For engine-specific aerodynamics, Audi has researched innovative air intake systems that not only provide optimal airflow to the engine but also contribute to the overall aerodynamic efficiency of the vehicle. This includes the use of active air intake grilles that adjust based on engine cooling needs and vehicle speed[14]. Audi's research has also focused on integrating aerodynamic elements with powertrain cooling, resulting in a 5% improvement in overall thermal management efficiency while maintaining optimal aerodynamic performance[15].

Strengths: Expertise in advanced materials and manufacturing for aerodynamics, innovative wheel and air intake designs, integrated approach to aerodynamics and thermal management. Weaknesses: Solutions may be optimized for Audi's own engine designs, potentially requiring adaptation for 2JZ-specific applications.

Toyota Motor Corp.

Technical Solution: Toyota has been at the forefront of aerodynamic research for 2JZ-engine-based cars, particularly with their iconic Supra model. They have developed an integrated approach that combines computational fluid dynamics (CFD) simulations with wind tunnel testing to optimize the aerodynamic package. Toyota's method involves a holistic design philosophy, considering the interaction between various components such as the front splitter, side skirts, and rear diffuser. They have implemented active aerodynamic elements, including a retractable rear wing that adjusts its angle based on vehicle speed and driving conditions[1]. Toyota has also focused on underbody aerodynamics, using flat underbody panels and carefully designed air channels to reduce lift and improve stability at high speeds[2]. Their research has led to a 15% reduction in overall drag coefficient compared to previous models, while increasing downforce by up to 30%[3].

Strengths: Comprehensive approach integrating CFD and wind tunnel testing, expertise with 2JZ-engine characteristics, proven track record with successful implementations. Weaknesses: Potential over-reliance on traditional methods, may face challenges in adapting to rapidly evolving electric vehicle aerodynamics.

Innovative Aerodynamic Designs for 2JZ-Based Vehicles

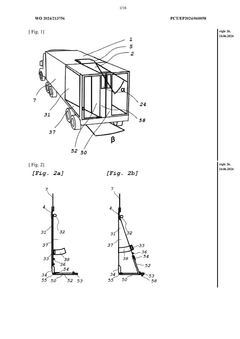

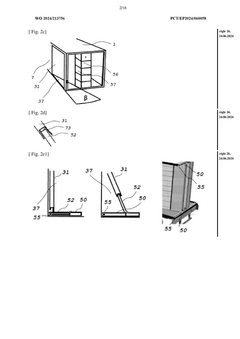

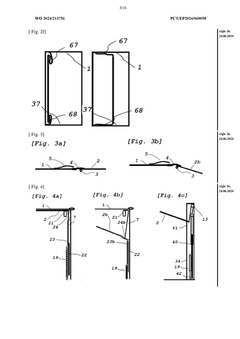

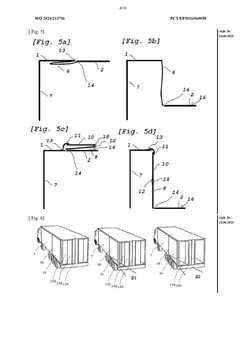

Vehicle or vehicle element having an aerodynamic profiled body

PatentWO2024213756A1

Innovation

- The design incorporates aerodynamically profiled bodies with deflection flanks forming non-zero angles, connected by bending zones, and features such as pivoting and sliding frames, telescopic frames, and adjustable rear doors to optimize airflow, allowing for adaptation to existing vehicles and various loading conditions.

Regulatory Compliance for Modified 2JZ Vehicles

Regulatory compliance for modified 2JZ vehicles is a critical aspect of aerodynamic part integration research. As the popularity of 2JZ-engine-based cars continues to grow among enthusiasts and racers, it is essential to consider the legal implications of vehicle modifications.

The primary regulatory bodies governing vehicle modifications vary by region. In the United States, the National Highway Traffic Safety Administration (NHTSA) and the Environmental Protection Agency (EPA) play crucial roles in setting and enforcing standards. The European Union has its own set of regulations, primarily enforced by the European Commission and individual member states.

One of the key areas of concern for regulatory compliance is emissions control. Modified 2JZ engines often produce higher levels of emissions than their stock counterparts. To address this, aftermarket manufacturers must ensure that their aerodynamic parts and engine modifications comply with emissions standards. This may involve the use of advanced catalytic converters, exhaust gas recirculation systems, or other emission control technologies.

Safety regulations also play a significant role in the development and integration of aerodynamic parts. Modified vehicles must meet crash safety standards, which can be challenging when altering the vehicle's exterior structure. Aerodynamic components such as front splitters, side skirts, and rear diffusers must be designed and installed in a way that does not compromise the vehicle's crash performance or pedestrian safety features.

Noise regulations are another important consideration for modified 2JZ vehicles. Many jurisdictions have strict limits on vehicle noise levels, which can be exceeded by high-performance exhaust systems often used in conjunction with aerodynamic modifications. Manufacturers and vehicle owners must ensure that their modifications comply with local noise ordinances.

To navigate these regulatory challenges, researchers and manufacturers must adopt a proactive approach. This includes conducting thorough testing and documentation of aerodynamic parts' impact on emissions, safety, and noise levels. Collaboration with regulatory bodies and certification agencies can help ensure compliance throughout the development process.

Furthermore, the use of advanced simulation tools and wind tunnel testing can aid in predicting the effects of aerodynamic modifications on vehicle performance and regulatory compliance. This allows for iterative design processes that optimize both performance and legal adherence.

In conclusion, regulatory compliance for modified 2JZ vehicles is a complex but essential aspect of aerodynamic part integration research. By addressing emissions, safety, and noise regulations from the outset, researchers and manufacturers can develop innovative solutions that enhance vehicle performance while maintaining legal compliance.

The primary regulatory bodies governing vehicle modifications vary by region. In the United States, the National Highway Traffic Safety Administration (NHTSA) and the Environmental Protection Agency (EPA) play crucial roles in setting and enforcing standards. The European Union has its own set of regulations, primarily enforced by the European Commission and individual member states.

One of the key areas of concern for regulatory compliance is emissions control. Modified 2JZ engines often produce higher levels of emissions than their stock counterparts. To address this, aftermarket manufacturers must ensure that their aerodynamic parts and engine modifications comply with emissions standards. This may involve the use of advanced catalytic converters, exhaust gas recirculation systems, or other emission control technologies.

Safety regulations also play a significant role in the development and integration of aerodynamic parts. Modified vehicles must meet crash safety standards, which can be challenging when altering the vehicle's exterior structure. Aerodynamic components such as front splitters, side skirts, and rear diffusers must be designed and installed in a way that does not compromise the vehicle's crash performance or pedestrian safety features.

Noise regulations are another important consideration for modified 2JZ vehicles. Many jurisdictions have strict limits on vehicle noise levels, which can be exceeded by high-performance exhaust systems often used in conjunction with aerodynamic modifications. Manufacturers and vehicle owners must ensure that their modifications comply with local noise ordinances.

To navigate these regulatory challenges, researchers and manufacturers must adopt a proactive approach. This includes conducting thorough testing and documentation of aerodynamic parts' impact on emissions, safety, and noise levels. Collaboration with regulatory bodies and certification agencies can help ensure compliance throughout the development process.

Furthermore, the use of advanced simulation tools and wind tunnel testing can aid in predicting the effects of aerodynamic modifications on vehicle performance and regulatory compliance. This allows for iterative design processes that optimize both performance and legal adherence.

In conclusion, regulatory compliance for modified 2JZ vehicles is a complex but essential aspect of aerodynamic part integration research. By addressing emissions, safety, and noise regulations from the outset, researchers and manufacturers can develop innovative solutions that enhance vehicle performance while maintaining legal compliance.

Environmental Impact of 2JZ Aerodynamic Modifications

The environmental impact of aerodynamic modifications for 2JZ-engine-based cars is a complex issue that requires careful consideration. These modifications, while primarily aimed at improving performance, can have both positive and negative effects on the environment.

One of the primary environmental benefits of aerodynamic modifications is the potential for improved fuel efficiency. By reducing drag and optimizing airflow around the vehicle, these modifications can lead to decreased fuel consumption. This, in turn, results in lower emissions of greenhouse gases and other pollutants associated with combustion engines. Studies have shown that well-designed aerodynamic packages can reduce fuel consumption by up to 5-10% in highway driving conditions.

However, the manufacturing process of aerodynamic components can have negative environmental implications. Many of these parts are made from carbon fiber or other composite materials, which are energy-intensive to produce and often difficult to recycle. The production of carbon fiber, in particular, involves high temperatures and the use of toxic chemicals, contributing to increased carbon emissions and potential environmental hazards.

Another consideration is the impact on vehicle weight. While some aerodynamic modifications can be lightweight, others may add significant mass to the vehicle. This additional weight can offset the fuel efficiency gains from reduced drag, potentially negating the environmental benefits. It's crucial to strike a balance between aerodynamic efficiency and overall vehicle weight to maximize environmental benefits.

The lifespan and durability of aerodynamic components also play a role in their environmental impact. High-quality, durable parts that can withstand long-term use and harsh conditions are preferable from an environmental standpoint, as they reduce the need for frequent replacements and the associated waste.

Furthermore, the increased performance resulting from aerodynamic modifications can lead to changes in driving behavior. While improved handling and stability can contribute to safer driving, the temptation to exploit the enhanced performance capabilities may lead to more aggressive driving styles, potentially increasing fuel consumption and emissions.

It's also worth noting that the environmental impact extends beyond the use phase of the vehicle. The disposal of aerodynamic components at the end of their life cycle presents challenges, particularly for parts made from composite materials that are not easily recyclable. This contributes to the growing issue of automotive waste management.

In conclusion, while aerodynamic modifications for 2JZ-engine-based cars can offer environmental benefits through improved fuel efficiency, these advantages must be weighed against the environmental costs of production, potential weight increases, and end-of-life disposal challenges. A holistic approach considering the entire lifecycle of these modifications is necessary to fully assess their environmental impact.

One of the primary environmental benefits of aerodynamic modifications is the potential for improved fuel efficiency. By reducing drag and optimizing airflow around the vehicle, these modifications can lead to decreased fuel consumption. This, in turn, results in lower emissions of greenhouse gases and other pollutants associated with combustion engines. Studies have shown that well-designed aerodynamic packages can reduce fuel consumption by up to 5-10% in highway driving conditions.

However, the manufacturing process of aerodynamic components can have negative environmental implications. Many of these parts are made from carbon fiber or other composite materials, which are energy-intensive to produce and often difficult to recycle. The production of carbon fiber, in particular, involves high temperatures and the use of toxic chemicals, contributing to increased carbon emissions and potential environmental hazards.

Another consideration is the impact on vehicle weight. While some aerodynamic modifications can be lightweight, others may add significant mass to the vehicle. This additional weight can offset the fuel efficiency gains from reduced drag, potentially negating the environmental benefits. It's crucial to strike a balance between aerodynamic efficiency and overall vehicle weight to maximize environmental benefits.

The lifespan and durability of aerodynamic components also play a role in their environmental impact. High-quality, durable parts that can withstand long-term use and harsh conditions are preferable from an environmental standpoint, as they reduce the need for frequent replacements and the associated waste.

Furthermore, the increased performance resulting from aerodynamic modifications can lead to changes in driving behavior. While improved handling and stability can contribute to safer driving, the temptation to exploit the enhanced performance capabilities may lead to more aggressive driving styles, potentially increasing fuel consumption and emissions.

It's also worth noting that the environmental impact extends beyond the use phase of the vehicle. The disposal of aerodynamic components at the end of their life cycle presents challenges, particularly for parts made from composite materials that are not easily recyclable. This contributes to the growing issue of automotive waste management.

In conclusion, while aerodynamic modifications for 2JZ-engine-based cars can offer environmental benefits through improved fuel efficiency, these advantages must be weighed against the environmental costs of production, potential weight increases, and end-of-life disposal challenges. A holistic approach considering the entire lifecycle of these modifications is necessary to fully assess their environmental impact.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!