The Science of Precision Machining in 2JZ Crankshafts

SEP 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

2JZ Crankshaft Evolution

The evolution of the 2JZ crankshaft is a testament to the advancements in precision machining and automotive engineering. Initially designed for Toyota's iconic 2JZ engine in the early 1990s, this crankshaft has undergone significant improvements over the years, reflecting the changing demands of high-performance engines and the capabilities of modern manufacturing techniques.

In its early iterations, the 2JZ crankshaft was primarily focused on reliability and durability to support the engine's robust design. Manufactured using traditional forging methods, these crankshafts were capable of handling the stock power output of the 2JZ engine, which ranged from 220 to 320 horsepower depending on the variant.

As the tuning community began to push the limits of the 2JZ engine, the demand for stronger crankshafts grew. This led to the development of aftermarket crankshafts in the late 1990s and early 2000s. These components were often made from higher-grade materials such as 4340 chromoly steel, offering improved strength and resistance to fatigue under high-stress conditions.

The mid-2000s saw a shift towards more advanced manufacturing processes. Computer Numerical Control (CNC) machining became increasingly prevalent, allowing for tighter tolerances and more complex designs. This era marked the introduction of lightweight crankshafts that maintained strength while reducing rotational mass, contributing to faster engine response and higher rev limits.

By the 2010s, the focus shifted to optimizing the crankshaft's design for specific power goals. Manufacturers began offering a range of stroke lengths, allowing engine builders to fine-tune displacement and power characteristics. Additionally, innovations in surface treatments, such as nitridation and micro-polishing, were introduced to enhance durability and reduce friction.

Recent years have seen the integration of computational fluid dynamics (CFD) and finite element analysis (FEA) in crankshaft design. These tools allow engineers to simulate and optimize oil flow and stress distribution, resulting in crankshafts capable of reliably supporting over 1,000 horsepower in highly tuned 2JZ engines.

The latest developments in 2JZ crankshaft technology include the use of advanced materials like billet steel and even exotic alloys for extreme applications. Some manufacturers are experimenting with hybrid designs that incorporate different materials or manufacturing techniques for various parts of the crankshaft to optimize performance and durability.

Throughout its evolution, the 2JZ crankshaft has remained a critical component in the engine's ability to produce and withstand high power outputs. From its humble beginnings to its current state-of-the-art iterations, the crankshaft's development mirrors the broader trends in precision machining and automotive engineering, showcasing the relentless pursuit of performance and reliability in the world of high-performance engines.

In its early iterations, the 2JZ crankshaft was primarily focused on reliability and durability to support the engine's robust design. Manufactured using traditional forging methods, these crankshafts were capable of handling the stock power output of the 2JZ engine, which ranged from 220 to 320 horsepower depending on the variant.

As the tuning community began to push the limits of the 2JZ engine, the demand for stronger crankshafts grew. This led to the development of aftermarket crankshafts in the late 1990s and early 2000s. These components were often made from higher-grade materials such as 4340 chromoly steel, offering improved strength and resistance to fatigue under high-stress conditions.

The mid-2000s saw a shift towards more advanced manufacturing processes. Computer Numerical Control (CNC) machining became increasingly prevalent, allowing for tighter tolerances and more complex designs. This era marked the introduction of lightweight crankshafts that maintained strength while reducing rotational mass, contributing to faster engine response and higher rev limits.

By the 2010s, the focus shifted to optimizing the crankshaft's design for specific power goals. Manufacturers began offering a range of stroke lengths, allowing engine builders to fine-tune displacement and power characteristics. Additionally, innovations in surface treatments, such as nitridation and micro-polishing, were introduced to enhance durability and reduce friction.

Recent years have seen the integration of computational fluid dynamics (CFD) and finite element analysis (FEA) in crankshaft design. These tools allow engineers to simulate and optimize oil flow and stress distribution, resulting in crankshafts capable of reliably supporting over 1,000 horsepower in highly tuned 2JZ engines.

The latest developments in 2JZ crankshaft technology include the use of advanced materials like billet steel and even exotic alloys for extreme applications. Some manufacturers are experimenting with hybrid designs that incorporate different materials or manufacturing techniques for various parts of the crankshaft to optimize performance and durability.

Throughout its evolution, the 2JZ crankshaft has remained a critical component in the engine's ability to produce and withstand high power outputs. From its humble beginnings to its current state-of-the-art iterations, the crankshaft's development mirrors the broader trends in precision machining and automotive engineering, showcasing the relentless pursuit of performance and reliability in the world of high-performance engines.

Market Demand Analysis

The market demand for precision-machined 2JZ crankshafts has been steadily growing, driven by the enduring popularity of the Toyota 2JZ engine among automotive enthusiasts and racing professionals. This iconic engine, known for its robustness and tuning potential, continues to be a favorite choice for high-performance applications, creating a sustained demand for high-quality, precision-engineered components.

In the aftermarket sector, there is a significant demand for upgraded crankshafts that can withstand the increased power outputs achieved through engine modifications. As enthusiasts push their 2JZ engines to higher horsepower levels, the need for stronger, more precisely balanced crankshafts becomes crucial. This has led to a niche market of specialized manufacturers and machine shops catering to this specific demand.

The racing industry, particularly in drag racing and drifting competitions, represents another substantial market segment for precision-machined 2JZ crankshafts. These motorsports often involve extreme engine stress, necessitating components that can withstand high RPMs and torque levels. As a result, there is a constant demand for crankshafts that offer improved strength, reduced weight, and enhanced balance characteristics.

Furthermore, the restomod trend in the automotive world has contributed to the market demand. As more classic vehicles are being retrofitted with modern 2JZ engines, there is an increased need for crankshafts that can bridge the gap between vintage aesthetics and contemporary performance standards.

The global nature of the automotive aftermarket has also expanded the market for 2JZ crankshafts. With online marketplaces and international shipping becoming more accessible, enthusiasts worldwide can source high-quality components, leading to a broader customer base for manufacturers specializing in precision-machined crankshafts.

However, it's important to note that the market faces challenges. The increasing electrification of vehicles and stricter emissions regulations in many countries could potentially impact the long-term demand for internal combustion engine components. Despite this, the 2JZ engine's cult status and the ongoing popularity of internal combustion engines in motorsports suggest that the market for precision-machined crankshafts will remain robust in the foreseeable future.

In terms of market size, while specific figures for 2JZ crankshafts are not readily available, the overall automotive aftermarket for performance parts continues to grow. This growth indicates a healthy ecosystem for specialized components like precision-machined crankshafts, especially for iconic engines with a dedicated following.

In the aftermarket sector, there is a significant demand for upgraded crankshafts that can withstand the increased power outputs achieved through engine modifications. As enthusiasts push their 2JZ engines to higher horsepower levels, the need for stronger, more precisely balanced crankshafts becomes crucial. This has led to a niche market of specialized manufacturers and machine shops catering to this specific demand.

The racing industry, particularly in drag racing and drifting competitions, represents another substantial market segment for precision-machined 2JZ crankshafts. These motorsports often involve extreme engine stress, necessitating components that can withstand high RPMs and torque levels. As a result, there is a constant demand for crankshafts that offer improved strength, reduced weight, and enhanced balance characteristics.

Furthermore, the restomod trend in the automotive world has contributed to the market demand. As more classic vehicles are being retrofitted with modern 2JZ engines, there is an increased need for crankshafts that can bridge the gap between vintage aesthetics and contemporary performance standards.

The global nature of the automotive aftermarket has also expanded the market for 2JZ crankshafts. With online marketplaces and international shipping becoming more accessible, enthusiasts worldwide can source high-quality components, leading to a broader customer base for manufacturers specializing in precision-machined crankshafts.

However, it's important to note that the market faces challenges. The increasing electrification of vehicles and stricter emissions regulations in many countries could potentially impact the long-term demand for internal combustion engine components. Despite this, the 2JZ engine's cult status and the ongoing popularity of internal combustion engines in motorsports suggest that the market for precision-machined crankshafts will remain robust in the foreseeable future.

In terms of market size, while specific figures for 2JZ crankshafts are not readily available, the overall automotive aftermarket for performance parts continues to grow. This growth indicates a healthy ecosystem for specialized components like precision-machined crankshafts, especially for iconic engines with a dedicated following.

Current Challenges

The precision machining of 2JZ crankshafts faces several significant challenges in the current technological landscape. One of the primary obstacles is achieving and maintaining the required level of accuracy and consistency across high-volume production. The 2JZ engine's reputation for reliability and performance demands exceptionally tight tolerances, often measured in microns, which pushes the limits of conventional machining techniques.

Material selection and preparation present another hurdle. The 2JZ crankshaft typically utilizes forged steel for its strength and durability, but this material's hardness can lead to rapid tool wear and increased machining time. Balancing the need for a robust material with machinability remains a constant challenge for manufacturers.

The complex geometry of the 2JZ crankshaft, with its multiple bearing journals and counterweights, necessitates sophisticated multi-axis machining processes. Coordinating these processes while maintaining precision across all features of the crankshaft is a formidable task. This complexity is further compounded by the need for specialized tooling and fixturing to handle the crankshaft's unique shape and size.

Heat management during the machining process is another critical challenge. The high-speed cutting operations generate significant heat, which can lead to thermal expansion and potential distortion of the workpiece. Controlling this heat to ensure dimensional stability throughout the machining process requires advanced cooling systems and careful process control.

Quality control and inspection pose additional challenges. The intricate nature of the 2JZ crankshaft demands comprehensive inspection techniques to verify adherence to specifications. Traditional measurement methods may struggle to capture all critical dimensions accurately, necessitating the development and implementation of advanced metrology solutions.

The industry also faces pressure to improve efficiency and reduce costs without compromising quality. This challenge is particularly acute given the high material costs associated with forged steel crankshafts and the extended machining times required to achieve the necessary precision. Balancing these economic factors with the uncompromising performance requirements of the 2JZ engine is an ongoing struggle for manufacturers.

Environmental concerns and sustainability requirements add another layer of complexity to the machining process. Reducing waste, minimizing the use of cutting fluids, and improving energy efficiency are becoming increasingly important considerations in crankshaft production. These factors must be addressed without sacrificing the precision and quality that define the 2JZ crankshaft.

Material selection and preparation present another hurdle. The 2JZ crankshaft typically utilizes forged steel for its strength and durability, but this material's hardness can lead to rapid tool wear and increased machining time. Balancing the need for a robust material with machinability remains a constant challenge for manufacturers.

The complex geometry of the 2JZ crankshaft, with its multiple bearing journals and counterweights, necessitates sophisticated multi-axis machining processes. Coordinating these processes while maintaining precision across all features of the crankshaft is a formidable task. This complexity is further compounded by the need for specialized tooling and fixturing to handle the crankshaft's unique shape and size.

Heat management during the machining process is another critical challenge. The high-speed cutting operations generate significant heat, which can lead to thermal expansion and potential distortion of the workpiece. Controlling this heat to ensure dimensional stability throughout the machining process requires advanced cooling systems and careful process control.

Quality control and inspection pose additional challenges. The intricate nature of the 2JZ crankshaft demands comprehensive inspection techniques to verify adherence to specifications. Traditional measurement methods may struggle to capture all critical dimensions accurately, necessitating the development and implementation of advanced metrology solutions.

The industry also faces pressure to improve efficiency and reduce costs without compromising quality. This challenge is particularly acute given the high material costs associated with forged steel crankshafts and the extended machining times required to achieve the necessary precision. Balancing these economic factors with the uncompromising performance requirements of the 2JZ engine is an ongoing struggle for manufacturers.

Environmental concerns and sustainability requirements add another layer of complexity to the machining process. Reducing waste, minimizing the use of cutting fluids, and improving energy efficiency are becoming increasingly important considerations in crankshaft production. These factors must be addressed without sacrificing the precision and quality that define the 2JZ crankshaft.

Precision Methods

01 Precision manufacturing of 2JZ crankshafts

Advanced manufacturing techniques are employed to produce high-precision 2JZ crankshafts. These methods ensure accurate dimensions, proper balance, and optimal surface finish, which are crucial for the performance and durability of the engine. Precision manufacturing may involve computer-controlled machining, specialized heat treatments, and rigorous quality control processes.- Precision manufacturing of 2JZ crankshafts: Advanced manufacturing techniques are employed to produce high-precision 2JZ crankshafts. These methods involve precise machining, balancing, and quality control processes to ensure optimal performance and durability in high-performance engines.

- Material selection for 2JZ crankshafts: Specific materials are chosen for 2JZ crankshafts to enhance strength, reduce weight, and improve overall engine performance. These materials may include high-grade steel alloys or other advanced composites designed to withstand the extreme conditions in high-performance engines.

- Surface treatment and coating of 2JZ crankshafts: Various surface treatments and coatings are applied to 2JZ crankshafts to improve wear resistance, reduce friction, and enhance overall durability. These treatments may include nitriding, shot peening, or the application of specialized coatings to critical surfaces.

- Balancing techniques for 2JZ crankshafts: Specialized balancing techniques are employed to ensure optimal performance of 2JZ crankshafts. These methods may involve dynamic balancing, counterweight design, and precision machining to minimize vibration and maximize engine efficiency at high RPMs.

- Quality control and testing of 2JZ crankshafts: Rigorous quality control measures and testing procedures are implemented to ensure the precision and reliability of 2JZ crankshafts. These may include non-destructive testing methods, dimensional inspections, and performance validation under simulated operating conditions.

02 Material selection for 2JZ crankshafts

The choice of materials for 2JZ crankshafts is critical to their performance and longevity. High-strength alloys, such as forged steel or billet steel, are commonly used to withstand the extreme forces and temperatures encountered in high-performance engines. The material selection process considers factors like tensile strength, fatigue resistance, and thermal stability.Expand Specific Solutions03 Surface treatment and coating of 2JZ crankshafts

Various surface treatments and coatings are applied to 2JZ crankshafts to enhance their performance and durability. These processes may include nitriding, shot peening, or the application of low-friction coatings. Such treatments can improve wear resistance, reduce friction, and increase the overall lifespan of the crankshaft.Expand Specific Solutions04 Balancing techniques for 2JZ crankshafts

Precise balancing of 2JZ crankshafts is essential for smooth engine operation and reduced vibration. Advanced balancing techniques may involve computer-aided analysis, dynamic balancing machines, and fine-tuning of counterweights. Proper balancing contributes to improved engine performance, reduced wear on bearings, and enhanced overall reliability.Expand Specific Solutions05 Quality control and testing of 2JZ crankshafts

Rigorous quality control measures and testing procedures are implemented to ensure the precision and reliability of 2JZ crankshafts. These may include non-destructive testing methods such as magnetic particle inspection, ultrasonic testing, and dimensional verification using coordinate measuring machines. Extensive testing helps identify any defects or inconsistencies before the crankshaft is installed in the engine.Expand Specific Solutions

Key Industry Players

The precision machining of 2JZ crankshafts represents a mature technology within the automotive industry, with a well-established market driven by performance enthusiasts and racing applications. The competitive landscape is characterized by a mix of established automotive manufacturers and specialized machining companies. Key players like Mazda, Suzuki, and Mitsubishi Heavy Industries bring extensive experience in engine component manufacturing, while specialized firms such as Kennametal and NILES-SIMMONS offer advanced machining solutions. The market size, though niche, remains stable due to the enduring popularity of the 2JZ engine. Technological advancements in CNC machining and materials science continue to drive incremental improvements in crankshaft performance and durability.

NIPPON STEEL CORP.

Technical Solution: NIPPON STEEL CORP. has developed advanced materials and manufacturing processes for precision machining of 2JZ crankshafts. Their approach involves using high-strength, low-alloy steels with optimized microstructures to enhance durability and performance. The company employs advanced forging techniques, including controlled cooling and heat treatment processes, to achieve precise dimensional control and superior mechanical properties. Their crankshafts undergo multi-stage machining processes, including rough turning, finish turning, and grinding, with tolerances as tight as ±5 μm [1]. NIPPON STEEL also utilizes advanced surface treatment technologies, such as nitriding and shot peening, to improve wear resistance and fatigue strength of the crankshafts [3].

Strengths: Superior material quality, advanced manufacturing processes, and tight dimensional control. Weaknesses: Potentially higher production costs and longer lead times due to complex processes.

Kennametal, Inc.

Technical Solution: Kennametal specializes in cutting tools and wear-resistant solutions for precision machining, including 2JZ crankshafts. Their approach focuses on developing advanced cutting tool materials and geometries optimized for high-speed machining of crankshafts. Kennametal's tooling solutions include ceramic-based inserts with enhanced wear resistance and thermal stability, allowing for higher cutting speeds and improved surface finish. They have also developed specialized coatings, such as AlTiN and TiAlN, which extend tool life by up to 30% in crankshaft machining applications [2]. Kennametal's tooling systems incorporate advanced chip control geometries to manage chip formation and evacuation, crucial for maintaining precision in deep-groove turning operations common in crankshaft manufacturing [4].

Strengths: Cutting-edge tool materials and geometries, specialized coatings for extended tool life. Weaknesses: Reliance on specific machine tool compatibility, potentially higher initial tooling costs.

Innovative Techniques

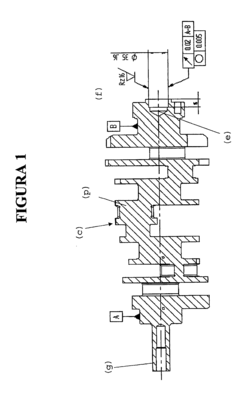

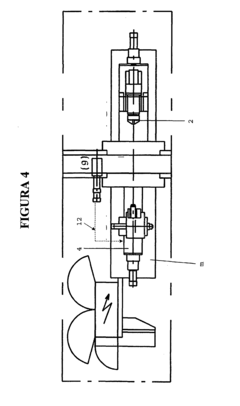

Method and device for precision machining of crankshafts or camshafts

PatentInactiveEP2445676A1

Innovation

- The method involves initial machining and hardening followed by final machining with CBN or PCD cutting inserts on an adjustable milling cutter, eliminating the need for grinding and enabling precise final shape production without cooling lubricants, thus achieving high surface quality and accuracy.

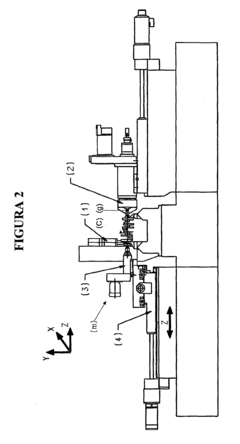

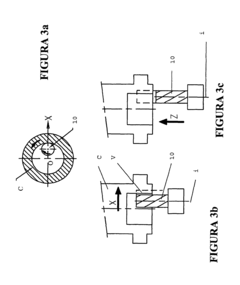

Precision machining method for inner diameters of holes in crankshafts and machine for same

PatentInactiveEP1522361A1

Innovation

- A precision machining method involving circular interpolation between the crankshaft and milling tool using two phases along the X and Z axes, with the crankshaft fixed and rotating at less than 50 rpm, allowing for controlled machining and compensation for diameter errors.

Material Science Impact

The material science impact on precision machining of 2JZ crankshafts is significant and multifaceted. The choice of materials plays a crucial role in determining the performance, durability, and manufacturability of these critical engine components. Traditionally, 2JZ crankshafts have been manufactured using forged steel, which offers excellent strength and fatigue resistance. However, advancements in material science have led to the exploration of alternative materials and treatments to enhance performance further.

One of the key areas of material science impact is the development of advanced alloys. These alloys, often incorporating elements such as chromium, molybdenum, and vanadium, offer improved strength-to-weight ratios and enhanced wear resistance. The precise composition of these alloys is carefully tailored to meet the specific demands of high-performance engines, balancing factors such as hardness, toughness, and machinability.

Surface treatments and coatings have also emerged as critical factors in crankshaft performance. Techniques such as nitriding, which introduces nitrogen into the surface layer of the metal, can significantly improve wear resistance and fatigue strength. Similarly, advanced coatings like diamond-like carbon (DLC) can reduce friction and wear, potentially extending the lifespan of the crankshaft and improving overall engine efficiency.

The microstructure of the material is another area where material science has made significant contributions. Through careful control of heat treatment processes, manufacturers can optimize the grain structure of the metal, enhancing its mechanical properties. This level of microstructural control is particularly important in high-stress areas of the crankshaft, such as the fillets and journal surfaces.

Advancements in non-destructive testing methods, rooted in material science, have also improved the quality control process for crankshaft manufacturing. Techniques such as ultrasonic testing and X-ray diffraction allow for the detection of internal defects and residual stresses, ensuring that only the highest quality components make it into production engines.

The impact of material science extends to the machining process itself. Understanding the material properties at a fundamental level allows for the optimization of cutting tools, speeds, and feeds. This knowledge enables manufacturers to achieve tighter tolerances and superior surface finishes, which are critical for the performance and longevity of 2JZ crankshafts.

Looking forward, emerging technologies in material science, such as metal matrix composites and advanced ceramics, may offer new possibilities for crankshaft design and performance. While these materials are not yet widely used in production engines, ongoing research suggests they could provide significant advantages in terms of weight reduction and heat resistance in the future.

One of the key areas of material science impact is the development of advanced alloys. These alloys, often incorporating elements such as chromium, molybdenum, and vanadium, offer improved strength-to-weight ratios and enhanced wear resistance. The precise composition of these alloys is carefully tailored to meet the specific demands of high-performance engines, balancing factors such as hardness, toughness, and machinability.

Surface treatments and coatings have also emerged as critical factors in crankshaft performance. Techniques such as nitriding, which introduces nitrogen into the surface layer of the metal, can significantly improve wear resistance and fatigue strength. Similarly, advanced coatings like diamond-like carbon (DLC) can reduce friction and wear, potentially extending the lifespan of the crankshaft and improving overall engine efficiency.

The microstructure of the material is another area where material science has made significant contributions. Through careful control of heat treatment processes, manufacturers can optimize the grain structure of the metal, enhancing its mechanical properties. This level of microstructural control is particularly important in high-stress areas of the crankshaft, such as the fillets and journal surfaces.

Advancements in non-destructive testing methods, rooted in material science, have also improved the quality control process for crankshaft manufacturing. Techniques such as ultrasonic testing and X-ray diffraction allow for the detection of internal defects and residual stresses, ensuring that only the highest quality components make it into production engines.

The impact of material science extends to the machining process itself. Understanding the material properties at a fundamental level allows for the optimization of cutting tools, speeds, and feeds. This knowledge enables manufacturers to achieve tighter tolerances and superior surface finishes, which are critical for the performance and longevity of 2JZ crankshafts.

Looking forward, emerging technologies in material science, such as metal matrix composites and advanced ceramics, may offer new possibilities for crankshaft design and performance. While these materials are not yet widely used in production engines, ongoing research suggests they could provide significant advantages in terms of weight reduction and heat resistance in the future.

Quality Control Measures

Quality control measures play a crucial role in the precision machining of 2JZ crankshafts, ensuring the highest standards of accuracy, reliability, and performance. The manufacturing process involves multiple stages, each requiring stringent quality checks to maintain the crankshaft's integrity and functionality.

At the initial stage, raw material inspection is conducted to verify the composition and properties of the steel alloy used. This includes spectrographic analysis and hardness testing to ensure the material meets the required specifications for strength and durability. Any deviations in material quality could lead to premature failure or reduced performance of the crankshaft.

During the machining process, dimensional accuracy is continuously monitored using advanced metrology equipment. Coordinate measuring machines (CMMs) are employed to verify critical dimensions, such as journal diameters, pin sizes, and overall length. These measurements are compared against CAD models and engineering specifications to ensure compliance with tight tolerances, typically within microns.

Surface finish quality is another critical aspect of crankshaft manufacturing. Roughness measurements are performed using profilometers to assess the smoothness of bearing surfaces. This is essential for reducing friction and wear during engine operation. Additionally, non-destructive testing methods like magnetic particle inspection and ultrasonic testing are utilized to detect any surface or subsurface defects that could compromise the crankshaft's integrity.

Heat treatment processes, crucial for enhancing the crankshaft's mechanical properties, are closely monitored. Temperature profiles and cooling rates are carefully controlled and recorded to ensure uniform hardening and tempering. Post-heat treatment, hardness testing is conducted at multiple points to verify the achieved material properties.

Final inspection involves a comprehensive check of all critical features. This includes runout measurements to ensure proper alignment of journals and pins, as well as balance testing to minimize vibration during engine operation. Each crankshaft is also subjected to a rigorous visual inspection to identify any cosmetic defects or machining errors.

Throughout the manufacturing process, statistical process control (SPC) techniques are employed to monitor key quality indicators and identify trends that may indicate potential issues. This proactive approach allows for timely adjustments to the manufacturing process, maintaining consistent quality across production runs.

Documentation and traceability are integral components of the quality control system. Each crankshaft is assigned a unique identifier, allowing for the tracking of its manufacturing history, including all inspection results and any corrective actions taken. This comprehensive approach to quality control ensures that every 2JZ crankshaft meets the exacting standards required for high-performance engine applications.

At the initial stage, raw material inspection is conducted to verify the composition and properties of the steel alloy used. This includes spectrographic analysis and hardness testing to ensure the material meets the required specifications for strength and durability. Any deviations in material quality could lead to premature failure or reduced performance of the crankshaft.

During the machining process, dimensional accuracy is continuously monitored using advanced metrology equipment. Coordinate measuring machines (CMMs) are employed to verify critical dimensions, such as journal diameters, pin sizes, and overall length. These measurements are compared against CAD models and engineering specifications to ensure compliance with tight tolerances, typically within microns.

Surface finish quality is another critical aspect of crankshaft manufacturing. Roughness measurements are performed using profilometers to assess the smoothness of bearing surfaces. This is essential for reducing friction and wear during engine operation. Additionally, non-destructive testing methods like magnetic particle inspection and ultrasonic testing are utilized to detect any surface or subsurface defects that could compromise the crankshaft's integrity.

Heat treatment processes, crucial for enhancing the crankshaft's mechanical properties, are closely monitored. Temperature profiles and cooling rates are carefully controlled and recorded to ensure uniform hardening and tempering. Post-heat treatment, hardness testing is conducted at multiple points to verify the achieved material properties.

Final inspection involves a comprehensive check of all critical features. This includes runout measurements to ensure proper alignment of journals and pins, as well as balance testing to minimize vibration during engine operation. Each crankshaft is also subjected to a rigorous visual inspection to identify any cosmetic defects or machining errors.

Throughout the manufacturing process, statistical process control (SPC) techniques are employed to monitor key quality indicators and identify trends that may indicate potential issues. This proactive approach allows for timely adjustments to the manufacturing process, maintaining consistent quality across production runs.

Documentation and traceability are integral components of the quality control system. Each crankshaft is assigned a unique identifier, allowing for the tracking of its manufacturing history, including all inspection results and any corrective actions taken. This comprehensive approach to quality control ensures that every 2JZ crankshaft meets the exacting standards required for high-performance engine applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!